The robot AGV has knocked on the door of the warehouse, and not as a passing guest, but as a new and welcome tenant. Automated Guided Vehicles - self-driving vehicles that perform handling tasks - represent a groundbreaking innovation for the world of intralogistics.

The innovation forms part of the wider one of Industry 4.0, which consists of connectivity and the Internet of Things, temperature, presence and movement sensors, RFID readers, and software that collects and analyses data to improve processes and perform predictive maintenance. These technologies are transforming production, but also other aspects of the supply chain.

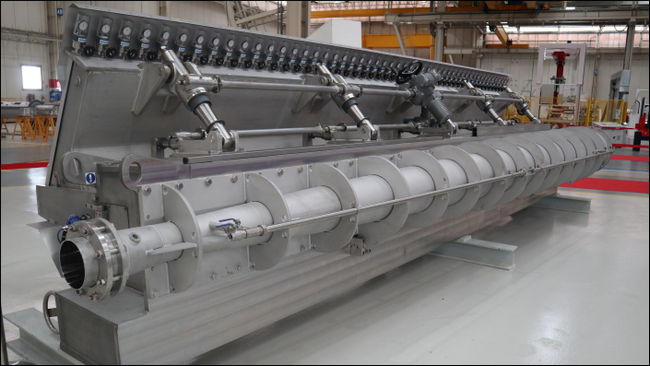

There are various types of AGVs suitable for handling different quantities and types of goods, all of which share some abilities that translate into advantages.

Autonomy guaranteed by software and sensors

The ability to move independently (thanks to a range of technologies: electrical, optical, magnetic, GPS, etc.) makes the presence of a driver superfluous. Vehicles equipped with software can be programmed to perform precise operations, while cameras and sensors allow machines to perceive the surrounding environment.

The strength of machines

In intralogistics, as in many other fields (such as construction), the strength of machines far exceeds that of humans. The weight-bearing capacity of robot AGVs can vary greatly, but is in all cases superior to that of a team of people and often also to that of the classic forklift truck. The most powerful models can handle loads weighing several tons.

Constant energy

Lithium batteries, which can be charged quickly, increase the productivity of AGVs and reduce downtime. It can be said, then, that the level of performance of a machine does not improve or suffer according to physical condition, tiredness, hunger or commitment, but remains constant.

Safety for workers and goods

Intrinsically safe design, bumpers, brakes, and sensors that detect the presence of obstacles all help to reduce the risk of accidents (collisions with other vehicles or people, falling of goods, etc.).

Precision without distraction

Mechanical arms designed according to the goods to be handled (bales of raw material, pallets, paper rolls, etc.) and sensors allow for precise and repeatable movements, not subject to variability or human error.

The speed of a tireless robot

It is certainly easier for a vehicle to travel long distances, from one warehouse to another or between very large warehouse departments, or to shuttle between the picking area and the logistics delivery area. The performance of a robot AGV does not depend on subjective factors, on tiredness, or on the bulk of the shifted goods.

Benefits of a flexible fleet

If a company wishes to expand its production department or warehouse, it can increase the fleet of Automated Guided Vehicles in a gradual and flexible manner without risk of interference or the need to train new personnel.

Taken individually and of course as a whole, these features demonstrate why robot AGVs are a powerful tool in terms of productivity, efficiency and savings. A single self-driving vehicle can do the work of one or more people in less time. Programming makes it possible to precisely define routes and actions for the robot, but the advantages of AGVs are maximised in the case of use for repetitive processes in the warehouse and/or on a large scale.

The future of human-robot collaboration

Will we be saying goodbye to workers in the warehouse, then? Not exactly. Robots can improve and transform intralogistics processes, as well as cost and productivity models. But they don't have to be seen as earth-shattering. Their technology is scalable: you can start with one or two, and then increase the fleet when you best see fit.

Moreover, since AGVs are essentially "workers", it is them that have to adapt to existing workflows, and not the other way around. Rather than disappear, warehouse staff will be able to devote themselves to activities of greater added value: supervision, management, planning, maintenance and shipment control (thereby increasing the precision of operations and the correctness of deliveries).

Relieved of heavy work, the staff can dedicate more time and energy to tasks of responsibility. It is therefore true that there will be "less human intervention", but not from a purely numerical point of view: the more the warehouse is automated and managed by software, the more its processes interact without the need for a person to solve problems, perform maintenance, move objects or assign tasks to colleagues. Human intervention is reduced because the problems are reduced.

Industry 4.0 therefore allows robots and people to coexist by sharing tasks and responsibilities. But there is no doubt, in any case, that a 4.0 warehouse requires fewer new staff, since if the load increases it is possible to assign more hours of work to an AGV or add to the fleet.

There is a faster return on investment in machines due to cutting of personnel costs, not to mention better productivity and efficiency. In short, AGVs must not be seen as something of which to be afraid: they can be used in warehouses without causing confusion or threatening the existing dynamics, and indeed with the promise of numerous benefits.

In this article we focused on one aspect - reduced human intervention - but we will also talk about the other advantages in our eBook "Forklifts VS AGV systems: what is best for the warehouse?". Download it now for free!