Displaying items by tag: pesmel

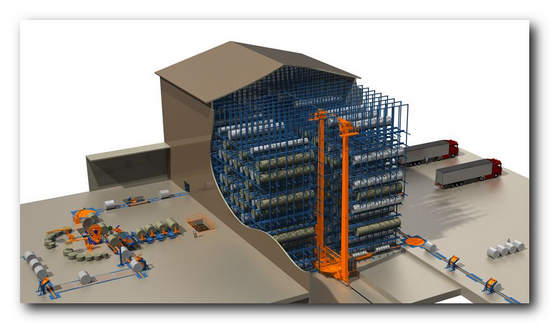

Automated Roll Warehouse (ARW) with large conveyor and wrapping system to Stora Enso

Stora Enso invests 70 MEUR in new polyethylene (PE) extrusion coating plant and an automated roll warehouse (ARW) at its Imatra mills in Finland. The Imatra complex, which comprises the Kaukopää and Tainionkoski mills, has a capacity of more than one million tons/yr of carton board and specialty packaging paper. With this investment Stora Enso aims to increase and meet increasing customer demand for food service board and liquid packaging board.

The full roll handling scope for this investment with the new automated warehouse was ordered from Pesmel, and it’s commissioning is expected to be completed early Q4/2017. The roll handling system is one of the biggest deliveries in Pesmel’s history requiring 80 man years work. ”The system is good example of our Material Flow How -concept, where the high bay warehouse synchronizes the production processes flexibly and efficiently. With packing and loading included, all the components of our concept will be delivered.” tells the vice president of paper division Mr. Kaj Fahllund from Pesmel.

TransRoll concept selected

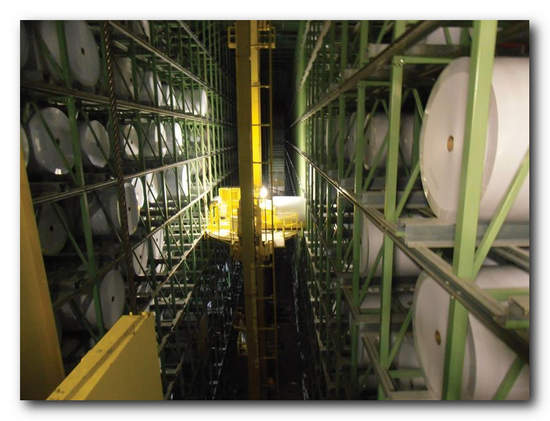

The heart of this new system layout is Pesmel’s TransRoll ARW concept, which is connected with 7 in-out connections at different floor levels between the mill production and converting lines. It has ~30,000 tons buffering capacity for intermediate rolls to be used at mill converting, and also for finished rolls to be shipped out to end customers.

This concepts storing volume can be expanded in the future, as well as the number of its connections. The whole footprint of this warehouse is only ~4500 m2 with high ~8 t/m2 effective storing density. And as true heart of mills material flow, it has whopping 900 t/h fully automated in-out handling and sorting capacity with two stacker cranes.

TransRoll ARW is equipped with full Pesmel WMS warehouse management system, which is connected to MIS (mill information system) to track the roll flow and to keep the real-time storage inventory for the converting and shipping operations.

Fully automated OptiWrap Multi Kraft wrapper

Pesmel’s roll handling scope includes along large connecting conveyor system also new high capacity kraft wrapping line, with robotized core plugging and head insertion. The handling capacity is set to 120 r/h, but this can be increased in the future 20 - 40%.

Automated truck loading eliminates the roll damages

With automated truck loading the unpacked rolls are transported from TransRoll warehouse to a coating mill situated one kilometer away. The rolls are loaded and unloaded fully automatically in horizontal position, which eliminates the possible roll end damages totally. Transferring the rolls unpacked generates remarkable savings to packing costs.

FlowCare to ensure efficiency and reliability

This delivery includes custom tailored Pesmel FlowCare portal. This digital IoT (Internet of things) interface collects, saves and analyzes information from the delivered system, and helps to foresee service needs and to eliminate mill’s bottlenecks with material flow. FlowCare portal gives access to e-shop, spare part, maintenance and document services, ticketing system and to 24/7 customer support.

Pesmel TransRoll ARW merits:

- Safety and quality

- Clamp handling eliminated in mills internal handling.

- Rack storages fire safety with inbuilt wet sprinkler system.

- Cost efficiency

- Automated, non clamp handling, with full inventory control.

- Minimized space utilization with possibility for future expansion.

- Production sorting and buffering capacity - no pre-sorting needed.

- Reliability

- Elimination of human errors - right products, at right time, to right address.

- Minimized need for handling equipment.

- FlowCare portal for service and operation support.

- Environment friendliness

- No need for fossil fuels.

- Minimized space need.

Pesmel:

Pesmel is global supplier of highly automated internal logistic, storing (AS/RS) and packing systems for the metal, paper and converting industries.

During the four decades Pesmel has delivered over 400 handling and packing projects and around 120 storage systems with more than 200 stacker cranes. The company employs over 200 professionals, of which abt. 120 is situated in Finland.

For more information, please visit www.pesmel.com

Stora Enso Imatra Mills:

Imatra Mills consist of two production units: Kaukopää and Tainionkoski. Together, they employ approximately 1,000 people and produce one million tonnes of board and paper annually. More than 90 per cent of production is exported, mostly to countries in Europe, but a substantial share is also exported to Southeast Asia.

Imatra produces liquid packaging board for beverage cartons and food service boards for paper cups and various food packages. Typical customers include the food, confectionery and tobacco industries.

High-quality packaging papers and graphical boards used for book covers, cards and luxury packaging are also made at the Imatra Mills.

The world's first automated pulp distribution center for Metsä Group's bioproduct mill in Äänekoski

Pesmel and Metsä Fibre, part of Metsä Group, have signed an agreement on the delivery of a pulp storage facility for the bioproduct mill to be constructed in Äänekoski. The storage facility will be implemented using the new TransBale distribution center concept, and it will be fully operational in the third quarter of 2017. In the concept to be delivered, the entire output of the mill, 1.3 million tonnes, will be taken to the distribution center, which will buffer, sort and distribute the pulp bale units to different transports. The delivery will be the first of its kind in the world.

The TransBale concept has been developed in cooperation with Metsä Fibre for a year and a half. The core of this automated distribution center is high-bay storage with two stacker cranes that operate like automatic robots. The system buffers and sorts pulp bale units by product type and customer orders, and controls all dispatch operations. The distribution center acts as a center stage of the logistics chain, which includes three main distribution channels. Approximately 800,000 tonnes of pulp is transported as export units by train to Vuosaari Harbour, 400,000 tonnes by train and trucks directly to customers, and the remaining 100,000 tonnes are refined in different units in the mill area.

The TransBale concept has been developed in cooperation with Metsä Fibre for a year and a half. The core of this automated distribution center is high-bay storage with two stacker cranes that operate like automatic robots. The system buffers and sorts pulp bale units by product type and customer orders, and controls all dispatch operations. The distribution center acts as a center stage of the logistics chain, which includes three main distribution channels. Approximately 800,000 tonnes of pulp is transported as export units by train to Vuosaari Harbour, 400,000 tonnes by train and trucks directly to customers, and the remaining 100,000 tonnes are refined in different units in the mill area.

One benefit of the chosen technology is its flexibility. Thanks to the adjustable sorting capacity, there is no need for any pre-sorting in production or allocation of storage space. This enables the optimal use of space, regardless of how much of different pulp grades are produced. The total capacity of the distribution center is 25,000 tonnes in an area of 3,000 square meters. “We were researching new solutions in the preliminary planning stage, and the handling capacity and storage efficiency of the TransBale concept convinced us,” says Timo Merikallio, a project director at Metsä Fibre.

In addition to the equipment, the delivery includes an extensive Warehouse Management System (WMS), which takes care of the distribution center's inventory management. The WMS is connected both to the production automation system and the mill's SAP system, and based on the product and dispatching information obtained from these systems, the WMS controls automated train and truck dispatch and loading operations. With automatic loading, trucks are loaded in five minutes, and a train with 22 cars carrying 1,400 tonnes in three hours. In addition to loading efficiency, automation minimizes work safety risks and damage to equipment and products.

“For a technology company like us, developing new concepts is crucial. With this project, we have a chance to extend our technology into a new business area. For this, we can thank Metsä Fibre's personnel, who took part in the project with an open-minded attitude from the start,” says Tony Leikas, president and CEO of Pesmel Oy.

For nearly four decades, Pesmel has delivered more than 400 handling and packing projects and approximately 150 storage systems. The company employs more than 150 specialists, of whom approximately 100 work in Finland.