Displaying items by tag: valmet

Valmet and Biochemtex to collaborate in developing technology for lignin derived biochemicals

Valmet and Biochemtex will start to cooperate in the field of conversion of lignin into biochemicals. The development project will combine and adapt LignoBoost and Moghi technologies. LignoBoost is Valmet's proprietary technology for the extraction of purified lignin from black liquor produced by pulp mills. Moghi in turn is Biochemtex's proprietary technology for the conversion of lignin into biofuels and biochemicals.

Valmet and Biochemtex will start to cooperate in the field of conversion of lignin into biochemicals. The development project will combine and adapt LignoBoost and Moghi technologies. LignoBoost is Valmet's proprietary technology for the extraction of purified lignin from black liquor produced by pulp mills. Moghi in turn is Biochemtex's proprietary technology for the conversion of lignin into biofuels and biochemicals.

This collaboration will create a high value market for lignin while providing the biochemical industry a consistent lignin stream to be used as a sustainable feedstock for the production of bioPET (bio based thermoplastic polymer).

"Valmet's industrially proven LignoBoost technology for lignin extraction plays an important role in this project. We are continuously developing new sustainable technologies for increasing the value of lignin. Combining LignoBoost and Moghi technologies is one of the very promising solutions we are looking into when developing biochemical technologies," says Rickard Andersson, Vice President for Valmet's Biotech and Environmental Systems.

"For us this partnership is an additional opportunity to provide the market with second generation biochemicals. We are already working with our own and Beta Renewables technologies. The cooperation with Valmet will allow to increase the feedstock available to produce bioPX, a key raw material for the production of PET made 100% from renewable sources. Existing pilot plant facilities, and the dedicated demo plant under construction in Italy, combined with the skills and know-how in both organizations, will provide a solid base to deliver fast and positive outcome for this exciting opportunity,"says Giovanni Bolcheni, CEO of Biochemtex.

About Biochemtex

Biochemtex is a leader in the technologies for the production of second generation biofuels and biochemicals. It is part of the Mossi Ghisolfi Group and a global leader in the development and engineering of technologies and bio-chemical processes based on the exclusive use of non-food biomass, as an alternative to oil.

VALMET

Corporate Communications

For further information, please contact:

Jussi Mäntyniemi, Director, Technology and R&D, Pulp and Energy, Valmet, tel. +358 40 769 8154

Alessandra Bogliano, R&D Director, Biochemtex, tel. +39 0131 88 28 11

Valmet to supply brown stock washing plant modernization to Södra Cell's Mörrum pulp mill in Sweden

Valmet will supply a modernization of the brown stock washing plant of the dissolving line to Södra Cell's Mörrum pulp mill in Sweden. The rebuild is part of the second stage of a long-term initiative at Södra Cell Mörrum mill.

The brown stock washing plant rebuild will increase the mill's pulp production capacity by 45,000 tons. The project will commence in spring 2016 and is scheduled for completion in the fourth quarter of 2017.

The order is included in Valmet's second quarter 2016 orders received. The value of the order will not be disclosed. A rebuild with this scope is usually valued below EUR 10 million.

"The successful cooperation with Valmet on the dissolving line that began in 2011 continues with the next step. The investment will enable increased production and increased opportunities to further enhance the production quality of our dissolving pulp," says Martin Säll, Engineer and Project Manager at Södra Cell Mörrum.

During the strategy period 2014-2020, Södra Cell Mörrum will gradually offer larger volumes and expand production capacity from 380 000 tons to 500 000 tons of which 200 000 tons will consist of high quality dissolving pulp.

Technical details about the delivery

The modernization of the brown stock washing plant mainly contains the installation of three new Valmet TwinRoll presses, two before the oxygen stage and one before the bleach plant.

"The latest Valmet TwinRoll generation takes dewatering and washing to a new level by increasing capacity by up to 30 percent, improving consistency, and optimizing operation while minimizing operational and maintenance costs.Our TwinRoll presses have proven their functionality in several dissolving lines over the years. We are confident that this is a good solution for Mörrum mill and look forward to a great collaboration also in this project," says Mikael Gustafsson, Sales Manager at Valmet.

About the customer Södra Cell

Södra is an economic association with a membership base of 51,000 forest owners in southern Sweden. Södra has built up a considerable production of paper pulp, wood products and biofuels. Södra employs about 3,800 people and has four business areas Södra Skog, Södra Cell, Södra Timber and Södra Interiör.

Södra Cell is one of the largest players in the world in the area of softwood pulp and operates three pulp mills in Sweden: Mörrum, Mönsterås and Värö. Södra Cell Mörrum currently produces high-quality pulp and is the only Södra mill to produce textile pulp, for which demand is growing rapidly.

For further information, please contact:

Mikael Gustafsson, Sales Manager, Pulp & Energy Business Line, Valmet tel. +46 70 653 38 09

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet AB delivers brown washing plant to Södra Cell Mörrum

In February 2016, Södra's Board of Directors decided to invest SEK 1 billion in a new evaporator and modernisation of the brown washing plant in the dissolving pulp line, where textile pulp is produced. Södra is now awarding Valmet AB the contract to supply the new brown washing plant.

Södra is growing together with its customers. During the 2014-2020 strategy period, Södra Cell Mörrum will gradually begin to offer larger volumes and increase production capacity from 380,000 tonnes to 500,000 tonnes, of which 200,000 tonnes will consist of high-quality dissolving pulp.

"The successful cooperation with Valmet AB in the dissolving pulp line that started in 2011 now continues with the next step. The investment will enable increased production and opportunities to further enhance the product quality of the dissolving pulp". Says Martin Säll, Project manager at Södra Cell Mörrum.

The start-up of the new upgraded pulp line is calculated to the fourth quarter 2017.

For further information, please contact:

Stefan Sandberg, mill manager Södra Cell Mörrum

+46(0)454-555 50

Valmet's Interim Review January 1 - March 31, 2016: Orders received, net sales and profitability increased

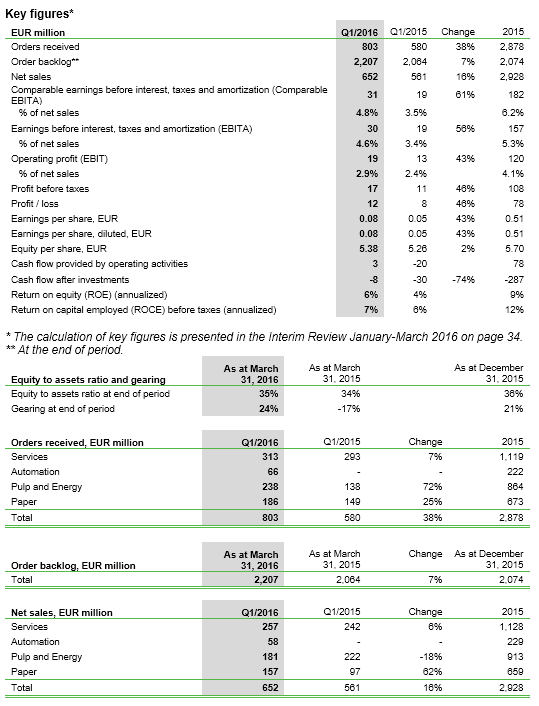

Figures in brackets, unless otherwise stated, refer to the comparison period, i.e. the same period of the previous year. Automation has been consolidated into Valmet's financials since April 1, 2015, when the acquisition of Automation was completed.

Due to new regulation by the European Securities and Market Authority concerning alternative performance measures, Valmet has decided to replace the performance measure 'EBITA before non-recurring items' with 'Comparable EBITA'. The content of items affecting comparability, i.e. items previously disclosed as non-recurring, remain unchanged and therefore 'Comparable EBITA' equals previously disclosed 'EBITA before non-recurring items'. Items affecting comparability consist of income and expenses arising from activities that amend the capacity of Valmet's operations or are incurred outside its normal course of business. Valmet discloses alternative performance measures to describe the underlying business performance and to improve comparability between reporting periods.

Due to new regulation by the European Securities and Market Authority concerning alternative performance measures, Valmet has decided to replace the performance measure 'EBITA before non-recurring items' with 'Comparable EBITA'. The content of items affecting comparability, i.e. items previously disclosed as non-recurring, remain unchanged and therefore 'Comparable EBITA' equals previously disclosed 'EBITA before non-recurring items'. Items affecting comparability consist of income and expenses arising from activities that amend the capacity of Valmet's operations or are incurred outside its normal course of business. Valmet discloses alternative performance measures to describe the underlying business performance and to improve comparability between reporting periods.

January-March 2016: Orders received, net sales and profitability increased

- Orders received increased to EUR 803 million (EUR 580 million).

- Orders received increased in the Pulp and Energy, Paper, and Services business lines.

- Automation contributed to orders received with EUR 66 million.

- Orders received more than doubled in EMEA (Europe, Middle East and Africa) and South America.

- Net sales increased to EUR 652 million (EUR 561 million).

- Net sales increased in the Paper and Services business lines and decreased in the Pulp and Energy business line.

- Automation contributed to net sales with EUR 58 million.

- Comparable earnings before interest, taxes and amortization (Comparable EBITA) were EUR 31 million (EUR 19 million), and the corresponding Comparable EBITA margin was 4.8 percent (3.5%). Earnings per share were EUR 0.08 (EUR 0.05).

- Profitability improved due to the higher level of net sales in Paper and Services business lines, improved gross profit, and the acquisition of Automation.

- Items affecting comparability amounted to EUR -2 million (EUR 0 million).

- Cash flow provided by operating activities was EUR 3 million (EUR -20 million).

Valmet reiterates its guidance for 2016

Valmet is reiterating its guidance presented on February 9, 2016 in which Valmet estimates that net sales in 2016 will remain at the same level with 2015 (EUR 2,928 million) and Comparable EBITA in 2016 will increase in comparison with 2015 (EUR 182 million).

Due to new regulation by the European Securities and Market Authority, Valmet has decided to replace the performance measure 'EBITA before non-recurring items' with 'Comparable EBITA'. The content of items affecting comparability, i.e. items previously disclosed as non-recurring, remain unchanged and therefore 'Comparable EBITA' equals previously disclosed 'EBITA before non-recurring items' (EUR 182 million in 2015). Items affecting comparability consist of income and expenses arising from activities that amend the capacity of Valmet's operations or are incurred outside its normal course of business.

Short-term outlook

General economic outlook

The baseline projection for global growth in 2016 is a modest 3.2 percent, broadly in line with last year, and a 0.2 percentage point downward revision relative to the January 2016 World Economic Outlook Update. The recovery is projected to strengthen in 2017 and beyond, driven primarily by emerging market and developing economies, as conditions in stressed economies start gradually to normalize. But uncertainty has increased, and risks of weaker growth scenarios are becoming more tangible. The fragile conjuncture increases the urgency of a broad-based policy response to raise growth and manage vulnerabilities. (International Monetary Fund, April 12, 2016)

Short-term market outlook

Valmet reiterates the good short-term market outlook for board and paper, and the satisfactory short-term market outlook for services, automation, pulp, energy, and tissue.

President and CEO Pasi Laine: Solid start of the year with increase in orders received, net sales and profitability

Valmet had a solid start of the year 2016 with an increase in orders received, net sales and profitability. Orders received increased in Pulp and Energy, Paper, and Services business lines. As a result of both customer activity and good work in all parts of the organization, the orders received development has been trending upwards in all business lines. The orders received were at an all-time high level in the Services business line. Profitability improved in the first quarter of the year compared to the first quarter of 2015.

Automation has now been a part of Valmet for a full year, and I am very pleased with the development. Summing up the year from the Automation perspective, the integration was a success. Both customers and employees are pleased and energized, we launched new automation products during the year, strengthened Valmet's position in Industrial Internet and, in financial terms, we can be satisfied with the development of the Automation business line. Furthermore, our four business lines have found a good and continuously improving way to cooperate in the customer interface and to bring benefits of our unique and market's widest offering to our customers.

News conference and webcast for analysts, investors and media

Valmet will arrange a news conference in English for investment analysts, investors, and media on Wednesday, April 27, 2016 at 2:00 p.m. Finnish time (EET). The news conference will be held at Valmet Head Office in Keilaniemi, Keilasatama 5, 02150 Espoo, Finland. The news conference can also be followed through a live webcast at www.valmet.com/webcasts.

It is also possible to take part in the news conference through a conference call. Conference call participants are requested to dial in at least five minutes prior to the start of the conference, at 1:55 p.m. (EET), at +44 1452 560304. The participants will be asked to provide the following conference ID: 82571086.

During the webcast and the conference call, all questions should be presented in English. After the webcast and the conference call, media has a possibility to interview the management in Finnish.

The event can also be followed in Twitter at www.twitter.com/valmetir.

Further information, please contact:

Hanna-Maria Heikkinen, Vice President, Investor Relations, Valmet, tel. +358 10 672 0007

Kari Saarinen, Chief Financial Officer, Valmet, tel. +358 10 672 0031

Valmet to supply a new screening and washing plant to Smurfit Kappa Cellulose Du Pin Biganos in France

Valmet will supply Smurfit Kappa Cellulose Du Pin Biganos pulp and paper mill in France with a new screening and brown stock washing plant for kraft liner pulp production. The new plant will replace old equipment and make the mill meet today's environmental requirements. The delivery is scheduled for the beginning of 2017, and the start-up for later the same year.

Valmet will supply Smurfit Kappa Cellulose Du Pin Biganos pulp and paper mill in France with a new screening and brown stock washing plant for kraft liner pulp production. The new plant will replace old equipment and make the mill meet today's environmental requirements. The delivery is scheduled for the beginning of 2017, and the start-up for later the same year.

The order was included in Valmet's fourth quarter 2015 orders received. The value of the order will not be disclosed. The value of an upgrade of this scope is usually valued below EUR 10 million.

"Valmet has proven technology for high kappa pulp production, based on a unique cooking, refining and washing concept. This order is a token of our leading position within the area of fiber lines for kraft liner. We are looking forward to an interesting project together with Smurfit Kappa," says Peter Rummel, Sales Manager, Valmet.

Technical information of the delivery

The order includes a new screening plant with a reject refiner and a washing stage consisting of a filter stage followed by two TwinRoll presses. The screening and brown stock washing plant will have a capacity of 1250 adt/d.

About the customer Smurfit Kappa

Smurfit Kappa Cellulosedu Pin, is one of the leading Europeanproducers ofpaper made fromvirgin fiberfor packaging. Based in Facture, Aquitaine(South-Westof France), its production unitis specializedin the manufacture ofcoverageKraft papercorrugated board.

For further information, please contact:

Peter Rummel, Sales Manager, Pulp and Energy Business Line, Valmet, tel. +46 70 653 3802

Yannick Duperrier, Senior Mill Sales Manager, EMEA Sales, Valmet, tel. +33 6 85 67 24 24

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

The Swedish Court of Patent Appeals has revoked Andritz's Swedish Patent on which Andritz had filed a summons application against Valmet in 2015

As Valmet announced by stock exchange release on February 20, 2015, Andritz Oy had filed a summons application with the Stockholm District Court against Valmet AB, a subsidiary of Valmet Corporation, regarding patent infringement. In the claim Andritz is asking that Valmet under a penalty ceases to utilize the system allegedly infringing Andritz's patent and to impose royalty and damages on Valmet AB with EUR 54 million and interest for the alleged infringement. Valmet has not made any provisions concerning the claim.

As Valmet announced by stock exchange release on February 20, 2015, Andritz Oy had filed a summons application with the Stockholm District Court against Valmet AB, a subsidiary of Valmet Corporation, regarding patent infringement. In the claim Andritz is asking that Valmet under a penalty ceases to utilize the system allegedly infringing Andritz's patent and to impose royalty and damages on Valmet AB with EUR 54 million and interest for the alleged infringement. Valmet has not made any provisions concerning the claim.

The validity of Andritz's patent has been challenged by Valmet, and this matter has been awaiting a decision from the Swedish Court of Patent Appeals. The Swedish Court of Patent Appeals has on March 23, 2016 decided to revoke Andritz's patent.

An appeal of the decision now made by the Swedish Court of Patent Appeals can be filed to the Supreme Administrative Court by May 23, 2016.

Further information, please contact:

Rasmus Oksala, General Counsel, Valmet, tel. +358 10 672 0026

Hanna-Maria Heikkinen, Vice President, Investor Relations, Valmet, tel. +358 10 672 0007

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet to deliver a new white liquor filter to Rottneros Vallvik pulp mill in Sweden

Valmet will deliver a white liquor filter to Rottneros Vallvik pulp mill located on the east coast of Sweden. White liquor filter is part of the pulp mill's chemical recovery process.

This investment is part of Rottneros AB's larger rebuild project called Agenda 500, which aims to increase availability and the total production volume at both of Rottneros AB's pulp mills, Rottneros Mill and Vallvik Mill, and with a target to reach a capacity of 500,000 tons per year.

Rottneros' Vallvik pulp mill. Photo: Rottneros image bank

The new white liquor filter will replace an existing filter delivered by Valmet in 1990. A larger filter is needed to handle the capacity increase at the mill. Start-up of the new filter is scheduled for autumn 2016.

The order is included in Valmet's first quarter 2016 orders received. The value of the order will not be disclosed. A white liquor filter is usually valued below EUR 5 million.

"Vallvik has great confidence in Valmet as a supplier and despite a very tough schedule, we have a good reason to assume that Valmet will deliver on time. In addition, I personally look forward to working with Valmet again because this is my third project with Valmet regarding installation of pressurized disc filter," says Per-Arne Nilsson, Project Manager at Vallvik mill.

"Despite being a trusted partner with Vallvik for more than 40 years in the white liquor area, the tight schedule of this project was a challenge when pursuing this project. All people involved in the sales phase participated in the strategic and proactive work to compress the delivery time, and they deserve big thanks for their efforts. We are very pleased and look forward to a good and safe project implementation phase," says Thomas Malmqvist, Sales Manager at Valmet.

Valmet will also deliver a new bleach plant to Rottneros pulp mill, which was published earlier this year.

Technical details about the delivery

Valmet's delivery includes a new PDW-type white liquor filter, erection, start-up services, basic engineering for piping, for instrument and for electrical and process control. The PDW pressure disc filter produces completely clear white liquor and washes the lime mud. The very high white liquor yield increases upstream capacity and eliminates the potential process disturbances that increased amount of dregs and other non-process elements (NPE's) in the white liquor can cause.

About the customer Rottneros and the Vallvik mill

The Rottneros Group produces paper pulp at two pulp mills. Chemical pulp is produced at the Vallvik Mill, while mechanical pulp is produced at the Rottneros Mill. Vallvik mill produces two grades of long-fiber sulphate pulp: fully bleached sulphate pulp - ECF (Elemental Chlorine Free) and unbleached sulphate pulp - UKP (Unbleached Kraft Pulp). The mill has recently received a permission to produce 255 000 tons per year.

For further information, please contact:

Thomas Malmqvist, Sales Manager, Pulp & Energy Business Line, Valmet tel. +46 54 14 23 87

Valmet to supply board machine key technology for two container board machines in China

Valmet will supply board machine key technology and machine control systems in two new containerboard machines in China. The customer remains confidential. Valmet's delivery includes headbox and press section technology and a machine control system.

Valmet will supply board machine key technology and machine control systems in two new containerboard machines in China. The customer remains confidential. Valmet's delivery includes headbox and press section technology and a machine control system.

The order is included in Valmet's first quarter 2016 orders received. The value of the order will not be disclosed. Typically, an upgrade of two lines of this scope is valued at EUR 20-30 million.

"In containerboard manufacturing, headbox and press section are one of the most important key technologies in order to secure high production quality. Our expertise and references convinced the customer to choose Valmet," comments Kari Räisänen, Area Sales Director from Valmet.

Technical information about the delivery

Valmet's delivery for the new containerboard machines will include all together five new OptiFlo Fourdrinier headboxes for improved product quality and increased productivity, two OptiPress Linear double-nip press sections with linear web run for excellent end product properties, high dewatering capacity and good runnability. All the delivered machinery will be equipped with machine control systems.

For further information, please contact:

- Petri Paukkunen, Vice President, Sales and Marketing, Paper Mills, Valmet, tel. +358 40 744 8182

- Fan Ze, Area Vice President, Sales, Valmet tel. +86 139 0133 6277

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

SKF Extends Global Agreement with Valmet

SKF’s long-term collaboration with Valmet continues, through the supply of bearings and lubrication system solutions

SKF (STO:SKFB) (STO:SKFA) (Pink Sheets:SKFRY) (LSE:SKFB) has signed an agreement that extends its long-term collaboration with Valmet. SKF will supply bearings, units and lubrication systems to Valmet, the global supplier of technologies, automation and services for the pulp, paper and energy industries.

![]() Erik Nelander, President, Industrial Sales, Europe and MEA, says: “We have been working with Valmet for over 60 years. Our commitment to adopting a design-to-cost approach in our product development also supports Valmet in maximising the efficiency of their own investments in technology development. Our manufacturing and R&D presence across Finland, Sweden and China provides the local knowledge and short lead-times that Valmet requires. By combining our expertise around the rotating shaft, end-users are able to maximise usage of their machinery.”

Erik Nelander, President, Industrial Sales, Europe and MEA, says: “We have been working with Valmet for over 60 years. Our commitment to adopting a design-to-cost approach in our product development also supports Valmet in maximising the efficiency of their own investments in technology development. Our manufacturing and R&D presence across Finland, Sweden and China provides the local knowledge and short lead-times that Valmet requires. By combining our expertise around the rotating shaft, end-users are able to maximise usage of their machinery.”

SKF’s tailored bearing and units solutions have been developed with a focus on reducing design and manufacturing costs for Valmet and decreasing operating costs for machine owners and operators.

SKF’s patented Flowline circulating oil systems provide accurate lubrication, whilst at the same time reducing the amount of circulating oil needed, reducing costs and environmental impact.

Aktiebolaget SKF (publ)

SKF is a leading global supplier of bearings, seals, mechatronics, lubrication systems, and services which include technical support, maintenance and reliability services, engineering consulting and training. SKF is represented in more than 130 countries and has around 17,000 distributor locations worldwide. Annual sales in 2015 were SEK 75 997 million and the number of employees was 46 635. www.skf.com

® SKF is a registered trademark of the SKF Group.

Valmet's new Service Center inaugurated in Brazil

Valmet has inaugurated its fourth Service Center in Brazil. The center is located in Imperatriz, in Maranhão state to serve customers in the northern and northeastern parts of Brazil. The opening ceremony of the center was held on March 16, 2016.

"This service center supports Valmet's strategy of being close to customers and growth markets. We can provide significant customer benefits by utilizing our full offering of process technology, automation and services, and by continuously developing our local and remote services," says Jukka Tiitinen, Business Line President, Services at Valmet.

The new service center focuses on serving the pulp, paper, tissue and panelboard industry. The offering includes advanced machinery maintenance, welding, component and equipment reconditioning and manufacturing, as well as on-site maintenance at customer mills. The center also incorporates a consignment stock for selected spare parts and consumables.

"This new service center is one proof of our commitment to move our customers' performance forward. We are now able to serve our customers in Maranhão and also in the other states in the region better than ever before. This strengthens our cooperation especially with Suzano Papel e Celulose mill located in Imperatriz," states Celso Tacla, Area President, South America, Valmet.

Valmet currently has a network of 100 service locations serving the pulp, paper and energy industries around the world. In addition, Valmet's experts are close to customers also with the help of Industrial Internet and remote connections.

For further information, please contact:

- Celso Tacla, Area President, South America, Valmet, tel. +55 41 3341 4581

- Jukka Tiitinen, Business Line President, Services, Valmet, tel. +1 404 433 0937

- Elio Krummenauer, Services Director, South America, Valmet, tel. +554199748123

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2015 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Picture captions.

-

pic 1 - The inauguration ceremonies were held on March 16, 2016. From left Elio Krummenauer, Sebastião Madeira, mayor of Imperatriz, Celso Tacla, Jukka Tiitinen -

pic 2 - Valmet's Imperatriz Service Center in Maranhão state in Brazil