ACHEMA 2015: With HIPRO-S V2, HIMA introduces first-of-its-kind safety protocol for efficiently migrating existing plants to new systems.

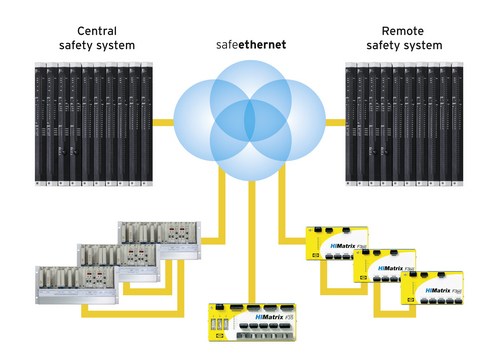

To help the process industry migrate to tomorrow’s digitally networked plants, HIMA Paul Hildebrandt GmbH will introduce at ACHEMA 2015 in Frankfurt, Germany, a new protocol that enables Ethernet-based, safety-related communication (SIL 3). Now safe communication is enabled between the company’s three controller families: HIMatrix, HIMax and HIQuad.

The new safety protocol HIPRO-S V2 enables Ethernet-based, safety-related communication (SIL 3) between the three HIMA product families: HIMatrix, HIMax and HIQuad.

“HIMA supports the incremental digitalization of our customers’ plants with very clear migration paths,” said Peter Sieber, Vice President Global Sales at HIMA. “Customers can select and combine the best HIMA controller for their application and know that the safe, reliable and fast networking of HIPRO-S V2 and safeethernet will allow them to efficiently operate their digitally networked plant, even in the future. The HIPRO-S V2 protocol will help to accelerate commissioning and ensure the fast restart of the plant and reduce the risk of delays. A long service life, and thus optimum investment protection, are guaranteed.”

Separate certification is not necessary

HIPRO-S V2 does not need a separate certificate, as it is a component of HIQuad, HIMax and HIMatrix controllers and is covered by their certificates. HIPRO-S V2 can be implemented universally.

Like safeethernet, HIPRO-S V2 uses UDP packets. These packets can be transmitted via standard Ethernet infrastructures, such as switches, firewalls, WLANs or devices, that are suitable for Ex zones. Use of these proven, industrial infrastructure components (COTS) enables economical and reliable solutions.

The new safety protocol HIPRO-S V2 enables Ethernet-based, safety-related communication (SIL 3) between the three HIMA product families HIMatrix, HIMax, and HIQuad.

HIMA safety protocols are distinct in that they can be operated in the same network with non-safe protocols; for example, Modbus TCP or the connection via OPC. Controllers can also be programmed via this network. This helps to reduces costs in generating and maintaining the network infrastructure.

About HIMA

HIMA is the world’s leading specialist for safety-related automation solutions. HIMA solutions provide maximum safety and maximum availability and can be integrated into any automation environment. During the past 45 years, more than 35,000 HIMA systems have been installed in over 80 countries to protect the equipment of the world’s largest companies in the oil, gas, chemical, pharmaceutical and power generation industries. In the fields of rail, logistics and machine safety, HIMA solutions are leading the way to increased safety and profitability. The HIMA LIFECYCLE SERVICES concept gives customers an overview of all the requirements of “functional safety” allowing them to always make the right decision at the appropriate time.

For more information about HIMA, please visit: www.hima.com