Croxley Heritage Re-launched in 2015

Prestigious British paper brand returns with a mission to reignite the romance in quality stationery.

One of the great British stationery brands Croxley Heritage is to be reintroduced to the desks of discerning business and private paper buyers via a relaunch at Paperworld, Frankfurt between Saturday 31 January – Tuesday 3 February 2015. Inspired by the original brands of John Dickinson & Co. Ltd of London, established in 1804, the stationery line will be reactivated by luxury paper manufacturer, James Cropper.

Inventor of continuous mechanised paper production techniques, John Dickinson (1782-1869) established mills across the world at the height of his powers as a leading, Victorian industrialist. However, it was his mill at Croxley Green, Hertfordshire on the banks of the Grand Union canal that gave some of the famous Dickinson brands - including Croxley – their names, with paper running off the production line there for 150 years until 1980.

Having been recently acquired by James Cropper – based in Cumbria at the heart of England’s Lake District – 2015 sees Croxley Heritage re-launched to carry the values and traditions of one of the world’s oldest and most sought after paper products, with the brand’s custodians encouraging buyers to rediscover the romance of beautifully made, traditional stationery.

Chris Brown, Commercial Director of James Cropper, said: “Croxley Heritage is a name synonymous with the best traditions of British paper manufacturing, born of a pioneering paper maker, John Dickinson. Like Dickinson, James Cropper - great-great-great grandfather of our Chairman Mark Cropper – believed in the production of only the highest quality papers. It is fitting that we have the opportunity to take this brand back onto the market in the best of their founding traditions.”

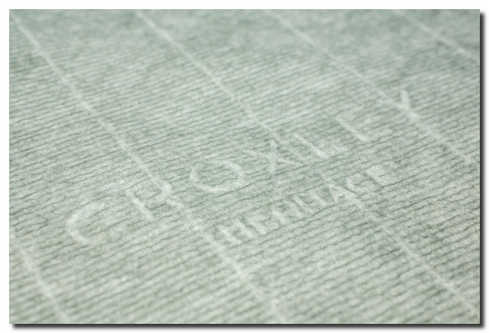

The paper fibre used to make the contemporary versions of Croxley Heritage will be comprised of 90% post-consumer waste and 10% reclaimed cup fibre from James Cropper’s own reclaimed fibre facility, opened last year following a £5million investment. The production process uses Hydro Power from a newly commissioned hydro plant on the river Kent (developed with Ellergreen Energy); ensuring Croxley Heritage is as clean to produce as it appears in its final form. Croxley Heritage is a watermarked paper range in a neutral colour palette – white, cream, silver, wedgwood – available in a selection of wove, laid and linen finishes.

Phil Wild, CEO of James Cropper, said: “Business users looking for a paper to reflect their credentials will find the Croxley Heritage range perfect for letterheads, business cards and other uses, but we also recognise that sustainable sourcing is also a reputational issue for all of our customers. The production process has been carefully designed to ensure the environmental impact of every sheet of paper is dramatically reduced by using state-of-the-art recycling technologies and sustainable energy procurement.”

ABOUT JAMES CROPPER & TECHNICAL FIBRE PRODUCTS (TFP):

James Cropper is based in the Lake District, England’s first and foremost National Park, with a paper-making heritage that started in 1845. Since its inception the business has been carefully stewarded and nurtured by six generations of the Cropper family.

Today the business is renowned globally for its luxury packaging papers, which accompany many of the world’s most exclusive brands, while the world’s leading artists, galleries and museums use its framing and archival boards alongside its range of conventional artists materials. As well as paper products, James Cropper also manufactures nonwovens from carbon, glass and polymer fibres, which play a key part in production of composites in the automotive, energy and aerospace sectors.

Technical Fibre Products (TFP) is a leading nonwoven manufacturer, offering a broad range of high quality, technically advanced nonwovens into the composites market, which can be customised to meet specific application requirements. Established nearly 30 years ago, TFP primarily operates within the automotive, and aerospace composite markets while also providing effective solutions in the defence, energy, consumer electronics, industrial, construction and healthcare markets. Utilising extensive materials knowledge within polymers, particulates & speciality fibres together with high specification lamination, metal fibre coating and converting capabilities, TFP provide a wide range of customised solutions.

To find out more about the innovative production methods, product range, responsible manufacturing principles and history of James Cropper and Technical Fibre Products, please visit www.jamescropper.com and www.tfpglobal.com