Displaying items by tag: voith paper

Sustainable investment decisions pay off in daily stock preparation operations

Sustainable production in stock preparation is not a vision for the future but already a reality today. Many existing plants benefit from solutions from Voith's leading BlueLine stock preparation portfolio. In the last five years, Voith experts have commissioned more than 30 plants with a total production capacity of 12.8 million tons per year. Voith has also launched more than 20 new innovative machines in recent years. Based on its experience, Voith is characterized by in-depth know-how and reliable, optimized process standards. In addition, the development of new solutions is part of Voith's sustainability program “Papermaking for Life.” Every year, the technology company invests around 100 million euros in research and development of impetus-giving innovations that are intended to further increase sustainability and efficiency.

- Based on profound know-how and many years of experience, Voith offers the most sustainable and efficient solutions for stock preparation

- Already today, optimized solutions can achieve efficiency increases of between 20 and 30 percent

- Sustainability and efficiency lead to significant cost savings and maximized output

"As the leading full-line supplier, we not only focus on the individual machine components but also on the entire stock preparation process," confirms Andreas Heilig, Vice President Products Fiber Systems at Voith Paper. "Our BlueLine stock preparation portfolio is used in new plants worldwide. But upgrading existing plants to our solutions also pays off – both economically and in terms of sustainability and efficiency."

Falk Albrecht, Head of Process Technology Fiber Systems at Voith Paper, mentions, among other things, pump energy, which accounts for up to 50 percent of the energy consumption of a stock preparation system. There is great potential for optimization here, especially with existing, older systems. In order to minimize energy consumption, Voith solutions strive for the highest possible consistency level of the achievable quality parameters with the same technological performance. Savings of between 20 and 30 percent are already possible through this measure. At the same time, great attention is given to low pressure levels. Another product example for increasing energy efficiency is Voith's LowEnergyFlotation technology (LEF). Through its use, energy savings of up to 50 percent can be achieved in the flotation pumps, without negatively affecting the technological result.

Customers also benefit from significantly lower water and energy consumption with the AquaLine water and wastewater management system, which is well thought-out in all aspects. The system, developed and optimized by Voith and Meri over many years, treats the process water biologically and thus reduces the COD and calcium content in the water. This saves fresh water and reduces the consumption of additive materials on the paper machine. The AquaLine Flex system variant enables fresh water consumption to be reduced to less than 5 liters per kg of paper produced. With the very technologically advanced AquaLine Zero solution, fresh water consumption is reduced to 1.5 liters per kg of paper produced. The use of the biogas produced as a substitute fuel for fossil fuels also led to a CO2 reduction of around 10 percent in one German installation.

In addition to water management, high-performance process components are important in stock preparation. Modern disc filters produce excellent filtrate qualities that can be fed directly to biological treatment. Additional primary clarification is no longer required, which has a very positive effect on yield, investment costs and the environment. Significant energy savings can also be achieved with the new InduraClean heavy-weight cleaning system compared with conventional solutions. As part of the BlueLine stock preparation family, Voith presented the system, which consists of an improved cleaner bank, the new InduraClean IDC-4 and the optimized InduraClean IDC-5. Depending on requirements, the modular cleaning technology can be configured for significantly increased production, a high specific energy reduction of up to 50 percent, or significantly improved separation efficiency.

The OnView.MassBalance digitalization solution is another example of how sustainability and efficiency are combined in Voith's product portfolio. The innovative digital tool displays losses in stock preparation in real time, allowing the operator to identify optimization opportunities in specific areas at a glance and initiate appropriate countermeasures. In this way, high losses can be avoided, which is why the solution pays for itself after less than a year. In the future, stock preparation will become even more digitalized and autonomous. Voith experts are working on 24/7 real-time analysis of complex system interactions, which will allow automatic adaptation of process parameters to individual situations. At the same time, the need for manual intervention is reduced to a minimum. In addition, Voith is developing self-optimizing control systems that enable an optimal balance between production volume, efficiency and quality while maintaining the highest reliability based on daily updated cost models.

Sustainability program Papermaking for Life

As part of the innovation and development offensive "Papermaking for Life," Voith Paper presents versatile technologies and initiatives that lead to more efficient and sustainable processes in papermaking. The emphasis is on the topics of water, energy and fiber savings as well as digitalization, innovations and partnerships as levers for more sustainable production. Another focus is on Voith's own activities at its locations worldwide. Learn more about Voith Paper's innovations in the area of sustainability: voith.com/papermaking-for-life/innovation.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 20,000 employees, sales of € 4.3 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from one source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

New design of the successful automation solution OnQ FormingSens ensures optimized real-time measurement of water weight in the forming section

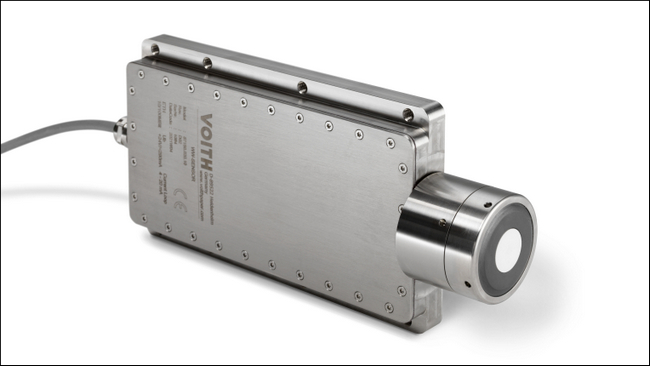

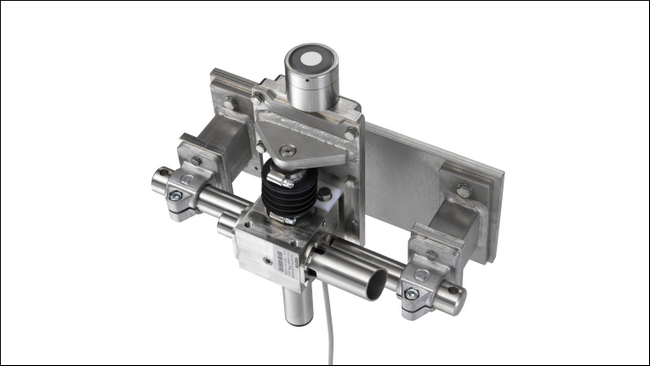

OnQ FormingSens has a long track record of benefitting paper manufacturers of different grades, with more than 100 systems are already in use in the forming section worldwide. Thanks to microwave technology, the leading solution measures fluctuations in water weight precisely, reliably and in real-time. Based on this information, papermakers can systematically improve their settings, achieve a stable dry content at the end of the forming section, and utilize the maximum dewatering capacity in the press section. At the same time, the optimized settings ensure less wear on the forming fabrics and ceramics. In addition, vacuum and drive energy usage can be reduced, which was confirmed, among others, by a Central European packaging papers manufacturer. Here, OnQ FormingSens reduces energy costs by around 130,000 euros per year and pays for itself in well under a year. For maximum user-friendliness and reliability, Voith experts have now further optimized the design of the solution.

- Based on many years of experience and profound know-how, Voith improves the design of OnQ FormingSens for optimized lifetime, reliability and operator friendliness

- Thanks to real-time measurement, the operator continuously receives information about the dry content in the forming section and can optimize the vacuum settings

- In combination with the OnC.Dewatering automatic vacuum control system, layer bonding in the forming section can be improved and energy requirements reduced

"Compared to the previous OnQ FormingSens, the new generation has a significantly longer service life, flexible connection options to existing process control systems, and improved mechanical stability, thus enabling extremely reliable measurement results," says the responsible project manager, Jörg Spindler, Manager Actuator Development at Voith Paper. The new design focuses on solid, low-vibration construction, as well as a simplified electrical design. Among other things, Voith's experts reworked the mechanical mount so that the operator can now fine-tune the penetration depth from outside the machine via waterproof mechanical gear. The sensor holder can be flexibly positioned on various existing dewatering elements in the former. Compared to hand-held measuring devices, the permanently installed application is characterized by higher safety, as no direct contact with the operator with the forming fabrics is necessary. An improved sensor housing ensures higher long-term stability. The new generation OnQ FormingSens is installed to a nearby terminal box, which can be serviced by Voith experts via a service connection. This allows the optimized solution to be better connected to customers' existing infrastructures, such as the process control system.

Combination with OnC.Dewatering control system

Based on the measurements of OnQ FormingSens, the control loop can be closed with the fully automatic dewatering control OnC.Dewatering. The control system defines and stabilizes the dry content of each layer produced and thus significantly increases ply bond on multi-ply machines. Further information on the automation solutions can be found here: https://voith.com/corp-en/products-services/automation-digital-solutions/onquality.html?130226%5B%5D=0

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 20,000 employees, sales of € 4.3 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Monitoring losses with the digitalization solution OnView.MassBalance for more sustainability and transparency in stock preparation

The recycling process in paper production is complex. Fluctuations in fiber quality and the degree of contamination of the recovered paper bales have a direct influence on production output. At the same time, resource efficiency is more important today than ever before. However, with the current state of the art, it is hardly possible to determine the specific causes of losses and optimize them directly. Yield is usually only measured on a weekly or monthly basis - by the time paper manufacturers receive the information, the losses have already occurred. Furthermore, it is very difficult to estimate whether losses in individual stock preparation areas have increased or decreased compared to the last analysis. To address these issues, the leading full-line supplier Voith has developed OnView.MassBalance.

The innovative digital tool displays losses in stock preparation in real time to further increase the sustainability and efficiency of paper production. At a glance, the operator can locate the specific areas with optimization potential on the screen. For this purpose, a Sankey diagram maps each feed, accepts and rejects at each process step. As soon as a critical value is reached, OnView.MassBalance reports this to avoid high losses. In this way, standardized processes can be established that can be quickly and easily performed by operators across different shifts. Suitable countermeasures can be, for example, checking the pressure drop or the feed consistency of the last screening stage.

Successful customer installation

"The solution is already being used very successfully, for example in an OCC mill in France with an annual capacity of 250,000 tons,” according to Flavio Granito, Global Product Manager Fiber System 4.0 at Voith Paper. “After the optimization phase, 600 tons of rejects, including raw material, could be saved per month. This corresponds to a two percent improvement in yield.” As there is less rejects to dispose of and at the same time more paper can be produced with the same amount of raw materials, the solution pays for itself in less than a year. Flavio Granito further explains: "OnView.MassBalance is another example of how digitalization can strengthen more sustainable and cost-efficient papermaking. As part of our major sustainability program Papermaking for Life, we have set the goal of optimizing recycling processes and minimizing fiber losses. We aim to achieve a 90 percent recycling rate by 2030."

Installation and operation support

To calculate the mass balance in stock preparation, the innovative tool uses the signals from the sensors installed in the stock preparation plant. Voith experts identify the sensors required for this and develop a suitable concept together with the customer. Voith also separately offers the OnPerformanceLab (OPL) service. Based on bundled know-how, the OPL provides pragmatic support in analyzing losses, defining and implementing new countermeasures, and preparing monthly reports in close coordination with the respective paper technologists.

Sustainability program Papermaking for Life

Optimal production and resource savings with the help of the Papermaking 4.0 digitalization and automation portfolio are key topics of Voith’s Papermaking for Life sustainability program. As part of the innovation and development offensive, Voith Paper presents versatile technologies and initiatives that lead to more efficient and sustainable processes in paper production. The focus is on water, energy and fiber savings as well as digitalization, innovations and partnerships as levers for more sustainable production. Learn more about Voith Paper's commitment to sustainability: voith.com/Papermaking-For-Life.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 20,000 employees, sales of € 4.3 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

How Laakirchen Papier AG optimizes the papermaking process with OnEfficiency.Strength

Current raw material prices are forcing paper manufacturers to reduce production costs and further optimize the efficiency of their production facilities. Digitalization plays a key role in achieving efficiency gains and cutting costs. This is because new technologies in particular enable significant improvements in existing and new plants. They allow better monitoring of all processes and thus more precise production control, which in turn leads to higher efficiency and better availability.

Reduced starch consumptionIn addition to fiber, starch is a major raw material cost factor in the production of packaging papers. Therefore, the goal of paper manufacturers is to reduce starch application and keep the amount of starch as low as possible - without falling below the required quality level.

However, continuous optimization with conventional tools quickly reaches its limits. Paper manufacturers are confronted with the situation that they cannot directly control important quality parameters such as strength, because the measurement of the relevant parameters only takes place at the end of each tambour in the laboratory and the values are not continuously available.

Digital solutions such as OnEfficiency.Strength from Voith now offer the ability to have important quality parameters constantly available thanks to virtual sensors and to have the process optimally controlled automatically.

How Laakirchen Papier AG optimizes the use of starchSince 2021, OnEfficiency.Strength has been used at PM 10 in Laakirchen, Austria, to optimize starch application. A positive side effect is also the resulting reduction in steam consumption in the after-dryer section. What was previously only possible either through manual measurements in the laboratory or automatic test line measurements is now realized by Laakirchen with the use of virtual sensors: the calculation of data on the most important strength values (SCT CD, CMT and burst).

"This continuous monitoring of important quality parameters enables continuous optimization of the process in terms of cost and quality. Manual laboratory measurements, on the other hand, take up to 30 minutes after sampling, and the parameters can then only be adjusted by manual intervention," says Korbinian Hitthaler, project manager for Papermaking 4.0 at Voith OnPerformance.Lab. "Thanks to the virtual sensors, the strength values are now available in real time, so the starch application can be controlled without losing time. Thanks to the automatic control of the jet-wire difference, strength potentials between MD and CD can be optimally balanced."

Christopher Dierkes-Leifeld, PM 10 technologist at Laakirchen Papier AG, further explains: "We have been using OnEfficiency.Strength since 2021 to consistently meet quality requirements and thus optimize the paper produced on PM 10 and compensate for process fluctuations. At the same time, we have also reduced our costs, because OnEfficiency.Strength enables optimum control of the starch application quantity and the jet-wire ratio.”

Real-time prediction of quality parameters and continuous optimization of the process has not only prevented quality fluctuations, but OnEfficiency.Strength has also enabled production costs to be reduced while reliably meeting quality targets. ”Since we started with Papermaking 4.0 in cooperation with Voith, the speed of our PM 10 has been increased. Nevertheless, we have achieved the strength properties required by our customers with up to 10 percent starch savings due to optimization by the control system," concludes Dierkes-Leifeld. For PM 10, OnEfficiency.Strength helped to save four percent starch in the first year and now up to 10 percent starch in the second year, while key quality parameters such as SCT CD and CMT remained within target values.

The OnEfficiency.Strength principle: visualize, stabilize, optimizeOnEfficiency.Strength combines three modules to create a new, powerful generation of advanced process controls (APC). The control system includes virtual sensors, also called soft sensors; model predictive control (MPC); and a cost optimizer. A special feature of the virtual and self-adaptive sensors is their high predictive accuracy, typically above 90 percent.

The virtual sensors precisely predict important quality parameters. Knowing these parameters in real time enables the MPC to control the papermaking process in such a way that the targeted values are permanently achieved through continuous adjustment. The cost optimizer ensures that this is done at the lowest possible cost. To find the customer-specific cost optimum, actuators and control strategies can be individually selected and flexibly adapted.

Laakirchen Papier AG was particularly impressed with the high savings potential offered by OnEfficiency.Strength. This was calculated in the Value-Add Assessment carried out in advance. "Before installation, we carry out a so-called Value-Add Assessment with our customers, in which we calculate the savings potential of OnEfficiency.Strength based on the individual customer data," says Dr. Julius Flitsch, head of the Voith OnPerformance.Lab. "We then guarantee this savings potential to our customer. In addition, we always determine the parameters and actuators to be controlled individually, depending on customer requirements and paper machine."

Laakirchen Papier AG and Voith: Lighthouse project in Papermaking 4.0Laakirchen Papier and Voith have been working on joint pilot projects in Papermaking 4.0 since 2019. "We’ve had very good experience working with Voith. In addition to the OnEfficiency.Strength project, we also have many other Papermaking 4.0 pilot projects being implemented at the site. These include OnEfficiency.BreakProtect, OnCumulus and most recently OnView.Energy. This enables us to continuously improve our papermaking process," says Jan Reibert, Production Manager PM 10 at Laakirchen Papier AG. "Our cooperation with Voith is always at a very high level and on an equal footing. During the OnEfficiency.Strength project phase, we were in close and intensive exchange. This enabled us to discuss potential challenges together, discuss appropriate solutions and implement them in a timely manner."

About the Voith GroupThe Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 20,000 employees, sales of € 4.3 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services, and products on the market, and offers paper manufacturers integrated solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its comprehensive automation products and leading digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Successful start-up of PM 6 of Shanxi Qiangwei Paper in Jinzhong

At the beginning of June, the XcelLine PM 6 supplied by Voith was successfully started up at the Jinzhong site in the central Chinese province of Shanxi by the paper manufacturer Shanxi Qiangwei Paper. As the leading full-line supplier, Voith delivered the entire production line. The machine has a wire width of 7 m, a design speed of 1,200 m/min and produces plasterboard liner and containerboard with a basis weight of 90 to 160 gsm. Annual production of over 300,000 tons is possible. Voith's latest solutions enable highly efficient, resource-saving and sustainable production.

- The XcelLine paper machine supplied by Voith was successfully started up at the Jinzhong Shanxi Qiangwei Paper´s site

- The new PM 6 will produce over 300,000 tons of plasterboard liner and containerboard per year at a design speed of 1,200 m/min

- Leading Voith technologies enable highly efficient and optimized production

Thanks to the joint efforts and cooperation of the Voith and Shanxi Qiangwei Paper teams, a fast installation and start-up of the entire line was achieved. The PM 6 has a high degree of automation, and the paper features a low tensile ratio, excellent surface quality and uniformity, as well as high breaking and folding strength. The dryness after the press is also very high, which leads to low specific steam consumption. The first paper web has thus fully achieved the customer´s expected quality level.

Latest technologies for optimum results

As the leading full-line supplier, Voith supplied the entire XcelLine paper machine. The customer-oriented concept is especially designed for maximum efficiency, robustness and sustainability. After Voith had cooperated very successfully with Shanxi Qiangwei Paper on the key equipment for PM 5, the papermaker had ordered the supply of the entire PM 6 from Voith. Voith's advanced technologies and concepts will help Shanxi Qiangwei Paper to secure its leading position in the plasterboard industry and further expand its market share in the packaging paper industry. Thus, a positive contribution can be made to the development of the surrounding region and the economy of Shanxi.

The full-line supplier Voith delivered two highly efficient MasterJet Pro headboxes, a Tandem NipcoFlex press section and a CombiDuoRun dryer section including a hood and machine air system. Optimum paper properties are ensured by a SpeedSizer AT and an EcoCal Hard calender. The reliable MasterReel reeling concept, including a parent roll handling system and discfilters for fiber recovery, is used for smooth production. Shanxi Qiangwei also relies on the latest automation solutions from the Voith Papermaking 4.0 portfolio to achieve additional efficiency increases and cost reductions. A control and information system (DCS) as well as the quality management system (QCS) OnQuality are integrated in the plant.

Successful cooperation between Voith and Shanxi Qiangwei

To ensure a smooth start-up of the paper machine, both sides worked closely together throughout the project. Lin Jiangbo, Vice President Order Execution at Voith Paper Asia, confirms: "With the challenges posed by the recent COVID-19 pandemic, Voith worked with a high degree of flexibility and in close cooperation with Shanxi Qiangwei to ensure an optimal start-up of PM 6. In the future, we will continue to provide comprehensive services for PM 6 throughout its life cycle with our technical expertise and take further steps together with Shanxi Qiangwei Paper."

About Shanxi Qiangwei Paper

Shanxi Qiangwei Paper Co. is a company integrating research and development, production and sales of surface protection plasterboard. The company is based on the concept of sustainable development "low carbon, environmental protection, high efficiency and energy-saving", and puts energy saving, emission reduction and environmental protection at the first place of the company's strategic planning. Advanced equipment, first-class technology, quality and brand in the first place - this is the company's business philosophy. The quality of Shanxi Qiangwei's products has long been a market leader and occupies a top position in this industry.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 20,000 employees, sales of € 4.3 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Indian customers rely on the Voith Paper Webshop for a quick and easy ordering process

Customers worldwide order products and services in real-time in the Voith Paper Webshop. In addition, to spare and wear parts, fabrics can also be purchased via the application with just one click for over a year now. Chandpur Enterprises Ltd. has been benefiting from the expansion of the product portfolio in the Voith Paper Webshop since March. "With the help of the personalized menu and the order history, we can now quickly identify our fabrics, order them and track the delivery status around the clock," says Mr Devesh K. Singhal, Technical Director of Chandpur Enterprises Ltd. "We are very satisfied with the Voith Paper Webshop and the cooperation with the Voith experts, who have been flexible to our requirements."

- Worldwide, the Voith Paper Webshop is already used by 180 customers

- Chandpur Enterprises Ltd. and other India customers have now also opted for the Voith Paper Webshop

- A fast, simple and personalized ordering process was the main reason for the decision.

In addition to Chandpur Enterprises, other Indian customers have already integrated the Voith Paper Webshop into their ordering process. In total, more than 180 customers already rely on digital applications. In the personalized "My Shop" section, the paper manufacturers can find all the necessary information from the original and current condition of the equipment as well as the order and quotation history, drawings, manuals and contracts.

F.l.t.r.: Praveen Batra (Head of Sales & Services FRS, Voith India), Devesh K. Singhal (Technical Director, Chandpur Enterprises Ltd.), Gaurav Singh (Senior Executive, Sales & Services FRS, Voith India) and Harsh Bakshi (Deputy Manager, Sales & Services FRS, Voith India).

F.l.t.r.: Praveen Batra (Head of Sales & Services FRS, Voith India), Devesh K. Singhal (Technical Director, Chandpur Enterprises Ltd.), Gaurav Singh (Senior Executive, Sales & Services FRS, Voith India) and Harsh Bakshi (Deputy Manager, Sales & Services FRS, Voith India).

Mr Devesh K. Singhal confirms the advantages: "Initially, we were not sure whether we should convert our previous ordering processes to the webshop and digitize them. However, we then decided in favour of the Voith Paper Webshop, because we were completely convinced by the functionality as well as the very clear user guidance. In addition, the onboarding process and subsequent registration of the individual users went smoothly. We are glad to have taken this step."

The Voith Paper Webshop is characterized by the highest data security standards. Different options can be booked depending on customer requirements. "Our goal is to enable our customers to optimize production with minimized downtimes," sums up Mr Gaurav Singh, Senior Executive Sales & Service India at Voith Paper. "One building block for this is the quick and easy ordering of fabrics. We offer customer-specific solution packages, which we are continuously developing further on a region-specific basis. The integration of the Webshop can be done smoothly for any customer worldwide."

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 20,000 employees, sales of € 4.3 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Dr. Michael Weiss is the new Chief Technology Officer at Voith Paper

Voith Paper appoints Dr. Michael Weiss, most recently Vice President Business & Research, as Chief Technology Officer and member of the Management Board. He started in his new role on February 1, 2022, succeeding Frank Opletal, who is going into well-deserved retirement after 38 years at Voith Paper. In his role, Dr. Michael Weiss reports directly to Andreas Endters, President & CEO of Voith Paper.

- Dr. Michael Weiss succeeds Frank Opletal as Chief Technology Officer and Member of the Management Board of Voith Paper

Since 2006, Dr. Michael Weiss has held various positions in the development of pioneering technologies and innovations at Voith Paper. As VP New Business & Research, he has been in charge of innovation management, the simulation department and the central laboratory at Voith Paper since 2017. As CTO, he will contribute his many years of experience in research and development to drive Voith Paper's innovation strategy around the differentiation criteria of sustainability, efficiency and full-line supplier. The main aim is to find answers to the megatrends of sustainability and digitalization and to make them usable for the paper industry.

Dr. Michael Weiss, born in 1970, joined Voith Paper in 2006 as a development engineer.

Dr. Michael Weiss, born in 1970, joined Voith Paper in 2006 as a development engineer.

“As the technology leader and full-line supplier, Voith Paper has always been a reliable partner for its customers when it comes to breaking new ground. Especially today, the paper industry needs more innovations to make production more efficient and sustainable. With his experience and his visionary view of the possibilities that lie in the sustainable material paper, we are pleased to appoint Michael Weiss to the Voith Paper Management Board,” says Andreas Endters, President & CEO of Voith Paper.

Dr. Michael Weiss, born in 1970, joined Voith Paper in 2006 as a development engineer. This was followed by various positions in research and development, where he dealt with the topics of process optimization, mathematical simulation, water management and wastewater treatment, among other things. From 2017 he held the position of Vice President New Business & Research. Dr. Weiss studied process engineering at the RWTH Aachen University. He completed his PhD in chemical engineering in 2004 at the University of Oxford, UK, followed by a two-year stay in France as a postdoc in industrial research and development.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 20,000 employees, sales of € 4.3 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services, and products on the market, and offers paper manufacturers integrated solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its comprehensive automation products and leading digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Smurfit Kappa relies on Voith’s advanced process control system OnEfficiency.Strength to reduce starch consumption

Voith’s digital solution package OnEfficiency.Strength, installed at Smurfit Kappa's Hoya mill in Lower Saxony in 2021, is showing very positive results from the first day. With virtual sensors and predictive control, OnEfficiency.Strength reduces the amount of starch applied while maintaining defined quality standards – a step that is leading to significantly lower costs and more sustainable paper production. The Hoya project is representative of how the two companies Voith and Smurfit Kappa are working together to drive digital transformation in the paper industry.

- The advanced process control system OnEfficiency.Strength has now been put into operation at the Hoya, Germany, site after a short installation period

- The solution from the Papermaking 4.0 portfolio ensures lower starch consumption, leading to significant cost savings and more stable paper quality

- The successful installation is a result of the strong cooperation between Voith and Smurfit Kappa and another important step towards more sustainable and efficient paper production with digital applications

"We chose Voith's digital solution approach because it offers significant cost savings with the latest technologies and pays for itself in less than a year," says Gerold Buck, Manager Operations at Smurfit Kappa Hoya. "With the implementation of OnEfficiency.Strength, we are successfully continuing our innovation and digitalization strategy while paying towards our sustainability goals."

In the first step, Voith had conducted a value-add assessment that identified optimization potential and significant cost reductions for production with the help of digital technologies. Subsequently, Voith experts analyzed all relevant process, laboratory and production data from the last few months, checked for anomalies and defined a control concept based on this. For smooth data exchange and efficient commissioning, the plant was also connected to the Voith OnCumulus Cloud. In addition, the personnel received training at an early stage in order to operate the application optimally. After the quick installation and start-up, OnEfficiency.Strength immediately showed potential savings in starch application.

In the first step, Voith had conducted a value-add assessment that identified optimization potential and significant cost reductions for production with the help of digital technologies. Subsequently, Voith experts analyzed all relevant process, laboratory and production data from the last few months, checked for anomalies and defined a control concept based on this. For smooth data exchange and efficient commissioning, the plant was also connected to the Voith OnCumulus Cloud. In addition, the personnel received training at an early stage in order to operate the application optimally. After the quick installation and start-up, OnEfficiency.Strength immediately showed potential savings in starch application.

"Due to rising raw material prices and highly competitive pressure, paper manufacturers are increasingly looking for ways to further optimize their production facilities and save costs - digital solutions can make a valuable contribution here," says Maria Knauer, Global Product Manager Efficiency Solutions at Voith. "OnEfficiency.Strength continuously monitors all relevant quality parameters during the manufacturing process and automatically regulates the appropriate settings. Smurfit Kappa thus saves costs and resources in production every day in a simple and automated way. We see great potential to integrate OnEfficiency.Strength at many more plants worldwide." Smurfit Kappa is also considering installing the digital solution from the Papermaking 4.0 portfolio at other sites based on the results of OnEfficiency.Strength at Hoya.

With the "PAPER IS ON" campaign, Voith highlights the focus topics of the Papermaking 4.0 digital product portfolio: full-line supplier, efficiency, sustainability, cloud solutions, automation and innovation. Learn more and visit our homepage: voith.com/PaperIsOn.

About Smurfit Kappa

Smurfit Kappa, a FTSE 100 company, is one of the leading providers of paper-based packaging solutions in the world, with approximately 46,000 employees in over 350 production sites across 36 countries and with revenue of €8.5 billion in 2020. The company is located in 23 countries in Europe, and 13 in the Americas. Smurfit Kappa's products are produced from 100% renewable energy, improving customers' environmental footprint.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 20,000 employees, sales of € 4.3 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Order execution in record time – Successful start-up of Sun Paper's XcelLine PM 2 in Beihai

Asian paper producer Sun Paper recently successfully started up PM 2 at its site in Beihai in Southeast China. The new line in visionary industrial design now produces high-quality white folding boxboard with a basis weight of 170 to 350 gsm and a wire width of 8,900 mm. With a design speed of 1,400 m/min, the planned annual capacity is over 1 million tons of paper. Thanks to the very successful cooperation between Sun Paper and Voith, the entire project from initial contracting to start-up in December took only 18 months – a new world record for a high-speed line of this type. This is the third paper machine that Voith has started up for Sun Paper in the last 12 months. In total, Voith has already delivered 12 XcelLine paper machines to Sun Paper.

- Voith sets a new world record for high-speed board machines with a project execution of only 18 months

- With a design speed of 1,400 m/min, the new PM 2 produces over one million tons of folding boxboard per year

- Voith and Sun Paper have a long and successful partnership

"Sun Paper and Voith are trustful partners,” said Li Lu, Chairman of Sun Holding Group. “From Laos PM 2’s 1-hour and 46-minute start-up to today’s Beihai PM 2, the fastest project execution at 18 months, we have created many world records together."

"We are very pleased that the paper machine started up smoothly thanks to the joint efforts of Voith and Sun Paper," said Ying Guangdong, Vice General Manager and Chief Engineer of Sun Paper. "The line produces the best board quality currently available on the market."

Start-up in record time

There was only seven and a half months between the start of installation and the successful machine start-up, even with the major challenges presented by COVID-19. To ensure the on-time arrival of all components, Voith stabilized all upstream global supply chains. Voith's excellent supply chain management and project management, as well as close coordination, high degree of flexibility and additional shifts, made it possible to meet the ambitious schedule.

"The high-speed plant uses the latest technologies," said Dr. Michael Trefz, President Projects at Voith Paper. "In combination with the visionary industrial design, the plant sets the highest standards in terms of efficiency, safety and sustainability. The start-up is another milestone in the successful and long-standing partnership between Voith and Sun Paper."

As a full-line supplier, Voith supplied the entire XcelLine paper machine in the new industrial design. The tailor-made concept focuses in particular on the efficiency and robustness of the individual components. For example, a DuoFormer ensures excellent formation and strength properties even at very high speeds. Automatic dewatering of the three shoe presses reduces thermal drying and thus saves significant energy costs. For an optimized paper surface, a SpeedSizer is used as well as four DynaCoaters, which apply the film evenly during sizing and coating. Furthermore, the CombiDuoRun dryer section with EvoDry steel dryer cylinder ensures maximum runnability and energy efficiency. In addition, two VariFlex high-performance winders ensure smooth production. Due to the visionary Voith industrial design of the entire line, optimized accessibility for maintenance work and improved occupational safety are also achieved.

Sun Paper also benefits from Voith's leading expertise in digitalization and automation for additional efficiency gains and cost reductions. The intelligent quality control system QCS as well as the solutions DCS and MCS enable complete control over the entire production line. In addition, Sun Paper relies on solutions from the Papermaking 4.0 portfolio with OnCare.Health. Thanks to a wide range of interfaces, the intelligent maintenance tool detects the smallest faults at an early stage and automatically assigns them to the affected points.

About Sun Paper

Founded in 1982, Shandong Sun Holdings Group is a global advanced integrated multinational paper group, a leader in the Chinese paper industry, ranked 306th among China's 500 largest companies and among the world's 30 largest paper manufacturers.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 20,000 employees, sales of € 4.3 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Voith expands Papermaking 4.0 portfolio with three new apps for higher process stability and efficiency in paper production

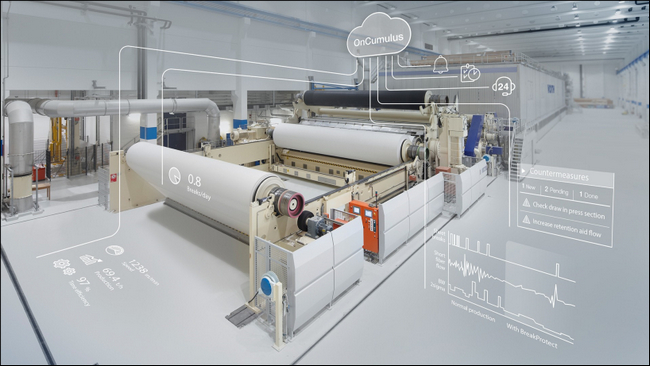

Customers worldwide rely on Voith's modular Papermaking 4.0 portfolio to individually optimize their production with the leading digital industrial applications. Based on extensive expertise, Voith is introducing OnEfficiency.BreakProtect, OnView.VirtualSensorBuilder and OnView.MassBalance, three new apps on the IIoT platform OnCumulus. The new digitalization solutions feature the highest safety standards, are quick to install and easy to use. The technologies are already successfully implemented in several plants worldwide. Due to the process optimizations and lower resource consumption, the applications often pay off in less than a year and pave the way to the digital paper mill.

- OnEfficiency.BreakProtect: Detect, understand and prevent paper break causes

- OnView.VirtualSensorBuilder: Quickly and easily calculate and visualize relevant quality parameters in real time

- OnView.MassBalance: Visualize raw material losses in stock preparation and increase yields

OnEfficiency.BreakProtect: Detect, understand and prevent paper break causes

The IIoT platform OnCumulus has already established itself as a central hub for data from multiple sources for numerous paper manufacturers. OnEfficiency.BreakProtect uses artificial intelligence to analyze the process data bundled in OnCumulus. Thereby, the innovative solution automatically detects various critical process conditions that can lead to breaks. This allows the development of specific countermeasures and the reliable prevention of tear-offs.

"I am always fascinated by the correlations that artificial intelligence can recognize," says Jürgen Käser, Director Process Applications at Voith. "Among other things, we were able to use OnEfficiency.BreakProtect to identify increased dirt and starch agglomerate loads – for which there is no measurement data at all – at the SpeedSizer pulper. In the past, these had repeatedly led to break-off series. A small mechanical rebuild, which prevents starch from entering the pulper in larger quantities, has permanently solved the previously undetected problem."

OnView.VirtualSensorBuilder: Calculate and visualize quality parameters quickly and easily using virtual sensors

Virtual sensors, also called soft sensors, have proven themselves in the process industry for many years. With the help of data models, the sensors calculate various quality parameters and thus reliably supplement laboratory tests. Until now, the use of virtual sensors required considerable time and, above all, data analysis skills. With OnView.VirtualSensorBuilder, Voith introduces a user-friendly app that allows paper manufacturers to quickly and easily create the virtual sensors themselves with just a few mouse clicks.

"With OnView.VirtualSensorBuilder, it only takes a few hours for a new soft sensor to be ready for use," says Maria Knauer, Global Product Manager Efficiency Solutions at Voith. "Previously, this required a time-consuming and costly process of several weeks."

Once installed, operators can use OnView.VirtualSensorBuilder to continuously calculate, visualize and control relevant quality values, such as strength values, in real time. Combined with OnCumulus.Suite, the digital application identifies critical values and provides preventive warnings, allowing personnel to make immediate improvement adjustments. The solution thus increases process stability, enables compliance with desired quality standards, reduces raw material costs and minimizes waste.

OnView.MassBalance: Visualize and reduce fiber losses in stock preparation

OnView.MassBalance maps the current stock flows in an intuitive Sankey diagram and provides information on deviations that are no longer within the standard range. If a defined warning threshold is exceeded, the application automatically highlights the relevant area in the diagram and recommends suitable action to avoid fiber losses. OnView.MassBalance thus leads to targeted process optimization in stock preparation and also enables centralized knowledge management.

With the help of OnView.DigitalEye, the accuracy of OnView.MassBalance can be increased even further. The innovation makes it possible for the first time to analyze recovered paper quality even before stock preparation with the help of artificial intelligence. The award-winning AI application OnView.DigitalEye is currently undergoing final testing as part of pilot installations at national and international customer sites and is expected to be available starting next year. Another application that will be launched in 2022 is OnView.Energy from Voith. The app visualizes and analyzes energy consumption and CO2 emissions in production. This enables significant savings potential to be identified, leading to lower energy costs, improved sustainability and competitiveness.

This release is part of the current "PAPER IS ON" campaign, in which Voith highlights the focus topics of the digital Papermaking 4.0 portfolio: full-line supplier, efficiency, sustainability, cloud solutions, automation and innovation. Learn more at voith.com/PaperIsOn. For more information on the solutions from the OnCumulus, OnView and OnEfficiency family as part of Voith's Papermaking 4.0 portfolio, please visit https://voith.com/corp-en/products-services/automation-digital-solutions/onefficiency.html. In addition, read more about OnView.DigitalEye receiving the AI Champions Award: https://voith.com/corp-en/news-room/press-releases/voith-wins-ai-champions-award-2021.html.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 20,000 employees, sales of € 4.3 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.