Displaying items by tag: Toscotec

Toscotec partners with Chemitex-Egypt to increase sales in Egypt

Toscotec signed an agency agreement for both its Tissue and Paper & Board divisions with Chemitex Egypt for Trading & Agencies, S.A.E. to increase its sales in the Egyptian market, where it recently landed a number of P&B rebuilding orders.

Toscotec entrusted Sameh Habib, founder and owner of Chemitex-Egypt, with the agency. Habib has fifteen years of sales experience in the tissue and paper industries in Egypt.

Following the deal with Toscotec, Habib said, “The Egyptian paper and tissue market has a high growth potential. Toscotec’s technology fits very well in this market for its strong focus on customization and flexibility, paired with energy reduction.Building on our customer portfolio and the relationships of mutual respect, trust, and cooperation we established, we expect to see promising results in the coming years”.

Toscotec Group’s service provider S.TO.R.I. expected to outperform its 2017 record-setting results

S.TO.R.I., owned by the Toscotec Group, specializes in maintenance services for all minor and major rolls used in papermaking and converting machinery of the tissue and paper industry. In 2017, S.TO.R.I. set a record for turnover in its forty-five year history. This positive performance derives from the strategic synergies achieved with Toscotec, who acquired 100% of S.TO.R.I.’s shares in December 2011. In the period from 2012 to 2017, S.TO.R.I. sustained a 30% growth rate and interim results in 2018 have been confirming this trend, leading to expectations that it will outperform last year’s achievements.

Since 2012, S.TO.R.I. and Toscotec have deepened their long-standing cooperation. By merging S.TO.R.I.’s specialization in rolls maintenance with Toscotec’s engineering capabilities, they accomplished full integration of expertise and higher efficiency in the design and services of roll refurbishing. S.TO.R.I.’s workshop and offices are located inside Toscotec’s headquarters, in Marlia (Lucca).

S.TO.R.I.’s professional experience was built over forty-six years, starting from its foundation in 1972, when it started providing maintenance for papermaking and converting machines. S.TO.R.I. focuses on the inspection, repair and overhaul of not only press rolls but all other rolls, such as forming roll, wire and felt rolls, pope reel drum, and spools. Its mission is to deliver highly specialized services on a continuous basis. The timing becomes important insomuch as customers aim to increase their OEE and reduce maintenance costs.

S.TO.R.I.’s specialists make a precise assessment of the wear conditions of a roll and evaluate its expected performance and risk of failure, so that overhauling can be scheduled efficiently, maximising operation life and minimizing maintenance costs. The majority of S.TO.R.I.’s customers nowadays rely on predictive maintenance. Through regular vibration analyses, S.TO.R.I. estimates the performance trend of a given roll and the possibility of failure. Based on these results, it predicts the period before the next maintenance. This assessment is always a balance of different factors. Drawing on their vast experience, S.TO.R.I.’s specialists can provide the customer with a number of solutions, factoring in time, quality and cost. Based on the contingent needs of the mill, they apply the best-customized solution at a given moment in time. As a result, S.TO.R.I.’s skilled technicians know the components inside out, including their history, weak points and features, much like a doctor knows his patients.

S.TO.R.I.’s range of highly specialized services include predictive maintenance, preventive maintenance, press roll revision and complete overhauling, dynamic balancing, upgrades and non-destructive examinations (NDE). For press roll overhauling, for instance, the company provides complete service packages, including inspection, repairs and spare parts.

Production capacity exceeds 450 components per year, of which suction press rolls and blind drilled press rolls account for approximately 40%, while the rest is made up of various rolls of tissue, paper and converting machines.

S.TO.R.I.’s client base is twofold. Toscotec-associated business accounts for approximately 20% of turnover and covers Europe, Africa, the Middle East, South America and South-East Asia. Italy-based paper mills and converting companies generate approximately 80% of turnover. Essity, Smurfit Kappa, Lucart, Sofidel, Wepa, Cartiere Carrara, Industrie Cartarie Tronchetti, Industrie Cartarie Pieretti, DS Smith, Renova, The Navigator Company are among its main customers. To this second client base, Stori provides maintenance for equipment supplied by any manufacturer. As a result, S.TO.R.I.’s expertise and experience encompasses a wide range of technical solutions designed throughout the years by all the main suppliers and it equips S.TO.R.I.’s experts with the ability to devise tailor-made upgrades for its customers.

Ricardo Domingues joins Toscotec.

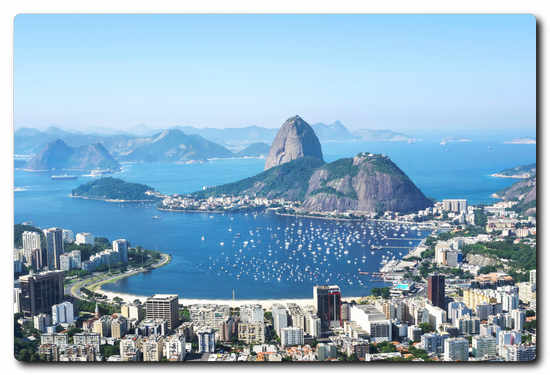

Toscotec has revealed plans to expand its tissue and paper & board businesses in Brazil. Toscotec announced that Ricardo Domingues has joined the group as Sales Manager of the Brazilian market, both for tissue and paper & board.

Toscotec is set to consolidate its market position with the support of Domingues, who brings over 20 years of experience in the tissue and paper industry in Brazil.

Thanks to Domingues’ international expertise in design, sales and services, Toscotec is taking a new step in growing its customer base in Brazil.

Hygienic Tissue Mills fired up a new TT WIND-P tissue rewinder supplied by Toscotec, in South Africa.

On July 27, Hygienic Tissue Mills started up a Toscotec-supplied TT WIND-P tissue rewinder at its Pietermaritzburg mill, in eastern South Africa. This is a repeated order for Toscotec, following the supply of a MODULO-PLUS tissue machine, PM2, in 2017. The TT WIND-P slitter rewinder serves PM2, processing 100% virgin pulp and recycled paper parent rolls.

The TT WIND-P slitter rewinder features 2 unwind stands and handles parent rolls of 2750 mm sheet trim and 2500 mm diameter, with a design speed of 1500 mpm. The pneumatically loaded slitting system has a minimum width of 150 mm. Toscotec supplied the complete electrification and control system, and the sectional drive system. The scope of supply also included the erection supervision, commissioning, start-up assistance, and on-site training.

Toscotec Start-up & Service Engineer David Ponte commented, “It was one of the fastest commissioning I have seen for a rewinder. The TT WIND reached its maximum speed in record time with a final product that was already sellable. Thanks to the great cooperation of Hygienic Tissue’s team, we completed fine tuning in two days with the machine running at top speed”.

Hygienic Tissue CEO Ashraf Jooma said, “On the day of start-up, we reached the maximum speed in a few hours. On this rewinder, we expect to get the same efficiency that we have on the MODULO-PLUS machine. High efficiency and consumption reduction are our priorities, and we are happy with the results we are getting in both areas”.

Matteo Giorgio Marrano, Toscotec Area Sales Manager said: “the TT WIND-P rewinder completed the scope of supply of a MODULO-PLUS tissue line that has been running efficiently for nearly one year and a half. This is a new achievement for Toscotec in the South African market, which has been growing steadily in the last few years. Hygienic Tissue’s strong focus on energy savings matches our mission of tailoring the design of high performing tissue machines to the mill’s specific working conditions, in order to optimize energy usage. The good performance of the slitter rewinder goes into this direction”.

John Holton joins Toscotec North America.

Toscotec North America, Inc. Green Bay, WI and Toscotec S.p.A. Lucca, Italy announced that John Holton has joined the group as Technical Support and Service Coordinator for North America.

Holton comes to Toscotec with over 30 years of Tissue Industry experience and will assist Toscotec’s growing customer base in North America.

Holton comes to Toscotec with over 30 years of Tissue Industry experience and will assist Toscotec’s growing customer base in North America.

Holton is a 30 Year TAPPI Member active at the Committee Level and past presenter and contributor to Tissue World Exhibitions in both the US and Europe.

Celupaper S.A. boosts production with a new Toscotec-supplied MODULO-PLUS in Argentina.

Toscotec will supply a new MODULO-PLUS tissue line to Celupaper S.A. of the leading South American group Grupo Vual, based in Argentina. The MODULO-PLUS machine - PM5 - is scheduled for delivery in autumn 2019 and it will be installed at Papelera Nicaragua mill.

The MODULO-PLUS has a daily production of 65 tpd and is equipped with TT SuctionPressRoll, TT SYD-3200MM and TT Milltech-MGYH Multigen hoods. The scope of supply also includes the approach flow system, the steam and condensate system and the machine and distribution control system.

PM5 is the fourth repeated order awarded by Celupaper to Toscotec in 4 years. The Italian manufacturer had previously supplied a major rebuild on PM2 in 2015, then a MODULO machine - PM3 - in 2016 and finally PM4, a MODULO-PLUS line, which started up in mid-July 2018.

Toscotec’s Area Sales Manager Gabriele Romanini said, “The fact that Celupaper chose to work again with us on their PM5 project is an exciting challenge to exceed their expectations on productivity and energy reduction. Our TT DOES (Drying Optimization for Energy Saving) package, in combination with our Multigen Hood in cogeneration mode, is the core of this effort. We are currently working on the engineering, where the design of our system will integrate into the mill’s cogeneration plant with a gas turbine. Back in 2011, our Energy and Environment department won the PPI Efficiency Improvements of the Year Award with the Spanish producer L.C. Paper 1881 SA, for the effective integration of the tissue machine’s hood system with the cogeneration facility. Drawing on that experience, we expect to achieve substantial energy recovery and very interesting cuts on the machine operating costs”.

Mario Speranza, CEO of Celupaper S.A. commented on the order, “We invest in leading-edge technology to step up our growth in the high-quality tissue market in South America. Toscotec’s tailor-made design has once again provided us with the flexibility and competitive advantage we need to succeed. We knew that Toscotec had significant experience with cogeneration plants and therefore we have great expectations for the performance and consumption of PM5”.

Toscotec to supply TTSteelDryers to Cascades Packaging at Cabano Mill, Canada.

Cascades Packaging selected Toscotec for the supply of TTSteelDryers to be installed at its Cabano mill in Canada. This is a repeated order, following a previous order by Cascades Packaging for a major dryer section rebuild at Kingsey Falls mill. Cascades Packaging confirmed its trust in Toscotec, as the right partner to achieve its strategic objectives of paper machine optimization.

On this project, Toscotec will supply seven TTSteelDryers for the first dryer section, specifically designed for an operating steam pressure of up to 11 barg. The new steel drying cylinders will allow a boost of production and an increase in sheet width at the beginning of the dryer section. Thanks to their reduced shell thickness, TTSteelDryers feature a higher heat transfer rate, compared with cast iron dryers. Since the thermal conductivity of steel and cast iron is similar in the range of operating temperatures, steel dryers with thinner shells offer a higher drying capacity. The scope of supply also includes erection supervision, commissioning and start-up assistance.

Toscotec thus further strengthens its partnership with the Cascades Group in North America. With this new reference, the Italian supplier also reinforces its leadership with respect to the design and upgrade of the dryer section of paper machines.

Delivery is expected for mid-November 2018.

About the Cascades Group

Established in 1964, Cascades produces, converts and markets packaging and tissue products that are composed mainly of recycled fibers. The Company employs 11,000 employees, who work in more than 90 production units located in North America and Europe. With its management philosophy, half a century of experience in recycling, and continuous efforts in research and development as driving forces, Cascades continues to deliver the innovative products that customers have come to rely on.

Vinda Personal Care fired up two new Toscotec-supplied AHEAD-2.0M tissue machines.

Two of Toscotec’s AHEAD-2.0M tissue machines started up at Vinda Personal Care (Guangdong) in Yangjiang, Guangdong, PRC. They will increase the group’s annual production by over 60,000 tons. With these start-ups, Vinda kicked off production at its new Yangjiang mill, strategically located by Yangjiang Port in south-west Guangdong.

Toscotec’s AHEAD-2.0M lines feature a second generation TT SYD-18FT of 5,486 mm diameter and state-of-the-art energy saving technology included in the profitable TT DOES package (Drying Optimization for Energy Savings). The two tissue machines started up on the same day at the same time, proving the high degree of proficiency of the start-up teams.

Throughout six years of close collaboration, Toscotec and Vinda have honed their synergy and consolidated their partnership. Toscotec’s Customer Care and Project Manager Stefano Raffaelli said, “Our teams have reached a very high efficiency of cooperation. Together we have optimized the project timing, during both installation and commissioning. We cut down the duration of tests at the mill, thanks to the thorough checks we perform during pre-assembly at our factory, as an integral part of our quality guarantee”.

Vinda International’s Project Development Center Director, Mr. Liang Weixiong commented, “After three months of intensive work on site, it is a great satisfaction to see these start-ups hit the targets of the scheduled date and time. It is indeed the result of very careful preparation on all the machine’s functions”.

Stefano Raffaelli added, “For all our Vinda’s machines we implemented an efficient use of steam and condensate with different levels of energy recovery. This carefully balanced system ensures the lowest possible energy consumptions. The dedication and competence of the Vinda and Toscotec teams bring out the best of our technology. We achieved good results in terms of energy usage, as well as production increase with speed-ups and optimizations, all of which exceed the original objectives of the projects”.

Toscotec’s tissue lines are currently running at six of Vinda’s production bases across China, in Shandong, Hubei, Sichuan, Zhejiang and Guangdong.

In the coming months, Vinda will fire up another four Toscotec’s lines at its new paper mill in Xiaogan, Hubei province.

Toscotec’s TTSteelDryers are going to land in Canada. Cascades Packaging selected Toscotec to supply a dryer section rebuild at Kingsey Falls Mill.

Cascades Packaging entrusted Toscotec with a major rebuild of the dryer section of PM1 at Kingsey Falls mill, Canada. In view of the challenging targets of the project, Cascades decided that Toscotec’s technology was the right match for this rebuild, thanks to the flexibility and high level of customization guaranteed by the Italian supplier with regards to the seamless integration between the existing equipment and the new tailor-made solution.

Toscotec’s rebuild will achieve an 8% production increase. The Italian supplier will accomplish this substantial upgrade without increasing the overall length of the dryer section and without increasing the actual width of the dryers’ frame in cross direction. Toscotec’s TTSteelDryer allows better performances in terms of specific evaporation rate, thanks to its reduced shell thickness. Due to its shorter taper length, TT SteelDryer dries a wider sheet with the same space requirements of a traditional dryer section.

The scope of supply includes a number of TTSteelDryers, specifically designed for an operating steam pressure of 14 barg, as well as doctors, wire tensioning system, guiding and sheet stabilizing components. Toscotec’s service specialists will also provide supervision, commissioning and start-up assistance.

With this new contract, Toscotec strengthens its reputation as a top P&B machinery supplier on technically demanding markets such as North America. In particular, through its proven ability to supply all-round tailor-made solutions based on the specific features of the existing equipment and to deliver significant upgrades, over the years Toscotec gained the trust of major papermaking producers across the globe.

Delivery is forecast within the end of August 2018.

About the Cascades Group

Established in 1964, Cascades produces, converts and markets packaging and tissue products that are composed mainly of recycled fibers. The Company employs 11,000 employees, who work in more than 90 production units located in North America and Europe. With its management philosophy, half a century of experience in recycling, and continuous efforts in research and development as driving forces, Cascades continues to deliver the innovative products that customers have come to rely on.

Toscotec boosts its green performance through sustainable operations.

Toscotec has successfully renewed its ISO 14001 certificate and EMAS (Eco-Management and Audit Scheme) registration for the twelfth consecutive year since 2006. It thereby confirms its long-standing commitment to eco-sustainability, starting from its own environmental performance.

In 2005, Toscotec began procedures to evaluate its internal processes according to the strictest international standards of environmental protection. This entailed undergoing an articulate and audited procedure, which led to the the draw up of an environmental management system and a three-year plan. Specifically for EMAS, the Italian supplier also issues an annual report, examined by private and public bodies, including external auditors and EMAS national Competent Body ISPRA.

As a result, back in 2006, Toscotec became the first Italian supplier of tissue and paper machinery to obtain both the ISO 14001 and the EMAS registration and to this day, it remains the only one in Italy.

Toscotec strives to step up the eco-efficiency of its operations on an annual basis. In this view, EMAS is a guarantee vis-à-vis the community and the market at large, as it ensures a comprehensive set of corporate behaviours with environmental impact is kept under serious scrutiny.

Andrea Marzaro, Toscotec’s Operations Director (COO), affirmed, “Toscotec is working towards a continued and tangible improvement of its environmental performance, on a voluntary basis. Full compliance with Italian laws and regulations is the minimum prerequisite for us. We are determined to go the extra mile, pursue the highest environment standards and achieve excellence. Eco-sustainability and environmental protection are our core values and as such inspire our operations. Energy reduction, in its widest sense, is a big part of it”.

In recent years, Toscotec has partly redesigned its layout to become a fully integrated and compact production base, thereby optimizing its manufacturing efficiency. Inspired by lean production, it streamlined its logistic operations and achieved a concrete reduction of power consumption, due to the rationalization of handling and transportation processes.

Toscotec’s headquarters currently include eight workshops, four of which dedicated to the pre-assembly of tissue and paper & board lines. Pre-assembly is one of the cornerstones of Toscotec’s quality guarantee. It aims to reduce the time, the energy and the costs of the erection at the mill and therefore achieve the performance guarantees in a shorter period.

Andrea Marzaro also pointed out “With respect to renewable energy, since 2011 we have been generating electric power from solar energy. In 2011, we implemented the first installation of solar panels on the roofs, covering an area of approximately 1,250 m2 and generating up to 190 kWh electricity, which we give back to the grid. Phase two was carried out in 2012, across 600 m2, with an output of 100 kWh. Phase three is currently underway”.

Toscotec is committed to protecting the environment at local level through its operations, and globally through the design and manufacture of its cutting-edge technology. The Italian manufacturer manages both direct environmental aspects - pertaining to its own operations, like waste, emissions, use of raw materials, energy and water resources, etc. - and indirect aspects.

With respect to its indirect environmental aspects, Toscotec’s Technical Director, Paolo Raffaelli pointed out, “through our advanced design and manufacturing process, we have achieved a significant reduction of the environmental impact generated by our machinery and process, confirmed by field data and positive customer feedback. Our engineering approach aims to enable paper mills to improve their overall performance, by reducing the need of fresh water, electricity and thermal energy, and minimizing their atmospheric emissions, including noise”.

From TT SYD and TT SteelDryers, to Energy Saving tissue lines, to TT SAF (Short Approach Flow) and TT DOES (Drying Optimization for Energy Saving), Toscotec is the leading supplier of technology specifically designed for energy savings and with view to this, it is extensively investing in R&D and innovation.