Displaying items by tag: greycon

Greycon Raises Funds for WasteAid by Completing Their Company-Wide Step Challenge

On Friday 1st October, members of the Greycon team began a collective companywide walk to raise money for WasteAid. The walk was split into three different parts with the first leg covering the distance between Greycon’s London office and the office located in Athens. During the first leg, the Greycon team walked a total of 3,466,000 steps covering 1,733 miles.

In the second leg, the Greycon team covered the distance from their Athens office to the Dusseldorf office of sister company WM Data. During this leg of the journey, a total of 3,064,000 steps were walked covering 1,532miles.

The final leg of the journey covered the distance from the WM Data office in Dusseldorf to the Greycon office in Montevideo, Uruguay. During this leg, a whopping 20,129,083 steps were walked covering 7,075 miles.

In total, 26,695,083 steps have been walked covering 10,340 miles!

Walking for a good cause

Greycon’s main aim with the Step Challenge incentive was to raise money for WasteAid. Upon completion of each leg, Greycon added £250 to the donation pot. A total of £852 has been raised so far. Donations for the incentive are still being taken. To donate, click here and visit the Step Challenge JustGiving page.

About WasteAid

WasteAid is an independent non-profit charity, set up by waste management professionals to share practical and low-cost waste management know-how with communities in low-income countries across the globe.

Around 1 in 3 people globally don’t have decent waste management.

Pollution caused by waste harms people’s health, the environment, and damages the local economy. In contrast, an affordable waste management system is relatively simple to implement, improving the environment, creating jobs and protecting public health – particularly for children.

Plastic pollution in the marine environment is of major global concern, and WasteAid is helping tackle this global problem. WasteAid work with upstream and coastal communities to set up small recycling centres and help keep plastic out of rivers and the oceans. They also share skills in managing organic waste, helping people make the most from the ‘waste’ materials they have.

WasteAid shares these skills with local trainers so that the knowledge can be passed on from community to community. They keep the cost of equipment as low as possible because $10 can make a big difference to the viability of a recycling start-up in a deprived community. WasteAid makes sure there are local markets for any products made from recycled materials, maximising the value to the local economy.

Thank You

Greycon extends a big thank you to all those who have made donations towards the incentive and to all of their staff members who took part in the incentive.

Konvertia Germany restructures dispatch logistics and IT system with nearshore experts WM-data

At the beginning of 2022, the entire shipping logistics of Konvertia Germany GmbH (formerly known as Pyroll Germany GmbH) were converted in a record time of two months.

The challenge was that, for operational reasons, the dispatch logistics had to be transferred back to the company from an external service provider at short notice, with the project to be completed within three months. In addition to this, equipment, staff and IT systems also had to be procured as part of the project. Conducting the project during the festive period and new year, as well as a rebranding of the company, made the situation more challenging.

Konvertia Germany GmbH were not able to complete this project with their internal resources, as they do not have an independent IT department to fulfil the requirements of the project. WM-data Germany, which had already delivered the BDE solution used at Konvertia, was commissioned with the implementation as a nearshore specialist for the paper industry.

The business model of Konvertia, which consists of assembling rolled goods for customers on behalf of its business partners, requires the handling of finished goods in the form of rolls and sheet pallets, as well as a large number of warehouse additions from different partners, especially in the logistics area. Since time-critical data was being exchanged between Konvertia and their partners, this important information could not be neglected.

Due to the short time available, a scrum project based on the FAGUS Paper Solution was chosen. With the company’s stance on the pandemic and the time sensitivities in place, small virtual workshops were implemented. Process analysis was carried out with the team at Konvertia, the detailed concept was created step by step, while the necessary hardware resources were ordered and tested remotely.

Konvertia ‘s existing warehouse had previously been managed by an external service provider, including the company's IT. Since the new infrastructure such as forklifts, scanners and staff were not yet available, the tests had to be heavily improvised. Procedures were created and checked using test data, while Konertia’s real-time stock inventory was to be imported into WM-data’s FAGUS solution by the agreed start date.

With the teams at Konvertia and WM-data working together closely, and a clear prioritisation of the tasks and necessary preliminary work, the project would not only meet the proposed changeover date but exceeded expectations.

Oliver Spraul, Managing Director of Konvertia Germany GmbH, spoke of his satisfaction with the changeover: "We couldn't have done it alone, there were too many tasks to be done at the same time. It was the right decision to entrust WM-data with the entire task. A big thank you goes to the teams at WM-data and Konvertia for their great commitment. We are pleased that we were able to implement our ambitious goals for optimising the flow of goods at such short notice. I assume that we will be able to support our customers more flexibly in the future."

Managing Director of WM-data Germany, Alexander Boden, is also delighted with the timely implementation: "We are currently still working on further additions and the processes to optimise. Such a project, especially if it is carried out remotely, can be managed well if there is a good, trusting relationship with the customer and we are particularly pleased about that in this case.”

About Konvertia

The Konvertia Group is the leading partner in cutting services for cardboard and paper in Europe, supplying state-of-the-art companies that provide their customers with high-quality packaging solutions made of cardboard and paper. As a customer-centric organization, helping our customers succeed - that's our ultimate drive every day! Cornerstones of our business are therefore based on our values of passion, respect and sustainability. Respect for our customers, employees and the environment makes us not only our customers' preferred partner but also a trusted employer in every region in which we operate. The service network is supported from four countries in Europe. In Finland we operate from two locations – Valkeakoski and Siltakylä , in the Netherlands we are located in the northern part of the country – Winschoten , in Poland we operate in the centre of the country – Strykow , and in Germany we have one facility in the south – Baienfurt . In total, our processing capacity is over 400,000 tons for formats and 50,000 tons for rewinding . Konvertia is also a proud employer of 250 employees.

About WM-data

WM-data Deutschland GmbH was founded in 1991 from the IT department of Feldmühle AG. Based on more than 30 years of experience, we offer our customers excellent know-how about processes, analyses and the introduction of MES systems. In addition, there is special knowledge in the area of connecting a wide variety of machines, which poses a special challenge in every project. As a nearshore partner, WM-data is now active in a group of companies as an industry-specific expert for companies in the paper, cardboard and film industry in Düsseldorf.

Greycon Provide Significant Performance Improvements and Productivity Gains For a Leading Paper Manufacturer

Incorporated in 1996, Bahl Paper Mills has emerged as one of the leading manufacturers of industrial packing papers, producing an extensive range of environmentally friendly graded paper. All the firm’s products are manufactured from 100% recycled wastepaper and include 180 to 600gsm duplex board, 18 to 110gsm poster paper and 18 to 160gsm kraft paper. The business produces nearly 300 tonnes of paper every day.

The senior team at Bahl wanted to improve productivity and machine efficiency, as well as reduce waste. One way to achieve this was to maximize the deckle width utilization of the papermaking machine. Bahl was keen to improve the productivity of the winders and sheet cutters while ensuring that the selected solution could be effectively integrated into the factory’s existing systems and processes. After an initial conversation between Greycon and Bahl, Greycon recommended their tried and tested trim optimization solution, X-Trim.

Greycon’s X-Trim provides the production planners at Bahl Paper with an extensive range of options to address the challenges/improvement opportunities they had identified. X-Trim was implemented with specific modules that offered their business a range of optimizers capable of managing reel and sheet orders in a single model. Leveraging the combination of optimizers and other features of the application, Bahl Paper has been able to increase the average deckle width for the jumbo, leading to higher machine efficiency and throughput. Alongside this, Bahl was able to increase the diameter of reels being fed to cutters and decrease the number of knife changes, both leading to higher productivity.

The Bahl team have been extremely impressed with X-Trim. The system’s highly intuitive user interface is a major step forward from the manual processes that were being used previously.

Overall operational planning is much improved, creating additional time for planners to deliver other value-added activities to support business growth.

“It did not take us long to decide that X-Trim was the solution that would completely satisfy our needs. The prompt response from the Greycon team helped lay to rest any concerns that we had. It has been a great investment, with significant savings.”

Naveen Jhanji, Managing Director.

About Greycon

Greycon is the leading provider of supply chain planning & optimization, production planning & detailed scheduling, trim optimization and manufacturing execution systems for roll-based & flat

sheet industries; specifically, the paper & board, film & flexible packaging, nonwoven, converting and metal industries.

Established in 1985, over 500 plants in 43 countries use our solutions. Our extremely skilled and talented employees cover 15 languages across our worldwide operation. www.greycon.com

Working Together to Deliver Automation and Digitisation, Creating More Efficient Ways of Working While Minimising Environmental Impacts

Satia Industries Limited (SIL) has grown to become one of the biggest wood and agro-based paper plants in India, producing wide range of paper from wood chips, veneer waste, wheat straw and sarkanda and other pulp substitutes. The firm has continually invested in modernisation to improve production processes and product quality while reducing waste and environmental pollution. SIL’s paper is used in the printing of textbooks, notebooks, directories, envelopes, diaries, calendars, computer stationery, annual reports and other high-quality printing for both domestic and export sales.

To achieve such an expansive product range the firm has invested in four paper production lines, two of which are used only to produce paper for the public sector. Each production line features winders, rewinders and simplex and duplex cutters. Each line is designed to produce finished paper as a defined SKU, ready for customers to purchase.

The demand from the retail market is for varying dimensions, and all the planning and production of different sized products were being carried out manually. While this had been an accepted way of working, it was not the most efficient approach, and it wasn’t unusual for errors and inaccuracies to occur. Subsequently, this would affect production output while trim losses had room for reduction.

The company’s young and dynamic management team are keen to invest in automation and digitisation where there is a robust business case and clear opportunities for improvement. Identifying that these two paper production lines would benefit from this investment, the firm went to the market to find potential suppliers. SIL had already invested in implementing SAP Hana, as part of this initiative.

After a detailed evaluation process, it was clear that Greycon’s X-Trim solution would provide the ideal solution to update and modernise the finishing house practices in the factory. X-Trim was well suited to the task, with a proven track record of reducing planning time and wasted materials. It was also a good fit with the firm’s culture of continuous investment in the latest technologies and digitisation and they were impressed with Greycon’s team and the ongoing support offered to clients.

Once Greycon’s team had evaluated the best way to implement X-Trim, and the solution had been deployed in the business, the firm started to recognise the benefits almost immediately.

As a result, both the efficiency and accuracy of slitting and sheet cutting planning has improved. The planners can now test out different scenarios in a short period of time. This ensures that the most efficient cutting and preparation scenarios have been considered and the appropriate one chosen. Not only have planning processes improved, but the team have also noted a measurable reduction in the volume of trim waste because of the new solution.

“At Satia group we are always looking to embrace world-class solutions which can help drive operating efficiencies” states Satia Executive Director, Chirag Satia. “Our people are very happy using the X-Trim solution since it has helped them to make far better decisions after evaluating multiple production options. It has also meant that the time required to produce a trim plan is far lower, providing them with much needed time for other value-added activities. We are extremely satisfied with this decision”.

The project has been hugely successful, representing another step towards full automation and digitisation and reinforcing the firm’s commitment to minimising the environmental impact of its activities.

About Greycon

Greycon is the leading provider of supply chain planning & optimisation, production planning & detailed scheduling, trim optimisation and manufacturing execution systems for roll-based & flat sheet industries; specifically, the paper & board, film & flexible packaging, nonwoven, converting and metal industries.

Established in 1985, over 500 plants in 43 countries use our solutions. Our extremely skilled and talented employees cover 15 languages across our worldwide operation.

GREYCON’S CHARITY WALK FROM LONDON TO ATHENS!

On Friday 1st October, members of the Greycon team started a collective walk covering the distance between their London office and their office located in Athens to raise money and awareness for WasteAid. Each member of the team is contributing their steps towards the challenge, which is an estimated 3,466,000 steps covering 1,733 miles.

Walking for a good cause

The main aim of the London to Athens incentive is to raise money for WasteAid, an independent non-profit charity, set up by waste management professionals to share practical and low-cost waste management know-how with communities in low-income countries across the globe. As Greycon specialise in lowering waste for manufacturers, WasteAid was the natural choice of charity.

Around 1 in 3 people globally don’t have decent waste management.

Pollution caused by waste harms people’s health, the environment, and damages the local economy. In contrast, an affordable waste management system is relatively simple to implement, improving the environment, creating jobs and protecting public health – particularly for children.

Plastic pollution in the marine environment is of major global concern, and WasteAid is helping tackle this global problem. WasteAid work with upstream and coastal communities to set up small recycling centres and help keep plastic out of rivers and the oceans. They also share skills in managing organic waste, helping people make the most from the ‘waste’ materials they have.

WasteAid share these skills with local trainers so that the knowledge can be passed on from community to community. They keep the cost of equipment as low as possible because $10 can make a big difference to the viability of a recycling start-up in a deprived community. WasteAid makes sure there are local markets for any products made from recycled materials, maximising the value to the local economy.

What do your donations go towards?

Here are three examples of how WasteAid will use donations.

£100 – Could train an unemployed young person to become a city waste champion.

£500 – Could equip a community group to transform organic waste into useful products.

£1000 – Could provide machinery for processing plastic waste, keeping cities clean and oceans plastic-free.

Greycon’s contribution

Upon completion of the London to Athens walk, Greycon will contribute £250 towards the JustGiving page.

Weekly Updates

Weekly updates can be found on the Greycon LinkedIn page. These updates will show progress completed alongside a leaderboard of the top walkers for the week!

Donate now!

Please donate to Greycon’s London to Athens JustGiving page here - www.justgiving.com/fundraising/greycon

About Greycon

Greycon is the leading provider of supply chain planning & optimisation, production planning & detailed scheduling, trim optimisation and manufacturing execution systems for roll-based & flat sheet industries; specifically, the paper & board, film & flexible packaging, nonwoven, converting and metal industries.

Established in 1985, over 500 plants in 43 countries use our solutions. Our extremely skilled and talented employees cover 15 languages across our worldwide operation.

PAPRESA IMPLEMENT X-TRIM TO MAXIMISE PERFORMANCE FOR FUTURE INFRASTRUCTURE DEVELOPMENT PROJECTS

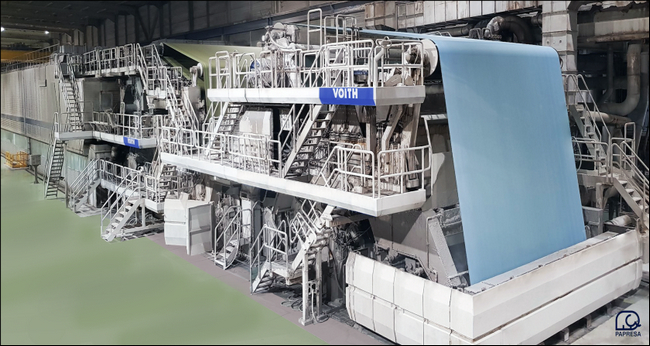

The Papresa Paper Mill in northern Spain produces newsprint paper and packaging paper from recycled paper. Mainly supplying newspaper publishers, together with other commercial printing, Papresa’s production capacity of 375,000 tons of paper is delivered by three paper machines and two de-inking plants. Following the firm’s recent acquisition by Quantum Group, and as part of the new owner’s industrial diversification plan - a response to the global decline in newsprint - the mill will now be producing new products such as cardboard packaging paper. This strategy responds to the growing demand for packaging as a result of the growth in e-commerce. This new plan will secure the future of the mill, the eighth-largest paper producer in Spain, and its 243 employees.

Successful implementation of the new strategy was going to rely on the use of technology to automate processes and facilitate more effective forward-planning and decision making. Most of the planning and trim processes were being carried out manually using Microsoft Excel, and, while this approach had been satisfactory for the production of a range of newspaper print reels, the firm was about to invest in both new and existing equipment and wanted to maximise productivity.

The investment in new equipment would include increasing production capabilities with a full rebuild of one paper machine scheduled for spring 2022, and a new OCC Plant to cover the requirements of raw material by the production increase. To accommodate the period of time when this machine was unavailable, and in advance of the completion of the rebuilding work, the factory needed to find ways to operate more efficiently in advance of work starting. Building automation to the planning processes was seen as a potential solution that would also be able to increase the visibility of future planning decisions.

Papresa’s USP is its ability to maintain a flexible production strategy to meet customer delivery dates. This meant that the solution needed to be able to measure production and switch over costs while ensuring every delivery date is achieved.

Greycon Ltd, experts in planning, scheduling, trimming and MES software, proposed their opt-Studio and X-Trim solutions to Papresa to help meet their goals. The trim optimisation tool reduces waste and improves machine efficiency while reacting to customer requirements by prioritising urgent orders without missing deadlines for other production throughput.

This is a powerful combination of tools that automates production to optimise trim processes and consequently deliver much-improved dispatch times. The solution facilitates daily production planning while identifying any conflicts in production capacities and capabilities at the same time as providing the commercial and logistics department with information about production plans, order delays and any backlogs.

Papresa’s investment in opt-Studio and X-Trim means they now have access to the most efficient planning tools in advance of the planned infrastructure upgrade, ensuring the business is well-positioned to maximise Quantum’s investments in the future of the mill. The project was proposed with an aggressive timeline of 4 months, including the systems live integration with their existing Navision installation. With that, Papresa could achieve an early ROI, and have already planned six days of trim sheets across two slitting machines. This could not have been achieved without excellent synergies between the teams at Papresa and Greycon.

“opt-Studio has allowed us to transform our production planning system, reducing the workload by automating the optimization of materials, reducing product in process, significantly reducing waste, and helping improve our competitiveness and profits” states Miguel Ángel Sánchez García, Papresa CEO. “I highly recommend its application as a powerful tool for productivity. We are very happy with the support and professionalism throughout the project, which was delivered impeccably and within the time constraints that we set. We are looking forward to a fruitful partnership with Greycon as we continue to upgrade our technologies.”

About Greycon

Greycon is the leading provider of supply chain planning & optimisation, production planning & detailed scheduling, trim optimisation and manufacturing execution systems for roll-based & flat sheet industries; specifically, the paper & board, film & flexible packaging, nonwoven, converting and metal industries.

Established in 1985, over 500 plants in 43 countries use our solutions. Our extremely skilled and talented employees cover 15 languages across our worldwide operation.

GREYCON LAUNCHES NEW WEBSITE

Greycon, a leading technology company focused on delivering planning, scheduling, trim optimisation, and MES solutions to assist manufacturers worldwide, is inviting visitors to explore their new website at https://www.greycon.com.

The website has been designed to offer an enhanced user-friendly experience with improved navigation and functionality while allowing users to see the full product portfolio Greycon can offer.

The website has been designed to offer an enhanced user-friendly experience with improved navigation and functionality while allowing users to see the full product portfolio Greycon can offer.

Created with the user experience in mind, the site includes many new features to help users to quickly and easily navigate the site and find the solutions that are right for them. New features include:

- Look Ahead Navigationto reduce the number of user clicks to navigate the site

- My Greycon which allows current Greycon customers access to exclusive content

- Customer Stories allow visitors to hear first-hand from individuals and companies just like them

- Advanced Device Compatibilityfocuses on site performance, ensuring it is compatible across all browsers and mobile devices

“We are delighted to debut our new company website to our clients and partners, who are looking to understand the breadth of Greycon’s products and services,” said Abder Guezour, Greycon’s Managing Director. “This website redesign allows each of our visitors to have a unique experience while having access to our service information, educational webinars, latest news and premium content for our existing customers.”

Greycon’s new website will be updated on a regular basis with news of product launches and software updates, essential customer information, corporate milestones and industry news through the new online blog.

Visitors are encouraged to explore the new website and sign up to the Greycon’s newsletter.

For more information on Greycon and to view the site, please visit https://www.greycon.com.

Greycon have partnered with Allard Emballages

With their business expanding, Allard Emballages decided it was the opportune moment to implement a planning and MES software to replace their internal customised system. Their older system worked well for them for many years, however, as with many internal systems, they started to experience the downfalls lacking support while the business complexity is changing. With objectives to reduce the risk of technology obsolescence and increase efficiencies, Allard Emballages decided the best solution for their requirements was to implement the Greycon software into their Varennes site.

“I would like to thank the Greycon team for the implementation of our new MES in our Varennes site. During this project, I worked with different Greycon representatives, all of whom had very good sense of customer relationships, good general knowledge about the process, and good expertise of the information systems of a paper mill. I’d like to say a special thank you to Leví, Nicolas and Angelos for visiting our site, I appreciated your skills and kindness throughout the whole process.”

Frédéric Bourge

Project Manager at Allard Emballages

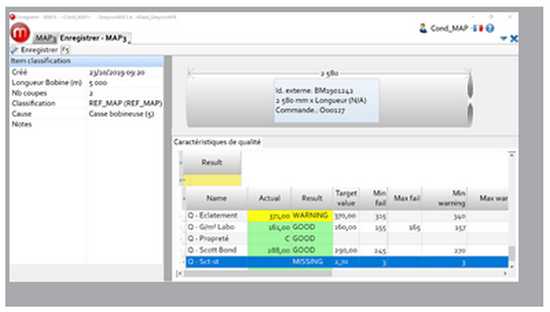

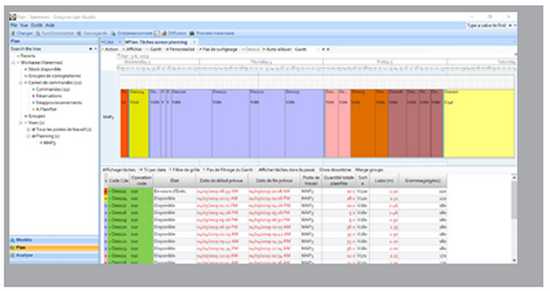

Working closely with Allard Emballages, considering their requirements and necessities, Greycon implemented opt-Studio for order entry, planning and scheduling, and GreyconMill for manufacturing execution. The software included production recording and tracking, quality management, transport planning and shipping, product labelling and reporting with GreyconMill capability to integrate with Microsoft Reporting Services.

GreyconMill Production Tracking and Quality Control

GreyconMill Production Tracking and Quality Control

The project was a great success with a smooth transition from the older in-house MES system to the new one, allowing the Varennes team to continue with their normal operations without issues.

BENEFITS

- Visibility of order flow and status

- Integrated system (covering planning, production, quality, logistics)

- Up-to-date technology & long-term support

opt-Studio Planning

opt-Studio Planning

Greycon provides APRIL Group with new planning software to improve customer service

Greycon is the world’s leading provider of production planning, forecasting, scheduling and manufacturing execution systems that have been designed specifically for roll-based and flat sheet industries.

Greycon was recently appointed by the APRIL Group, one of the largest, most technologically advanced and efficient makers of pulp and paper products in the world, to further optimize its sales and operations planning by integrating Greycon sales and operations solution “opt-Studio” with APRIL’s

Greycon was recently appointed by the APRIL Group, one of the largest, most technologically advanced and efficient makers of pulp and paper products in the world, to further optimize its sales and operations planning by integrating Greycon sales and operations solution “opt-Studio” with APRIL’s

Enterprise Resource Planning and Manufacturing Execution Systems. Greycon worked together with the APRIL Group and Accenture to deliver this solution.

Praveen Singhavi, President, APRIL Group, said: “In order to continue to meet customer demand and deliver high levels of customer service, we have integrated opt-Studio with our existing solutions.

“opt-Studio has improved end-to-end visibility of our sales orders, while being able to better optimize paper production (block planning) and finishing area scheduling.”

Vassilis Gkamouras, Senior Consultant at Greycon said: “APRIL Group is one of the most efficient pulp and paper mills in the world. The project was divided in three phased roll-outs to enable quick deployment of capabilities and took 14 months to complete.”

“The roll-out required expertise in global project management, change management, supply chain enablement and systems integration. The project was delivered on-time, in-full and within budget due to excellent team work between the partners involved.”

About APRIL Group

APRIL Group is a leading producer of fibre, pulp and paper with manufacturing operations in Pangkalan Kerinci, Riau Province, Indonesia. APRIL is a pioneer in the implementation of sustainability best practices in Indonesia’s pulp and paper industry, including the elimination of deforestation from its supply chain. APRIL Group is working towards conserving, protecting and restoring one hectare of high value conservation forest for every hectare of renewable plantation concession. Today, APRIL Group conserves more than 250,000 hectares with a further 150,000 hectares undergoing ecosystem restoration. For more information, visit www.aprilasia.com and follow twitter @aprilpulp.

About Greycon

Greycon is the world’s leading provider of production planning, forecasting, scheduling and manufacturing execution systems that have been designed specifically for roll-based & flat sheet industries. Greycon

operates throughout the world. Greycon’s strength is the extensive range of specialist software solutions for Plastic Films & Flexible Packaging, Nonwovens, Metals, Converting, Paper and Board industries supported by powerful optimisation algorithms and a highly experienced team of consultants.

Sunshine Paper automates scheduling planning processes to improve efficiencies

China’s largest producer of coated and uncoated white top test liner and world-class preprint home base, Sunshine Paper, has automated its scheduling process for its five cutters by integrating opt-Studio with its SAP ERP solution. The system went live last month (April 2018).

Shandong Century Sunshine Paper Group Company Limited, founded in 2000, listed on the Hong Kong Stock Exchange Market in 2007 owning total assets of RMB 10 billion. Sunshine Paper has a total paper capacity of 1.3 million tons per year, is one of China’s top 15 papermakers and a global top 100 papermaker.

Shandong Century Sunshine Paper Group Company Limited, founded in 2000, listed on the Hong Kong Stock Exchange Market in 2007 owning total assets of RMB 10 billion. Sunshine Paper has a total paper capacity of 1.3 million tons per year, is one of China’s top 15 papermakers and a global top 100 papermaker.

Mr. Li Jinhai, CIO, at Sunshine Paper said: “In our endeavours to improve and optimise production processes to mitigate the increased environmental costs due to the new Environmental Protection Tax which has been implemented in China, we approached Greycon which implemented its X-Trim trim optimisation application for us in 2009, to review the planning functionality for our sheeting processes. Following its review, and based on the success of its trim solution X-Trim which they implemented for us in 2009, we requested Greycon integrate its advanced scheduling planning software, opt-Studio, with our ERP to schedule the sheet orders in our five cutters.

“The adoption of opt-Studio provides us with improved short and mid-term planning capabilities; we can refresh the schedule automatically on every machine in seconds, giving the planner and other users full visibility of the impact of the decisions or external events.”

Tian Jinlong, Business Development Director at Greycon said: “Rising environmental costs will intensify the competition in the paper industry and companies are implementing new solutions and upgrading existing products to ensure efficiencies are maximised. Profitable Chinese companies are finding it easier to invest in upgrading however, smaller companies are under more pressure and may even be squeezed out the market.

“Sunshine Paper approached us with a brief to optimise its planning functionality on its cutters. The integration of opt-Studio enables the optimisation of schedules, improving the production throughput. Since the system manages the scheduling of the orders, the effort of the planners will now be diverted to analysis and optimisation instead of the routine work to feed the orders and their sequence into the ERP-system. opt-Studio will also change decision-making from that of being based on past experience, to fact-based decision-making. The powerful what-if functionality allows the planners to perform different kind of analyses to determine the most efficient way forward.

“The integration was organised using Greycon’s standard methods, Integration Manager and schedule release to Microsoft SQL Server based database table,” said Jinlong.