Displaying items by tag: södra

Södra invests in AI company and becomes a partner in Nordic Forestry Automation

Södra Ädla is a new partner of Nordic Forestry Automation (NFA). The company develops next-generation operator support systems for forest machines based on sensor technology from autonomous vehicles and AI algorithms. The investment is done together with Sveaskog and Almi Invest Syd and comprises a total of SEK 10 million.

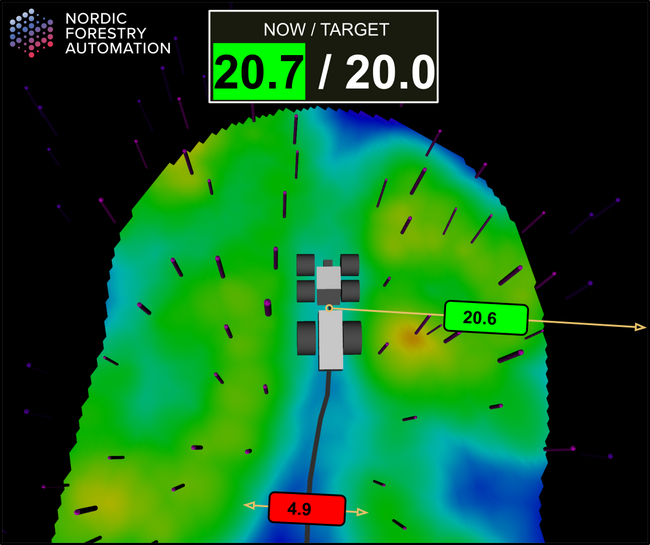

Thinning a forest involves constant decision-making about which, and how many, trees to harvest in order to best promote the various values of the forest. How the thinning operation is carried out is important for the long-term development of the forest, but is usually done manually and based on the experience of each individual operator. To make the thinning task easier, Nordic Forestry Automation (NFA) has developed an AI-based system to continuously support the operator in forest management decisions.

The company started in 2021 based on the founders’ research work on self-driving vehicles and AI algorithms. The founders met during their PhD studies through the national Swedish research initiative Wallenberg AI, Autonomous Systems and Software Program (WASP). NFA recently received investment capital of SEK 10 million from Södra’s investment company Södra Ädla, Sveaskog and Almi Invest.

“Forest thinning is a craft that requires 100-percent focus and takes several years to master. The total cognitive load is comparable to that of a fighter pilot. Sensor-based operator support provides better conditions for operators and forest owners to promote forest values. We are grateful for the opportunity to continue developing this technology together with our new partners,” said Lars Svensson, CEO of NFA.

Investment to accelerate development

By supporting the operator, the NFA system makes harvesting more cost-efficient, which improves profitability for forest owners. In addition, the technology creates new opportunities for local forest adaptations, and enables systematic and cost-efficient execution of alternative forest management methods that promote biodiversity and carbon storage.

The new investment will enable NFA to further accelerate the pace of its development. In 2022 and 2023, the system was tested in pilot projects with SCA and Sveaskog and in the autumn of 2023, the company will start rolling out preseries products with Södra, Sveaskog and SCA.

“The investment and close collaboration with forest companies means that we can deploy the systems at an early stage and continue working closely with the operators. This is absolutely essential for building systems that can make a real difference out in the forest – for both operators and forest owners,” said Lars Svensson.

Better opportunities for forest owners

NFA’s operator support can be retrofitted to any type of forest harvester and supports operators in forest management decisions. The system measures, positions and classifies all trees around the machine automatically and in real time. It also gives the position of the machine and cutting head with centimetre accuracy. Data on each individual tree is continuously collected and delivered to the forest owner together with a report, enabling increased transparency, quality assurance of the harvesting and new opportunities for forest owners to apply alternative methods of management.

This factor and an improved work environment for machine operators are some of the reasons for Södra Ädla’s investment.

“We are delighted with our investment in NFA. The company’s AI-based operator support is a good example of the business models and technology that Södra Ädla wants, and intends, to invest in. The technology makes thinning easier and more precise, and enables a wider range of forestry measures. The technology also makes thinning easier for operators, which could eventually attract more contractors and forest machine operators to the industry. NFA’s technology generates direct value for forest estates and we are looking forward to contributing to the company’s development,” said Erik Bengtson, Investment Manager for Södra Ädla.

For contact or further information, please contact:

Lars Svensson, CEO, Nordic Forestry Automation

Tel: +46 (0)734-60 68 34

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Erik Bengtson, Investment Manager, Södra Ädla

Tel: +46 (0)340-63 34 32

E-mail: This email address is being protected from spambots. You need JavaScript enabled to view it.

Södra was founded in 1938 on the idea that we are stronger together. We are now the largest forest-owner association in Sweden, with 52,000 family forest owners as members. Together, Södra’s members own a world-leading industry that processes forest raw material into renewable products such as pulp, timber, building systems, liquid bioproducts and energy. About 3,300 people are employed in our forest industry and in 2022, Södra generated sales of SEK 33 billion. Our products are exported all over the world and together, we are contributing to a more natural way of living. Rooted in the forest, we grow the future.

New product area to strengthen Södra’s energy and chemicals business

The energy and chemicals business plays a key role in Södra’s strategy and is an area that will grow and further contribute to a fossil-free future. As a result, the Södra Bioproducts product area is now being formed to further strengthen the customer offering through a more coherent business structure and sales.

Södra’s future product portfolio consists of five main businesses – sawn timber, pulp, building systems, carbon, and energy and chemicals. The energy and chemicals business will continue to grow and provide additional support for Södra, where the whole tree is processed for tomorrow’s green economy. To develop and optimise the existing business, the Södra Bioproducts product area is now being formed to gather the customer offering in energy and chemicals. Johannes Bogren, currently Vice President of Södra Cell Bioproducts, will become new Vice President Marketing & Sales, Södra Bioproducts.

“By taking an overall approach to our entire energy and chemicals business, we will to be able to offer our customers a broader portfolio of products, better service and a developed customer offering. We also want to play a clear role in the transition to a fossil-free future, and there is a major need for green products. This will make Södra an even more attractive partner,” said Johannes Bogren.

Södra Bioproducts will be responsible for developing and optimising the existing business, which includes electricity, district heating, dissolving pulp, solid fuel products and liquid products such as biomethanol, tall oil, and turpentine. The responsibility for production will remain with Södra’s various business areas.

Key area for strategic development

Energy and chemicals currently account for 7 percent of income and is an area in which Södra will continue to grow. By developing the energy and chemicals business, we are strengthening the profitability of forest estates in both the short and long term. It is also a way to step up measures to address climate change, for both us and our customers.

“Through better coordination, data-driven decision making and a leading customer offering for our existing products, we will be able make considerable progress. We are also planning to develop new business over time, such as lignin and investments for large-scale biorefinery operations. This is an important part of our strategy and our mission,” said Malin Nordin, Director of Strategy.

The new Södra Bioproducts product area will be formed on 13 March.

Products included in Södra Bioproducts

Dissolving pulp, tall oil, turpentine, biomethanol, electricity, district heating, pellets, briquettes, cutter shavings, bark, sawdust, dry chips, forest residue chips and fuel wood.

For more information, please contact

Johannes Bogren

This email address is being protected from spambots. You need JavaScript enabled to view it.

Södra commits to science-based targets

In line with its ambition to be a leader in society’s transition to climate neutrality, Södra has laid out its commitment to science-based targets for 2030 in its annual and sustainability report, and to reach net zero by 2040.

The Science Based Target initiative (SBTi) approved Södra’s targets in December 2022 and will provide support in quantifying its emissions and following up emission reductions in a way which is structured, recognised and transparent.

SBTi enables Södra to set its emission-reduction targets in the context of the goals of the 2015 Paris Agreement. Near term, Södra is committed to reducing emissions in line with a global warming limit of 1.5°C, compared with pre-industrial levels, by 2030, which is the scope of the science-based target.

“We are ambitious in our targets and longer-term goals,” said Anders Norén, Director of Sustainability at Södra. “The commitment of the Paris Agreement is to halve scope 1, 2 and 3 greenhouse gas emissions by 2030, with 2020 as the base year, and reach net zero by 2050. Södra’s climate ambition is indeed to halve scope 1, 2 and 3 greenhouse gas (GHG) emissions by 2030 but our goal is to reach net zero by 2040, which is ahead even of Sweden’s target to be the first welfare state to reach net zero by 2045.”

Consistent with the goal of “Fossil-Free Södra"

Science-based targets are consistent with the goal of “Fossil-Free Södra,” the Group’s programme of current and planned projects for emission reduction, which is the engine driving its climate ambitions.

“Working with customers has always been a defining Södra characteristic, and science-based targets emphasise this vital relationship,” said Anders Norén. “After all, our scope 1 and 2 GHG emissions become our customers’ scope 3 GHG emissions and vice versa. ‘Walking the walk’ is the best contribution we can make to the transition to climate neutrality, supporting, and being supported by, all those in our value chain.

“Our intention is to increase climate benefits all the way from our members’ forests to customers’ products. With this in mind, Södra has committed that 70 percent of customers, by emissions, will have set science-based targets themselves by 2027: almost 35 percent, by emissions, have already done so. With strong support already evident among our customer base, we can look forward to a future with more joined-up thinking when it comes to the transition to a net-zero economy.”

As a large organization, Södra can have a strong impact on climate transition. The group is one of Sweden’s largest buyers of transportation, for example, and intends to continue its leadership in the use of biofuels and electrification of road transport and rail, and to look at all possible measures to decarbonise logistics from its members’ forests to the customer’s gate.

For full details of Södra GHG emissions in 2022, please consult the annual report.

Södra was founded in 1938 on the idea that we are stronger together. We are now the largest forest-owner association in Sweden, with 51,000 family forest owners as members. Together, Södra’s members own a world-leading industry that processes forest raw material into renewable products such as pulp, timber, building systems, liquid bioproducts and energy. About 3,300 people are employed in our forest industry and in 2022, Södra generated sales of SEK 33 billion. Our products are exported all over the world and together, we are contributing to a more natural way of living. Rooted in the forest, we grow the future.

Södra plans to add lignin to the range of forest-based sustainable alternatives to fossil materials

Södra plans to add lignin within its range of forest-based materials and seeks partners to develop lignin-based sustainable alternatives to fossil materials in a range of applications.

Södra is the largest forest-owner association in Sweden and an international forest industry group. With raw material from 52,000 forest owners sustainable managed forests, Södra produce timber products, pulp and green energy – and is always looking to develop new products from this renewable material.

Södra is today a leading supplier of pulp with customers across large parts of the world and a global logistics network. The pulp mills produce both paper pulp for paper production and dissolving pulp for the textile industry.

Significant potential in lignin as a sustainable material

In the unique OnceMore® process, Södra recycle textile fibres on a large scale and enable circular flows within the textile industry. Products from the mills also include biomethanol, tall oil and turpentine marketed under the Liquid Forest™ brand which contribute to a responsible use of the raw material. The plans to make lignin available to the market, in large quantities and in consistent quality, are the latest example of the aspiration that no part of the tree should ever go to waste.

As one of the world’s largest producers of pulp from forest raw materials, Södra extracts millions of tonnes of lignin from wood annually. However, with its bonding properties, lignin has significant potential as a sustainable material.

Significant potential in lignin as a sustainable material

Significant potential in lignin as a sustainable material

Just as it does inside a tree, lignin today is used mostly as a binder in the chemical industry, and above all in different types of glue. But a much wider use of lignin is possible since its phenolic structure is excellent as a base for chemicals and raw materials that are currently based on fossil materials. Lignin has been used for several decades for various applications, including as a dispersant for concrete and plasterboard, and as a binder in road stabilization and animal feed. Now the second-generation lignin is here, a kraft lignin available in solid form, offering many new uses.

“Need to find new ways of using natural resources”

Södra plans to make large volumes of this new type of lignin ready for the market and looks for new partnerships to do so. This is important to find answers to the questions: Where can lignin do the most good? And how could lignin make a difference to you and to the transition to a fossil-free society?

“A sustainable society needs to find new ways of using natural resources,” said Vice President Södra Cell Bioproducts Johannes Bogren. “Around a quarter of a tree consists of lignin which means our pulp mills produce it in large quantities. We always strive to make the best possible use of our forest raw material and lignin has the potential to replace fossil materials and contribute to the green transition.”

Södra Cell Bioproducts Sales Manager Viktor Odenbrink:

“Research is underway for everything from lightweight automotive components to a sustainable ingredient in road surfacing. We are already talking to several like-minded companies about lignin, but our type of kraft lignin is still a new and largely unexplored raw material. That’s why we’re looking for people who’d like to start a conversation on supporting a fossil-free society together. Could lignin be a future raw material for you and your business? If so, come and explore its potential with us”.

Potential partners should contact Johannes Bogren, Vice President Södra Cell Bioproducts or Viktor Odenbrink, Sales Manager Södra Cell Bioproducts for further information.

Founded in 1938, Södra is Sweden’s largest forest-owner association, with 52,000 forest owners as its members. We conduct modern and responsible forestry, and operate state-of-the-art mills in which we process our raw material. In 2021, net sales amounted to SEK 27 billion and employees totalled 3,100. Through value-generating relationships and a long-term approach, Södra shows the way for the next generation of forestry.

Södra delivers robust result in uncertain times

Södra posted a robust result for the second quarter of 2022. The result reflects the sustained strong market for Södra’s core products in pulp and sawn timber, but the market outlook is highly uncertain.

In the second quarter of 2022, net sales for the Södra Group amounted to SEK 8,953 million (7,287), up 23 percent compared with the year-earlier period. Operating profit totalled SEK 2,325 million (1,326), the highest quarterly result for Södra to date.

Operating profit for the first half of 2022 totalled SEK 4,299 million (1,873). Return on capital employed was 39 percent (18), and the equity ratio was 61 percent at the end of the period.

Operating profit for the first half of 2022 totalled SEK 4,299 million (1,873). Return on capital employed was 39 percent (18), and the equity ratio was 61 percent at the end of the period.

The second-quarter result reflects the favourable market conditions, with strong demand and highly favourable prices for Södra’s core products, primarily pulp. In addition, Södra’s mills delivered high production volumes with stable quality and Södra Cell, for example, increased both production volumes and outbound deliveries during the period.

“The result is gratifying for us and for Södra’s 52,000 members. Price levels for our core products have been favourable for a long time and the production volumes of our mills have been high. Combined with the hard work of Södra’s members and employees, this led to a strong result for the second quarter of 2022,” said Lotta Lyrå, President and CEO.

“Market uncertainty has increased considerably due to global turmoil and negative economic growth. This could affect our core products moving forward, as slowing demand in Europe’s consumer-oriented building materials trade at the end of the quarter has already shown. We are monitoring the situation closely, continuing to focus on what we can influence and working hard every day to strengthen Södra’s long-term competitiveness,” said Lotta Lyrå.

Several investments during the quarter

In the second quarter, Södra made several decisions that will benefit the association’s 52,000 members and strengthen the profitability of their forest estates.

- During the quarter, Södra’s project for improving efficiency – World-class Efficiency – continued. The aim is to improve underlying profitability by an annual rate of SEK 1 billion, and the project strengthened the result during the quarter. Södra has now achieved efficiency gains corresponding to SEK 157 million on a 12-month basis. A decision to invest in the lime kiln at Värö was also made, which will improve stability and equip the mill for the future.

- A nature conservation premium was introduced. This means that members who set aside a higher percentage of forest land than is required by forest management certification – and contribute to the joint nature conservation activities – will be paid more for their wood. The aim of the nature conservation premium is to reward the benefits created by many of our family forest owners who have diverse objectives and management methods for their forest estates.

- Södra Ädla was formed. This new unit was formed to attract technologies and skills to family forestry. Södra Ädla will invest SEK 200 million in new companies that, in one way or another, can strengthen the profitability of Södra’s 52,000 members. This could be companies that are developing forest management methods, new forestry practices or alternative revenue models.

Serious accident in sawmill

There was a serious workplace accident in the second quarter. On 15 June, one of Södra’s employees was killed and another person was seriously injured at Södra Wood Orrefors.

“This is a horribly tragic event, and our thoughts are first and foremost with the families of those affected. The cause is being investigated by the authorities together with Södra, but whenever a tragedy like this occurs, it is obvious that our safety procedures should be – and must be – at the top of our agenda. Every workplace injury is one too many – no one should ever be exposed to risk at work,” said Lotta Lyrå.

Södra took immediate action in connection with the accident at all affected units and will continue working to improve safety. The cause of the accident is being investigated by the authorities in cooperation with Södra.

Business area results for the second quarter of 2022

In the Södra Skog business area, operating profit for the period totalled SEK 39 million (61). The change in earnings was primarily due to higher fuel costs.

In the Södra Wood business area, operating profit for the period totalled SEK 866 million (827) and reflects the sustained favourable prices for sawn timber. At the same time, demand for sawn timber decreased during the quarter.

In the Södra Cell business area, operating profit for the period totalled SEK 1,696 million (662). The earnings improvement was due to a considerably stronger price level for pulp and a favourable exchange rate for Södra, while both production volumes and outbound deliveries increased.

In the Södra Innovation business area, operating profit for the period totalled SEK 20 million (loss: 43). The positive trend was due to a favourable performance by SunPine and the fact that Södra’s holding in Silva Green Fuel is now recognised as profit from shares in partnerships and charged to net financial items.

Founded in 1938, Södra is Sweden’s largest forest-owner association, with 52,000 forest owners as its members. We conduct modern and responsible forestry, and operate state-of-the-art mills in which we process our raw material. In 2021, net sales amounted to SEK 27 billion and employees totalled 3,100. Through value-generating relationships and a long-term approach, Södra shows the way for the next generation of forestry.

Strong result for Södra’s electricity generation

Domestic electricity for 45,000 homes for one year. That was the total excess from Södra’s own electricity generation according to new figures from 2021.

With efficiencies, investments and industrial development, Södra is maximising the value of its members’ forest products, as well as the by-products.

New figures show that Södra’s pulp mills at Värö, Mörrum and Mönsterås generated 1,790 GWh in 2021, corresponding to nearly 120 percent of the Group’s annual electricity needs. This means that Södra generated nearly 260 GWh of excess electricity during the year, which was distributed through the local electricity grid and added to the electricity supply in Götaland.

The excess electricity corresponds to the total annual consumption of domestic electricity for 45,000 homes, based on figures from Statistics Sweden*.

Head of Energy: Three major benefits of electricity generation

Södra’s own electricity generation and excess electricity play a key role in production stability and value generation for Södra’s members.

“Electricity generation at Södra’s pulp mills creates three major benefits: our members get more value for their forest raw material, our production is robust, and we are supporting our local communities with a continuous supply of green electricity. Electricity generation has played a particularly important role during the winter, when energy prices could otherwise affect the stability of production in our mills,” said Henrik Brodin, Head of Energy at Södra.

Making use of a by-product

The electricity from Södra’s three pulp mills is a product of resource efficiency. It is mainly generated by using the energy in black liquor, which is a by-product of the pulping process. From this energy, steam is produced that is used to drive the turbines which, in turn, generate electricity. There have been turbines at Södra’s pulp mills since 1958 and they have been improved in line with development. Södra currently has a total of nine turbines in operation.

“It is important for Södra to be self-sufficient in electricity. Our production processes require a lot of energy, and by using turbines, we are taking our responsibility for energy and much more. The energy business has been a priority for Södra for many years, and will remain so. The key to a strong energy business is to always maintain a central focus on energy and resource efficiencies. We will continue to invest in our energy efficiency,” said Andreas Martinsson, energy strategist at Södra.

In 2021, Södra Cell Värö generated 770 GWh, while Södra Cell Mönsterås generated 680 GWh and Södra Cell Mörrum accounted for just over 300 GWh. In addition to electricity, Södra delivered nearly 4 TWh of solid biofuels to power plants in electricity price areas 3 and 4 and delivered excess heat from its processes to the district heating networks of Varberg, Karlshamn and Mönsterås.

*According to figures from Statistics Sweden, normal electricity consumption for a home that does not use electricity for heating is about 5,700 kWh per year.

Södra initiates OnceMore® investment – will tenfold production capacity

A new investment in Södra’s pulp mill at Mörrum will achieve a tenfold increase in Södra’s production capacity, while also increasing the proportion of recycled textile in the pulp.

Södra’s OnceMore® initiative – the world’s first process for industrial-scale recycling of textile waste of blended fibers – will now be even bigger. Södra has decided to invest in new machinery at Södra’s pulp mill at Mörrum, which will be commissioned in the first half of 2022. The new investment will increase the production capacity of OnceMore® pulp tenfold, bringing it to a full 6,000 tonnes. The proportion of recycled textile in the pulp will also increase.

“The new investment in OnceMore® is a major step towards our long-term ambition of creating a circular textile industry. The initiative has been highly successful since the start in 2019 and is a key element of Södra’s innovation agenda. We think now is a good time to scale up production. Our investment will further improve textile recycling and maximise the value of the raw material from our members’ forests,” said Catrin Gustavsson, President of Södra Innovation Business Area.

Step on the journey towards 25,000 tonnes

The investment is the second step towards the target of processing 25,000 tonnes of textile waste, and offering OnceMore® pulp based on Södra’s forest raw material and 50 percent recycled fabrics. This target has been set for 2025.

OnceMore® makes it possible to convert large volumes of used cotton textiles and cotton-polyester blends into new clothing and textiles. The RCS (Recycled Claim Standard) certified pulp is also attracting interest from the market. Södra has held several meetings with interested brands and recently signed a long-term collaborative agreement with the global textile giant Lenzing.

“OnceMore® has received a highly positive reception and the strong market demand is steadily growing. Södra delivers regular supplies of OnceMore® pulp to a number of textile manufacturers around the world. This new investment and our partnership with Lenzing will help us create world-class textile recycling and grow the business. OnceMore® has the potential to transform the textile industry,” said Johannes Bogren, Vice President, Södra Cell Bioproducts.

Founded in 1938, Södra is Sweden’s largest forest-owner association, with 53,000 forest owners as its members. We conduct modern and responsible forestry, and operate state-of-the-art mills in which we process our raw material. In 2020, net sales amounted to SEK 20 billion and employees totalled 3,100. Through value-generating relationships and a long-term approach, Södra shows the way for the next generation of forestry.

Two champions of post-consumer textile recycling joining forces

Together, Lenzing and Södra take a giant leap further towards closing the loop from fiber to fiber in fashion.

Lenzing, a leading global supplier of wood-based specialty fibers, and Södra, a world-class producer of pulp, signed a cooperation agreement on, June 02, 2021, with the clear objective of making a decisive contribution to addressing the enormous textile waste challenges of the industry and the society. The cooperation involves the transfer of knowledge between the two companies, which have been proactively driving the circular economy issue for many years, and a joint process development followed by a capacity expansion for pulp from post-consumer waste. The goal is to process 25,000 tons of textile waste per year by 2025.

The fashion industry is one of the major polluting industries in the world. Millions of tons of textile waste are created each year, most of it ends up in landfills. In the spirit of the circular economy transition, both Lenzing and Södra have independently addressed the issue and developed appropriate solution options so far. Both companies are experts in their respective fields with many years of large-scale industrial experience.

Södra CEO: "We now taking the next step on our journey"

Together, they give textile recycling a huge boost by developing technologies further towards a broader, industrial-scale use of post-consumer cellulosic waste. The jointly developed pulp OnceMore® will subsequently also be used as a raw material for the production of Lenzing’s TENCEL™ x REFIBRA™ branded specialty fibers.

“The cooperation with Södra is a major milestone towards achieving our ambitious climate and sustainability goals. We are proud to be able to go this way with a competent partner. One company alone cannot solve the pressing issue of textile waste. It is proactive partnerships like this that enable us to move forward and bring about real systemic change”, says Christian Skilich, Member of the Managing Board of Lenzing.

“With OnceMore® pulp, Södra has created a globally unique solution to base textile on a recycled source. By joining forces with Lenzing, we now taking the next step on our journey and will bring world-class recycling to the textile value chain. Through a new investment, we will also ten-fold our production capacity of OnceMore® pulp during 2022 and have a higher level of recycled textile content. These are important steps towards our long-term target to create a circular textile industry”, says Lotta Lyrå, President and CEO of Södra.

“In this turn around decade for our planet, making forest-based fabrics from recycled textiles is critical to protect biodiversity, alleviate pressure on forests and address the growing climate crisis. Canopy is excited to see these two major producers join forces to bring vital Next Generation Solutions to the fashion industry. We look forward to seeing greater commercial volumes come to market”, says Nicole Rycroft, Canopy’s Founder and Executive Director.

Two companies with bold visions and large-scale solutions for the reuse of waste

In line with its circular economy vision, “We give waste a new life. Every day”, Lenzing drives the industry towards a fully-fledged circular economy by striving to give waste a new life in all aspects of its core business and by co-developing circular solutions with potential partners in and outside the current value chain. Lenzing has extensive knowledge in developing cutting-edge innovations in recycling such as its REFIBRA™ and Eco Cycle technologies. Besides virgin dissolving wood pulp, these technologies allow the processing of a substantial proportion of recycled materials based on pre-consumer cottons scraps and post-consumer garments.

OnceMore® by Södra is the world’s first process for industrial-scale recycling of textile waste of blended fibers, and it’s the forest who makes that possible. The process combines wood cellulose with textile waste to create a pure, high-quality dissolving pulp which can be used to produce new clothing and other textile products. During 2022, a new investment will ten-fold the production capacity of OnceMore® pulp and reach a higher level of recycled textile content. The goal for 2025 is to process 25,000 tons of textile and offer a OnceMore® pulp based on our wood material and 50 percent recycled textile material.

About the Lenzing Group

The Lenzing Group stands for ecologically responsible production of specialty fibers made from the renewable raw material wood. As an innovation leader, Lenzing is a partner of global textile and nonwoven manufacturers and drives many new technological developments.

The Lenzing Group’s high-quality fibers form the basis for a variety of textile applications ranging from elegant ladies clothing to versatile denims and high-performance sports clothing. Due to their consistent high quality, their biodegradability and compostability Lenzing fibers are also highly suitable for hygiene products and agricultural applications.

The business model of the Lenzing Group goes far beyond that of a traditional fiber producer. Together with its customers and partners, Lenzing develops innovative products along the value chain, creating added value for consumers. The Lenzing Group strives for the efficient utilization and processing of all raw materials and offers solutions to help redirect the textile sector towards a closed-loop economy. In order to reduce the speed of global warming and to accomplish the targets of the Paris Climate Agreement and the “Green Deal” of the EU Commission, Lenzing has a clear vision: namely to make a zero-carbon future come true.

Key Facts & Figures Lenzing Group 2020

Revenue: EUR 1.63 bn

Nameplate capacity: 1,045,000 tons

Employees: 7,358

TENCEL™, VEOCEL™, LENZING™, REFIBRA™, ECOVERO™, LENZING MODAL™, LENZING VISCOSE™, MICROMODAL™ and PROMODAL™ are trademarks of Lenzing AG.

About Södra

Södra was founded in 1938 and is the largest forest-owner association in Sweden, with a membership of 53,000 forest owners. Södra is also an international forest industry Group, with 3,000 employees around the world. Net sales in 2020 were 20 SEK billion. Balancing production efficiency with nature conservation guides everything that we do. We produce timber products, pulp for paper and textiles, and green energy. We use every part of the tree, and are always looking to develop new products from this fantastic, renewable raw material. Södra is a world-leading producer of market pulp and also owns one of the largest sawmill operations in Europe. Through value-generating relationships and a long-term approach, Södra is leading the way for the future of sustainable forestry.

Key Facts & Figures Södra 2020

Net sales: SEK 20,351 million

Operating profit: SEK 891 million

Employees: 3,100

Södra delivers stable result in current market condition

The current market conditions had a significant impact on Södra’s operating profit in the third quarter. Despite higher year-on-year delivery volumes for Södra’s core products, the price formation for market pulp was weaker. For the third quarter, Södra’s sales amounted to SEK 4,925 million (5,391) and operating profit to SEK 93 million (512). For the first nine months of the year, operating profit totalled SEK 541 million (2,520). Return on capital employed was 3 percent (16) and the equity ratio was 57 percent.

“The global economy is projected to contract this year due to COVID-19, despite a slight and recent recovery. A more stable and sustainable turnaround in the years ahead will require an easing of the uncertainty created by the pandemic. In view of the current market conditions and geopolitical uncertainty, Södra’s operating profit to date this year can be considered stable,” said Peter Karlsson, Interim President and CEO.

Peter Karlsson, Interim President and CEO

Peter Karlsson, Interim President and CEO

“Both the decrease in sales and decline in earnings were due to considerably lower prices for market pulp compared with the year-earlier period. A weak upward trajectory meant that prices were slightly higher at the end of the quarter compared with the beginning of the year. To date this year, the price of sawn timber is lower year-on-year. Demand for Södra’s core products remained favourable, while production was stable at a high level,” said Peter Karlsson.

A mobilisation of Södra’s entire chain – from owners, contractors and employees to the mills – combined with favourable weather conditions minimised the negative effects of the spruce bark beetle outbreaks. Despite a 50-percent reduction compared with last year, the level of damage is 1 million m³sub on Södra members’ estates, which is still extremely high.

“A key element of Södra’s strategy for sustainable and profitable growth is efficient use of forest products. We are therefore proud to have inaugurated the world’s first fossil-free biomethanol plant at the pulp mill in Mönsterås in early October. The facility is one the forest industry’s many contributions to the transition to a bioeconomy,” said Peter Karlsson.

The biomethanol is made from the crude methanol recovered from the pulp manufacturing process and is part of the circular process that already exists at the pulp mill. The facility was inaugurated by the Swedish Minister for Enterprise, Ibrahim Baylan, at a virtual ceremony.

Financial key indicators:

During the quarter, consolidated net sales declined 9 percent to SEK 4,925 million (5,391). The operating margin was 2 percent (9). The negative sales trend was due to considerably lower prices for market pulp, while delivery volumes for Södra’s core products were higher year-on-year, both during the quarter and cumulative. Cumulative net sales amounted to SEK 15,918 million (17,908). Return on capital employed was 3 percent (16) and the equity ratio was 57 percent.

Södra Skog

Södra Skog’s operating profit for the period totalled SEK 35 million (26). The result is attributable to favourable volumes from field operations and reduced imports. During the period, Södra Skog acquired 3.7 million m³sub, comprising 62 percent pulpwood and cellulose chips, 31 percent saw logs and 7 percent biofuels. Cumulative operating profit amounted to SEK 88 million (161).

Södra Wood

Södra Wood’s operating profit for the period totalled SEK 128 million (39), reflecting the positive price formation for sawn timber and continued high demand for sawn timber. The delivery volume from Södra Wood rose to 520 thousand m³sw, compared with 490 thousand m³sw in the year-earlier period. Sales for the quarter amounted to SEK 1,524 million (1,395). Cumulative sales amounted to SEK 4,611 million (4,485) and operating profit was SEK 212 million (304).

Södra Cell

Södra Cell’s operating loss for the period totalled SEK 8 million (profit: 551). The earnings decline was due to lower prices for market pulp. Sales for the quarter amounted to SEK 2,545 million (3,054). The production volume totalled 468 ktonnes, comprising 401 ktonnes of softwood sulphate pulp, 29 ktonnes of hardwood sulphate pulp and 38 ktonnes of dissolving pulp. Cumulative sales amounted to SEK 8,039 million (9,804) and operating profit to SEK 544 million (2,416).

Founded in 1938, Södra is Sweden’s largest forest-owner association, with 53,000 forest owners as its members. We conduct modern and responsible forestry, and operate state-of-the-art mills in which we process our raw material. In 2019, net sales amounted to SEK 23 billion and employees totalled 3,100. Through value-generating relationships and a long-term approach, Södra shows the way for the next generation of forestry.

Inauguration of the world’s first fossil-free biomethanol plant

On Wednesday, 7 October, Sweden’s Minister for Enterprise Ibrahim Baylan inaugurated Södra’s plant for commercial biomethanol at the pulp mill in Mönsterås. Members of the European Parliament Fredrik Federley, Jytte Guteland and Jessica Polfjärd were present at the inauguration as well as Professor Johan Kuylenstierna of the Swedish Climate Policy Council.

“Södra’s investment is entirely in line with the European Green Deal as set out by the European Commission, which has the aim of dramatically reducing our carbon footprint and reducing emissions. By manufacturing the world’s first fossil-free biomethanol, we are demonstrating how engineering prowess and innovation can contribute to the transition of society. We are pleased that the importance of this kind of investment is understood by politicians,” said Lena Ek, Chairman of Södra.

The transition to a bioeconomy means that all raw materials must be used efficiently. The biomethanol will be made from the crude methanol derived from the manufacturing process at Södra’s pulp mill, where the premise is that all of the parts of the renewable wood raw material are used as efficiently as possible.

“Södra’s strength lies in its extensive value chain, from sustainable forestry and renewable raw materials to modern industries and a healthy tradition of research and development. This means that we have the expertise required to develop these types of complex and innovative products,” said Catrin Gustavsson, Senior Vice President of Innovation and New Business at Södra.

Södra is investing extensively in liquid biofuel and has robust sustainability targets of its own for entirely fossil-free transportation by 2030.

“With this dynamic move and climate-friendly investment, we are looking outward and showing the way to reduced fossil dependency across several markets. At the same time, this is just the beginning of a journey in which we have the opportunity to develop products together with our customers. We can already see substantial interest from different segments and stakeholders from across the globe,” said Magnus Björkman, Business Area President Södra Cell.

Founded in 1938, Södra is Sweden’s largest forest-owner association, with 53,000 forest owners as its members. We conduct modern and responsible forestry, and operate state-of-the-art mills in which we process our raw material. In 2019, net sales amounted to SEK 23 billion and employees totalled 3,100. Through value-generating relationships and a long-term approach, Södra shows the way for the next generation of forestry.