Displaying items by tag: Södra Cell AB

Södra's income statement for the first quarter of 2012

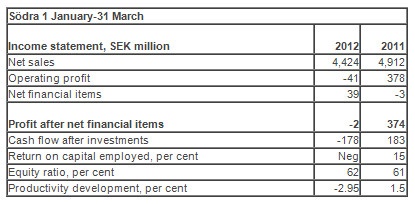

Södra's operating profit for the first quarter of 2012 amounted to SEK -41 million. Profit after net financial items amounted to SEK -2 million. Reduced production and a number of market stoppages characterised the first quarter of the year.

"We started the year with most of our sawmills implementing market stoppages, while production at two of our Norwegian pulp mills was down for much of the quarter. Production at our pulp mills was just 73 per cent of our normal capacity. For the sawmills, the corresponding figure was a low 70 per cent," said Group Chief Executive Leif Brodén. Together with the first quarter of 2009, this is historically the lowest level of capacity utilisation the company has seen. January and February experienced the lowest production figures, but they also mark the turning point. All production units have been back to normal production capacity since 20 March.

"We are seeing a recovering pulp market and anticipating economic recovery," said Brodén. Price announcements have been accepted, and as of 1 April the price of NSBK is USD 870 per tonne. We are now seeing strong increases in volumes to China, which up to now has been more or less solely responsible for the increase. We are expecting to see higher prices for sawn timber products over the course of the year, but only small volume increases. Viewed from a new development perspective, it seems that 2012 will be another lost year. The sawmill structure will probably need further streamlining.

"For the rest of 2012, we will see normal capacity utilisation, and we think we will see a profit for the year which is just below last year's result, along with a 7 to 8 per cent return on capital employed," said Brodén.

The pulp market started to show signs of recovery during the first quarter of 2012. The world market price of bleached softwood sulphate pulp went up as inventories decreased.

Pulp production at Södra's five mills over the period amounted to 380,000 tonnes, compared with 522,000 tonnes over the same period last year. This reduction is due to the market stoppages which took place at Södra Cell Tofte and Södra Cell Folla.

Textile pulp is now being produced at Södra Cell Mörrum. Annual production is expected to reach 170,000 tonnes, which will give Södra a competitive textile pulp product based on hardwood.

Production of DuraPulp is ongoing at Södra Cell Värö. This is a material which has attracted significant attention due to its unique properties, combined with the fact that it is renewable and biodegradable. DuraPulp is made up of a specially selected pulp from Södra Cell and a renewable biopolymer. On further processing, these two components provide special properties such as moisture resistance, strength and hardness. For the most part, a lamp and a children's chair have been in the spotlight to date, and work is now ongoing with a number of partners which are testing the material at their production facilities.

The market for sawn timber products remains weak, although supply and demand remain balanced. High raw material prices combined with the weak market are having an adverse impact on profitability.

Södra produced 371,000 m3 of sawn timber products over the period, compared with 391,000 m3 over the same period last year. Production at the new sawmill in Värö is continuing to develop positively towards stable, high production levels as planned.

The market for interior products is hesitant in Sweden and remains weak in Denmark, but both sales and earning capacity are strong in Norway.

Over the quarter, Södra Interiör acquired parquet flooring manufacturer Berg & Berg in Kallinge, employing around 90 staff. The company produces more than 500,000 m2 of high quality parquet flooring per year, with net sales of around SEK 130 million. This acquisition will further increase the range of products available to Södra Interiör's customers, while at the same time providing good opportunities for synergies between the businesses in fields such as marketing, logistics and product development.

As a consequence of the sawmill and pulp mill stoppages, the volumes handled by Södra Skog over the first quarter were 800,000 m3 lower than at normal capacity. The price of softwood pulp timber was reduced by SEK 25 on 16 January to SEK 300 per cubic metre sub (solid volume under bark). Since the end of the quarter on 13 April, the price of softwood pulp timber and the assortment mixed hardwood has been reduced by SEK 20 to SEK 280 per m3sub. At the same time, the price of aspen pulp timber went up by SEK 25 to SEK 325 per m3sub.

Over the period, Södra has installed and commissioned a new machine for applying wax protection to its bare root saplings and "plug plus one" saplings as an effective, non-toxic means of protecting against pine weevil damage. This machine is the first of its type. The wax makes it difficult for pine weevils to gnaw their way through to the bark and has been specially developed for high elasticity. This project is a cooperation between Södra Skogsplantor, Ramlösa Plantskola and Sundins Skogsplantor.

The forestry plans, with a newly prepared plan, have been available online to Södra members since March thanks to a newly developed function on Skogsägarnätet, the forest owners' network. The Skogsägare - forest owners - app was launched at the same time, making it possible to access the forestry plans on the iPhone and iPad.

Productivity improvement within the group continues apace, mainly due to ideas contributed by staff.

"We have implemented 1,281 suggested improvements over the quarter. These ideas will improve our profits by a total of SEK 32 million per year. However, overall productivity fell by 2.95 per cent over the quarter, mainly due to the fact that this figure is calculated on the basis of volumes supplied. March saw the marking of the 20,000th idea implemented since we started our systematic productivity programmes in 2000," added Brodén.

Södra Cell begins commercial production of DuraPulp

"A large number of companies have been in touch and are interested in this material. We are currently working with a number of partners who are testing DuraPulp as part of their production processes," said Henrik Wettergren, Business Area Manager for graphic paper and speciality paper.

Production of the new composite material DuraPulp is now beginning at Södra Cell in Värö. This new biodegradable and renewable material has huge potential as an alternative to plastic.

Production of the new composite material DuraPulp is now beginning at Södra Cell in Värö. This new biodegradable and renewable material has huge potential as an alternative to plastic.

DuraPulp has been in the spotlight for a couple of years within Södra because of its exciting combination of a renewable, biodegradable material which is also very strong. A lamp and a children's chair have already been made out of DuraPulp attracting huge interest, and commercial production of the new composite has now begun.

"A large number of companies have been in touch and are interested in this material. We are currently working with a number of partners who are testing DuraPulp as part of their production processes," said Henrik Wettergren, Business Area Manager for graphic paper and speciality paper.

DuraPulp is the result of several years of collaboration between Södra and the research company Innventia. The starting point for the work was to create a new, fibre-based material which could be a biodegradable alternative to plastic.

DuraPulp is made up of a specially selected pulp from Södra Cell and a biopolymer. On further processing, these two components take on special properties such as moisture resistance, strength and hardness.

DuraPulp was exhibited for the first time at the Milan Furniture Fair in 2009 as part of the Parupu children's chair developed by design company Claesson Koivisto Rune. The latter has also used DuraPulp to create its award-winning w101 lamp.

Södra textile pulp production in progress

Under full operation, annual production is expected to amount to 170 000 tonnes, and the investment in Mörrum will give Södra competitive textile pulp production based on hardwood.

Production of textile pulp at Södra Cell Mörrum has now begun. Under full operation, annual production is expected to amount to 170 000 tonnes, and the investment in Mörrum will give Södra competitive textile pulp production based on hardwood.

Södra made a decision to invest in the production of textile pulp back in December 2010. The Group is anticipating strong market development for textile pulp as it is renewable and timber-based, and it will replace oil-based and cotton fibres. Since this decision was made, implementation of the investment and development of a new market organisation for the new customer segment have been taking place in parallel.

"We are focusing on textile pulp as this is a growing market to which we can supply a certified, renewable forest raw material," says Gunilla Saltin, president of Södra Cell.

"For Södra Cell Mörrum, this is an important step in the reinforcement of the profitability and competitiveness of the mill," says Magnus Olsson, Site Manager for Södra Cell Mörrum.

Södra's executive committee has also made a decision in principle about an appropriation limit for production of textile pulp on a further pulp line at one of the company's pulp mills. A definitive decision on a second textile pulp line at Södra will be made in 2012.

Vaahto Group to rebuild Södra Cell Mönsterås Pulp Drying Machine

Vaahto Pulp & Paper Machinery has received an important order from Sörda Cell Mönsterås mill in Sweden. The pulp dryer TM5 of the chemical pulp mill will be revamped for higher production output and better runability. The machine produces both softwood pulp and hardwood pulp.

Vaahto Pulp & Paper Machinery has received an important order from Sörda Cell Mönsterås mill in Sweden. The pulp dryer TM5 of the chemical pulp mill will be revamped for higher production output and better runability. The machine produces both softwood pulp and hardwood pulp.

Vaahto´s supplies include water removal elements, steam-box, lead rolls and suction roll technology as well a major extension of the vacuum systems of the line. Installation, start-up and training services are essential parts of the delivery.

The wire width of the machine is 4650 mm and design speed 250 m/min. The maximum daily output of the dryer can reach 950 tons.

Equipment will be manufactured in Vaahto´s workshops in Hollola and Tampere in Finland. The start-up is scheduled for October 2012. The value of this kind of order amounts usually between 5 and 7 million euros.

Vaahto Pulp & Paper Machinery is part of Vaahto Group, which is a globally operating high technology company serving process industry in the fields of pulp and paper machinery and process machinery.

Södra's Pulp price remains $950 per tonne for February 2011

The pulp market remains well balanced. Södra Cell’s price in Europe for softwood pulp will therefore remain unchanged from January levels at USD 950 per tonne.

For further information, please contact:

Ulf Edman, President of Södra Cell International, +46 70 677 8769

Per Braconier, Director of Corporate Communications, Södra, +46 70 534 5166

Södra Pulp price remains USD950/t for January 2011

Södra has confirmed that it is maintaining its price for softwood pulp in Europe at USD 950 per tonne, valid from 1 January 2011. “The market for softwood pulp is balanced”, said Ulf Edman, president of Södra Cell International.

For further information, please contact:

Ulf Edman, President of Södra Cell International, +46 70 677 8769

Per Braconier, Director of Corporate Communications, Södra, +46 70 534 5166

Pöyry awarded tall oil plant EPC contract in Sweden

Pöyry's Energy business group has been awarded the engineering, procurement and construction contract for a tall oil plant of Mörrum Mill in Sweden by Södra Cell AB. The value of the assignment is not disclosed. The project will be executed over a period of ten months.

The assignment includes a 4.2 t/h crude tall oil plant with auxiliaries based on the HDS® (Hydro Dynamic Separation) technology, which is Pöyry´s proprietary know-how. Similar technology based equipment has already been installed in the 20 most modern pulp mills in Europe, the USA, Canada and China. Currently, Pöyry has one similar project under construction in Austria. The plant has high yield, good availability and low maintenance costs and it produces high-quality crude tall oil.

Södra Cell AB is one of the world's leading suppliers of paper pulp. The Group has five pulp mills; Mönterås, Mörrum and Varö in Sweden and Tofte and Folla in Norway.

PÖYRY PLC

Additional information by:

Ari Asikainen, President, Energy business group, Pöyry PLC, Finland

Tel. +358 10 33 24476

Tero Vainiomäki, Vice President, Project Management, EPC projects, Pöyry Finland Oy, Energy business unit

Tel. +358 10 33 24538

Pöyry is a global consulting and engineering company dedicated to balanced sustainability and responsible business. With quality and integrity at our core, we deliver best-in-class management consulting, total solutions, and design and supervision. Our in-depth expertise extends to the fields of energy, industry, urban & mobility and water & environment. Pöyry has 7000 experts and the local office network in about 50 countries. Pöyry's net sales in 2009 were EUR 674 million and the company's shares are quoted on NASDAQ OMX Helsinki. (Pöyry PLC: POY1V).

DISTRIBUTION: