Displaying items by tag: Toscotec

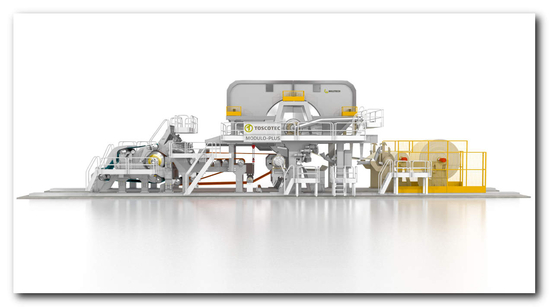

The parternship between Toscotec and EuroVast continues: a new MODULO-PLUS will be supplied for Cartiera della Basilica at Botticino’s plant.

The Italian company EuroVast has chosen Toscotec again to expand the capacity of its Cartiera della Basilica at Botticino’s plant.

The new machine, a MODULO-PLUS crescent former with single press configuration, TT SYD-3200MM and TT MilltechHood, is the perfect solution to meet Eurovast’s need: high quality tissue product, attention to energy saving and eco-sustainability were determining factors in choosing advanced Toscotec’s technology for this project .

The new TM with a maximum production capacity up to 30,000 tonnes/year and a paper trim width of 2740 mm will replace the existing suction breast roll machine and will be started up in the last quarter of 2017.

Engineering services, installation supervision, commissioning and start-up are all included in Toscotec’s scope of supply.

“Technological innovation begins purchasing new state-of-the-art production lines, involving not only an increase of production but above all achieving higher quality products to better meet our consumer needs. After almost 25 years of experience in the private label sector we are ready to satisfy every customer request, always focusing on the promotion of the product and in the development of new solutions.” said Vincenzo Romano, owner of Eurovast SpA.

The new tissue machine will increase the production of the four existing tissue plants: Botticino - LU, Bagni di Lucca - LU (that already houses a Toscotec MODULO-PLUS), Fabbriche di Vergemoli - LU and Lanciole - PT and the converting facilities of Toringo - LU and Socciglia - LU. Currently the production capacity of EuroVast Group is over 110.000 tons/year.

About Toscotec S.p.A.

Toscotec is a turnkey projects supplier to the global paper industry. Since 1948, the company offers complete production lines, plant retrofits, turnkey projects and individual machineries for the tissue, paper and board. Toscotec serves all the leading paper producers with customized solutions, leveraging on the experience gained in more than 60 years of activities.

For more info: www.toscotec.com

Toscotec to rebuild Cartiera Olona’s dryer section in Gorla Minore, Varese (Italy).

Toscotec has been awarded a contract to deliver a dryer section rebuilding of Cartiera Olona S.R.L. paper machine in Varese, Italy. The start-up of the rebuilt machine is scheduled for the second quarter of 2017.

Cartiera Olona was founded in the 1960’ in the Olona River Valley, Varese, covering an area of approximately 20.000 square meters. Currently the paper mill is equipped with a continuous production line for grey coreboard. The annual production is of 50,000 tons of paper suitable for the manufacturing of spiral and parallel wound cores, edge protectors, textile cones and honey comb.

The flexibility and intense activity of research and development enable Cartiera Olona srl to supply products in different qualities to meet customer requirements. Commitment to new technology has allowed the company , for half a century, to serve Italian, European, Middle Eastern and Nord African customers resulting in long lasting partnerships.

According to its philosophy the Company has decided to choose Toscotec for its dryer section rebuild on the paper machine. The purpose of the rebuilding is to implement machine efficiency, reliability and safety in operations. Toscotec’s delivery includes 25 new TT SteelDryers in place of casted iron dryers, that will allow the paper mill to increase its drying capacity, production and the width of the paper produced. The existing mechanical drive will be replaced with a new silent drive system. Tail threading will be ropeless from the press section through the new dryer section up to the pope reel.

This new project consolidates Toscotec capabilities to provide, not only a wide range of new machinery but also complex rebuild projects based on turn-key concept.

For further information about the product, click here TT SteelDryer .

Two new Toscotec’s tissue machines delivered to Vinda Paper (Zhejiang) Co., Ltd

In December 2016, the Italian supplier Toscotec S.p.A. has delivered two tissue machines, TM 3 and 4, to Vinda Paper (Zhejiang) to be installed at its Longyou mill. The machines are scheduled to begin installation in the spring and complete start-up in mid-2017.

Vinda Zhejiang mill, catering for east China area market with Shanghai in the proximity of which is strategically located, has registered a sustained growth, since the first two Toscotec supplied tissue machines, TM 1 and 2, were fired up in the last quarter of 2014.

Building on the outstanding results of the previous machines, Vinda has decided to invest again in Toscotec’s technology in Zhejiang province and in the second half of 2016 has sealed the new orders with the Italian supplier. With these two new machines, TM 3 and 4, Vinda Zhejiang mill is expected to achieve a total production capacity of 210,000 tons/year.

Following start-up in 2016 of other three Toscotec supplied machines in Guangdong and Shandong provinces, with a total production increase of 90,000 tons/year, the Vinda Group continues uninterrupted its strategic growth in a period of slowdown for the Chinese market. The new tissue machines delivered to Vinda Zhejiang will bring a further increase of 60,000 tons/year.

In line with the long-established and fruitful cooperation between Toscotec and Vinda, Vinda Zhejiang’s TM3 and TM4 also present superior technological advantages, benefiting from a wide-ranging energy saving concept, the TT DOES solution (Drying Optimization for Energy Saving), as well as delivering premium quality tissue.

Toscotec STEEL YANKEE DRYER TT SYD-22FT: the biggest ever done is on its way.

On 15th December 2016, Toscotec shipped the first two TT SYD-22FT of 2° generation (diameter 6705 mm) from the port of Marina di Carrara, Tuscany.

The first two Steel Yankee Dryers of the largest diameter ever built have left the dockand this is further proof of Toscotec's leadership in the design and manufacturing of the main component of the tissue drying section. The TT SYD-22FT is at the heart of Toscotec PRODERGY tissue machine, which is equipped with a Steam Hood to achieve the maximum operating speed of 2000 mpm. This extraordinary achievement is the result of Toscotec’s investment strategy, aimed to enhance its strength in the tissue and paper industry with the opening of a new technology center dedicated to the complete production cycle of TT SYDs.

Toscotec - rebuilt tissue machine started-up at Lucart Laval sur Vologne mill in France.

After a comprehensive rebuild supplied by Toscotec the rebuilt PM10 at Lucart Laval sur Vologne mill in France has been successfully started. The rebuild will boost the machine speed from the current 1300 mpm to 1600 mpm for the production of high-quality tissue from virgin or recycled fibers.

Toscotec's turn-key supply included wire and felt section modifications, a new TT SYD-12FT, Yankee steam & condensate, and a TT MachineBrokePulper-MBP75. Complete engineering, erection, commissioning and start-up assistance were also included in the order.

The new TT SYD has replaced the existing cast iron one. The greater evaporation rate increases the production capacity and the Yankee deckle insulations allows an additional saving on steam consumption.

In 2010 Toscotec already supplied a TT SuctionPressRoll (diameter of 1045 mm).

Lucart decided to go ahead with Toscotec finding in the offered technology the right solution to its need of leader tissue producer.

“This investment is a strategic step to strengthen our presence in Central Europe and is part of our integrated strategy of reducing energy consumption in our paper making process” said Massimo Pasquini, Lucart Group CEO.

“We are happy to continue to support Lucart. Our technology is the right partner for its mission which sets continuous innovation, overall product quality, respect for the environment and total client orientation as fundamental values. The same which Toscotec is clearly inspired since its foundation.” said Marco Dalle Piagge, Sales Director of Toscotec S.p.A..

About Lucart

Lucart Group is Europe’s largest producer of thin MG paper for flexible packaging and is one of the top European manufacturers of paper, airlaid and tissue products. More than 60 years of experience have allowed Lucart to develop the necessary know-how and technology to create quality products that can satisfy customers' requirements.

The production capacity of Lucart Group is 300,000 tons/year with 10 paper machines and 55 converting lines. The consolidated turnover is around 400 million euro and the number of employees is around 1,300.

About Toscotec

Toscotec is a turnkey projects supplier to the global paper industry. Since 1948, the company offers complete production lines, plant retrofits, turnkey projects and individual machineries for the tissue, paper and board. Toscotec serves all the leading paper producers with customized solutions, leveraging on the experience gained in more than 60 years of activities.

For more info: www.toscotec.com

Toscotec to supply two MODULO-PLUS ES tissue machines to Hengan Group.

These MODULO-PLUS ES are the first two tissue machines supplied by Toscotec to Hengan Group. They have a production speed of 1,600 m/min and a net sheet width of 2.8 m. They are equipped with TT Headbox SLT full hydraulic single layer headbox, TT SuctionPressRoll-SPR1200 big diameter suction press roll, TT SYD-12FT 2°GENERATION steel yankee with optimized rib design, TT Milltech high efficiency natural gas heated hybrid hood, Steam and Condensate System. The scope of supply also includes complete control system and electrical plant (MSC,DCS and Drive system), as well as erection supervision, commissioning, start up assistance and training programs. Hengan Group has favored the advantages of Toscotec’s well known TT DOES (Drying Optimization for Energy Saving) solution at the dry end, as well as the latest design at wet end including headbox, which ensures the highest drying capacity at the lowest energy cost for the mill, and the high quality finished product. These two MODULO-PLUS ES machines are scheduled for start-up within 2017. With this Hengan order, Toscotec becomes the unique supplier in the market who is able to serve all the top four tissue players in China.

These MODULO-PLUS ES are the first two tissue machines supplied by Toscotec to Hengan Group. They have a production speed of 1,600 m/min and a net sheet width of 2.8 m. They are equipped with TT Headbox SLT full hydraulic single layer headbox, TT SuctionPressRoll-SPR1200 big diameter suction press roll, TT SYD-12FT 2°GENERATION steel yankee with optimized rib design, TT Milltech high efficiency natural gas heated hybrid hood, Steam and Condensate System. The scope of supply also includes complete control system and electrical plant (MSC,DCS and Drive system), as well as erection supervision, commissioning, start up assistance and training programs. Hengan Group has favored the advantages of Toscotec’s well known TT DOES (Drying Optimization for Energy Saving) solution at the dry end, as well as the latest design at wet end including headbox, which ensures the highest drying capacity at the lowest energy cost for the mill, and the high quality finished product. These two MODULO-PLUS ES machines are scheduled for start-up within 2017. With this Hengan order, Toscotec becomes the unique supplier in the market who is able to serve all the top four tissue players in China.

About Toscotec

Toscotec is a turnkey projects supplier to the global paper industry. Since 1948, Toscotec offers complete production lines, plant retrofits, turnkey projects and individual machineries. The Group serves all the leading paper producers with customized solutions, leveraging on the experience gained in more than 60 years of activities.

Toscotec to rebuild PM1 tissue machine at Correll Tissue, South Africa.

Toscotec has been awarded a contract to rebuild PM1 at Correll Tissue, in Durban, South Africa. The start-up of the rebuilt machine is scheduled for the second half of 2017.

Correll Tissue is the primary tissue paper manufacturing plant of Novus Holdings, one of the most technologically advanced print manufacturing operations in Africa. The plant, located in Phoenix Industrial Park, harnesses the potential of waste paper, produced by the extensive printing operations of the Group, to make domestic tissue paper. With the plant’s sufficient converting capacity, investment in recycling processes has been made which sees a large quantity of the plant’s water requirements being reprocessed.

Correll Tissue is the primary tissue paper manufacturing plant of Novus Holdings, one of the most technologically advanced print manufacturing operations in Africa. The plant, located in Phoenix Industrial Park, harnesses the potential of waste paper, produced by the extensive printing operations of the Group, to make domestic tissue paper. With the plant’s sufficient converting capacity, investment in recycling processes has been made which sees a large quantity of the plant’s water requirements being reprocessed.

The scope of supply will include a major rebuild of the existing fourdrinier tissue machine into a MODULO crescent former with a new TT Headbox-SLT. The delivery also includes a rebuilding of the existing approach flow system and the felt run, as well as the YD doctoring system.

Electrification and control system for the new parts, erection supervision, start-up assistance and training will complete the Toscotec’s package. The new machine parts will be designed for a future speed of 1000 mpm with a reel width of 2460 mm.

“Partnering with a credible supplier on this project is of key importance and we are confident in the service Toscotec provides. We look forward to achieving great results on the rebuild,” says Conrad Rademeyer, Group Executive: Coldset and Tissue at Novus Holdings.

Toscotec has previously supplied Correll Tissue with another key component: the TT SYD in 2006.

This new project consolidates Toscotec's capabilities to provide, not only a wide range of new machinery but also complex rebuild projects based on turn-key concept.

About Toscotec

Toscotec is a turnkey projects supplier to the global paper industry. Since 1948, Toscotec offers complete production lines, plant retrofits, turnkey projects and individual machineries. The Group serves all the leading paper producers with customized solutions, leveraging on the experience gained in more than 60 years of activities.

For more info: www.toscotec.com

Twinsaver Group is set to become the largest tissue manufacturer in Sub-Saharan Africa

Twinsaver Group is set to become the largest tissue manufacturer in Sub-Saharan Africa through the installation of a new Toscotec AHEAD-2.0S tissue production line.

Twinsaver Group, the major manufacturer of tissue products in South Africa, announced that they will proceed with a R500 million investment in the country's local manufacturing sector by investing in a state-of-the-art new plant at its Kliprivier operations site in Gauteng, South Africa. The line, supplied by Toscotec, will be started-up in the last quarter of 2017.

Twinsaver Group is mainly focused on a sustainable business and it is a branded organization with innovation and consumers’ needs in the center of the growth strategies. By investing in new capacity, Twinsaver has chosen Toscotec AHEAD tissue line to improve the production and keep the leadership in the market.

The company ground-breaking ceremony took place in Kliprivier manufacturing site on 7th October 2016 at the presence of the major country authorities.

The turn-key delivery for the new TM#5 will include a stock preparation system for virgin pulp, an AHEAD-2.0S tissue machine, tissue machine and plant auxiliaries, electrification & control systems. Full engineering, erection, erection supervision, training, start-up and commissioning complete Toscotec scope of supply.

The tissue machine will have a width of 2.75 m and will be designed for 2,000 mpm speed. The new line will produce, among the other grades, high-quality super-soft toilet tissue. The greenfield project will be focused on energy savings and low emission concepts with a great attention to the environment.

About Twinsaver

Twinsaver Group is the number 1 South African manufacturer, marketer and distributor of branded tissue products. The product range includes toilet tissue, facial tissues, roller towels, house and leisure and away from home products. Twinsaver Group head-office is located in Bryanston, South Africa, with manufacturing and converting facilities in Kliprivier, Pretoria, Durban and Cape Town.

About Toscotec

Toscotec is a turnkey projects supplier to the global paper industry. Since 1948, Toscotec offers complete production lines, plant retrofits, turnkey projects and individual machineries. The Group serves all the leading paper producers with customized solutions, leveraging on the experience gained in more than 60 years of activities.

Toscotec’s new technological facility for large-diameter Steel Yankee Dryers opens its doors.

Toscotec pursues its investment strategy in order to enhance its strength in the tissue and paper industry. Inspired by its trust in innovation and a custom-oriented spirit, the company - pioneer and world leader in the Steel Yankee Dryer market - opens the new facility dedicated to the complete production cycle of TT SYDs.

The architectural heart of the facility is the central hall that houses all the stages of the production line: 180m long, 40m wide overall and up to 18m high. From metalworking and precision mechanical processing to thermal treatment in a 10m x 10m oven, all the tests and stamps are made on site according to European (PED), American (ASME), Chinese (CSEI) and Japanese (JIS) regulations. The new center also houses technical and production offices, as well as a conference room and lounge for customers.

The facility is located in Massa, 50 km from Lucca, a location chosen for its easy seaport access for quick overseas shipments.

The new center marks a breakthrough in Steel Yankee Dryer manufacturing and has a clear aim: to increase efficiency and ensure the best product worldwide, allowing Toscotec to further enhance its leadership role in technological innovation.

Customer visits will be organized during MIAC 2016 . For more information, please write to: This email address is being protected from spambots. You need JavaScript enabled to view it.

Toscotec achieves a new record for Steel Yankee width in rebuilding project at ST Tissue.

Toscotec has been chosen to supply ST Tissue in Franklin, Virginia, with the widest Steel Yankee ever to be manufactured. ST Tissue F-5 machine will be converted to produce bathroom tissue and kitchen towel.

The market leader in Steel Yankee Technology, Toscotec will rebuild the dry-end section and redesign the F-5 machine to convert it to dry crepe tissue.

The current paper machine configuration, consisting in a forming section, nip-press section, dryers section and Reel drum, will be converted to dry crepe tissue machine keeping the existing fourdrinier and redesigning the nip-press section to felt run arrangement which includes new Toscotec dry end equipment. Toscotec scope of supply includes TT SuctionPressRoll-SPR1045, an under machine broke pulper TT MachineBrokePulper-MBP75, and a TT SYD-12FT x 257” face width (6530 mm), the widest Steel Yankee Dryer ever manufactured.

The TT SYD-12FT, second generation rib design, fits the customer needs thanks to the high drying capacity performance and energy saving concept which includes Toscotec’s Patented Head Insulation.

All the existing drying drums will be removed, and a new Toscotec tail feeding system will be provided and installed between the Toscotec Steel Yankee and the existing pope reel.

Erection supervision, commissioning and start up will be performed by Toscotec Service Team. The PM5 conversion is part of a plan of investments that ST tissue has decided to implement with the aim to follow the market's demand.

About ST Paper & ST Tissue

Founded in 2007 by Sharad Tak and his son Sahil Tak, ST Paper & ST Tissue operate in Oconto Falls, WI and Isle of Wight, VA, respectively. In 2012 the Tak's purchased a portion of a shuttered paper mill in Isle of Wight, VA from International Paper and transformed it into a tissue mill by 2013. In the process, ST Tissue helped revitalized the surrounding communities by bringing back almost 90 direct jobs and hundreds more indirect jobs