International technology Group ANDRITZ has received an order from Panel Plus MDF Co. Ltd. to supply pressurized refining equipment and chip washing systems for MDF (medium-density fiberboard) production lines I and II at the Hat Yai mill, Thailand. Start-up is scheduled for September 2017.

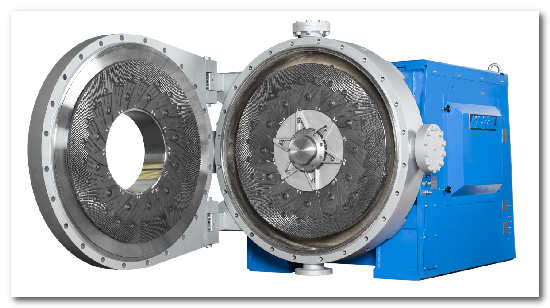

ANDRITZ will deliver a chip washing system with pre-steaming bin for line I, which will process 100% rubber wood as raw material. For line II, whose raw material input will be a variable mix of 80-100% rubber wood and of 0-20% mixed hardwood, ANDRITZ will supply a chip washing and pressurized refining system with a capacity of 30 bdmt/h. ANDRITZ pressurized refining systems feature highly efficient pre-steaming, excellent dewatering in the plug-screw feeder, and low specific energy consumption by the overall system.

The high technological standard of the ANDRITZ processes for the panelboard industry, the high number of successful references for pressurized refining systems worldwide – with more than ten installations in Thailand – as well as the maintenance-friendliness and high reliability of the components were decisive for Panel Plus to place the order with ANDRITZ.

Panel Plus is a leading international company for the production of particle board, medium-density fiberboard and melamine impregnated papers that are used as wood substitute materials for various applications. The company is well-recognized in Asia, serving the needs of both domestic and overseas markets.

ANDRITZ PULP & PAPER is a leading global supplier of equipment, systems, and services for the production and processing of all types of pulp, paper, tissue, and cardboard. The technologies cover the processing of logs, annual fibers, and waste paper; the production of chemical pulp, mechanical pulp, and recycled fibers; the recovery and reuse of chemicals; the preparation of paper machine furnish; the production of paper, tissue, and cardboard; the calendering and coating of paper; as well as treatment of reject materials and sludge. The service range includes modernization, rebuilds, spare and wear parts, service and maintenance, as well as machine transfer and second-hand equipment. Biomass, steam, and recovery boilers, as well as gasification plants for power generation, flue gas cleaning plants, plants for the production of nonwovens, dissolving pulp, and panelboards (MDF), as well as recycling plants are also allocated to the business area.

For further information, please contact:

Michael Buchbauer

Head of Corporate Communications

This email address is being protected from spambots. You need JavaScript enabled to view it.