Displaying items by tag: valmet

Valmet to supply a board machine rebuild to Umka in Serbia

Valmet will supply a board machine rebuild to Umka Cardboard Mill in Serbia. The main target of the rebuild is to increase the customer’s production capacity. The start-up of the rebuilt paper machine PM 1 is scheduled for the second half of 2021.

The order is included in Valmet's orders received of the fourth quarter 2019. The value of the order will not be disclosed. The total value of an order of this type is typically around EUR 15-20 million.

"This rebuild is one of the most important strategic decisions we have made in the course of 80 years long history of the mill. We are pleased that this project is going to be completed by Valmet, a global leader in the supply of process technology in the paper industry. I strongly believe in the success and bright future of Umka Cardboard Mill, with planned capacity of over 200,000 tonnes, further quality improvements and wider product portfolio,” says Milos Ljusic, Managing Director of Umka.

"The co-operation between Valmet’s and Umka’s teams has been excellent. Together, we built up a solution which will help Umka increase production capacity and improve their end product quality," says Pekka Turtinen, Senior Sales Manager at Valmet.

Umka’s and Valmet’s teams at the Umka 80-year anniversary celebration. From left: Kari Räisänen (Valmet), Milos Ljusic (Umka), Jadranka Priljeva (Umka), Staniša Lukić (Umka), Nikola Pejović (Umka) and Pekka Turtinen (Valmet)

Umka’s and Valmet’s teams at the Umka 80-year anniversary celebration. From left: Kari Räisänen (Valmet), Milos Ljusic (Umka), Jadranka Priljeva (Umka), Staniša Lukić (Umka), Nikola Pejović (Umka) and Pekka Turtinen (Valmet)

Improved production capacity

Valmet's delivery will include major changes in the wet end of the paper machine PM1 with broke collection, approach flow system and three OptiFlo Foudrinier headboxes to meet the growing productivity and quality requirements of high-quality board machine, as well as an OptiFormer Multi forming section with multiple foudriniers and modifications in the press section.

The delivery will also include an OptiCoat Layer curtain coating station with supply system and an OptiDry Turn air dryer and an OptiWin Drum two-drum winder. Related spare parts and paper machine clothing for start-up and Valmet DNA Machine Controls System will also be included. A two-year Valmet Performance Center on-demand expert support will further help Umka to reach its targets.

The 3,700-mm-wide (wire) PM1 will produce white lined chipboard grades with a basis weight range of 160-450 g/m2. The design speed of the new parts will be 440 m/min. The daily design capacity will be approximately 620 tonnes.

Information about the customer Umka

Umka Cardboard Mill has been a part of KappaStar Group since its privatization in 2003. Mill’s production capacity is currently 130,000 tonnes per year. Umka exports over 80% of its production to over 30 European countries. The most important export markets are Poland, Hungary, Romania and Russia. Umka’s cardboard is widely used in the manufacturing of cardboard packaging for the food, confectionery, pharmaceutical, chemical, tobacco, textile, and automotive industries, as well as for spare parts production within the machine industry. It is also used for lamination in the manufacture of transport packaging.

Valmet to start co-determination negotiations in the Fabrics Business Unit in Finland

Valmet is planning changes in the Fabrics Business Unit which is part of the Services Business Line in order to secure the unit’s profitability and future competitiveness. The most important action in the preliminary plan is to move the dryer fabric and wide filter fabric production from Tampere in Finland to Valmet’s unit in Portugal. The possible actions will have employee impacts. The functions under consideration are part of Valmet Technologies Oy.

As a consequence of the above, Valmet starts co-determination negotiations in Fabrics’ operations in Tampere on January 21, 2020. The co-determination negotiations are estimated to last six weeks and they include Fabrics’ personnel in Tampere. The co-determination negotiations can result in the reduction of 90 persons at maximum mainly during year 2021 by estimate, and in possible temporary lay-offs and part-time work during 2020. Fabrics Business Unit employs altogether approximately 500 persons in its Tampere operations.

As a consequence of the above, Valmet starts co-determination negotiations in Fabrics’ operations in Tampere on January 21, 2020. The co-determination negotiations are estimated to last six weeks and they include Fabrics’ personnel in Tampere. The co-determination negotiations can result in the reduction of 90 persons at maximum mainly during year 2021 by estimate, and in possible temporary lay-offs and part-time work during 2020. Fabrics Business Unit employs altogether approximately 500 persons in its Tampere operations.

Fabrics Business Unit develops and manufactures press felts, shoe press belts, dryer fabrics and wide filter fabrics in Tampere. Valmet’s location in Portugal, to which the dryer fabric and wide filter fabric production possibly is relocated, develops and manufactures filter fabrics and other industrial textiles.

Active review of operations’ locations is part of Valmet’s normal business development globally. In recent years, for example, Valmet’s production of evaporation plants from Sweden and the production of Quality Control Systems (QCS) from China have been relocated to Finland. Valmet employs 5,100 persons in Finland of which 2,000 in Tampere. At the moment Valmet has approximately 160 open positions in Finland.

Valmet launches a new microwave consistency measurement for pulp and paper makers

Valmet launches a completely redesigned Valmet Microwave Consistency Measurement – Valmet MCA (patent pending) for pulp and paper makers. Valmet MCA is now provided by digital electronics and the new Direct Sweep Detection measurement to offer higher performance measurement sensitivity and accuracy than competing analog designs.

A wider applicability with the new Twin Blade sensor

Valmet MCA’s new Twin Blade sensor complements the offering, along with the newly redesigned Flow Through sensor, by allowing paper and pulp makers to install it in larger pipe diameters. The Flow Through sensors are totally interchangeable with earlier installations.

Valmet Microwave Consistency Measurement

Valmet Microwave Consistency Measurement

With a wider applicability, the new Twin Blade sensor can also be used to measure unscreened pulp. The sensor’s completely redesigned clamp mounted probe is suitable for the much higher conductivity environment of chemical pulping.

“This new measurement technology is a leap forward in terms of performance and usability. For long Valmet has been the market leader in microwave consistency measurements with more than 6,000 deliveries. The new Valmet MCA now leads the way for all pulp and paper needs,” says Marko Heikkinen, Product Manager, Automation business line, Valmet.

The new and easy-to-use operating unit

Commissioning and operation have also been enhanced with the Valmet Bridge user interface, a new 7’’ touch screen control platform designed for use with Valmet process sensors and analyzers. With comprehensive diagnostics, Wi-Fi and Industrial Internet ready capabilities, Valmet Bridge user interface provides a user-friendly experience and intuitive access to transmitter operation and remote services from Valmet.

The industrial standard in total consistency measurement

Valmet MCA measures total consistency of the pulp process stream independent of fiber length, freeness, wood species or blend. The measurement is not affected by flow rate, brightness or color and enables better control for more efficient production, improved quality and economic savings with fewer process upsets and less off grade product. With low lifetime costs, the sensor is simple to install and requires no regular maintenance to keep commissioning and running costs to a minimum.

Read more: https://www.valmet.com/valmetmca

Valmet will supply a new Advantage DCT tissue production line to Alas Doradas in El Salvador

Valmet will supply an Advantage DCT100HS tissue production line, including a de-inking plant and an extensive automation package, to Alas Doradas in El Salvador. The order also includes a Valmet Performance Center agreement to support efficient production with Industrial Internet. The new tissue line will fulfill Alas Doradas’ demand for new capacity of high-quality tissue products in the region. The start-up is planned for the first half of 2021.

The order is included in Valmet's orders received of the fourth quarter 2019. The value of the order is not disclosed.

“Our cooperation with Valmet started with the rebuild of our existing machine where the press section was upgraded with an Advantage ViscoNip press combined with Advantage ReDry technology. With the results achieved, we are convinced that Valmet’s technology is what we need to differentiate from competition and become the frontrunner in the Central American tissue market. Even more important is the collaboration with a reliable partner as Valmet. We see this as the first step in a long-term partnership. Valmet has met and exceeded all expectations as a reliable partner during our cooperation,” says Paul Ekman, CEO, Alas Doradas.

“To be chosen as preferred partner to Alas Doradas is an important statement for us. We appreciate our relationship greatly. The new Advantage DCT tissue machine will be equipped with all the latest technologies which shows that our role as technology leader and advisor fulfills customer’s needs in the important South American market”, says Kent Nika, Sales Director for South America, Tissue, Valmet.

Both companies are looking forward to the future with a shared aim – to realize Alas Doradas’ expansion plan and provide high-quality tissue products to their customers.

Alas Doradas’ and Valmet’s team

Alas Doradas’ and Valmet’s team

Technical information about the delivery

The new tissue machine will have a width of 2,8 meters and a design speed of 2,000 meters/minute. It will add 35,000 tons tissue paper per year to Alas Doradas’ current production of high-quality toilet tissue, napkins and kitchen towels.

Valmet's scope of delivery will comprise a tissue production line featuring complete Deinking plant and an Advantage DCT 100HS tissue machine. The machine is equipped with OptiFlo headbox and Valmet cast iron Yankee cylinder as well as the Advantage technology including ViscoNip press, AirCap hood, WetDust dust system and SoftReel reel. The delivery also includes an extensive automation package with Valmet DNA, Valmet IQ quality controls, Industrial Internet applications, Valmet Performance Center agreement and tissue line training simulator. Engineering, supervision, training, start-up and commissioning are also included in the delivery.

Valmet and Fabio Perini start Industrial Internet ecosystem partnership to provide digital solutions for tissue production and converting

Valmet and Fabio Perini have established an Industrial Internet ecosystem partnership to strengthen collaboration in the tissue industry. The target is to allow tissue producers and converters to work together more efficiently, and to exchange knowledge and resources for the benefit of their customers.

The partnership combines Valmet's comprehensive tissue making technology and process optimization know-how with Fabio Perini’s strong expertise in complete solutions for converting and packaging machines as well as in the converting process and technology. The two companies’ solid expertise combined with data from tissue mills and converting plants will provide a new dimension to tissue mill optimization.

The collaboration aims at providing an unbroken chain of production data from the tissue machine to the converting line and utilizing artificial intelligence-driven applications in the tissue production process to make the converting operations downstream more efficient. This will bring significant mill-level quality and efficiency improvements for tissue producers and converters.

The collaboration aims at providing an unbroken chain of production data from the tissue machine to the converting line and utilizing artificial intelligence-driven applications in the tissue production process to make the converting operations downstream more efficient. This will bring significant mill-level quality and efficiency improvements for tissue producers and converters.

“Starting from customer needs, Valmet and Fabio Perini are now taking the first steps to develop solutions where innovation goes beyond company borders, covering both tissue production and converting processes. Through collaboration with our common customers we can provide new digital solutions and services to help move tissue mills’ performance forward,” says Jari Almi, Vice President, Industrial Internet, Valmet.

“We believe an open innovation model is a key concept through which companies within tissue business can create different partnerships to make their innovation process more efficient, as well as exchange knowledge and resources. By combining the strengths of our companies, we can facilitate broad innovation and fast adaptation, enable new business and service models and help improve the profitability of companies in the tissue business,” says Oswaldo Cruz Junior, CEO of Körber's Business Area Tissue.

Both Valmet and Fabio Perini have a long history in offering measurement and optimization applications for tissue production. These reliable measurements have provided proven results for their customers.

Information about Fabio Perini

Fabio Perini S.p.A. with the brands Fabio Perini, Casmatic and Concept X, is specialized in the production of machinery, lines and integrated systems, for the converting and packaging of tissue paper, for a wide range of products: toilet rolls, kitchen towels, industrial rolls. Founded in 1966 at Lucca, the Italian district of tissue production and converting technology, Fabio Perini is a point of reference for its high level of innovation and advanced technology. Fabio Perini S.p.A. is the leading company of the Körber Group’s Business Area Tissue. www.fabioperini.com

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2018 were approximately EUR 3.3 billion. Our more than 13,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Valmet receives a repeat order for an Advantage ThruAir tissue production line from Irving Consumer Products in the United States

Valmet has received an order for an Advantage ThruAir machine from Irving Consumer Products. This is a repeat order of the Advantage ThruAir machine that was started up recently in 2019. The new machine is planned to start-up in 2022 and will continue to support Irving’s commitment to provide ultra-premium products to the North American market.

The order is included in Valmet’s orders received of the fourth quarter 2019. The value of the order is not disclosed.

Valmet and Irving share a long history of partnership and this will be their fifth tissue project together. Previously Valmet has delivered one ThruAir machine to Macon, Fort Edward, Toronto, and major rebuilds of tissue machines TM1 and TM2 to Saint John. Irving recently announced they are doubling their capacity of ultra-premium household paper products at their Macon plant and are immediately initiating an expansion of the plant.

Valmet Advantage ThruAir tissue machine

Valmet Advantage ThruAir tissue machine

“The new TAD machine will help Irving Consumer Products continue to grow and deliver ultra-premium quality tissue paper products to our customers,” says Robert K. Irving, President of Irving Consumer Products.

“Valmet and Irving have a long relationship of successful projects. We are excited to work with them to reach the production and quality targets. Their products have been very much appreciated by the demanding North American market which requires the best softness, bulk and absorbency. The success is obvious with the rapid decision to invest in tissue machine TM 9. Our relationship is built on trust, setting joint targets and delivering results,” says Jan Erikson, VP Sales, Valmet.

Technical information about the delivery

Valmet’s delivery will comprise of a complete tissue production line with stock preparation equipment. The new line will include an Advantage ThruAir tissue machine including an OptiFlo II TIS headbox, ThruAir Dryers and Air system and an Advantage SoftReel reel. The scope also includes mist and dust systems, automation systems, basic mill engineering and advisory services. The production line will add a capacity of 75,000 annual tonnes of tissue to Irving’s current production.

Information about Irving Consumer Products

Irving Consumer Products is one of North America's leading manufacturers of household paper and baby diaper products. Irving Consumer Product companies include Irving Tissue and Irving Personal Care. Irving Tissue produces premium household store brand paper products for many of North America's top retailers, in addition to some of the top-selling tissue brands in the marketplace. Irving Personal Care is the only manufacturer of baby diapers and training pants in Canada. Using state-of-the-art equipment and technology, they produce premium quality private label products for major North American customers. Read more at www.irvingconsumerproducts.com.

For further information, please contact:

Jan Eriksson, Vice President, Sales, Tissue Mills Business Unit, Valmet, tel. +46 705 17 14 90

Soren Eriksson, Sales Director, Tissue Mills Business Unit, Valmet, tel. +1404-242-8845

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2018 were approximately EUR 3.3 billion. Our 13,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Valmet delivers key technology for Bracell’s new pulp mill in Brazil

Valmet will deliver key technology for Bracell’s project to build a new pulp production line at the mill located in Lençóis Paulista, São Paulo state, Brazil. Valmet’s delivery includes an evaporation plant and a white liquor plant, in which the lime kilns are fueled with gasified biomass.

The order was included in Valmet's orders received of the third quarter 2019. The value of the delivery will not be disclosed. However, a project of this size and scope is typically valued around EUR 200-250 million.

In May 2019, Bracell announced its plan for a substantial expansion of the São Paulo pulp mill in Lençóis Paulista (formerly Lwarcel) to increase its current production capacity of 250,000 tons per year (tpy) by an additional 1,250,000 tpy to reach 1.5 million tpy. The project is expected to be completed by the end of 2021.

In May 2019, Bracell announced its plan for a substantial expansion of the São Paulo pulp mill in Lençóis Paulista (formerly Lwarcel) to increase its current production capacity of 250,000 tons per year (tpy) by an additional 1,250,000 tpy to reach 1.5 million tpy. The project is expected to be completed by the end of 2021.

“The new São Paulo unit in Lençóis Paulista will feature best-in-class technology with a flexible line designed primarily to produce dissolving pulp. This project is the largest private investment in the São Paulo state in the last 20 years and it generates employment opportunities for the entire region,” tells Carlos Pastrana, Projects Director from Bracell.

“Our technology represents new innovations and is designed for flexible production with high energy efficiency. The project will have a significant employment impact both for engineering and production in Brazil and the Nordics,” says Bertel Karlstedt, Business Line President, Pulp and Energy, Valmet.

About Valmet’s delivery

Valmet’s delivery includes an evaporation plant with a super concentrator. The plant features Valmet’s TUBEL technology for highest availability and easy washing. The evaporation is designed for high energy efficiency with energy recovery from hot weak black liquor.

The white liquor plant is an essential part in the mill’s chemical recovery process. Valmet’s delivery includes the complete white liquor plant with recausticizing and two lime kilns. In addition, Valmet delivers two biomass dryers and two biomass gasifiers. The two lime kilns are fueled with biogas decreasing the need for fossil fuels. The white liquor plant is designed for producing high quality white liquor for cooking with lower operating cost with renewable furnace fuels and low specific heat consumption.

Valmet also delivers non-condensable gas (NCG) handling system to control and minimize the odors emerging from the chemical recovery processes.

“Valmet has extensive experience in delivering fossil fuel free lime kilns, which are fueled with either wood powder or gasified biomass. Using gasified biomass is a sustainable and economical solution for large mills. Our solution works seamlessly together throughout the whole process from biomass drying, gasification and lime kiln to emission control. Our evaporation technology represents leading energy efficiency and is designed for long lifetime and high availability,” says Fernando Scucuglia, Director, Pulp & Energy, South America, Valmet.

Information about the customer Bracell

Bracell is one of the largest specialty cellulose producers in the world. Bracell has operated in Brazil for 15 years. The company has main operations in Bahia Specialty Cellulose in Camacari, Bahia and in Lençóis Paulista, São Paulo. By the time the expansion project completes in 2021, Bracell will have annual production capacity of 2.0 million tons of dissolving pulp and will employ 7,300 direct and indirect employees.

For further information, please contact:

Bertel Karlstedt, Business Line President, Pulp & Energy, Valmet, tel. +358 10 672 0000

Celso Tacla, Area President, South America, Valmet, tel. +55 41 3341 4581

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2018 were approximately EUR 3.3 billion. Our more than 13,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

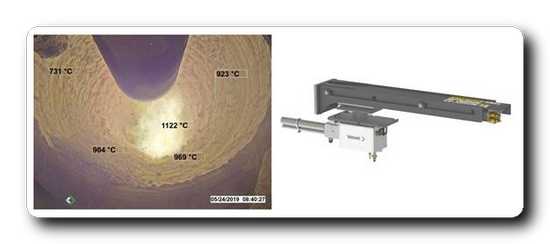

Valmet introduces new visible imaging system for pulp mill lime kilns

Valmet has launched a new Valmet Visible Thermal Imaging System, which provides the highest quality lime kiln process monitoring for pulp mills. Combining the camera temperature information with process controls can improve combustion optimization and reburned lime quality, and reduce emissions. The system also allows visual evaluation of flame shape, size, and temperature profile. Reduced maintenance costs and greater visibility during start-up and full load conditions can also be achieved.

The Valmet Visible Thermal Imaging System is a rugged, air-cooled, HD visible camera paired with a high-resolution thermal sensor for real-time product temperature measurements. Designed for comprehensive observation and analysis of kiln environments, the camera system provides unparalleled image quality from start-up to full load conditions.

Example output from Valmet Visible Thermal Imaging System

Example output from Valmet Visible Thermal Imaging System

“There has been a very positive and enthusiastic use of this camera system during the initial pilot cases, most especially in observing and tuning the kiln burner flame during operation and start-up. It is exciting to see such an active customer engagement in using the camera features to monitor and improve their processes,” says Rodeo Winchell, Product Manager, Automation, Valmet.

The highest definition visible sensor results in superior image quality

Valmet Visible Thermal Imaging Systems are engineered for durability and longevity inside of hot, dusty environments, providing a low maintenance solution to many complex process challenges. Optional automatic retraction hardware protects the camera from overheating in the cooling air loss. Digital-only data transmission improves the reliability of video streams, eliminating unwanted noise or image signal degradation.

The Valmet Visible Thermal Viewer software combines the HD visible image with a high-resolution thermal sensor array. With up to eight customizable regions of interest for calculating temperature, users have full control over their data. Coupled with a user-friendly interface, it is simple to record images, view historical data trends, and configure temperature threshold alerts.

Read more: https://www.valmet.com/kilncamera

For further information, please contact:

Rodeo Winchell, Product Manager, Valmet Visible Thermal Imaging System, Automation business line, Valmet, tel. +1 360 402 9685

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2018 were approximately EUR 3.3 billion. Our more than 13,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Valmet to deliver a new lime kiln and a fiberline upgrade for SCA Obbola kraftliner expansion project in Sweden

Valmet will deliver key technology for upgrading the SCA Obbola mill’s pulp production in Sweden. Valmet’s delivery includes a new fossil free lime kiln and upgrade of the existing fiberline. The pulp production upgrades will happen in stages. The upgraded fiberline will start up in June 2021 and the new lime kiln is scheduled to start up during the last quarter of 2021.

The order is included in Valmet’s orders received of the fourth quarter 2019. The value of the order will not be disclosed. A project of this size and scope is typically valued at around EUR 50 million.

Valmet’s delivery is part of SCA’s major investment to increase the annual production of kraftliner in Obbola mill from the current 450,000 tonnes to 725,000 tonnes per year. The total investment amounts to SEK 7.5 billion (about EUR 700 million) over a five-year period.

“With the investment in Obbola mill, we can meet the increased demand for sustainable packaging. We selected Valmet to deliver new technology for our pulp mill upgrade as we have had good experiences of Valmet technology at both our Obbola mill and other SCA mills,” tells Per Stand, Project Director from SCA.

“This order strengthens our cooperation with SCA. Delivering fossil fuel free lime kiln solution is very much aligned with the strategies of both our companies. SCA valued our technical leadership in lime kilns as well as robust and reliable solutions both for the lime kiln and fiberline,” says Bertel Karlstedt, Pulp and Energy Business Line President, Valmet

Valmet will deliver key pulp technology for increasing the production for SCA Obbola mill’s new kraftliner paper machine. (Photo: SCA/Bergslagsbild)

Valmet will deliver key pulp technology for increasing the production for SCA Obbola mill’s new kraftliner paper machine. (Photo: SCA/Bergslagsbild)

Technical details about Valmet’s delivery

The new lime kiln system delivered by Valmet replaces two old oil fueled lime kilns and will have a daily capacity of 220 tonnes burned lime. The solution includes OptiDisc Lime Mud Filter, Flash Dryer for lime mud drying, high efficiency Rotary Cooler and a full Wood Powder Firing System for the lime kiln, including storage and grinding of wood pellets. This solution makes the lime kiln 100 percent fossil free. SCA also operates a wood powder fired lime kiln delivered by Valmet at its Munksund mill.

The fiberline upgrade includes a new hot stock refining after the digester using Conflo refiners. The brown stock washing will be improved by adding a new TwinRoll press as last washing stage before the storage towers for the paper machine. As a result of the fiber line upgrade the daily capacity will increase from today’s 850 air dry tons to 1,100 air dry tons. The capacity increase is done with improved washing with the same water consumption.

Information about the customer SCA

SCA offers paper for packaging and print, pulp, wood products, renewable energy, services for forest owners and efficient transport solutions. In 2018 SCA had approximately 4,000 employees and sales amounted to approximately EUR 1.8 bn. SCA was founded in 1929 and has four pulp and paper mills in Sweden. In September 2019 SCA announced its plan to build a new paper machine for the production of kraftliner at its Obbola paper mill in Umeå.

For further information, please contact:

Claus Jensen-Holm, Director Lime Kiln Technology, Pulp and Energy, Valmet, tel. +45 6023 8810, This email address is being protected from spambots. You need JavaScript enabled to view it.

Mikael Gustafsson, Senior Sales Manager, Fiberline Sales, Pulp and Energy, Valmet, tel. +46706533809, This email address is being protected from spambots. You need JavaScript enabled to view it.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2018 were approximately EUR 3.3 billion. Our more than 13,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Valmet introduces versatile new solution for fiber recovery and pulp thickening

Valmet announces the launch of Valmet Pressure-fed Bow Screen, a versatile new addition to its stock preparation offering. The solution reinvents the traditional bow screen with a new, user-friendly design and improved nozzle arrangement enabling higher capacity and greater runnability than before.

Working to maximize the effectiveness of fiber recovery and pulp thickening processes, Valmet Pressure-fed Bow Screen is ideal for tissue making applications. Other primary applications of the equipment include shower water protection filtration, police filtration, felt hair removal and deinking stock washing.

Working to maximize the effectiveness of fiber recovery and pulp thickening processes, Valmet Pressure-fed Bow Screen is ideal for tissue making applications. Other primary applications of the equipment include shower water protection filtration, police filtration, felt hair removal and deinking stock washing.

“A primary driving force behind the new design was our goal to provide a better, safer user experience for our operators at the mill level,” explains Tony Bjorkenius, Business Manager, Disc Filters, Services, Valmet. “The equipment is engineered to provide better accessibility than ever before, with the focus on service, maintenance and everyday use.”

Valmet Pressure-fed Bow Screen is the company’s first new product that specifically leverages the technology, engineering and expertise gained from the acquired company GL&V. The product launch reinforces Valmet’s services approach “Shared Journey Forward”, a set of commitments that promises customers solutions built on their unique needs, safety, trust and accessibility.

For further information, please contact:

Tony Bjorkenius, Business Manager, Disc Filters, Services, Stock Preparation, Valmet, tel. +46 8 522 444 56, This email address is being protected from spambots. You need JavaScript enabled to view it.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2018 were approximately EUR 3.3 billion. Our more than 13,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com