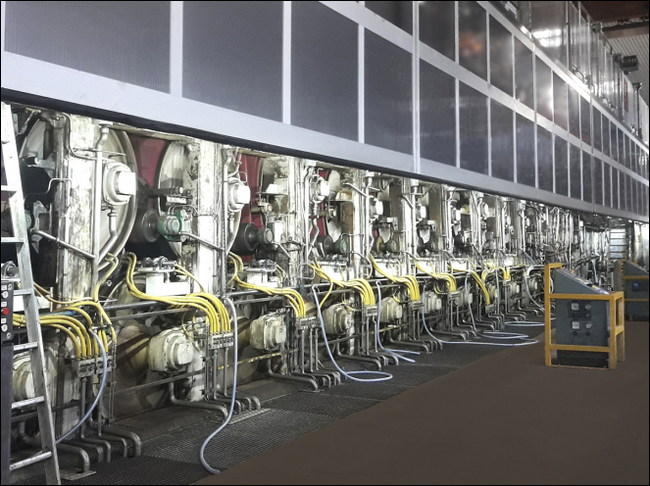

Lucart has selected Toscotec for the complete rebuild of PM14’s Yankee hoods and air system at their Aranguren tissue mill in Spain. The project is scheduled for the first quarter of 2024.

Tailor-made solution for drastic consumption reduction

Based on an onsite survey conducted to verify the existing system’s performance, Toscotec developed a customized solution designed to deliver gas consumption reductions exceeding 30%, as well as a significant increase in machine run-ability.

The scope includes a high efficiency, gas fired TT Hood-Duo system, which ensures a perfectly uniform Cross Direction (CD) moisture profile. The new air system features low-emission burners, several stages of energy recovery, and Toscotec’s TT Swing, a patent pending solution that delivers maximum flexibility and energy savings in regulating the air system operation mode. By switching between a parallel and a hybrid configuration based on production needs, TT Swing guarantees optimal energy efficiency in the drying section of the tissue machine.

Luca Bini, Paper Mill Project Engineer at Lucart, comments, “We selected Toscotec because they proved their ability to dig deep and offer an efficient solution to the root causes of our problem, instead of patching up the old system. Based on our long cooperation, we are confident they will deliver the best possible outcome for Lucart both in the short and the long term.”

Elena Troia, Energy & Environment Sales Manager at Toscotec, says, “Lucart has quickly validated our technical offer, because of the substantial consumption reductions we can guarantee and Toscotec’s strong expertise in energy saving solutions. With this level of savings, we were able to guarantee a ROI of less than 2 years.”

Long standing partnership

Lucart and Toscotec have a long established cooperation. Toscotec installed a complete tissue line (PM12) in 2018 at their Porcari mill, as well as 4 rebuilding projects including a hood and air system rebuild (PM4) in 2016, and 3 TT SYD Steel Yankee Dryer installations in France and Italy as replacements of cast iron Yankees in 2016, 2019 and 2020.

About Lucart

Lucart is a multinational group that promotes a sustainable way of making paper. This is achieved by adopting a systemic approach designed to optimise the use of raw materials and reduce waste by turning them into new resources. Lucart makes airlaid, MG paper, and many tissue products (toilet paper, kitchen paper, napkins, tablecloths, handkerchiefs, etc.). The production activities of the company founded by the Pasquini family in 1953 are organised across three Business Units (Business to Business, Away from Home, and Consumer), engaged in the development and sale of products with brands, such as Tenderly, Tutto, Grazie Natural, and Smile (Consumer market) and Lucart Professional, Fato, Tenderly Professional, and Velo (Away from Home market). The production capacity is over 396,000 tonnes/year of paper on 12 paper machines. The consolidated turnover is over EUR 700 million and 1,700 people are employed at 10 production plants (5 in Italy, 1 in France, 1 in Hungary, 2 in Spain and 1 in the UK) and a logistics hub. Lucart joined the United Nations Global Compact Network Italy in 2020 and has been awarded a “Platinum” sustainability rating by the independent certification company Ecovadis.

Contact

Elena Troia

Energy & Environment Sales Manager, Toscotec

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.