Measurement technology for ensuring maximum fabric and machine efficiency

SeamTech, a division of the US technology corporation Xerium and its leading clothing division Huyck.Wangner, is providing forming fabric and paper manufacturers with unique measurement technology: the Fabric Scanning Profiler. It measures the fabric profiles during production and directly at the paper machine, thus providing important information for optimizing process stability.

The forming fabric plays a key role in perfect sheet forming and paper quality during paper production. The drainage and formation processes are largely determined by optimum clothing and thickness cross profiles as well as trouble-free running properties. The technicians at SeamTech have developed the Fabric Scanning Profiler in order to keep an eye on these important parameters and individually adjust them to the specific paper production as needed. The Xerium division SeamTech, which began developing the first fully automated seaming machines for continuous seams of forming fabrics 25 years ago, is now the worldwide leading supplier of fully automated seam machines SeamMaster as well as other machines and components for producing forming and dry fabrics.

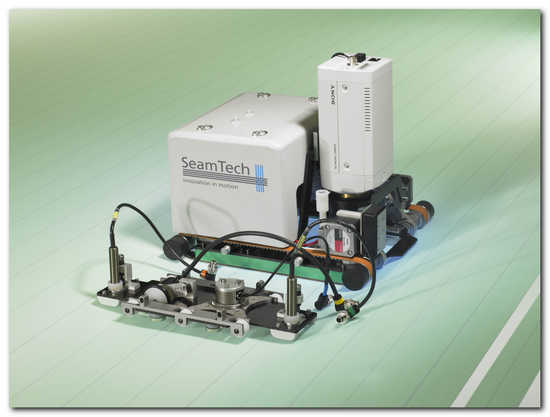

With the Fabric Scanning Profiler (FSP), the technicians at SeamTech are now providing another instrument for keeping the fabrics under control and individually adjusting them to the specific paper production as needed. This uniquely configured measuring instrument records all relevant information and provides data on the most important parameters of the clothing by precisely presenting the main bases for the analysis in order to maintain top-level fabric quality and paper machine efficiency at all times.

Modular configuration for universal use

The Fabric Scanning Profiler is mobile and runs automatically, and can also be controlled and steered via remote control, making it useable in virtually any situation. The tension and fabric thickness measurement runs across the fabric can be made at an inclination of up to 45°. Control and data recording are conducted via W-LAN. This enables detailed, dependable analysis of the forming fabric or other clothing components with data output and storage directly on location – even if the paper machine is stopped briefly. The measuring instrument features a modular configuration and is offered for measuring clothing thickness and tension, and is available with an optional camera module for visual inspection of the fabric surface. The camera can be used to examine the forming fabric at targeted points, thus enabling continuous visual monitoring of the fabric surfaces (on the running side as well as the paper side).

W-LAN is used to control the Fabric Scanning Profiler precisely at the point to be examined.

Increase in productivity and paper quality

The measurement data recorded on the machine run’s effect on the fabric can immediately be analysed, processed and saved. The fabric can then be continuously adjusted quickly, precisely and in a traceable manner. And it offers many other advantages:

• exact, data-supported determination of the fabric’s clothing and cross profile

• simple monitoring of all important parameters,

• direct documentation and interpretation of the measurement results obtained to ensure quick and targeted analysis,

• recording of periodic profile faults via FFT analysis,

• visual inspection via camera module at any desired point on the fabric,

• reliable determination of the clothing’s remaining running time,

• maximum user-friendliness and

• high individual application possibilities thanks to the modular configuration.

Edgar Hofstetter, Head of SeamTech, sums up the extensive performance spectrum of FSP measurement technology as follows: “The advantages of ideal analysis and optimal forming fabric output are obvious to forming fabric and paper manufacturers. These benefits come together at the bottom line in outstanding drainage performance with increased production efficiency and top paper quality – an added value which pays off in hard cash.”

Whereas everyone had been developing and using their own measuring instruments in the past, all worldwide leading forming fabric manufacturers now use SeamTech’s patented Fabric Scanning Profiler – and with great success. So much so that the machine has conquered a firm place in the service portfolio for paper machines and quality optimization in production.