Displaying items by tag: voith

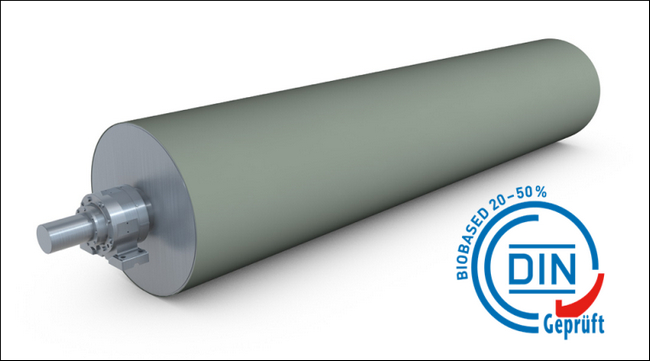

With AiroGuide Tune Green, Voith launches the first DIN CERTCO-certified bio-based guide roll cover for more sustainable paper production

With the AiroGuide Tune Green, Voith is setting a new standard in the field of papermaking products made of renewable raw materials. As the latest member of the AiroGuide guide roll cover family, AiroGuide Tune Green is certified according to the internationally recognized DIN CERTCO for bio-based products. The guide roll cover combines all the advantages of the proven AiroGuide technology while enabling the reduction of the carbon footprint. The new innovation aligns with Voith's long-time commitment and ambitious goals to accelerate sustainability for papermakers as well as in its own production.

- First guide roll cover certified according to DIN CERTCO for bio-based products

- Successful step in the development of sustainable products as part of the Papermaking for Life program

- Renewable raw materials reduce carbon footprint

- Less wear of fabrics and reduced waste

“With AiroGuide Tune Green, we are the first in the market to provide a DIN CERTCO-certified guide roll cover made with bio-based materials. We offer our customers a sustainable alternative and thus set a new milestone on the way to a more sustainable future of paper production,” says Ralf Moser, Global Product Manager at Voith.

AiroGuide Tune Green is a composite cover using bio-based raw material with mineral fiber reinforcement. It is particularly designed for the wet end and features improved corrosion protection with enhanced edge sealing to meet the corrosion requirements in humid areas. Its good stress resistance and high wear resistance result in less grinding and maintenance requirements compared to standard covers. Therefore, the roll cover leads not only to less wear of the fabrics and reduced waste but also contributes to important resource savings in paper production.

Due to the combined development of the AiroGuide Tune Green and SkyClean doctor blades, the machine can operate without additional lubrication showers – targeting less water consumption and reduced misting.

“As part of our sustainability program Papermaking for Life, we are focusing on the entire product life cycle, among other things. The importance of this is also reflected in our customers' strategic orientation and diverse activities,” says Thomas Jäger, Senior Vice President Sales Fabric & Roll Systems EMEA. “This certification confirms that Voith, as a full-line supplier, provides products and services that support the global commitment to sustainable and resource-saving paper production.”

Sustainability program “Papermaking for Life”

The sustainability of our own activities is a key focus of the recently launched “Papermaking for Life” sustainability program. As part of the innovation and development offensive, Voith Paper is also presenting versatile technologies and initiatives that lead to more efficient and sustainable processes in paper production. The focus is on water, energy and fiber savings as well as digitalization, innovations and partnerships as levers for more sustainable production. Find more information here: Voith.com/Papermaking-for-Life/Own-Activities.

About DIN CERTCO

DIN CERTCO is the certification body of TÜV Rheinland Group and is the certification body for the issuance of the DIN-Marks and further certification marks. The internationally recognized "DIN-Geprüft biobased" label verifies the use of renewable raw materials in the manufacturing of the product.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 20,000 employees, sales of € 4.3 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services, and products on the market, and offers paper manufacturers integrated solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its comprehensive automation products and leading digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

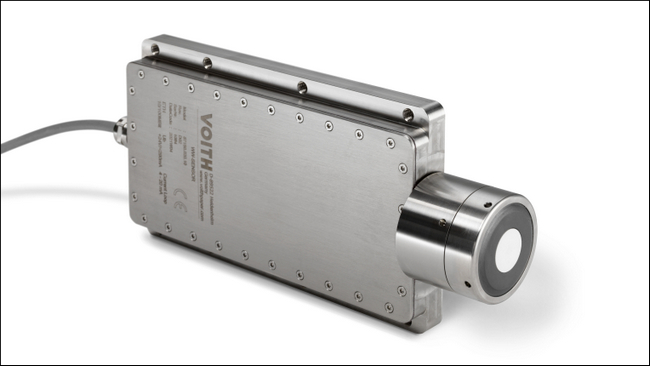

New design of the successful automation solution OnQ FormingSens ensures optimized real-time measurement of water weight in the forming section

OnQ FormingSens has a long track record of benefitting paper manufacturers of different grades, with more than 100 systems are already in use in the forming section worldwide. Thanks to microwave technology, the leading solution measures fluctuations in water weight precisely, reliably and in real-time. Based on this information, papermakers can systematically improve their settings, achieve a stable dry content at the end of the forming section, and utilize the maximum dewatering capacity in the press section. At the same time, the optimized settings ensure less wear on the forming fabrics and ceramics. In addition, vacuum and drive energy usage can be reduced, which was confirmed, among others, by a Central European packaging papers manufacturer. Here, OnQ FormingSens reduces energy costs by around 130,000 euros per year and pays for itself in well under a year. For maximum user-friendliness and reliability, Voith experts have now further optimized the design of the solution.

- Based on many years of experience and profound know-how, Voith improves the design of OnQ FormingSens for optimized lifetime, reliability and operator friendliness

- Thanks to real-time measurement, the operator continuously receives information about the dry content in the forming section and can optimize the vacuum settings

- In combination with the OnC.Dewatering automatic vacuum control system, layer bonding in the forming section can be improved and energy requirements reduced

"Compared to the previous OnQ FormingSens, the new generation has a significantly longer service life, flexible connection options to existing process control systems, and improved mechanical stability, thus enabling extremely reliable measurement results," says the responsible project manager, Jörg Spindler, Manager Actuator Development at Voith Paper. The new design focuses on solid, low-vibration construction, as well as a simplified electrical design. Among other things, Voith's experts reworked the mechanical mount so that the operator can now fine-tune the penetration depth from outside the machine via waterproof mechanical gear. The sensor holder can be flexibly positioned on various existing dewatering elements in the former. Compared to hand-held measuring devices, the permanently installed application is characterized by higher safety, as no direct contact with the operator with the forming fabrics is necessary. An improved sensor housing ensures higher long-term stability. The new generation OnQ FormingSens is installed to a nearby terminal box, which can be serviced by Voith experts via a service connection. This allows the optimized solution to be better connected to customers' existing infrastructures, such as the process control system.

Combination with OnC.Dewatering control system

Based on the measurements of OnQ FormingSens, the control loop can be closed with the fully automatic dewatering control OnC.Dewatering. The control system defines and stabilizes the dry content of each layer produced and thus significantly increases ply bond on multi-ply machines. Further information on the automation solutions can be found here: https://voith.com/corp-en/products-services/automation-digital-solutions/onquality.html?130226%5B%5D=0

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 20,000 employees, sales of € 4.3 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Monitoring losses with the digitalization solution OnView.MassBalance for more sustainability and transparency in stock preparation

The recycling process in paper production is complex. Fluctuations in fiber quality and the degree of contamination of the recovered paper bales have a direct influence on production output. At the same time, resource efficiency is more important today than ever before. However, with the current state of the art, it is hardly possible to determine the specific causes of losses and optimize them directly. Yield is usually only measured on a weekly or monthly basis - by the time paper manufacturers receive the information, the losses have already occurred. Furthermore, it is very difficult to estimate whether losses in individual stock preparation areas have increased or decreased compared to the last analysis. To address these issues, the leading full-line supplier Voith has developed OnView.MassBalance.

The innovative digital tool displays losses in stock preparation in real time to further increase the sustainability and efficiency of paper production. At a glance, the operator can locate the specific areas with optimization potential on the screen. For this purpose, a Sankey diagram maps each feed, accepts and rejects at each process step. As soon as a critical value is reached, OnView.MassBalance reports this to avoid high losses. In this way, standardized processes can be established that can be quickly and easily performed by operators across different shifts. Suitable countermeasures can be, for example, checking the pressure drop or the feed consistency of the last screening stage.

Successful customer installation

"The solution is already being used very successfully, for example in an OCC mill in France with an annual capacity of 250,000 tons,” according to Flavio Granito, Global Product Manager Fiber System 4.0 at Voith Paper. “After the optimization phase, 600 tons of rejects, including raw material, could be saved per month. This corresponds to a two percent improvement in yield.” As there is less rejects to dispose of and at the same time more paper can be produced with the same amount of raw materials, the solution pays for itself in less than a year. Flavio Granito further explains: "OnView.MassBalance is another example of how digitalization can strengthen more sustainable and cost-efficient papermaking. As part of our major sustainability program Papermaking for Life, we have set the goal of optimizing recycling processes and minimizing fiber losses. We aim to achieve a 90 percent recycling rate by 2030."

Installation and operation support

To calculate the mass balance in stock preparation, the innovative tool uses the signals from the sensors installed in the stock preparation plant. Voith experts identify the sensors required for this and develop a suitable concept together with the customer. Voith also separately offers the OnPerformanceLab (OPL) service. Based on bundled know-how, the OPL provides pragmatic support in analyzing losses, defining and implementing new countermeasures, and preparing monthly reports in close coordination with the respective paper technologists.

Sustainability program Papermaking for Life

Optimal production and resource savings with the help of the Papermaking 4.0 digitalization and automation portfolio are key topics of Voith’s Papermaking for Life sustainability program. As part of the innovation and development offensive, Voith Paper presents versatile technologies and initiatives that lead to more efficient and sustainable processes in paper production. The focus is on water, energy and fiber savings as well as digitalization, innovations and partnerships as levers for more sustainable production. Learn more about Voith Paper's commitment to sustainability: voith.com/Papermaking-For-Life.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 20,000 employees, sales of € 4.3 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Voith again achieves top ISS ESG rating for sustainability

After 2021, the international rating agency ISS ESG has again awarded the Voith Group’s sustainability performance a B- rating this year. According to the current rating, Voith is among the three best companies worldwide in terms of sustainability, compared with 176 other plant and mechanical engineering companies. With the current rating, Voith achieves prime status for the 5th time.

“I’m pleased that we were able to maintain our top position as a leading company in our sector in terms of sustainability. Being awarded B- again confirms our sustainability strategy to date and is also an incentive to rigorously continue our commitment,” says Dr. Toralf Haag, CEO of the Voith Group.

The independent rating agency ISS ESG (Institutional Shareholder Services – Ecological Social Governance) evaluates the sustainability performance of companies around the world. The agency currently lists about 5,000 companies and analyzes their performance in the areas of environment, social issues and corporate management. The ESG company rating uses a twelve-point grading system, ranging from A+ (excellent performance) to D- (poor performance or lack of transparency for a performance assessment). The rating is not only an important indicator of the effectiveness of sustainability measures, by now banks also increasingly use it as a criterion for granting credit.

The external evaluation by ISS ESG is mainly based on the current Voith Sustainability Report, which has been published annually since 2011. Additional measures in the areas of energy management, supply chain and diversity & inclusion played an important role in stabilizing Voith’s rating.

Sustainability program “Papermaking for Life”

The sustainability of Voith's own activities is a focus topic of the recently launched sustainability campaign Papermaking for Life. As part of the innovation and development offensive, Voith Paper is also presenting versatile technologies and initiatives that lead to more efficient and sustainable processes in paper production. The focus is on water, energy and fiber savings as well as digitalization, innovations and partnerships as levers for more sustainable production. Find more information here: https://voith.com/Papermaking-for-Life/Own-Activities.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 20,000 employees, sales of € 4.3 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

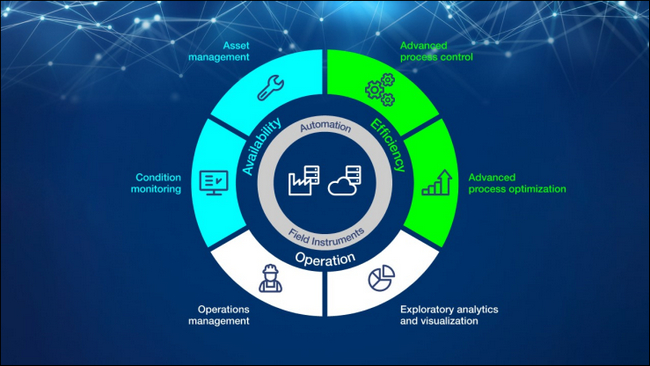

Voith and BTG present joint automation and digitalization portfolio

For maximum savings in pulp and paper production with the help of automation and digitalization, Voith and its wholly owned subsidiary BTG are merging their product portfolios. The two established data platforms, Voith’s OnCumulus and BTG’s dataPARC, will be merged into an integrated, hybrid system solution. OnCumulus will henceforth be offered under the name dataPARC cloud, while BTG’s MACS advanced process control solutions will join the OnEfficiency product family, thereby strengthening the Efficiency Solutions of the Voith’s Papermaking 4.0 portfolio. With the combined product portfolio, customers benefit from the best offerings of both companies – for the entire pulp and paper production.

- With extensive know-how and bundled experience, the leading full-line supplier Voith and its subsidiary BTG are optimizing their Papermaking 4.0 digitalization and automation portfolio to increase the overall customer experience

- OnCumulus becomes dataPARC cloud

- MACS solutions become part of OnEfficiency portfolio

“Many years of know-how, bundled experience and an excellent partnership between Voith and BTG are the basis for the optimized digitalization and automation portfolio Papermaking 4.0," says Peter Eisen, Vice President Digital Product Management at Voith Paper. "As the leading full-line supplier, our goal is to enable paper manufacturers worldwide to achieve significant productivity and cost advantages."

"The solutions offered by the OnEfficiency portfolio optimize the process in pulp and paper mills to significantly reduce variability and operating costs and increase productivity," says Dan Smith, Business Director Process Solutions at BTG. "This enables savings of between €2 and €10 per ton of paper produced. At the same time, the solutions ensure more sustainable production with lower resource consumption."

OnCumulus becomes dataPARC cloud

The combination of Voith's cloud solution OnCumulus and BTG's on-premise installation dataPARC combines the respective strengths of the platforms. In the cloud, for example, the almost unlimited computing power offers advantages for training AI models and simplifies cross-location solutions as well as location-independent access to data. The strengths of on-premise installations lie in processing high-frequency data or closed control loops. Thomas Greil, Vice President IIoT Technology & Advanced Applications at Voith, summarizes: "Our goal is to create a completely hybrid solution by 2025 that seamlessly combines on-premise and cloud, with a unified user interface, bridging the IT/OT gap. Hybrid and multi-cloud solutions permit all stakeholders to leverage data in a secure way that is efficient and most relevant to them. The user will no longer notice any difference between an application running locally or running in the cloud, and the benefits of both solutions can be optimally exploited."

MACS becomes OnEfficiency

With the integration of MACS into OnEfficiency, Voith is expanding its portfolio for cross-process controls and AI-supported process optimization, especially in the area of pulp production. Specifically, the following applications will be newly integrated and offered going forward under the name OnEfficiency.Pulp:

- Advanced process control combined with high-frequency single point kappa (SPK) measurements to improve kappa stability by 10 to 15 percent and optimize fiber yield (formerly MACScook).

- Improvement of the washing process in terms of carryover and black liquor solids (formerly MACSwash).

- Oxygen delignification optimization using SPK for high-frequency measurement of incoming and outgoing kappa (formerly MACSo2).

- Bleach optimization to minimize chemical consumption and stabilize distribution and brightness. The unique total kappa transmitter (BLT), brightness transmitters (BT) and pH management are also used for this purpose (formerly MACSbleach).

Optimized product portfolio from Voith and BTG

The addition of dataPARC and MACS to the Papermaking 4.0 portfolio completes the full-line offering from the global technology company Voith for digitalization in the pulp and paper industry. DataPARC cloud serves as the central platform and backbone of all applications in the Papermaking 4.0 portfolio. The proven automation solutions OnControl and OnQuality in the field of Automation, as well as the combined instrument portfolios of Voith and BTG – including control loops, sensors and actuators – form the basis for the solutions from the Availability, Efficiency and Operation areas. The solutions from the OnEfficiency portfolio optimize the production process for higher efficiency, lower costs and stable quality thanks to open or closed control loops using advanced process controls and AI. In the Availability arena, the OnCare family solutions help to improve maintenance processes and increase machine availability. In the area of Operations, Voith and BTG also offer intuitive applications for a wide range of functions. These can be used for analyzing and visualizing data; generating virtual sensors; displaying dashboards; and collecting and managing data, including generating reports and notifications. The experts of the OnPerformance.Lab (OPL) support with the installation and operation of the digitalization and automation solutions from the Papermaking 4.0 portfolio.

Further information can be found here: Voith.com/PaperIsOn.

About BTG

BTG Group is a multinational provider of integrated, highly specialized process solutions for the global pulp and paper industry. BTG's mission is to help its customers sustainably improve their business performance. https://www.linkedin.com/company/btggroupsa/

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 20,000 employees, sales of € 4.3 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

How Laakirchen Papier AG optimizes the papermaking process with OnEfficiency.Strength

Current raw material prices are forcing paper manufacturers to reduce production costs and further optimize the efficiency of their production facilities. Digitalization plays a key role in achieving efficiency gains and cutting costs. This is because new technologies in particular enable significant improvements in existing and new plants. They allow better monitoring of all processes and thus more precise production control, which in turn leads to higher efficiency and better availability.

Reduced starch consumptionIn addition to fiber, starch is a major raw material cost factor in the production of packaging papers. Therefore, the goal of paper manufacturers is to reduce starch application and keep the amount of starch as low as possible - without falling below the required quality level.

However, continuous optimization with conventional tools quickly reaches its limits. Paper manufacturers are confronted with the situation that they cannot directly control important quality parameters such as strength, because the measurement of the relevant parameters only takes place at the end of each tambour in the laboratory and the values are not continuously available.

Digital solutions such as OnEfficiency.Strength from Voith now offer the ability to have important quality parameters constantly available thanks to virtual sensors and to have the process optimally controlled automatically.

How Laakirchen Papier AG optimizes the use of starchSince 2021, OnEfficiency.Strength has been used at PM 10 in Laakirchen, Austria, to optimize starch application. A positive side effect is also the resulting reduction in steam consumption in the after-dryer section. What was previously only possible either through manual measurements in the laboratory or automatic test line measurements is now realized by Laakirchen with the use of virtual sensors: the calculation of data on the most important strength values (SCT CD, CMT and burst).

"This continuous monitoring of important quality parameters enables continuous optimization of the process in terms of cost and quality. Manual laboratory measurements, on the other hand, take up to 30 minutes after sampling, and the parameters can then only be adjusted by manual intervention," says Korbinian Hitthaler, project manager for Papermaking 4.0 at Voith OnPerformance.Lab. "Thanks to the virtual sensors, the strength values are now available in real time, so the starch application can be controlled without losing time. Thanks to the automatic control of the jet-wire difference, strength potentials between MD and CD can be optimally balanced."

Christopher Dierkes-Leifeld, PM 10 technologist at Laakirchen Papier AG, further explains: "We have been using OnEfficiency.Strength since 2021 to consistently meet quality requirements and thus optimize the paper produced on PM 10 and compensate for process fluctuations. At the same time, we have also reduced our costs, because OnEfficiency.Strength enables optimum control of the starch application quantity and the jet-wire ratio.”

Real-time prediction of quality parameters and continuous optimization of the process has not only prevented quality fluctuations, but OnEfficiency.Strength has also enabled production costs to be reduced while reliably meeting quality targets. ”Since we started with Papermaking 4.0 in cooperation with Voith, the speed of our PM 10 has been increased. Nevertheless, we have achieved the strength properties required by our customers with up to 10 percent starch savings due to optimization by the control system," concludes Dierkes-Leifeld. For PM 10, OnEfficiency.Strength helped to save four percent starch in the first year and now up to 10 percent starch in the second year, while key quality parameters such as SCT CD and CMT remained within target values.

The OnEfficiency.Strength principle: visualize, stabilize, optimizeOnEfficiency.Strength combines three modules to create a new, powerful generation of advanced process controls (APC). The control system includes virtual sensors, also called soft sensors; model predictive control (MPC); and a cost optimizer. A special feature of the virtual and self-adaptive sensors is their high predictive accuracy, typically above 90 percent.

The virtual sensors precisely predict important quality parameters. Knowing these parameters in real time enables the MPC to control the papermaking process in such a way that the targeted values are permanently achieved through continuous adjustment. The cost optimizer ensures that this is done at the lowest possible cost. To find the customer-specific cost optimum, actuators and control strategies can be individually selected and flexibly adapted.

Laakirchen Papier AG was particularly impressed with the high savings potential offered by OnEfficiency.Strength. This was calculated in the Value-Add Assessment carried out in advance. "Before installation, we carry out a so-called Value-Add Assessment with our customers, in which we calculate the savings potential of OnEfficiency.Strength based on the individual customer data," says Dr. Julius Flitsch, head of the Voith OnPerformance.Lab. "We then guarantee this savings potential to our customer. In addition, we always determine the parameters and actuators to be controlled individually, depending on customer requirements and paper machine."

Laakirchen Papier AG and Voith: Lighthouse project in Papermaking 4.0Laakirchen Papier and Voith have been working on joint pilot projects in Papermaking 4.0 since 2019. "We’ve had very good experience working with Voith. In addition to the OnEfficiency.Strength project, we also have many other Papermaking 4.0 pilot projects being implemented at the site. These include OnEfficiency.BreakProtect, OnCumulus and most recently OnView.Energy. This enables us to continuously improve our papermaking process," says Jan Reibert, Production Manager PM 10 at Laakirchen Papier AG. "Our cooperation with Voith is always at a very high level and on an equal footing. During the OnEfficiency.Strength project phase, we were in close and intensive exchange. This enabled us to discuss potential challenges together, discuss appropriate solutions and implement them in a timely manner."

About the Voith GroupThe Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 20,000 employees, sales of € 4.3 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services, and products on the market, and offers paper manufacturers integrated solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its comprehensive automation products and leading digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Successful start-up of PM 6 of Shanxi Qiangwei Paper in Jinzhong

At the beginning of June, the XcelLine PM 6 supplied by Voith was successfully started up at the Jinzhong site in the central Chinese province of Shanxi by the paper manufacturer Shanxi Qiangwei Paper. As the leading full-line supplier, Voith delivered the entire production line. The machine has a wire width of 7 m, a design speed of 1,200 m/min and produces plasterboard liner and containerboard with a basis weight of 90 to 160 gsm. Annual production of over 300,000 tons is possible. Voith's latest solutions enable highly efficient, resource-saving and sustainable production.

- The XcelLine paper machine supplied by Voith was successfully started up at the Jinzhong Shanxi Qiangwei Paper´s site

- The new PM 6 will produce over 300,000 tons of plasterboard liner and containerboard per year at a design speed of 1,200 m/min

- Leading Voith technologies enable highly efficient and optimized production

Thanks to the joint efforts and cooperation of the Voith and Shanxi Qiangwei Paper teams, a fast installation and start-up of the entire line was achieved. The PM 6 has a high degree of automation, and the paper features a low tensile ratio, excellent surface quality and uniformity, as well as high breaking and folding strength. The dryness after the press is also very high, which leads to low specific steam consumption. The first paper web has thus fully achieved the customer´s expected quality level.

Latest technologies for optimum results

As the leading full-line supplier, Voith supplied the entire XcelLine paper machine. The customer-oriented concept is especially designed for maximum efficiency, robustness and sustainability. After Voith had cooperated very successfully with Shanxi Qiangwei Paper on the key equipment for PM 5, the papermaker had ordered the supply of the entire PM 6 from Voith. Voith's advanced technologies and concepts will help Shanxi Qiangwei Paper to secure its leading position in the plasterboard industry and further expand its market share in the packaging paper industry. Thus, a positive contribution can be made to the development of the surrounding region and the economy of Shanxi.

The full-line supplier Voith delivered two highly efficient MasterJet Pro headboxes, a Tandem NipcoFlex press section and a CombiDuoRun dryer section including a hood and machine air system. Optimum paper properties are ensured by a SpeedSizer AT and an EcoCal Hard calender. The reliable MasterReel reeling concept, including a parent roll handling system and discfilters for fiber recovery, is used for smooth production. Shanxi Qiangwei also relies on the latest automation solutions from the Voith Papermaking 4.0 portfolio to achieve additional efficiency increases and cost reductions. A control and information system (DCS) as well as the quality management system (QCS) OnQuality are integrated in the plant.

Successful cooperation between Voith and Shanxi Qiangwei

To ensure a smooth start-up of the paper machine, both sides worked closely together throughout the project. Lin Jiangbo, Vice President Order Execution at Voith Paper Asia, confirms: "With the challenges posed by the recent COVID-19 pandemic, Voith worked with a high degree of flexibility and in close cooperation with Shanxi Qiangwei to ensure an optimal start-up of PM 6. In the future, we will continue to provide comprehensive services for PM 6 throughout its life cycle with our technical expertise and take further steps together with Shanxi Qiangwei Paper."

About Shanxi Qiangwei Paper

Shanxi Qiangwei Paper Co. is a company integrating research and development, production and sales of surface protection plasterboard. The company is based on the concept of sustainable development "low carbon, environmental protection, high efficiency and energy-saving", and puts energy saving, emission reduction and environmental protection at the first place of the company's strategic planning. Advanced equipment, first-class technology, quality and brand in the first place - this is the company's business philosophy. The quality of Shanxi Qiangwei's products has long been a market leader and occupies a top position in this industry.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 20,000 employees, sales of € 4.3 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

With OnQuality 4.0, Voith sets new standards in the field of quality control systems

OnQuality.Scanners and OnQuality.Sensors are successfully used in over 750 installations worldwide to continuously improve production and quality processes. Thanks to their compact design, the scanners can be installed extremely flexibly in existing and new plants. Based on the leading solutions, Voith now presents OnQuality 4.0, the next level for digitalization of the paper mill. The new system consists of all the important elements required for perfect quality measurement and control: a secure cloud solution with many analysis tools and functions, virtual sensors for online and real-time measurement, as well as location- and time-independent technology consulting. The OnQuality 4.0 system can be upgraded modularly for all Voith OnQuality systems already installed and is ready for use within a very short time.

- OnQuality 4.0 increases data transparency, enhances quality measurements, optimizes control strategies and thus leads to significant cost savings

- Analyses, dashboards and reports can be created with a few clicks and accessed on smartphones and tablets

- Latest generation of virtual sensors complement the classic physical sensor portfolio and provide new possibilities in online quality measurement

"With OnQuality 4.0, we are introducing the most advanced quality measurement and quality control system currently available for manufacturers of all paper grades," confirms Marc Stampfer, Global Product Manager QCS Scanners & Sensors at Voith Paper. "Time-consuming collection, search and conclusion of quality data and control strategies are a thing of the past. With our intuitive cloud solution, virtual sensors as well as remote technology consulting, the foundation for the digitalization of your paper mill is laid."

Perfect interaction between cloud solution, sensors and technology consulting

OnQuality 4.0 uses virtual sensors to overcome the limitations of classic physical online sensor technology. Using artificial intelligence, the virtual sensors continuously, reliably and in real time predict quality parameters such as tensile strength, stiffness and softness that can otherwise only be measured in the laboratory. The cloud platform collects and stores all relevant production and quality data and enables users to perform in-depth analyses through personalized dashboards. With just a few clicks, profile charts, color maps, maintenance cockpits, trends and reports can be intuitively created and viewed on mobile devices. OnQuality 4.0 thus quickly and directly shows deviations from the critical target quality and enables significant savings in resources, scrap and costs.

The OnPerformance.Lab (OPL) remote service center completes OnQuality 4.0, with OPL experts providing round-the-clock support for real-time emergencies. With the help of the in-depth know-how in the field of paper and control technology, tailor-made optimization measures are carried out together with the customer, such as for MD and CD controls and grade change processes. Consequently, the efficiency of the machine increases while costs decrease.

Further optimizations are planned for the future. Voith is currently working on visionary OnQuality.Scanner concepts, which are being developed as part of the Papermaking Vision design study. "With intuitive and state-of-the-art operating and visualization interfaces directly on the scanners; an intelligent light and alarm system; and an attractive, maintenance-friendly design, we will once again make everyday work much easier for operating and maintenance personnel," sums up Marc Stampfer.

Find more information here: Voith Quality Control System (QCS) OnQuality | Voith.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 20,000 employees, sales of € 4.3 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Indian customers rely on the Voith Paper Webshop for a quick and easy ordering process

Customers worldwide order products and services in real-time in the Voith Paper Webshop. In addition, to spare and wear parts, fabrics can also be purchased via the application with just one click for over a year now. Chandpur Enterprises Ltd. has been benefiting from the expansion of the product portfolio in the Voith Paper Webshop since March. "With the help of the personalized menu and the order history, we can now quickly identify our fabrics, order them and track the delivery status around the clock," says Mr Devesh K. Singhal, Technical Director of Chandpur Enterprises Ltd. "We are very satisfied with the Voith Paper Webshop and the cooperation with the Voith experts, who have been flexible to our requirements."

- Worldwide, the Voith Paper Webshop is already used by 180 customers

- Chandpur Enterprises Ltd. and other India customers have now also opted for the Voith Paper Webshop

- A fast, simple and personalized ordering process was the main reason for the decision.

In addition to Chandpur Enterprises, other Indian customers have already integrated the Voith Paper Webshop into their ordering process. In total, more than 180 customers already rely on digital applications. In the personalized "My Shop" section, the paper manufacturers can find all the necessary information from the original and current condition of the equipment as well as the order and quotation history, drawings, manuals and contracts.

F.l.t.r.: Praveen Batra (Head of Sales & Services FRS, Voith India), Devesh K. Singhal (Technical Director, Chandpur Enterprises Ltd.), Gaurav Singh (Senior Executive, Sales & Services FRS, Voith India) and Harsh Bakshi (Deputy Manager, Sales & Services FRS, Voith India).

F.l.t.r.: Praveen Batra (Head of Sales & Services FRS, Voith India), Devesh K. Singhal (Technical Director, Chandpur Enterprises Ltd.), Gaurav Singh (Senior Executive, Sales & Services FRS, Voith India) and Harsh Bakshi (Deputy Manager, Sales & Services FRS, Voith India).

Mr Devesh K. Singhal confirms the advantages: "Initially, we were not sure whether we should convert our previous ordering processes to the webshop and digitize them. However, we then decided in favour of the Voith Paper Webshop, because we were completely convinced by the functionality as well as the very clear user guidance. In addition, the onboarding process and subsequent registration of the individual users went smoothly. We are glad to have taken this step."

The Voith Paper Webshop is characterized by the highest data security standards. Different options can be booked depending on customer requirements. "Our goal is to enable our customers to optimize production with minimized downtimes," sums up Mr Gaurav Singh, Senior Executive Sales & Service India at Voith Paper. "One building block for this is the quick and easy ordering of fabrics. We offer customer-specific solution packages, which we are continuously developing further on a region-specific basis. The integration of the Webshop can be done smoothly for any customer worldwide."

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 20,000 employees, sales of € 4.3 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

Big savings of starch with the help of Voith's Papermaking 4.0 solutions – successful digitalization project with Saica

The results are clear: Just a few months after Voith's comprehensive digitalization solutions were commissioned at PM 9 in El Burgo, Saica Group's investment in the Papermaking 4.0 package has already paid off. The Spanish paper manufacturer produces around 430,000 tons of paper per year at the facility, located around 25 kilometers from Zaragoza. At the end of 2020, the company decided to digitalize production. After a thoroughly positive experience with the digitalization of PM 4 in Venizel, France, Voith was awarded the contract to implement the project for PM 9, which includes OnCumulus applications and the two solution packages OnView.MassBalance and OnEfficiency.Strength.

- Comprehensive Papermaking 4.0 package for PM 9 in El Burgo

- OnCumulus, OnView.MassBalance and OnEfficiency.Strength enable significant resource savings

- Saica plans to expand its digitalization strategy

"Voith has been a great partner along the digitalization journey in our mills," says Fernando Carroquino, Industrial Director at Saica Group. "Our perception of Voith Paper as one of the main digital solutions provider is reaffirmed every day, and we are very glad with the cooperation with Voith over the last years. We have the full commitment of both companies, which makes us look forward to the next successful cases."

The main goal of OnEfficiency.Strength on a paper machine for container board is to reduce the consumption of starch without negatively affecting the strength properties of the paper. The solution uses virtual sensors as a basis on which innovative advanced process control is built. OnEfficiency.Strength has already proven a high benefit in several references and significantly reduced the product cost. At PM 9, too, the high potential of digitalization became apparent shortly after commissioning.

Fernando Vicente, Production Manager at PM 9 El Burgo, says: "Although the plant has been continuously optimized in recent years, we have now been able to significantly reduce our starch usage in the first few weeks with the help of OnEfficiency.Strength. The tool is very easy to use, and the operators are very motivated to integrate it into their daily work. We are confident that, in the future, savings can be increased even further. Now it is much easier to sustainably achieve the targeted quality at the lowest possible cost."

OnView.MassBalance starts at an earlier point in paper production. The app's data maps the current stock flows in a diagram and depicts deviations from the standard. As soon as a defined threshold is exceeded, the application automatically highlights the relevant area in the diagram and recommends suitable courses of action to avoid fiber losses. In this way, OnView.MassBalance leads to targeted process optimization in stock preparation and provides the operating team with all relevant information if a different process setting is required. Both applications are integrated on Voith's OnCumulus platform. The platform provides users with an overview of all important process parameters, includes several industry-specific applications and also acts as a reliable and secure data repository. Building on the initial positive results, regular meetings are held between the Saica and Voith teams to jointly discuss progress, results and schedules. The goal is to further push the optimization of the system.

Juan Luis Mendoza, Digital Process Officer at Saica, explains how the new solutions have already opened up a whole new perspective: "The integration of OnEfficiency.Strength into the existing automation technology of PM 9 was seamless. This is now reflected in our very positive results. The digital tools support us in achieving our ambitious targets in an intelligent way." For Mendoza, there is no doubt that the company will also implement Voith's Papermaking 4.0 solution on other machines in the coming years.

From Voith’s perspective as the technology partner, the balance of the project is thoroughly positive: "The solution we offered has proven itself and leads to resource important savings with qualitatively consistent results," sums up Renan Fusco, Head of Digital Solutions Sales at Voith Paper. "Voith has clearly positioned itself as a reliable partner on the path to digitalization. This confirms our commitment to continuously advance our products in order to continue to be an innovation driver in paper production."

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, the company today has around 20,000 employees, sales of € 4.3 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market and offers paper manufacturers holistic solutions from a single source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its leading automation products and digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.