Displaying items by tag: james cropper paper

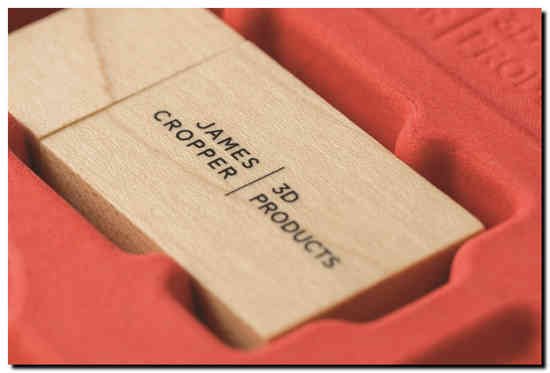

James Cropper 3d products unveils new generation of sustainable packaging

James Cropper 3D Products is poised to revolutionize the sustainable packaging sector with the launch of COLOURFORM™, a renewable, recyclable and coloured moulded fibre packaging product that helps brands stand out sustainably.

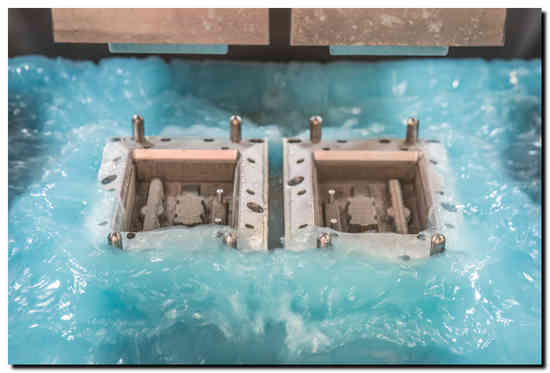

Made from 100 per cent renewable, natural wood fibres from well-managed forests and high-quality recycled content from James Cropper’s own world-class recycling plant, COLOURFORM™ acts as a sustainable alternative to plastic and other packaging materials and aims to help brands reduce their carbon footprint.

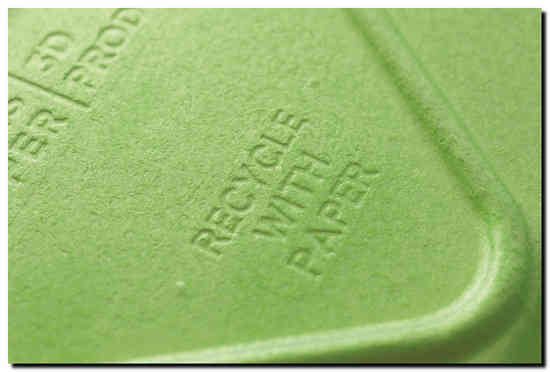

COLOURFORM™ is easily recycled with household paper – and the precision embossing enables clear information to help consumers recycle appropriately. However, even if the customer chooses not to recycle and the product ends up in a landfill, it is naturally biodegradable and therefore leaves no trace whatsoever.

Click on the picture below to see more

Benefitting from over 170 years of world-leading innovation and expertise in coloured paper and fibre products, every product is designed and made specifically to customer requirements and can be manufactured to match any colour with guaranteed consistency and a quality, tactile finish.

Matthew Miller, business director at James Cropper 3D Products, said: “Sustainability is higher on the agenda of businesses than ever before, with consumer brands, in particular, looking to tackle the landfill crisis by sourcing more environmentally responsible ways to package their products. With COLOURFORM™, we’re allowing such companies to boost their ‘green’ credentials while helping end consumers to recycle easily – a huge milestone for packaging.”

James Cropper 3D Products works with world-class brands who are leading the way to a sustainable future with COLOURFORM™. Typical applications include box inserts to support, display and protect products, outer packaging, and packaging components.

Matthew added: “Historically, moulded fibre packaging has been rather prosaic and only available in a limited number of colours and textures. However, with our bespoke, design-engineered approach and exact colour matching capabilities, we can offer brands unrivaled quality, appeal, and design, which enables them to enhance their brand identity while reducing their environmental impact.

“Brands really do now have all the creative freedom they need to stand out sustainably.”

For more information about COLOURFORM™, please visit www.colourformpackaging.com

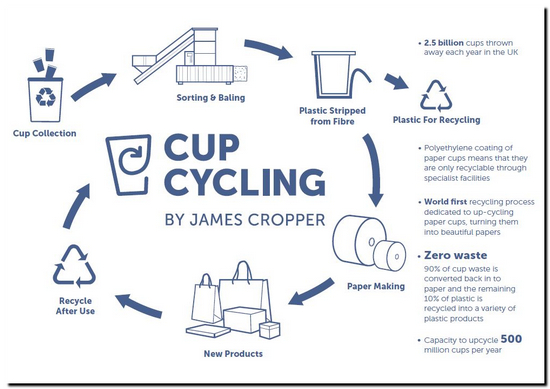

James Cropper launches cupcycling™ technology

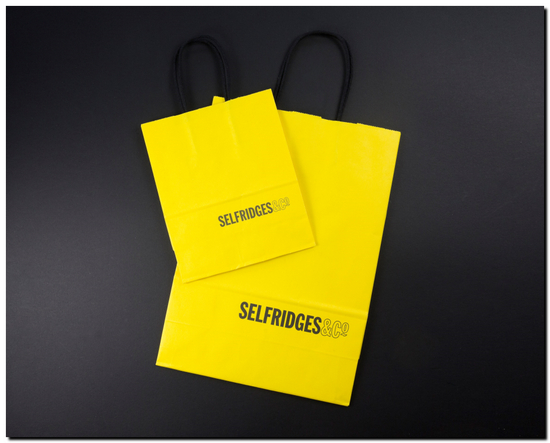

Selfridges Go Full Circle in World First for Recycling

James Cropper is to reprocess disposable coffee cups collected by environmental solutions provider Veolia from Selfridges’ Oxford Street headquarters and stores, with the resulting paper being used to create the retailer’s iconic yellow shopping bags in a completely unique closed-loop recycling solution.

Once used, disposable cups from the food hall and offices at the department store will be ‘tipped, flipped and stacked’ – a process to ensure any remaining liquid is drained and the lid, sleeve and cup are separated. Veolia then undertakes a further separation process to guarantee all rogue items have been removed. The cups are checked for quality, then baled and delivered to paper manufacturer James Cropper for reprocessing at its innovative CupCycling™ plant.

The disposable cups will be upcycled into paper that will then be converted into the yellow shopping bags, with the final product containing 20 percent cup fibre, meaning one large bag will contain the equivalent of one 8oz cup. The remaining paper fibre will continue to be PEFC certified. The bags will display the CupCycling™ logo, verifying that the waste fibre has been processed through James Cropper’s unique facility, and after use will be able to be recycled in the standard paper waste stream.

Click picture above to see more

It is estimated that 2.5 billion paper cups are used in the UK each year. Until recently, these were unable to be recycled due to their polyethylene lining; however, James Cropper’s facility, which was opened by HM the Queen in 2013, possesses the technology to separate the two components. The paper fibre is rescued and turned into luxury papers and the polyethylene is recycled into products such as plastic tubing and cable wraps.

Chris Brant, director of retail projects and FM at Selfridges, said: “As part of our ‘Buying Better, Inspiring Change’ approach, we are constantly looking for new ways to make our business more efficient. One way we’re doing this is by reducing the amount of single use plastics we use. In 2015, as part of our Project Ocean campaign with the Zoological Society of London, we removed plastic carrier bags, microbeads from our beauty hall and single-use plastic cups and bottles from our stores and back of house. As we are already at zero waste to landfill, we are looking at further innovative ways to capture and treat recyclable materials.

“With our partners James Cropper and Veolia, we can take coffee cups, a waste product of ours, and transform them into our yellow kraft bags, thereby closing the loop on that particular waste stream. Not only that, but the bags can still be recycled for years to come. We’re proud to be the first retailer to upcycle our cups in this way. Our customers are becoming ever more aware of global waste issues and I think they will appreciate the story behind the bag.”

James Cropper will be showcasing its CupCycling™ solution at the Luxury Packaging Innovations event taking place in London in September, where its global packaging director, Susan Wilson, will take part in a panel discussion on ‘Packaging as Part of the Brand Story’. The discussion will be led by Vincent Villeger, a luxury packaging creative consultant and former director of packaging design at Burberry, with Susan being joined on stage by Abby Chicken, sustainability manager at Selfridges, for the Luxury Forum.

Steve Adams, managing director of James Cropper, said: “The fibre used to create paper cups is very high quality as only ‘virgin’ pulp is used to satisfy food contact requirements. Seeing this go to waste on such a huge scale is what inspired us to develop the technology to separate the two components. What we’re left with is material that’s virtually indistinguishable from fresh fibre and can therefore be used to create paper products of the highest quality, such as Selfridges’ bags.

“Our plant has so far recycled more than six million used cups – a figure that with partnerships like those with Selfridges, Veolia and others is expected to continue to rise. And we’re more than prepared to cope with such a boom, with the plant currently having the capacity to recycle 500 million paper cups each year. With CupCycling™, we’re enabling brands to work with us towards a world that’s less wasteful and become part of a movement that has the potential to revolutionise paper cup recycling forever.”

Gavin Graveson, chief operating officer of public and commercial at Veolia UK, said: “This is a great example to show how coffee cups are being reused as part of the circular economy. I’d like to take this opportunity to further encourage a mass collaboration between designers, manufacturers, vendors and consumers as we all have a part to play in making all of our packaging more environmentally friendly and ensuring our resources are kept in the loop for longer.”

James Cropper in bloom at Turkish tulips exhibition

British master papermaker James Cropper has supplied paper for the Turkish Tulips exhibition at The Bowes museum, County Durham. The exhibition, which opened on the 29 July and will run until the 5 November, is showcasing a colourful origami tulip display made exclusively from James Cropper’s Vanguard range.

James Cropper has attended the exhibition on 24 August, taking along some handmade paper tulips, which were added to the museum’s display. The trail of tulips runs alongside over 30 contemporary artists’ work including Damien Hirst, Cornelia Parker, Gavin Turk and Sir Peter Blake.

Click the picture above to see more

Vanguard, James Cropper’s most popular coloured paper range, lends itself well to an array of custom-made paper products due to its smooth uncoated surface and extensive collection of pastel and intense colours. The tulip-inspired shades for the display include the likes of Gold, Tangerine, Cherry, Raspberry, Jade and Purple.

The floral treasure trail at the exhibition winds through the grand halls of the Bowes Museum, delving into Britain’s historical relationship with Europe and the Middle East. Curated by Gavin Turk, Turkish Tulips is staged as part of the museum’s 125th anniversary celebrations and combines contemporary art with antique artefacts. Thought-provoking artworks are hidden among the collection, all of which illustrate the iconic flower.

Geoff Leech, art and framing director at James Cropper Paper, said: “Culture and heritage play a huge role in the Turkish Tulips exhibition and, with these being key values of our own, we’re honoured to play a part in its history. The display is incredibly colourful and we’re thrilled that the Bowes museum called upon our expertise to complete the exhibition.”

Based in the Lake District, James Cropper has long been associated with the world of art, providing high-quality British papers for many leading art galleries, designers, conservationists, artists, writers and poets. Currently in production is the new James Cropper Art Selector, which showcases many of the artist papers made at the historic mill.

Geoff added: “The James Cropper Art Selector is an exciting project for us as we celebrate all of the specialty artists’ papers created at our mill. Like the works of art they support, our papers truly stand the test of time and it’s great to see them brought together in this way.”

James Cropper will be showcasing its Art Selector at Packaging Innovations, which takes place on 13 and 14 September at Olympia, London. The company will be at stand H14.

For more information, visit www.jamescropper.com/

James Cropper brings home a third award for sustainability initiative

British master papermaker James Cropper has added another trophy to its award cabinet following its win of the prestigious Green Award at Luxe Pack New York.

The company won the award at the exhibition for its support of the Burneside Community Energy (BCE) project, a social initiative that saw the installation of a 250KW Solar PV Array on the roof of James Cropper’s mill in the village of Burneside in the Lake District.

The multi-award winning project, which launched in December 2015, generates clean, green electricity, and enables residents of the village – many of whom are also employees – to benefit from investment in renewable energy.

James Cropper recently won in the same category for this project at Luxe Pack’s Shanghai edition. This time, James Cropper was selected as a winner by an esteemed panel of judges comprising senior packaging consultants from brands including Elizabeth Arden, Bacardi and Estee Lauder, as well as the editor-in-chief of Beauty Packaging.

Susan Wilson, group packaging director at James Cropper, said: “We’re absolutely thrilled to have picked up the Green Award again for a project so close to our hearts. The installation generates 200,000 kWh of renewable electricity per year, which is enough to offset the energy requirements of our specialist laminating and technical coating facility, or the equivalent of powering 50 UK homes. It’s also been calculated that the initiative will reduce our carbon dioxide emissions by 1.91 million kilograms over the next two decades.”

As well as the positive impact on the environment, the BCE scheme delivers a five per cent annual dividend to investors, and an additional £50,000 for a community fund to deliver projects of social and environmental benefit to Burneside over a 20-year period. The scheme has been widely praised as a sustainable, eco-friendly solution that benefits the local parish and demonstrates James Cropper’s long-term commitment to supporting sustainable initiatives in the community.

Luxe Pack is the premier exhibition for creative and innovative packaging and this year marked its 15th show in New York, which took place on 10 and 11 May at Pier 92 in the city. The event played host to over 250 leading global packaging manufacturers and suppliers within the beauty, fragrance, wine and spirit, and gourmet food markets.

Susan added: “We’ve been loyal exhibitors at Luxe Pack for many years now and have witnessed more and more brands and suppliers plough investment into sustainability initiatives as green credentials become increasingly important to consumers. At James Cropper, we’ve always strived to innovate in this arena, and to be recognised within the packaging industry for this commitment means a great deal indeed.”

James Cropper was also recently highly commended at Insider Media’s 2017 Made in the North West Awards in the Green / Sustainable Manufacturer category.

For more information about James Cropper, visit www.jamescropper.com.

About James Cropper

James Cropper are prestige paper innovators based in the English Lake District, supplying distinct, custom-made paper products to many of the world’s leading luxury brands, art galleries and designers. Celebrating 170 years of high quality paper production in 2015, the business has been carefully stewarded and nurtured by six generations of the Cropper family and is renowned globally for individual expertise in colour, dedicated responses to the most challenging custom projects and award-winning commitment to the highest standards of sustainability.

A network of global sales and production facilities from Europe to the Far East provides local customer service to international clients, while its historic base in the village of Burneside retains nearly two centuries worth of papermaking expertise.

About Technical Fibre Products (TFP)

As well as paper products, James Cropper plc also incorporates Technical Fibre Products (TFP), manufacturers of non-woven materials from carbon, glass and polymer fibres, which play a key part in production of composites in the automotive, energy and aerospace sectors.

About James Cropper 3D Products

With James Cropper 3D Products, James Cropper plc has created the next generation of sustainable moulded paper packaging. Available in a wide variety of colours and with a naturally tactile finish, the product has a clear focus on quality and is design-engineered to suit all packaging needs. Features to improve product value and packaging integrity, such as personal embossing, natural hinges and cut-outs, enhance brand impact. All packaging products are recyclable and made from 100 per cent renewable natural fibres.

For further information visit: www.jamescropper.com , www.jc3dp.com and www.tfpglobal.com.

James Cropper’s commitment to sustainability recognised with prestigious award

British master papermaker James Cropper has scooped this year’s Green Award at Luxe Pack Shanghai for its support of the Burneside Community Energy (BCE) project.

The project is a social initiative, which has seen the installation of a 250KW Solar PV Array on the roof of Cropper’s Burneside mill to generate clean, green electricity, and enables residents – many of whom are also employees – in the parish local to the business’ headquarters to benefit from investment in renewable energy.

The multi-award winning project, which launched in December 2015, has been praised as a sustainable eco-friendly solution, while James Cropper was commended for its commitment to green energy and the local community.

The installation generates 200,000 kWh of renewable electricity per annum – enough to offset the energy requirements of James Cropper’s specialist laminating and technical coating facility, or the equivalent of powering 50 UK homes.

Susan Wilson, group packaging director at James Cropper, presented the scheme to a panel of industry experts, including British sustainability advisor, Charlie Mathews and Damien Parenteau, vice president of purchasing and development from Chanel.

Susan said: “We’re thrilled that the Burneside Community Energy Scheme has been recognised by Luxe Pack. It’s just one of many green initiatives that we’re proud to be involved in. There is an enormous appetite for sustainability in the industry at the moment, from manufacturers like us to end clients and everyone in between. We’ve made a strong commitment to proactively innovate in this area, from ensuring our pulp supply is FSC® regulated to installing the a unique reclaimed fibre plant with the capability of recycling paper cups at our mill in 2013.”

As well as the positive impact on the environment, the scheme delivers a five per cent annual dividend to investors, and an additional £50,000 for a community fund to deliver projects of social and environmental benefit to Burneside over a 20-year period.

Julie Tomlinson, part of the James Cropper sustainability team, commented: “With BCE we set out to generate greener energy in a way that doesn’t compromise the special ecology or superb landscape of Burneside and Cumbria and the project also rewards the parish and its investors with ethical energy and financial benefits. It really is terrific to see that our efforts are paying off already. It’s estimated that the initiative will reduce our carbon dioxide emissions by 1.91 million kilograms over the next two decades.

“The scheme will create an invaluable amount of environmental and social benefit for the community, ranging from help and advice for those in fuel poverty and support for young people and the school, to provision of community services and conservation and wildlife enhancement. It’s helping to create a positive, sustainable legacy for future generations in Burneside, while reducing our dependency on fossil fuels.”

The scheme profits will be generated through the Government’s feed-in tariff and from the sale of electricity to James Cropper PLC, as part of the manufacturer’s long-term commitment to supporting the community of Burneside and reducing its carbon dioxide emissions.

Luxe Pack, which celebrated its 10-year anniversary this year, also acknowledged James Cropper as a loyal exhibitor since its inception at a special reception and award ceremony.

James Cropper has also recently been shortlisted for Insider Media’s Made in the Northwest Awards in its Green Manufacturer / Sustainable Manufacturer Award category.

For more information about James Cropper, visit www.jamescropper.com.

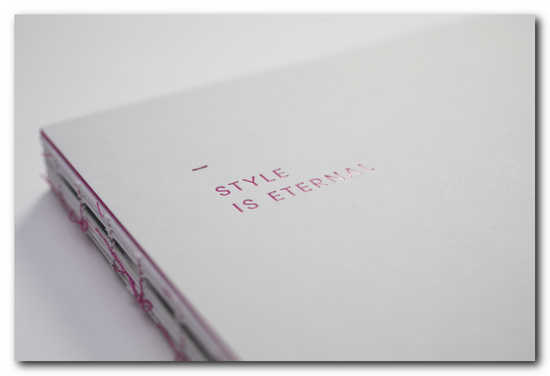

James Cropper brings tailor made to the big apple

British master papermaker James Cropper is ramping up its presence across the pond with the launch of its Tailor Made service at this year’s Luxe Pack New York exhibition.

Attendees at the event, which takes place on 10 and 11 May 2017, will be able to delve further into the company’s Tailor Made service, which has been launched to allow brands to develop unique, custom-made paper solutions for brand presentation and packaging.

Susan Wilson, group packaging director at James Cropper, said: “We’ve always focused on creating personalised solutions for brands but now, with Tailor Made, we’re taking our bespoke service to a new level – and we’re sure it will be well received in a city as stylish as New York. With a wealth of experience in the world of premium and luxury, we’re very aware of how important it is for luxury brands to stand out and express their individuality through their packaging, and we’re here to work closely with them to facilitate that.”

The Tailor Made service offers a wide range of bespoke solutions, with clients able to choose everything from the individual fibres used to make paper to the ways they’re engineered, coloured, embossed and converted. For example, beautiful shades of unusual and tactile paper finishes can be developed for a sophisticated impression.

Retailers looking to boost their environmental credentials are expected to be impressed with James Cropper’s policy of all fresh fibre being sourced from sustainably managed forests, as well as its use of ingredients such as coffee cup fibre or post-consumer waste.

James Cropper has been carefully stewarded and nurtured by six generations of the Cropper family from its historic home in the English Lake District, and is renowned globally for its expertise in colour, dedicated responses to the most challenging custom projects and award-winning commitment to the highest standards of sustainability.

Ivan Iannetta, packaging industry expert and USA sales manager at James Cropper, said: “The Tailor Made service allows clients to focus on their vision and let their imaginations run wild, enabling them to tell their story through paper and packaging. We bring these ideas to life, using the experience, tools and expertise we’ve developed over almost two centuries.

“Our rich papermaking know-how and capability, combined with an innovative approach and superior craftsmanship, mean that the creative possibilities of such a versatile product are virtually endless. The result is a truly custom-made and sustainable paper that perfectly complements and elevates a brand’s offering.

“James Cropper takes great pride in producing papers with a difference, unique to each brand. Combining our world-leading skills in colour-matching and post-production capabilities – such as embossing, laminating and coating – enables us to create papers for an extensive range of retail applications across presentation boxes, retail display, luxurious packaging and beautiful bags.”

Vincent Villeger, a creative consultant for the luxury packaging sector, said: “Uncoated, coloured papers provide an understated, warm and tactile feel, also allowing for maximum contrast against metallic foils. I consider them an essential component of brand consistency, and an integral part of the luxury packaging experience, which is why I try to use them whenever the project allows.

“Throughout my career, I have had the opportunity to develop many bespoke shades – a real treat for any designer – and in order to justify the decision to develop a bespoke paper, the results must be nothing short of perfectly accurate and consistent. James Cropper understands this and, thanks to the dedication of their teams and their collaborative approach, they have always been able to deliver to my high standards.”

To find out more about the ‘Tailor Made’ service, visit James Cropper at Stand B116.

About James Cropper

James Cropper are prestige paper innovators based in the English Lake District, supplying distinct, custom-made paper products to many of the world’s leading luxury brands, art galleries and designers. Celebrating 170 years of high quality paper production in 2015, the business has been carefully stewarded and nurtured by six generations of the Cropper family and is renowned globally for individual expertise in colour, dedicated responses to the most challenging custom projects and award-winning commitment to the highest standards of sustainability.

A network of global sales and production facilities from Europe to the Far East provides local customer service to international clients, while its historic base in the village of Burneside retains nearly two centuries worth of papermaking expertise.

About Technical Fibre Products (TFP)

As well as paper products, James Cropper plc also incorporates Technical Fibre Products (TFP), manufacturers of non-woven materials from carbon, glass and polymer fibres, which play a key part in production of composites in the automotive, energy and aerospace sectors.

About James Cropper 3D Products

With James Cropper 3D Products, James Cropper plc has created the next generation of sustainable moulded paper packaging. Available in a wide variety of colours and with a naturally tactile finish, the product has a clear focus on quality and is design-engineered to suit all packaging needs. Features to improve product value and packaging integrity, such as personal embossing, natural hinges and cut-outs, enhance brand impact. All packaging products are recyclable and made from 100 per cent renewable natural fibres.

For further information visit: www.jamescropper.com , www.jc3dp.com and www.tfpglobal.com.

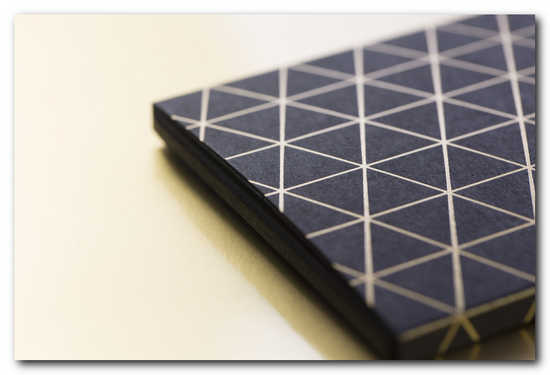

James Cropper expands offering in China ahead of luxepack

British master papermaker James Cropper has expanded its offering in China with the launch of a new paper, Genuine UK Black, which will be showcased at LuxePack Shanghai on 12 and 13 April 2017.

The non-carbon, deep black paper, which has been designed especially for the Chinese market, has a very high rub resistance and the colour is bleed-fast. It is also FSC certified, and with 40 per cent of its composition being post-consumer waste, makes it an environmentally conscious choice.

Genuine UK Black is the latest in a sequence of paper innovations by internationally renowned James Cropper, who have been perfecting the art of papermaking in their English Lake District location for six generations.

Maurice Tsang, regional manager for Asia at James Cropper, said: “With Genuine UK Black, we’ve harnessed technology, science and skill to create a unique black paper with a strong environmental pedigree. Matching dyes, pigments and fibres, we’ve created a paper that, being non-carbon, lends itself perfectly to creative work incorporating metallic foil printing.”

The new paper is suitable for a range of applications, including luxury goods, packaging, printing, advertising brochures and annual reports, and is available locally from the new James Cropper warehouse in Shenzen (Guangdong).

James Cropper has also launched to the Chinese market its existing Carvetian Suede range of papers, which mimics the luxurious look and feel of suede in paper form.

Maurice added: “We’re delighted to be bringing to market both a brand new product in Genuine UK Black and what’s already become a popular choice among luxury packaging designers, Carvetian Suede. We’ve been making exceptional quality papers at our mill in Great Britain for over 170 years and are excited to be growing our presence in China with these new launches that are serviced by our team in China – we can’t wait to see how they’re received.”

James Cropper will be showcasing these products – along with its first range of food contact-approved papers, Dolcelicious, and its Tailor Made service offering bespoke papers in customer-specified colours, weights, textures and finishes – at the creative packaging exhibition LuxePack Shanghai.

James Cropper will be at stand E12.

For more information about James Cropper, visit www.jamescropper.com. For more information about Genuine UK Black, contact This email address is being protected from spambots. You need JavaScript enabled to view it..

About James Cropper

James Cropper are prestige paper innovators based in the English Lake District, supplying distinct, custom-made paper products to many of the world’s leading luxury brands, art galleries and designers. Celebrating 170 years of high quality paper production in 2015, the business has been carefully stewarded and nurtured by six generations of the Cropper family and is renowned globally for individual expertise in colour, dedicated responses to the most challenging custom projects and award-winning commitment to the highest standards of sustainability.

A network of global sales and production facilities from Europe to the Far East provides local customer service to international clients, while its historic base in the village of Burneside retains nearly two centuries worth of papermaking expertise.

About Technical Fibre Products (TFP)

As well as paper products, James Cropper plc also incorporates Technical Fibre Products (TFP), manufacturers of non-woven materials from carbon, glass and polymer fibres, which play a key part in production of composites in the automotive, energy and aerospace sectors.

About James Cropper 3D Products

With James Cropper 3D Products, James Cropper plc has created the next generation of sustainable moulded paper packaging. Available in a wide variety of colours and with a naturally tactile finish, the product has a clear focus on quality and is design-engineered to suit all packaging needs. Features to improve product value and packaging integrity, such as personal embossing, natural hinges and cut-outs, enhance brand impact. All packaging products are recyclable and made from 100 per cent renewable natural fibres.

For further information visit: www.jamescropper.com , www.jc3dp.com and www.tfpglobal.com.

Lib Dem leader visits leading manufacturing firm

South Lakeland MP Tim Farron recently visited Cumbria-based manufacturing firm James Cropper PLC to hear about the latest developments at the company and discuss the challenges facing the industry.

Tim met with the CEO and group finance director of the company, and heard how James Cropper PLC continues to grow and develop, taking on more staff and expanding into new areas, in addition to their traditional paper business. Also on the agenda was the need for a British industrial strategy that supports the manufacturing industry, as well as the challenges that are faced post-Brexit.

Tim said: “It was fantastic to visit James Cropper once again and to hear about the exciting developments at the company, particularly as the firm expands into new markets. As the largest private sector employer in our area, the company’s success is good news for all of us.

“James Cropper is a shining example of the best of British manufacturing, complementing their traditional paper business with the latest technology and innovation, and creating skilled local jobs and apprenticeships. As a country, it is vital that we support businesses and develop the skill base required so that other firms can follow James Cropper’s example. I will also continue to push the government to ensure that any post-Brexit deal does not harm the ability of businesses like James Cropper to trade with the EU.”

Phil Wild, CEO at James Cropper, said: “The paper manufacturing industry has seen a lot of changes in recent years, so the need to innovate, develop and improve is more important than ever. Our people sit at the heart of these initiatives.

“Continued investment into research and development in technology, whether that’s in technology, equipment, product development or materials, is crucial for us to maintain and expand our foothold in the industry. We sell our products all over the world to sectors ranging from luxury goods to aerospace. Our customers demand information on the environmental impact and sustainability of our processes and on working practices.This is an increasingly important objective for businesses as they strive to reduce their impact on the environment. In the papermaking arm of the business, our unique coffee-cup reclaimed fibre plant has enabled us to become an unrivalled driving force in eco-friendly innovation in our sector. In our Technical Fibre Products (TFP) business, new products have been introduced to provide super lightweight solutions for aerospace composite bodies; and the newest division 3D Products (3DP), provides sustainable alternatives to plastic packaging using highly engineered, brightly coloured moulded fibres.”

Isabelle Maddock, finance director at James Cropper, adds: “The global market continues to be essential for growth and development, with about 50 per cent of our products being exported. Post-Brexit, there is some concern about how it will affect industry in the UK. Britain offers a huge pool of knowledge and skills supporting innovation, therefore we would strongly oppose the introduction of tariffs as they restrict trade and ultimately have a detrimental effect on innovation, which is driven by the reinvestment of profits. That said, our global business model has proven to be robust and the group is well placed to face the challenges of Brexit.”

About James Cropper

James Cropper are prestige paper innovators based in the English Lake District, supplying distinct, custom-made paper products to many of the world’s leading luxury brands, art galleries and designers. Celebrating 170 years of high quality paper production in 2015, the business has been carefully stewarded and nurtured by six generations of the Cropper family and is renowned globally for individual expertise in colour, dedicated responses to the most challenging custom projects and award-winning commitment to the highest standards of sustainability.

A network of global sales and production facilities from Europe to the Far East provides local customer service to international clients, while its historic base in the village of Burneside retains nearly two centuries worth of papermaking expertise.

About James Cropper 3D Products

James Cropper 3D Products answers a global demand for sustainable packaging with the next generation of moulded paper packaging. Available in a wide variety of colours and with a naturally tactile finish, the product is design-engineered and has a clear focus on quality. Features to improve product value and packaging integrity, such as personal embossing, natural hinges and cut-outs, enhance brand impact. 3D Products are made from 100 per cent renewable natural fibres and are recyclable with paper.

About Technical Fibre Products (TFP)

As well as paper products, James Cropper plc also incorporates Technical Fibre Products (TFP),manufacturers of non-woven materials from carbon, glass and polymer fibres, which play a key part in production of composites in the automotive, energy and aerospace sectors.

For further information visit: www.jamescropper.com www.jc3dp.com and www.tfpglobal.com.

James Cropper makes trio of appointments

British master papermaker James Cropper has made a number of appointments across senior roles within the company.

Steve Adams, who was appointed as managing director of the company’s paper business in September 2016, has now commenced his post.

Steve Adams, who was appointed as managing director of the company’s paper business in September 2016, has now commenced his post.

He brings with him more than 30 years’ experience and has a strong commercial and business leadership background. Formerly working for 3M across Europe, his roles included business director for display and graphics and, most recently, business director for electronics and energy.

Steve said: “I’m excited to join James Cropper at a time when the business is flourishing and looking to grow and develop in new areas. The company has a fantastic reputation in the paper manufacturing arena and I look forward to bringing my knowledge and skills to help it build and further cement its position.”

Alison Daniels has joined James Cropper as marketing director, and will oversee the marketing strategy of the paper manufacturing arm of the business. She joins the company after 15 years’ marketing experience with Bayer Crop Science UK.

Alison Daniels has joined James Cropper as marketing director, and will oversee the marketing strategy of the paper manufacturing arm of the business. She joins the company after 15 years’ marketing experience with Bayer Crop Science UK.

Completing the trio, Ivan Iannetta, a paper and packaging industry expert, has been appointed as sales manager for the east coast of the USA to provide local client support and promote the company’s offering in the region.

Phil Wild, CEO at James Cropper, said: “The paper manufacturing industry has seen a lot of changes in recent years, so the need to innovate, develop and improve is more important than ever. Our people sit at the heart of these initiatives.

“2017 is set to be another exciting year for James Cropper with the roll out of our latest paper range, Dolcelicious – a food contact approved paper – and our Tailor Made paper service across global markets.”

“We’re confident that our latest recruits bring with them the necessary skills and experience that will help us in our continued quest to be at the forefront of our industry, whether it’s technical development, enhanced marketing strategies or increased sales.”

For more information about James Cropper, visit www.jamescropper.com

James Cropper gears up for Paperworld

British master papermaker James Cropper is making the final preparations for its appearance at Paperworld 2017, with plans to promote a number of its products and services.

Some of the highlights showcased at the exhibition – which takes place from 28 to 31 January in Frankfurt – will be the company’s new Tailor Made service, its new range of food contact-approved papers and its Kendal Manilla collection.

Tailor Made was launched to allow brands to work with James Cropper to develop unique, custom-made paper solutions for brand presentation and packaging. The extensive variables available through the service range from the individual fibres used to make paper to the ways they’re engineered, coloured, embossed and converted.

Andy Smith, director of export sales at James Cropper, said: “We’ve always worked with brands to create personalised solutions for them but now, with Tailor Made, we’re taking this service to the next level.

“It’s absolutely vital for brands to stand out, and a lot of that comes down to expressing their individuality through the materials they use – whether that be the use of post-consumer waste in production to champion sustainability, or using unique shades of soft-touch papers to evoke sophistication.”

Meanwhile, Dolcelicious – a range of premium food contact-approved papers – has been developed to help food and drink brands elevate the packaging experience and is suitable for contact with dry, moist and fatty foodstuffs. The range is available in 11 eye-catching colours, including Lemon Drizzle, Liquorice, Silver Spoon and Kiwi Fizz.

Norbert Spiegel, sales manager for the DACH region, adds: “With the launch of the Dolcelicious collection, we have another string to our bow. We’re now able to widen our service to German brands in the food and drink industry, allowing them to benefit from the range’s diverse colours and textures – from subtle and natural to glamorous and bold.”

In addition, James Cropper will feature Kendal Manilla, the papermaker’s range of high-quality boards established as a benchmark for outstanding performance within the filing and stationery markets.

Norbert added: “Kendal Manilla is one of our core ranges of papers and has been a go-to product for business folders and files for many years. With its versatility and wide range of weights and colours, we’re looking forward to bringing this stationery stalwart to Paperworld.”

For more information about Dolcelicious or to request a sample, visit www.dolcelicious.com. For more information about Tailor Made, Kendal Manilla or the James Cropper brand, visit www.jamescropper.com.