Displaying items by tag: voith

Voith successfully commissions its first virtual reality training system worldwide at LEIPA with OnCall.Video

LEIPA is the world’s first paper mill to employ virtual reality (VR) from Voith as a modern and immersive training method. At the Schwedt location, the company trains its employees extremely effectively using the VR system. To perform the installation in spite of the contact restrictions imposed as a result of the coronavirus pandemic, Voith and LEIPA drew on a new tool for remote video support: OnCall.Video. LEIPA has been using this audiovisual communication system with wireless data glasses since January 2020.

With the VR application, LEIPA employees can complete hands-on training in the computer-generated environment at any time and without any danger. From simple exploration of a paper machine for newbies to the complex process of changing the press sleeve on a modern shoe press, the system offers every employee a completely new training experience. This is made possible by 3D visualization in a headset combined with control devices for the interaction. The employee can move freely in the virtual reality setting and is guided through various tasks step by step.

Specifically for the VR training from the Voith PaperSchool, LEIPA set up a futuristically designed room, the "LEIPA Virtual Reality Center," at the Schwedt location. A special design and lighting concept underscores the modernity of the VR technology. Voith also supplied a touchscreen and wireless VR equipment to meet the special customer request for a cable-free studio.

How the OnCall.Video remote video support tool can increase efficiency and thereby give customers traceable added value became clear with this start-up. "The room was already prepared and the sensors attached," recalls Patrick Dengel, Digital Tools Manager at Voith. "We handled the details via OnCall.Video. To accomplish this, the glasses were integrated into the LEIPA WLAN, via which a video and audio connection to the Voith experts in Heidenheim was established." Without the remote connection, the VR system would not have been functional as quickly.

OnCall.Video offers LEIPA clear advantages especially for problems in the production flow, because the papermaker can draw on know-how outside the company to find solutions with virtually no delay and with cost savings. "Required expert knowledge is not always available on site, so integration of external know-how is that much more important," stresses Patrick Dengel.

"In principle, I can guide everything with the tool," adds his colleague Stefan Endras, Product Manager, OnCall.Video. "Our main emphasis is on quickly connecting the customer with the experts. In this way, we can also partially compensate for the lack of skilled workers." However, added value is also offered to the customer through the fact that various locations can easily be connected to each other and, as a result, internal exchange of specialized information and knowledge transfer are promoted.

With the virtual reality solution and OnCall.Video, LEIPA underscores its digital competence. "Which papermaker can claim to have the most modern media in use before anyone else?" argues Steffen Deszpot, Senior Manager Maintenance at LEIPA. "Industry 4.0 has already arrived here – and we are happy to show it."

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport and automotive. Founded in 1867, the company today has more than 19,000 employees, sales of €4.3 billion and locations in more than 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services, components and products on the market, and offers paper manufacturers solutions from a single source. The company’s continuous stream of innovations takes papermaking to the next level and facilitates resource-conserving production. With its Servolution concept, Voith offers its customers tailored service solutions for all sections of the production process. Voith Papermaking 4.0 ensures that equipment is optimally connected, while the secure use of generated data enables paper manufacturers to improve plant availability and efficiency.

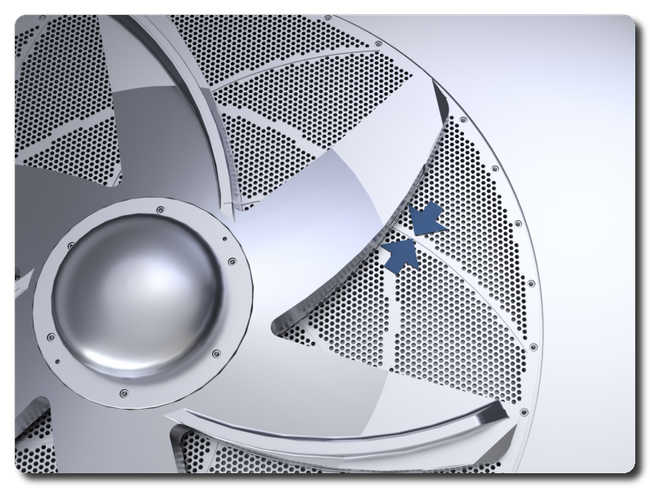

CurvedBar: Voith presents new screen plate with significantly extended service life for recovered paper pulping

Voith introduces a new screen plate design for pulpers used in recovered paper pulping. The CurvedBar screen plate extends service life in Voith's IntensaPulper IP-R by more than 50 percent and improves the quality of fiber suspension. The results are less maintenance effort and material use, as well as fewer downtimes, leading to a more efficient overall process and lower costs. Chinese paper manufacturer Shanying International Holding Co. LTD., has tested the CurvedBar screen plate on its PM 5 in Maanshan and is now equipping other pulping systems with the innovative solution.

"With the new CurvedBar technology, we substantially reduced downtime and extended maintenance intervals at the pulper with consistently high operating quality," says Wan Tao, Vice President Production at Shanying International Holding Co. LTD. "We also achieved very positive results from the coarse screening."

- Innovative screen plate geometry with more than 50 percent longer service life

- Optimal interaction of pulper, rotor and screen plate for a higher quality fiber suspension

- Reduced costs for operation and maintenance

To reduce the high mechanical loads on the screen plate, Voith developed an innovative curved bar design and optimally matched to the geometries of pulper, rotor and screen plate. "This results in a much longer service life compared to conventional screen plates," explains Oliver Lüdtke, Global Service and Product Manager at Voith Paper. The lower friction also reduces energy consumption. "Combined with savings in material and maintenance, significant cost-saving potential can be realized, and the customer’s carbon footprint is reduced due to greater sustainability," says Lüdtke.

Lower shearing forces, higher quality fiber suspension and problem-free ragger formation

Thanks to the lower shearing forces on the screen plate, far fewer contaminants are shredded. This improves the quality of the fiber suspension, reduces the amount of small rejects that need to be laboriously removed in the downstream process steps, and allows trouble-free ragger formation. Furthermore, the risk of bar breakage and deformation of the screen plate is significantly reduced. The CurvedBar screen plate has proven its effectiveness at Shanying in Maanshan, China, and other locations.

"With the new curved technology and premium W material, we optimized and reduced the flake content and are maintaining high-efficiency pulping performance in the long term," says Song Jie, Manager of the Technical Department at Shanying International Holding Co. LTD. "The flake content is about 15 percent, the lifetime of high-efficiency pulping performance is extended from two months to five months."

"We still keep very good collaborating relation with Voith for the OCC stock preparation and paper machine, especially for testing the performance of the screen plate with CurvedBar and premium W material," Jie adds. "We value the excellent and professional support provided by Voith during installation and commissioning of the screen plates. At all times, Voith was in close contact with us to continually optimize the equipment. We are very satisfied with the results and happy to have Voith as a strong partner by our side."

Following the successful pilot phase, the company has already awarded Voith several follow-up orders to successively retrofit other pulpers with the new components. Other customers have also placed repeat orders for the innovative screen plate design following successful testing.

For more information about CurvedBar please visit: http://voith.com/corp-en/papermaking/pulping-solutions.html

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport and automotive. Founded in 1867, the company today has more than 19,000 employees, sales of € 4.3 billion and locations in more than 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services, components and products on the market, and offers paper manufacturers solutions from a single source. The company’s continuous stream of innovations takes papermaking to the next level and facilitates resource-conserving production. With its Servolution concept, Voith offers its customers tailored service solutions for all sections of the production process. Voith Papermaking 4.0 ensures that equipment is optimally connected, while the secure use of generated data enables paper manufacturers to improve plant availability and efficiency.

Voith successfully executes start-up of five BlueLine OCC stock preparation lines for Nine Dragons Paper

In early 2017, Voith received an order for six BlueLine OCC stock preparation lines from Nine Dragons, the largest manufacturer of packaging paper in Asia. With the recently commissioned PM 41 at the customer’s Hebei site, five Voith BlueLine OCC lines, each with a production capacity of 2,000 tons per day, have now been successfully launched. The handover of the sixth line is planned for 2022.

- The new capacity with Voith machines strengthens Nine Dragons’ leading position as Asia’s biggest recycled paper manufacturer

- Voith BlueLine OCC portfolio supports Nine Dragons’ sustainable and low-carbon development philosophy

Nine Dragons is leading the industry in sustainable paper manufacturing based on the management philosophy "no environmental management, no papermaking." The continuous expansion of new production capacity benefits Nine Dragons in strengthening its leading position in the packaging industry.

The five OCC stock preparation lines are the sole expansion that Nine Dragons has carried out over the past three years. Voith received the contract as the full-line supplier to deliver the entire approach flow systems together with the complete stock preparation portfolio.

The five OCC stock preparation lines are the sole expansion that Nine Dragons has carried out over the past three years. Voith received the contract as the full-line supplier to deliver the entire approach flow systems together with the complete stock preparation portfolio.

While China is implementing restrictions on recovered fiber imports and stringent environmental regulations, papermakers are partnering up with suppliers who are offering leading sustainable solutions and technology in plant operations and stock preparation. Voith’s complete OCC solution creates sustainable and eco-friendly competitive production lines with 15 to 20 percent reduction in energy consumption and at least 0.5 percent fiber savings.

The Nine Dragons project demonstrates Voith’s ability to collaborate and manage the installation and commissioning of multiple orders on time, even under a tight project schedule and with the impact of COVID-19. When the pandemic strongly affected the project due to traffic and logistics interruption, Voith used all means of communication to collaborate with its customer. With a proactive and problem-solving attitude, the Voith team successfully completed the projects.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport and automotive. Founded in 1867, the company today has more than 19,000 employees, sales of € 4.3 billion and locations in more than 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services, components and products on the market, and offers paper manufacturers solutions from a single source. The company’s continuous stream of innovations takes papermaking to the next level and facilitates resource-conserving production. With its Servolution concept, Voith offers its customers tailored service solutions for all sections of the production process. Voith Papermaking 4.0 ensures that equipment is optimally connected, while the secure use of generated data enables paper manufacturers to improve plant availability and efficiency.

OnCall.Video: Voith adds new tool for remote video support to its digital service portfolio

Voith has added a new tool for remote video support to its service portfolio, offering customers access to expert support at any time and from any location. OnCall.Video enables fast problem-solving and cuts downtimes, resulting in improved machine availability and productivity. With this tool, Voith is playing an important role in making processes even more efficient and sustainable through the use of digital solutions.

Video-assisted communication tool for access to expertise at any time and from any location

Thanks to the audio-visual communication system OnCall.Video, customers worldwide can draw on Voith expertise via an internet-based video collaboration platform at any time and from any location. Using OnCall.Video, the Voith specialist can see in real time exactly what the customer or operator is seeing at the production facility. In addition to recommending action and documentation, important information can be quickly conveyed to staff on site to provide an optimum level of support.

The digital solution is device-independent, so any device can be used for communication purposes. To perform servicing work with the machine still running, the technician can also wear industrial-grade smart data glasses that allow optimum communication with the Voith expert thanks to integrated voice control and active noise cancellation. Moreover, the smart glasses allow operators to keep their hands free, are splash-proof and dust-tight, and are compatible with the necessary PPE.

Wide-ranging applications for improved machine availability and productivity

“With the help of OnCall.Video, we can quickly analyze mechanical or technological problems and then recommend specific courses of action,” says Patrick Dengel, Manager Remote Solutions at Voith. “In addition to problem analyses, inspections and general service support, the system can also be used to assist with factory acceptance tests and commissioning.”

“Following an emergency in the wet end of our PM 1, the local Voith service team was able to carry out the necessary repairs quickly and professionally with expert support via OnCall.Video,” says Franz Gstettenhofer, Authorized Signatory and Member of the Management Board at Lenzing Papier GmbH in Austria. “This reduced the machine downtime and we were able to restart production shortly afterwards.”

Knowledge transfer across locations

Apart from providing a way to connect quickly with Voith experts, OnCall.Video can also improve knowledge transfer within a company. “This is an option both for our customers, who can then optimally connect their various sites with each other, and for Voith,” says Stefan Endras, Product Manager OnCall.Video at Voith. “Using OnCall.Video, collaboration between specialists across all distances can be accomplished quickly and easily. We have already been able to use the solution successfully for service assignments without the expert in charge having to travel to the relevant site.”

Even when travel options are limited, OnCall.Video provides fast and reliable support to ensure on-time delivery and commissioning.

For more information on OnCall.Video please visit: www.voith.com/OnCallVideo

Successful startup of cutting-edge packaging paper machine Propapier PM 3

German paper manufacturer Progroup AG has successfully commissioned the PM 3, one of the most modern packaging paper machines in the world, at the company’s Sandersdorf-Brehna facility in Saxony-Anhalt. The PM 3 is set to produce 750,000 tons of testliner and corrugated medium annually. A comprehensive sustainability concept ensures the least possible consumption of resources.

- New production line at Progroup AG is setting benchmarks for efficiency and sustainability

- Voith realized the project as a full-line supplier and developed customer-specific solutions

- Timely startup despite pandemic

Thanks to its exceptional flexibility and the close consultation between all project participants, the companies managed to complete the PM 3 within the original schedule despite the restrictions imposed by the coronavirus pandemic. “The successful startup within the planned schedule represents an important milestone in our growth strategy,” explains Maximilian Heindl, Member of the Board and Chief Development Officer at Progroup AG. “By deploying extra personnel and working additional day and night shifts, we were able to accelerate the work in such a way as to enable us to meet the commissioning date,” says René Bauer, Project Manager at Voith.

The PM 3 in Sandersdorf-Brehna is setting new benchmarks for efficiency and sustainability.

The PM 3 in Sandersdorf-Brehna is setting new benchmarks for efficiency and sustainability.

As a full-line supplier, Voith delivered the entire production line including a BlueLine stock preparation with the new IntensaDrum Duo drum pulper, which can process almost 3,000 tons of recovered paper a day. The XcelLine paper machine has a wire width of 10,000 mm and an operating speed of 1,600 m/min. The TwinDrive double unwind also included in the scope of supply increases winder capacity by up to 20 percent and allows automated full reel changes. It is complemented by the high-performance winder VariFlex Performance. The scope of supply also includes the process air and hall ventilation systems. Based on a long and successful cooperation, Voith also received a comprehensive startup clothing package for all sections of the paper machine.

Other key innovations include the closed water loop that Voith developed in collaboration with Progroup. In this system, all water used in the paper production process is cleaned in the company’s own water treatment facility using anaerobic and aerobic biological treatments and is then returned to the production process in a resource-conserving manner. This allows a wastewater-free paper production process.

Closed water loop: All water used in production is cleaned in the company’s own water treatment plant and then returned to the production process.

Closed water loop: All water used in production is cleaned in the company’s own water treatment plant and then returned to the production process.

“Thanks to the integrated water treatment plant, we save about 3.75 million liters of fresh water annually. This is equivalent to the water consumption of more than 80,000 people,” explains Maximilian Heindl. “The Eco-Management and Audit Scheme (EMAS) certification of the European Union verifies the sustainability of our facility.” For the new facility, Progroup is additionally investing around €100 million in resource-saving technologies and environmental protection.

Apart from its particularly efficient and resource-conserving operation, the paper machine is also a cutting-edge solution thanks to the components from the new XcelLine machine and equipment design. Streamlined structures and exceptional materials ensure a professional structured impression and calm overall effect. The optimization of functional elements, such as the improved walkway design of PM 3, has simplified operation. Moreover, the headbox foundation, VariFlex Performance winder and Sirius winding system have been integrated into the new design of the entire paper machine. These changes simplify maintenance work and at the same time improve occupational safety

From left to right: René Bauer, Project Manager at Voith Paper; Peter Resvanis, Project Manager at Progroup AG; Maximilian Heindl, Member of the Board and Chief Development Officer at Progroup AG; and Dr. Michael Trefz, President Projects at Voith Paper.

From left to right: René Bauer, Project Manager at Voith Paper; Peter Resvanis, Project Manager at Progroup AG; Maximilian Heindl, Member of the Board and Chief Development Officer at Progroup AG; and Dr. Michael Trefz, President Projects at Voith Paper.

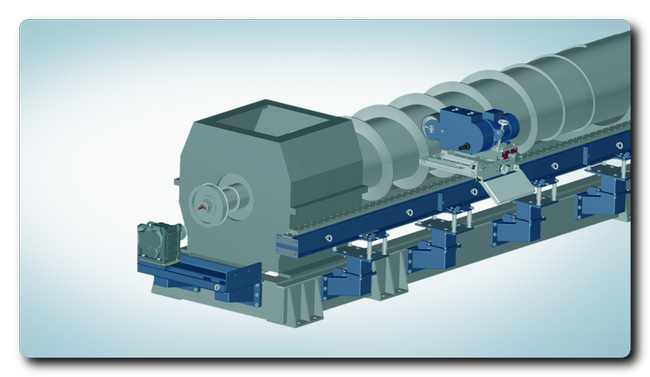

SmartGrinder: Voith introduces new refurbishment service for screw presses

Voith’s new refurbishment service for screw presses enables the full restoration of screw performance and reduces downtimes by up to 20 percent compared to conventional repair methods. With SmartGrinder, the new refurbishment service, customers can restore original screw performance and achieve an optimum balance between operating costs and technological performance – a decisive factor for paper quality and cost efficiency in paper production.

- Full restoration of original screw performance with SmartGrinder

- Reduction of downtimes by up to 20 percent

- No need to dismantle the screw or to use spare screws

SmartGrinder: restoration of original screw performance and reduced downtimes

SmartGrinder is a modular system that can be set up during operation according to the size and requirements of the screw press to be serviced in order to minimize downtime and production losses. Before proceeding with the repair, a detailed digitized condition measurement is carried out for the screw stem and flights. This allows a professional analysis of the existing wear pattern, indicating the areas that require additional attention.

Smartgrinder

Smartgrinder

The design of the SmartGrinder allows a fast and highly precise restoration of the press screw diameter. "It can thus follow the flight geometry exactly, reducing downtimes by up to 20 percent compared to conventional repairs," says Geert Tichler, Senior Product Management & Global Expert Refurbishment Technologies, Voith Paper. "As our service provides the flights with the required sharp edges, this results in an optimum removal from the fibermat."

No need to dismantle the screw or to use spare screws

After the first service, the SmartGrinder can be replaced even faster because the assembly plates remain on the screw press. In addition, all new Voith screw presses are already equipped with designated assembly plates, allowing fast and specialized Voith on-site services. When repaired using the SmartGrinder, there is no need to dismantle the screw or to use spare screws, and costly screw transport is eliminated.

Expansion of Servolution portfolio with refurbishment services

The SmartGrinder ideally complements Voith’s Servolution portfolio. Similar systems for the reconditioning of product geometries are already in use not only for screw presses but also, for example, for disc filter centershaft repairs.

For further information about our optimization services for screw presses please visit: http://voith.com/corp-en/screw-press-optimization.html

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport and automotive. Founded in 1867, the company today has more than 19,000 employees, sales of € 4.3 billion and locations in more than 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services, components and products on the market, and offers paper manufacturers solutions from a single source. The company’s continuous stream of innovations takes papermaking to the next level and facilitates resource-conserving production. With its Servolution concept, Voith offers its customers tailored service solutions for all sections of the production process. Voith Papermaking 4.0 ensures that equipment is optimally connected, while the secure use of generated data enables paper manufacturers to improve plant availability and efficiency.

Voith Group successfully completes the acquisition of Toscotec.

Toscotec is pleased to announce that, following the obtainment of all required regulatory approvals, Voith has successfully completed its acquisition of Toscotec. Toscotec is now part of the Voith Group.

Andreas Endters, President and CEO of Voith Paper, says: “Toscotec’s acquisition matches Voith’s targets of strategic growth in a perfect way. Toscotec’s range of products and services effectively supports our portfolio and further strengthens our position as a full-line supplier in important areas of the paper industry.”

Toscotec will continue to offer its portfolio as established. The company will remain entrepreneurial in nature and will operate under the established Toscotec brand. In the area of tissue, Toscotec will carry out the business with new lines and major rebuilds for the whole Voith Group in the future. Voith Paper will continue to serve its delivered tissue machines. All other business activities will remain unaffected, and Voith and Toscotec customers will be able to purchase via their existing sales channels as usual.

Alessandro Mennucci, CEO of Toscotec, says: “This acquisition is a landmark in the history of our company. By joining forces with Voith, we plan to pursue new ambitious goals. We will build on our expertise and strong reference base in the paper industry and will be able to offer added value to our customers.”

Established in 1948, Toscotec specializes in the design and manufacture of machinery and equipment for the production of tissue, paper, and board. Headquartered in Lucca, Italy, and with subsidiaries in China and the USA, Toscotec provides its customers with state-of-the-art technologies and customized solutions from complete production lines to rebuilds and single components. Technology Group Voith acquired 90 percent of the shares.

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, the company today has more than 19,000 employees, sales of € 4.3 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

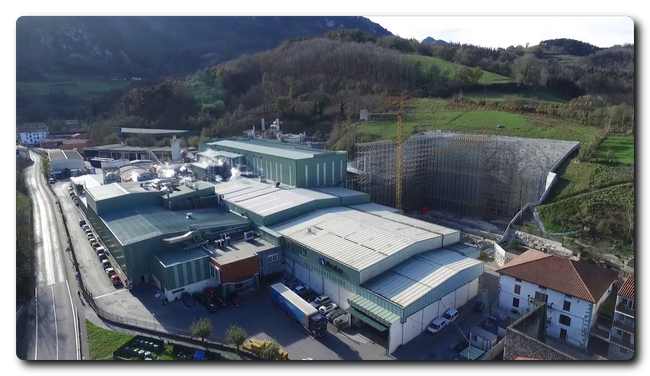

Paper machine for sustainable wet wipes by Voith and Trützschler for Papel Aralar S.A.

The Spanish paper factory Papel Aralar commissioned Voith and the nonwoven fabric expert Trützschler Nonwovens to deliver a new system for specialty paper production. The PM 5 was developed as a joint project by both companies specifically for the wiping cloth industry. Delivery is planned for September 2020.

Aralar site in Amezketa, Spain

Aralar site in Amezketa, Spain

The special sustainable feature of the wet-laid machine ordered is that the adult and baby wet wipes it produces are completely plastic-free, flushable and biodegradable, a characteristic that conventional wet wipes do not have.

HydroFormer and AquaJet for high-performance Wet-Laid Spunlacing

Voith supplies the HydroFormer, which is one of the main components of the new system. The HydroFormer technology draws on Voith’s extensive experience in the paper-making and pulp industries. In this technology, the suspension is heavily diluted to produce nonwoven materials made completely of cellulose, a renewable resource. Besides the HydroFormer, the Heidenheim-based technology company also supplies the stock preparation system, a master reel, and the wet end process for the new system constructed in accordance with the Process Line Package (PLP). A comprehensive automation and control package is also included in the delivery.

Trützschler Nonwovens completes the production process with the proven AquaJet technology for spunlacing and a multi-drum dryer. The many years of expertise and experience of the Trützschler company form the basis of the components that have been adapted to the needs of the wet-laid process.

OnQuality: Voith launches new generation of sensors

Voith has developed a new generation of sensors with regards to availability, reliability and maintenance handling. As the main components of the Quality Measurement System, the sensors measure the most important quality parameters of the paper being produced, such as basis weight, moisture, caliper and ash. The Quality Control System reduces as much as possible the variability in machine direction (MD) and cross direction (CD). This allows paper manufacturers to move quality targets in the most profitable operational zones – for example to maximize the moisture content of the paper.

- Higher product quality due to modular and fully independent sensors with optimized housings and integrated temperature stabilization

- Increased reliability and availability of the MD-Controls

- Delivering more power within smaller and lighter sensors that require less machine space

- Minimized maintenance effort through new plug & play standards

Higher product quality due to modular and fully independent sensors with optimized housings and integrated temperature stabilization

The sensors and components are designed to operate in challenging environments under harsh conditions of the paper mill. Special, high-temperature housing options are no longer needed. The new temperature-stabilized housings are designed for ambient temperatures up to 100° C / 212° F.

The new sensor generation features a compact, lightweight design and increases the reliability and availability of the machine direction controls.

The new sensor generation features a compact, lightweight design and increases the reliability and availability of the machine direction controls.

Increased reliability and availability of the machine direction controls

A distinctive feature of Voith’s control concept are the machine direction controls based on physical models of the paper machine. Voith’s supervisory controls replicate the physical behavior of the process. The controls manage even high-frequent process disturbances. They also effectively reduce the time for grade changes and therefore minimize production losses.

Delivering more power within smaller and lighter sensors

The new sensor slots have been optimized in their width from 13 cm to 7.5 cm, which leads to smaller and lighter sensor packages, allowing more sensors to be installed in the available machine space.

Minimized maintenance effort with new plug & play principle

The heart of the new sensors is a processor board that provides precise and fast signal and data processing. Sensor features are easy expandable via firmware upgrades. Configurations and calibration parameters are stored inside the sensor and can be changed remotely. Furthermore, the new plug & play functionality reduces complexity in maintenance.

Voith has developed a new generation of senonquality soluntionssors that measure the most important quality parameters of the paper being produced, such as basis weight, moisture, caliper and ash.

Voith has developed a new generation of senonquality soluntionssors that measure the most important quality parameters of the paper being produced, such as basis weight, moisture, caliper and ash.

Anchored in the Servolution approach, Voith takes care of the whole maintenance spectrum. Based on deep domain knowledge, the focus is not only on system maintenance. Voith service experts also check the measurement and control performances, monitor overall equipment condition and provide suggestions to optimize the process. Additionally, Voith is able to preserve the customer’s investments by interfacing most types of existing third-party scanners and actuators.

For more information about the new sensor generation, please visit: http://www.voith.com/OnQuality

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, the company today has more than 19,000 employees, sales of € 4.3 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services, components and products on the market, and offers paper manufacturers solutions from a single source. The company’s continuous stream of innovations takes papermaking to the next level and facilitates resource-conserving production. With its Servolution concept, Voith offers its customers tailored service solutions for all sections of the production process. Voith Papermaking 4.0 ensures that equipment is optimally connected, while the secure use of generated data enables paper manufacturers to improve plant availability and efficiency.

UpElement: Unique felt technology to quickly reach full production speed

Voith introduces UpElement to its expanding portfolio of tissue press fabrics. The modular treatment increases efficiency by achieving significantly faster startup times. Through an optimized surface enhancement UpElement improves dewatering properties during startup. As a result, manufacturers benefit from a higher production yield over the run of one felt cycle.

Smooth performance during startup is crucial for maximum efficiency in tissue production. With UpElement Voith offers an innovative solution that is specially tailored to meet these production challenges. As part of the Voith’s Element-Series of add-on solutions, the modular treatment complements the manufacturer’s existing press fabrics portfolio for tissue, and thus fits in well with the PressMax AdvancedPRODUCTS.

The modular treatment UpElement enables faster startup times and higher production gains.

The modular treatment UpElement enables faster startup times and higher production gains.

Faster startup time, stable operating conditions

Due to their unique technology, the felts have a higher saturation capability during startup which ensures optimal dewatering of the paper web. UpElement makes startup up to 50 percent faster compared to standard press fabrics, without compromising operational stability or long-term performance.

Higher production yield with each Voith felt

By reaching full machine speed significantly faster, UpElement not only keeps energy consumption to a minimum, but also delivers notably higher production output per felt: Depending on the operating setup, UpElement can increase output by an additional 100,000 € worth of saleable product per year. In this way, a quick return on investment can be expected.

“UpElement has proven itself in several trial runs resulting in immediate repeat orders from international tissue manufacturers,“ says Susanne Klaschka, Global Product Manager Press Section, Voith Paper. “We are proud to provide customers with yet another innovative solution to make tissue production even more efficient, more profitable and more sustainable.”

For more information about UpElement please visit: www.voith.com/fabrics

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, the company today has more than 19,000 employees, sales of € 4.3 billion and locations in over 60 countries worldwide and is thus one of the larger family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services, components and products on the market and offers paper manufacturers solutions from one single source. The company’s continuous stream of innovations takes papermaking to the next level and facilitates resource-conserving production. With its Servolution concept, Voith offers its customers tailored service solutions for all sections of the production process. Voith Papermaking 4.0 ensures that equipment is optimally connected, while the secure use of generated data enables paper manufacturers to improve plant availability and efficiency.