Displaying items by tag: Metsä Board

Metsä Board updates its strategic 2030 sustainability targets

Metsä Board, a leading supplier of fresh fibre paperboards and part of Metsä Group, has updated its strategic 2030 sustainability targets. The new targets highlight its commitment to safeguarding natural biodiversity, mitigating climate change, promoting the sustainable use of natural resources, healthy workplace communities and ethical operations. The sustainability targets are categorised according to the ESG perspectives.

Natural biodiversity is safeguarded in wood sourcing through measures that increase the diversity of tree species and the amount of decaying wood, and by preserving valuable habitats. The 2030 targets are monitored with a comprehensive, more than doubled set of indicators. Also climate-positive actions in forests have been increased.

Metsä Board’s target regarding climate change is unchanged. To mitigate climate change Metsä Board is aiming for 100% fossil free production and products by the end of the year 2030. This target includes both emissions from the company’s own energy production (scope 1) as well as purchased energy (scope 2). Currently, 87% of the energy used at Metsä Board mills is fossil free.

For water use, Metsä Board has set an even stricter target of 35% (previously 30%) reduction in process water use per product tonne and continues to aim at a minimum of a 10% energy efficiency improvement by the end of the year 2030 compared to the 2018 level.

Several indicators related to ethical operations and well-being at work have been added in target setting. Metsä Board will monitor job satisfaction, the implementation of anonymous recruitment processes, and the share of women in leadership positions.

Indicators related to society and supply chain sustainability include the share of certified wood, supplier surveys and audits, and shared sustainability targets with key partners.

Metsä Board’s sustainability targets are in line with the strategic sustainability 2030 objectives of Metsä Group. The sustainability target updates are based on materiality analysis based on discussions with various stakeholder groups. The analysis was carried out in the autumn 2022.

More information about Metsä Board’s sustainability and all new sustainability targets for 2030 can be found at the company’s website.

Metsä Board

metsagroup.com/metsaboard

Metsä Board is a leading European producer of premium fresh fibre paperboards. We focus on lightweight and high-quality folding boxboards, food service boards and white kraftliners. The pure fresh fibres we use in our products are a renewable and recyclable resource, that can be traced back to sustainably managed northern forests. We are a forerunner in sustainability, and we aim to have completely fossil free mills and raw materials by the end of 2030.

Together with our customers we develop innovative packaging solutions to create better consumer experiences with less environmental impact. In 2022 our sales totaled EUR 2.5 billion, and we have around 2,250 employees. Metsä Board, part of Metsä Group, is listed on the Nasdaq Helsinki.

Metsä Group

metsagroup.com

Metsä Group leads the way in the bioeconomy. We invest in growth, developing bioproducts and a fossil free future. The raw material for our products is renewable wood from sustainably managed northern forests. We focus on the growth sectors of the forest industry: wood supply and forest services, wood products, pulp, fresh fibre paperboards, and tissue and greaseproof papers.

Metsä Group’s annual sales is approximately EUR 7 billion, and we have around 9,500 employees in 30 countries. Our international Group has its roots in the Finnish forest: our parent company is Metsäliitto Cooperative owned by over 90,000 forest owners.

Metsä Board recognised again with triple CDP ‘A’ score for transparency on climate change, forests and water security

Metsä Board, part of Metsä Group, has been recognised for leadership in corporate transparency and performance on climate change, forests and water security by global environmental non-profit CDP, securing a place on its annual ‘A List’. Based on data reported through CDP’s 2022 Climate Change, Forests and Water Security questionnaires, Metsä Board is one of only 12 companies that achieved a triple ‘A’ – out of nearly 15,000 companies scored. This was the second consecutive year that Metsä Board scored the outstanding triple ‘A’.

“We have ambitious sustainability targets including 100% fossil free production and raw materials by the end of 2030. In order to follow our way towards the goals it is essential that we report our sustainability work comprehensively, transparently and openly. These ‘A List’ positions are a recognition of our systematic work," says Mika Joukio, CEO of Metsä Board. Earlier this year Metsä Board published new detailed, interactive roadmaps to help visualise the measures it will take to achieve its 2030 sustainability targets regarding climate change and water use.

This is the seventh year that Metsä Board achieved the position on the CDP Climate A list and the CDP Water A list, and the second time on the CDP Forest A list.

CDP’s annual environmental disclosure and scoring process is widely recognised as the gold standard of corporate environmental transparency. The full list of companies that made this year’s CDP A List is available here, along with other publicly available company scores:

https://www.cdp.net/en/companies/companies-scores

Metsä Board

https://www.metsagroup.com/metsaboard

Metsä Board is a leading European producer of premium fresh fibre paperboards. We focus on lightweight and high-quality folding boxboards, food service boards and white kraftliners. The pure fresh fibres we use in our products are a renewable and recyclable resource, that can be traced back to sustainably managed northern forests. We are a forerunner in sustainability, and we aim to have completely fossil free mills and raw materials by the end of 2030.

Together with our customers we develop innovative packaging solutions to create better consumer experiences with less environmental impact. In 2021 our sales totaled EUR 2.1 billion, and we have around 2,400 employees. Metsä Board, part of Metsä Group, is listed on the Nasdaq Helsinki.

Metsä Group

https://www.metsagroup.com

Metsä Group leads the way in the bioeconomy. We invest in growth, developing bioproducts and a fossil free future. The raw material for our products is renewable wood from sustainably managed northern forests. We focus on the growth sectors of the forest industry: wood supply and forest services, wood products, pulp, fresh fibre paperboards, and tissue and greaseproof papers.

Metsä Group’s annual sales is approximately EUR 6 billion, and we have around 9,500 employees in 30 countries. Our international Group has its roots in the Finnish forest: our parent company is Metsäliitto Cooperative owned by nearly 100,000 forest owners.

Final call for Better with Less – Design Challenge 2022

Last June, Metsä Board announced the Better with Less – Design Challenge. Now is the final call to enter.

The Better with Less – Design Challenge 2022 is inviting designers around the world to create the zero-waste packaging of the future. The competition is open for submissions for another four weeks, until 1 December, 2022.

The world-class jury of renowned package design experts will be looking for lighter, smarter, and circular solutions for some of the most common consumer packages. Says the competition chairman, Ilkka Harju: “We want to discover innovative, fit-for-purpose designs for all types of packaging that have circularity as starting point for design. This is a great opportunity to get your ideas seen and to make your mark on the circular packaging of the future.“

The competition jury includes:

Andrew Gibbs, Founder & Editor in Chief, The Dieline

Ben Parker, Co-founder of creative design studio Made Thought

Brandi Parker, Head of Sustainability, Pearlfisher

Brian Collins, Chief Creative Officer, Collins

Carin Blidholm Svensson, Creative Director & Founder, BVD

Diana Sanchez, Visual Design Associate Manager, Accenture Song

Jennifer Patrick, Global Packaging & Brand Director, Patagonia

Sian Sutherland, Co-founder, Plastic Planet

Ilkka Harju, Packaging Services Director EMEA and APAC, Metsä Board and the jury chairman

The jury will award the three best zero-waste packaging designs with EUR 10,000, EUR 3,000 and EUR 2,000 prizes. For student participants there will be an additional award - an internship at the company’s Excellence Centre in Finland.

The Better with Less – Design Challenge is an initiative to inspire packaging designers all over the world to create packaging solutions that could have a big impact on the world – while reducing the impact of packaging on the environment. The previous Better with Less – Design Challenge inspired entries from 28 countries to contribute their work and showcase their environmentally-friendly packaging solutions. The competition is organised by a leading European paperboard producer Metsä Board, part of Metsä Group.

For more information and to enter: www.betterwithless.org

Better with Less – Design Challenge in social media: Twitter and Instagram

Metsä Board

https://www.metsagroup.com/metsaboard

Metsä Board is a leading European producer of premium fresh fibre paperboards. We focus on lightweight and high-quality folding boxboards, food service boards and white kraftliners. The pure fresh fibres we use in our products are a renewable and recyclable resource, that can be traced back to sustainably managed northern forests. We are a forerunner in sustainability, and we aim to have completely fossil free mills and raw materials by the end of 2030.

Together with our customers we develop innovative packaging solutions to create better consumer experiences with less environmental impact. In 2021 our sales totaled EUR 2.1 billion, and we have around 2,400 employees. Metsä Board, part of Metsä Group, is listed on the Nasdaq Helsinki.

Metsä Group

https://www.metsagroup.com

Metsä Group leads the way in the bioeconomy. We invest in growth, developing bioproducts and a fossil free future. The raw material for our products is renewable wood from sustainably managed northern forests. We focus on the growth sectors of the forest industry: wood supply and forest services, wood products, pulp, fresh fibre paperboards, and tissue and greaseproof papers.

Metsä Group’s annual sales is approximately EUR 6 billion, and we have around 9,500 employees in 30 countries. Our international Group has its roots in the Finnish forest: our parent company is Metsäliitto Cooperative owned by nearly 100,000 forest owners.

New bakery packaging concept reduces CO2 emissions by a third

Viipurilainen Kotileipomo is a nearly 100-year-old company that produces pastries and artisan breads from local ingredients using traditional methods. When the bakery was looking for a new solution for its cake packaging, its key criteria were to reduce the environmental footprint of the packaging, and to make assembly quick and easy.

Viipurilainen Kotileipomo and Metsä Board's packaging design team based at Metsä Board's Excellence Centre jointly developed a resource-efficient and 100% recyclable bakery packaging. The new eye-catching packaging reduces material requirements by 25%, and carbon dioxide emissions by 34% compared to the previous packaging. At the same time, the bakery was able to reduce its use of plastic by moving away from a PE-coated board. In addition to the environmental benefits, the design of the new bakery box makes it quicker and easier to assemble.

"Packaging sustainability is important to us and our customers, and it's great to be able to spread the word about reducing plastic and promoting recycling. The whole product development process was carried out in a structured way at the Excellence Centre and the new stylish packaging was quickly brought to market," says Teppo Ylä-Hemmilä, Bread Artist and Innovation Director, Viipurilainen Kotileipomo.

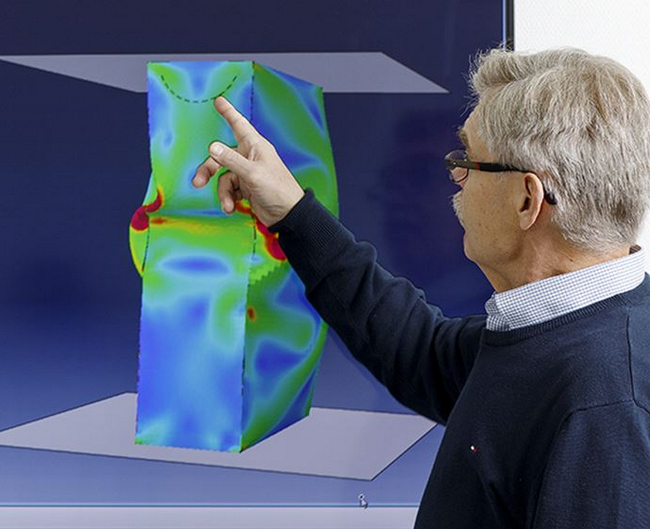

"The new concept is an excellent example of innovative solutions made possible by joint brainstorming. In designing the packaging, we used a virtual model at our Excellence Centre to quickly and accurately visualise the material, structure and its sustainability," says Ilkka Harju, Packaging Services Director, EMEA and APAC, Metsä Board.

The bakery packaging is made of lightweight MetsäBoard Prime FBB EB, a dispersion coated barrier board, which can be recycled using paper or paperboard collection waste streams. The MetsäBoard Prime FBB EB board is thick and resistant to grease, which is key for food that naturally have a high fat content such as pastries and cakes.

Metsä Board

www.metsaboard.com

Metsä Board is a leading European producer of premium fresh fibre paperboards. We focus on lightweight and high-quality folding boxboards, food service boards and white kraftliners. The pure fresh fibres we use in our products are a renewable and recyclable resource, that can be traced back to sustainably managed northern forests We are a forerunner in sustainability, and we aim to have completely fossil free mills and raw materials by the end of 2030.

Together with our customers we develop innovative packaging solutions to create better consumer experiences with less environmental impact. In 2021 our sales totalled EUR 2.1 billion, and we have around 2,400 employees. Metsä Board, part of Metsä Group, is listed on the Nasdaq Helsinki.

Metsä Group

www.metsagroup.com

Metsä Group leads the way in the bioeconomy. We invest in growth, developing bioproducts and a fossil free future. The raw material for our products is renewable wood from sustainably managed northern forests. We focus on the growth sectors of the forest industry: wood supply and forest services, wood products, pulp, fresh fibre paperboards, and tissue and greaseproof papers.

Metsä Group’s annual sales is approximately EUR 6 billion, and we have around 9,500 employees in 30 countries. Our international Group has its roots in the Finnish forest: our parent company is Metsäliitto Cooperative owned by nearly 100,000 forest owners.

Metsä Board launches a state-of-the-art Excellence Centre to accelerate paperboard and packaging innovation

Growing consumption and demand for more sustainable packaging is boosting the need for new innovations. To develop solutions for packaging today and into the future, Metsä Board, part of Metsä Group, has started up operations in its new Excellence Centre at the unique bioeconomy site in Äänekoski, Finland.

The centre, with its cutting-edge technology for R&D, packaging design and paperboard and packaging performance, aims to accelerate material and packaging innovation and provide a collaboration platform for customers and technology partners globally.

“As the amount of packaging continues to grow, new, sustainable solutions are needed to replace fossil-based materials and ensure circularity. The Excellence Centre concept enables paperboard and packaging solutions that look at the entire value chain, and not just at its separate parts. With the material knowhow, competence and tools now available, we can optimise performance throughout the packaging lifecycle”, says Mika Joukio, CEO of Metsä Board.

Metsä Board Excellence Centre

Metsä Board Excellence Centre

The Excellence Centre, which covers a total of 1,500 square meters, includes R&D facilities, a packaging design studio, a customer feedback centre and a state-of-the art laboratory providing more than 100 different measurement methods and analytics. The centre also features a virtual store and a computer-aided engineering (CAE) tool to allow sophisticated simulation and analysis of packaging performance.

Metsä Board’s Excellence Centre brings together Metsä Board’s own competencies and deep expertise in fibre-based solutions with that of various experts and partners, such as material suppliers, technology providers, start-up companies, universities and research companies. Virtual collaboration workshops have also been developed to enable joint development and co-creation if physical meetings are not possible.

“Renewable and recyclable fresh fibre paperboard can be utilised for packaging in many ways. Fibre-based packaging has a lot to offer, and together with our partners and the new Excellence Centre, we are able to explore the possibilities even more comprehensively. I am excited about the opportunities this will bring for today and the future,” says Metsä Board’s CEO Mika Joukio.

Äänekoski’s world-unique bioeconomy ecosystem includes a next-generation bioproduct mill, a paperboard mill, plywood mill, the Pro Nemus visitor centre, and a textile fibre demo plant.

Metsä Board

www.metsaboard.com

Metsä Board is a leading European producer of premium fresh fibre paperboards and forerunner in sustainability. We produce premium lightweight folding boxboards, food service boards and white kraftliners for consumer goods packaging as well as retail-ready and food service applications. We work together with our customers on a global scale to innovate solutions for better consumer experiences with less environmental impact. The pure fresh fibres Metsä Board uses are a renewable resource, traceable to origin in sustainably managed northern forests. We aim for completely fossil-free mills and raw materials by 2030.

The global sales network of Metsä Board supports customers worldwide, including brand owners, retailers, converters and merchants. In 2019, the company’s sales totalled EUR 1.9 billion, and it has approximately 2,400 employees. Metsä Board, part of Metsä Group, is listed on the Nasdaq Helsinki.

Metsä Group

www.metsagroup.com

Metsä Group is a forerunner in sustainable bioeconomy utilising renewable wood from sustainably managed northern forests. Metsä Group focuses on wood supply and forest services, wood products, pulp, fresh fibre paperboards and tissue and greaseproof papers.

In 2019, Metsä Group’s sales totalled EUR 5.5 billion, and it employs approximately 9,300 people. Metsäliitto Cooperative is the parent company of Metsä Group and is owned by approximately 100,000 Finnish forest owners.

Metsä Board’s co-creation workshop results in an innovative insect hotel

Finnish Golf Coat Oy is launching a new golf ball packaging that, when empty, takes on a second life as an insect hotel. The innovative packaging is a result of a co-creation workshop organised by Metsä Board, part of Metsä Group. The workshops are part of Metsä Board’s 360 Services that cover the whole packaging value chain by utilising the state-of-the-art Excellence Centre in Äänekoski, Finland. The design of the golf ball packaging was a collaboration involving a packaging design agency, Metsä Board's own packaging design team, the packaging manufacturer and Metsä Board's technical service.

“The packaging is an excellent example of how teamwork can create something totally new. In 2021 we organised 36 virtual workshops with our customers and partners. The process concentrated on improving the current package whilst creating something completely new, like this insect hotel”, says Gunilla Nykopp, Customer Experience Manager from Metsä Board’s packaging design team.

When empty the packaging can be turned into an insect hotel providing shelter for bugs and larvae thanks to separate parts made of paperboard included in the cover. The packaging was manufactured by PackageMedia Oy, part of Pyroll Packaging using MetsäBoard Pro FBB Bright folding boxboard.

Metsä Board

www.metsaboard.com

Metsä Board is a leading European producer of premium fresh fibre paperboards. We focus on lightweight and high-quality folding boxboards, food service boards and white kraftliners. The pure fresh fibres we use in our products are a renewable resource, traceable to origin in sustainably managed northern forests. We are a forerunner in sustainability, and we aim for completely fossil free mills and raw materials by 2030.

Together with our customers we develop innovative packaging solutions to create better consumer experiences with less environmental impact. In 2020, our sales totalled EUR 1.9 billion, and we have about 2,400 employees. Metsä Board, part of Metsä Group, is listed on the Nasdaq Helsinki.

Metsä Group

www.metsagroup.com

Metsä Group leads the way in the bioeconomy. We invest in growth, developing bioproducts and a fossil free future. The raw material for our products is renewable wood from sustainably managed northern forests. We focus on the growth sectors of the forest industry: wood supply and forest services, wood products, pulp, fresh fibre paperboards, and tissue and greaseproof papers.

Metsä Group’s annual sales is approximately EUR 5.5 billion, and we have around 9,200 employees in 30 countries. Our international Group has its roots in the Finnish forest: our parent company is Metsäliitto Cooperative owned by 100,000 forest owners.

Metsä Board minimises environmental impact of packaging with Dassault Systèmes’ simulation platform

Metsä Board, the leading European producer of premium fresh fibre paperboards and part of Metsä Group, has successfully started to deploy Dassault Systèmes’ 3DEXPERIENCE platform in development and testing of packaging solutions at its Excellence Centre. With packaging simulation Metsä Board can notably speed up packaging development and reduce carbon footprint of packaging.

Simulation enables 85% faster development compared to the traditional way of making multiple tests with physical prototypes. Simulation technologies help manage the development of the entire product life cycle, from material selection to delivery. The new technology helps Metsä Board recommend optimal packaging materials as well as packaging structures to its customers.

“We wanted to accelerate our rate of innovation to help our customers – packaging manufacturers as well as brand owners – with optimal packaging solutions and reduce their carbon footprint. For example, box compression as well as drop tests can now be made in hours compared to several days or even weeks with traditional physical testing methods,” says Markku Leskelä, SVP Development, Metsä Board.

The state-of-the-art solution of Dassault Systèmes and their expertise from past engagements in the aerospace and automotive industry has helped deploy new technologies to the manufacturing of fibre-based packaging.

Metsä Board

www.metsaboard.com

Metsä Board is a leading European producer of premium fresh fibre paperboards. We focus on lightweight and high-quality folding boxboards, food service boards and white kraftliners. The pure fresh fibres we use in our products are a renewable resource, traceable to origin in sustainably managed northern forests. We are a forerunner in sustainability, and we aim for completely fossil free mills and raw materials by 2030.

Together with our customers we develop innovative packaging solutions to create better consumer experiences with less environmental impact. In 2020, our sales totalled EUR 1.9 billion, and we have about 2,400 employees. Metsä Board, part of Metsä Group, is listed on the Nasdaq Helsinki.

Metsä Group

www.metsagroup.com

Metsä Group leads the way in the bioeconomy. We invest in growth, developing bioproducts and a fossil free future. The raw material for our products is renewable wood from sustainably managed northern forests. We focus on the growth sectors of the forest industry: wood supply and forest services, wood products, pulp, fresh fibre paperboards, and tissue and greaseproof papers.

Metsä Group’s annual sales is approximately EUR 5.5 billion, and we have around 9,200 employees in 30 countries. Our international Group has its roots in the Finnish forest: our parent company is Metsäliitto Cooperative owned by 100,000 forest owners.

Metsä Board is progressing with its fossil free target at its Kyro mill

The Hämeenkyrön Voima power plant, from which Metsä Board's Kyro mill buys energy, has replaced the peat it burns with renewable energy. In the future, the power plant aims to use wood-based fuels from Metsä Group's production and wood procurement by-products. By not burning peat, Metsä Board Kyro's share of fossil fuels in total fuel demand will be reduced from just over a quarter to about a tenth.

The phase-out of peat has required significant investments in power plant technology to control boiler corrosion damage and optimise running conditions. Previously approximately one fifth of the fuel used by the plant has been peat. Thanks to the investments, the energy and local district heat from the mill will be produced in a more environmentally friendly way.

Metsaboard Kryo Mill Aerial photo

Metsaboard Kryo Mill Aerial photo

Metsä Board, part of Metsä Group, targets to achieve fossil-free production and products by the end of 2030. Moving away from peat-based energy will help Metsä Board towards these goals.

Metsä Board

Metsä Board is a leading European producer of premium fresh fibre paperboards. We focus on lightweight and high-quality folding boxboards, food service boards and white kraftliners. The pure fresh fibres we use in our products are a renewable resource, traceable to origin in sustainably managed northern forests. We are a forerunner in sustainability, and we aim for completely fossil free mills and raw materials by 2030.

Together with our customers we develop innovative packaging solutions to create better consumer experiences with less environmental impact. In 2020, our sales totalled EUR 1.9 billion, and we have about 2,400 employees. Metsä Board, part of Metsä Group, is listed on the Nasdaq Helsinki.

Metsä Group

Metsä Group leads the way in the bioeconomy. We invest in growth, developing bioproducts and a fossil free future. The raw material for our products is renewable wood from sustainably managed northern forests. We focus on the growth sectors of the forest industry: wood supply and forest services, wood products, pulp, fresh fibre paperboards, and tissue and greaseproof papers.

Metsä Group’s annual sales is approximately EUR 5.5 billion, and we have around 9,200 employees in 30 countries. Our international Group has its roots in the Finnish forest: our parent company is Metsäliitto Cooperative owned by 100,000 forest owners.

Metsä Board Kyro mill’s new modernised finishing area starts up

The modernisation of the Metsä Board Kyro mill’s finishing area has now been completed and the finishing line with new advanced equipment has started up. During the mill’s annual maintenance shutdown in October, a new state-of-the-art reeler and winder were installed on the production line, and the reel broke handling system was significantly upgraded. The investment, announced in December 2019, was worth EUR 20 million. Metsä Board is part of Metsä Group.

"The new high automation finishing line will further improve the quality consistency of the paperboard reels and increase the runnability on our customers' converting lines. In addition, the automation will improve upon the existing occupational safety level in the mill's finishing area and reduce the physical workload," says Petri Huiko, Mill Manager at Metsä Board Kyro mill.

The Kyro mill produces coated high-quality folding boxboard and innovative dispersion coated barrier board, which helps reduce plastic in consumer packaging. The mill has a production capacity of 190,000 tonnes per year.

Metsä Board

www.metsaboard.com

Metsä Board is a leading European producer of premium fresh fibre paperboards. We focus on lightweight and high-quality folding boxboards, food service boards and white kraftliners. The pure fresh fibres we use in our products are a renewable resource, traceable to origin in sustainably managed northern forests. We are a forerunner in sustainability, and we aim for completely fossil free mills and raw materials by 2030.

Together with our customers we develop innovative packaging solutions to create better consumer experiences with less environmental impact. In 2020, our sales totalled EUR 1.9 billion, and we have about 2,400 employees. Metsä Board, part of Metsä Group, is listed on the Nasdaq Helsinki.

Metsä Group

www.metsagroup.com

Metsä Group leads the way in the bioeconomy. We invest in growth, developing bioproducts and a fossil free future. The raw material for our products is renewable wood from sustainably managed northern forests. We focus on the growth sectors of the forest industry: wood supply and forest services, wood products, pulp, fresh fibre paperboards, and tissue and greaseproof papers.

Metsä Group’s annual sales is approximately EUR 5.5 billion, and we have around 9,200 employees in 30 countries. Our international Group has its roots in the Finnish forest: our parent company is Metsäliitto Cooperative owned by 100,000 forest owners.

Innovative corrugated face mask bin wins a ScanStar 2021

An innovative corrugated bin for face masks by Metsä Board, part of Metsä Group, has been awarded a ScanStar in a Nordic packaging design competition organised by the Scandinavian Packaging Association. The mask bin, made of lightweight and durable corrugated board, helps to collect and dispose of used face masks easily and safely. Metsä Board developed the concept together with packaging design agency Futupack and corrugated board converter Capertum.

The competition jury commented: “A simple but clever solution for a new problem – mask littering. The bin is made from corrugated material, and is easy to assemble even without the instructions which have been printed on the bin itself. The lid makes the light packaging more rigid and, if you turn the lid, it closes the package when it is full. Good printing supports the product. The bin is also accessible to those who have disabilities.”

“The Covid-19 pandemic has brought its own challenges to waste management and together with Futupack and Capertum we wanted to develop a solution to this. In our design, we paid special attention to the lightness of the material, its durability and the ease of use and consumer guidance,” said Ilkka Harju, Packaging Services Director EMEA and APAC at Metsä Board.

MetsäBoard Pro WKL 160 g/m2 coated white kraftliner was used as the top liner of the mask bin. The Finnish corrugated board converter Capertum printed the E-flute corrugated board in silk screen. Thanks to fresh fibre board the waste bin is strong but light, which reduces the carbon footprint.

Metsä Board

Metsä Board is a leading European producer of premium fresh fibre paperboards. We focus on lightweight and high-quality folding boxboards, food service boards and white kraftliners. The pure fresh fibres we use in our products are a renewable resource, traceable to origin in sustainably managed northern forests. We are a forerunner in sustainability, and we aim for completely fossil free mills and raw materials by 2030.

Together with our customers we develop innovative packaging solutions to create better consumer experiences with less environmental impact. In 2020, our sales totalled EUR 1.9 billion, and we have about 2,400 employees. Metsä Board, part of Metsä Group, is listed on the Nasdaq Helsinki.

Metsä Group

www.metsagroup.com

Metsä Group leads the way in the bioeconomy. We invest in growth, developing bioproducts and a fossil free future. The raw material for our products is renewable wood from sustainably managed northern forests. We focus on the growth sectors of the forest industry: wood supply and forest services, wood products, pulp, fresh fibre paperboards, and tissue and greaseproof papers.

Metsä Group’s annual sales is approximately EUR 5.5 billion, and we have around 9,200 employees in 30 countries. Our international Group has its roots in the Finnish forest: our parent company is Metsäliitto Cooperative owned by 100,000 forest owners.