Ian Melin-Jones

Award to Circular textile paper project

Archana Ashok was awarded the Bo Rydin Foundation for Scientific Research grant for Best Master’s Thesis Project 2017. Her project “Textile paper as a circular material” was carried out within the transdisciplinary TechMark Arena master students’ academy at RISE Bioeconomy division.

Bo Rydin Foundation for Scientific Research annually awards a grant for the year's best master's degree project within SCA's strategic areas; personal hygiene products, tissue paper or forest products.

Archana Ashok, KTH, is rewarded for her project “Textile paper as a circular material” which evaluated circularity of a new paper manufacturing concept where the raw material is largely made up of low value fibres from textile recycling plants. According to the circular economy framework, this is a cascade recycling of fibres from the textile industry to the paper industry, forming thus an industrial symbiosis.

Previously, the textile paper material was produced on a pilot scale at RISE and used as the cover of the Global Outlook report A Cellulose-Based Society, demonstrating thus technical feasibility of producing this circular material. Archana's project took the concept to a new level by investigating whether the textile paper is suitable as a circular packaging material for paper bags. In particular, evaluations of technical performance, environmental and economic aspects of the new material as well as market conditions were combined in a multi-dimensional context of circular economy. The result showed that it could be better to use low value textile fibres as a circular material instead of incinerating it, which is a common practice nowadays.

“Archana's project was unique because it was the first time that we both evaluated and quantified the circularity of a new material by applying circular economy framework. Both research and industry actors will be able to use her results as a guideline and inspiration in evaluating their materials and products,” says Tatjana Karpenja, one of the supervisors at RISE.

“The 6 months journey at RISE was really exciting and fun-filled with the TechMark Arena group having lots of discussions and workshops on circular economy,” says Archana Ashok.

This is the second time in three years this prize goes to a student at TechMark Arena. This transdisciplinary academy brings together master students from various backgrounds in order to work on a common theme. This arrangement encourages a broader approach to a topic and ensures a greater exchange of ideas between students and increased knowledge sharing between different projects. Archana’s supervising team involved Tatjana Karpenja, Marie-Claude Béland, Karin Edström, Hjalmar Granberg and Ida Kulander.

Another project from TechMark Arena 2017 was nominated for the award. Emma Dahlgren at Linköping University with her project “Exploring biodegradable electronics”, aimed at an innovative area, using cellulose substrates for electronics, which would bring both environmental benefits and cost advantages. This research field is an expanding research area currently being explored within RISE.

For more information, please contact Tatjana Karpenja, +46 768767026, This email address is being protected from spambots. You need JavaScript enabled to view it.

For information about the textile paper, see http://www.innventia.com/en/About-us/News1/New-circular-material-with-industrial-symbiosis-in-focus/

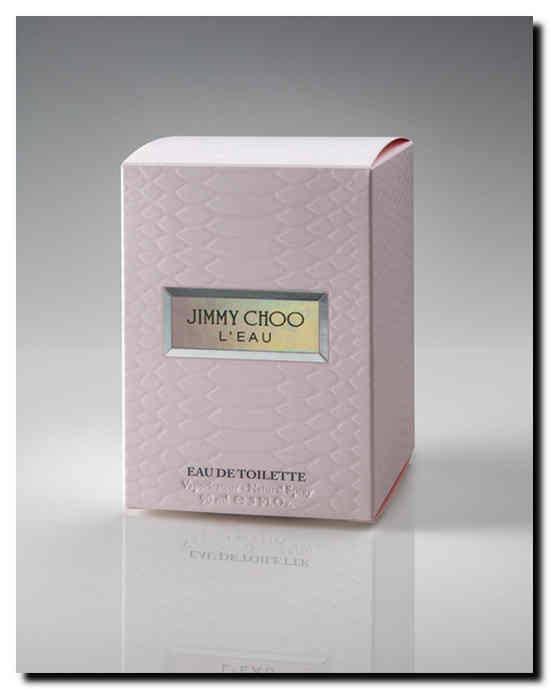

Simple and minimalist with great complexity

In the world of packaging it is sometimes complicated to achieve something that looks simple, minimalist and elegant. The paperboard cartons for Jimmy Choo’s L’EAU that was launched in summer 2017 is a clear example of this. Its colour is pale pink apart from the brand, the name of the contents, and the fact that it is an eau de toilette. Yet the packaging has passed through twelve finishing stages.

The carton is made of Invercote from Iggesund Paperboard. Conversion is by the distinguished French printing company Draeger on behalf of Interparfums. The packaging is offset printed on both the inside and outside. The printing on the inside is in a pale pink shade, which creates the mood around the bottle. Externally the packaging has a blind-embossed snakeskin pattern plus two rows of text on the front. The outside is also laminated with soft touch film, matt varnished, and foil embossed with both silver film and holographic film.

Jimmy Choo’s L’EAU is an example of a simple and minimalist design that requires complex processing. For the project the converters Draeger and licensee Interparfums chose to use Invercote from Iggesund Paperboard. ©Iggesund

Jimmy Choo’s L’EAU is an example of a simple and minimalist design that requires complex processing. For the project the converters Draeger and licensee Interparfums chose to use Invercote from Iggesund Paperboard. ©Iggesund

“Our choice to use Invercote G was motivated by the fact that its smooth surface allowed a very faithful reproduction of our design in terms of color and hot foil stamping. It also brings great embossing properties to achieve the impressive snakeskin pattern on the whole packaging” says Axel Marot, Supply Chain & Operations Director at Interparfums. For producers of advanced paperboard packaging involving many finishing stages, one paperboard property can be of critical importance to the end result: dimensional stability. This may not be the first thing people consider when choosing a material but experienced converters always include it in their calculations.

“If you have twelve finishing stages and get a misregister at stage ten, you don’t just lose the material but also all the work you invested prior to that,” explains Edvin Thurfjell, product manager for Invercote. “In today’s world of ever-increasing time pressure you also risk missing delivery times – and for many projects that just cannot be allowed to happen.”

In Invercote’s case the secret is a combination of a high proportion of long cellulose fibres from pine and spruce plus the sulphate process that extracts these fibres in a gentle way. In addition, the paperboard is constructed in several layers. This is not only important for dimensional stability; it also reduces the risk of cracks in creases compared with single-ply paperboard and paper. However, there is no simple measurement of dimensional stability that customers can find among the lists of specifications from paperboard manufacturers.

“For people who do read these specifications, two clues are high values for tearing strength and tensile strength. But I believe that a large proportion of our customers have discovered this strength from their own experience,” Thurfjell says.

As a product manager he believes, naturally enough, that people should pay more attention to their choice of material.

“As someone who is interested in packaging, I think it’s a pity when people compromise on their choice of material and endanger all the work that’s been invested before the production even starts. When people hire the best creatives and choose star photographers and models but don’t understand that the quality of the packaging material must be correspondingly high, then I do wonder if they’re thinking along the right lines.”

Iggesund

Iggesund Paperboard is part of the Swedish forest industry group Holmen, one of the world’s 100 most sustainable companies listed on the United Nations Global Compact Index. Iggesund’s turnover is just over €500 million and its flagship product Invercote is sold in more than 100 countries. The company has two brand families, Invercote and Incada, both positioned at the high end of their respective segments. Since 2010 Iggesund has invested more than €380 million to increase its energy efficiency and reduce the fossil emissions from its production.

Iggesund and the Holmen Group report all their fossil carbon emissions to the Carbon Disclosure Project. The environmental data form an integral part of an annual report that complies with the Global Reporting Initiative’s highest level of sustainability reporting. Iggesund was founded as an iron mill in 1685, but has been making paperboard for more than 50 years. The two mills, in northern Sweden and northern England employ 1500 people.

Sappi expands its speciality and packaging paper capacity; will acquire the speciality paper business of Cham Paper Group Holding AG (CPG)

Sappi Limited, a leading global producer of dissolving wood pulp, speciality and packaging papers, graphic (printing and writing) paper and biomaterials, today announced that it had signed an agreement to acquire the speciality paper business of Cham Paper Group Holding AG (CPG) for CHF146.5 million (approximately $149 million).

The transaction includes the acquisition of CPG’s Carmignano and Condino Mills in Italy, its digital imaging business located in Cham, Switzerland as well as all brands and know-how. It will be funded through internal cash resources. The transaction is conditional on the approval from certain competition authorities. We expect the acquisition to be completed during the first calendar quarter of 2018.

The transaction includes the acquisition of CPG’s Carmignano and Condino Mills in Italy, its digital imaging business located in Cham, Switzerland as well as all brands and know-how. It will be funded through internal cash resources. The transaction is conditional on the approval from certain competition authorities. We expect the acquisition to be completed during the first calendar quarter of 2018.

The main benefits of the acquisition include:

- Supports Sappi’s diversification strategy and 2020vision to grow in higher margin growth segments

- Strengthens Sappi Europe’s speciality and packaging papers footprint and skills; adds 160,000 tons of speciality paper to our capacity

- Increases Sappi’s relevance in speciality papers, opening up new customers and markets to Sappi’s existing products and generating economies of scale and synergies

- Gaining greater share-of-wallet with valued brand owners; accelerating innovation and new product development

- Improved near-term profitability and serve as platform for organic growth and further acquisitions. Will add €183 million of sales and approximately €20 million of EBITDA before taking into account synergies

- Builds on the investments currently underway to increase speciality paper capacity at our Somerset, Maastricht and Alfeld Mills

- Unlocks the growth potential of the CPG speciality paper business

Commenting on the transaction Steve Binnie, Chief Executive Officer of Sappi Limited, said:

“This acquisition further strengthens Sappi’s speciality paper business both in Europe and globally by combining Cham’s strong brands and assets with Sappi’s global reach. This transaction will increase profitability and unlock the significant growth and innovation potential inherent within the speciality paper market. I am very pleased that we have taken another signification step towards realizing our Vision2020 goal.”

Berry Wiersum, CEO Sappi Europe stated:

“We are very excited about the possibilities this transaction opens up for Sappi as well as for Cham’s highly respected business. The products and brands which have been acquired are an excellent complement to our market offering, enabling us to offer our existing, as well as new customers in Europe, North America and globally, a broader range of products coupled with excellent customer service.”

The speciality paper business of CPG will continue to operate separately and independently from Sappi until clearances from the authorities are obtained.

About Sappi Limited

A global leader in dissolving wood pulp and paper-based solutions, Sappi Limited (listed and in the Top 40 on the JSE - SAP), is headquartered in Johannesburg, South Africa; has over 12,000 employees; manufacturing facilities on three continents, in seven countries (eight operations in Europe, three operations in America and five operations in South Africa) and customers in over 150 countries worldwide

Sappi works closely with customers to provide relevant and sustainable dissolving wood pulp, paper (speciality, packaging and graphic), paper pulp, and biomaterial products and related services and innovations. Our market-leading range of paper products includes: flexible packaging, label, release liner, containerboard and fluting, coated fine papers, casting release papers and in our Southern African region newsprint, uncoated graphic and business papers. These products serve the fashion, FMCG and industrial sectors. Our dissolving wood pulp products are used worldwide by converters to produce viscose fibre, pharmaceutical products as well as a wide range of household and consumer products.

We continue to grow into a profitable and cash-generative diversified business with an exciting future in woodfibre, a renewable resource.

About Cham Paper Group Holding AG (CPG): CPGN (SWX) The Cham Paper Group Holding AG is a leading manufacturer of coated speciality papers. The company was founded in 1657. Following the divestment of the paper business, the company will focus on its real estate business and will operate under the name «Cham Group».

Carmignano Mill (Carmignano di Brenta, Padua, Italy): This is a non-integrated paper mill with two paper machines. The plant can produce 100 000 tons of paper and employs 210 people. Paper grades include C1S FlexPack, C1S Label Papers, Wet Glue and Self-Adhesive applications, base paper for metallisation

Condino Mill (Borgo Chiese, Trento, Italy): This is a non-integrated paper mill, with one paper machine. The mill employs 120 employees and can produce 60 000 tons of paper per year. Paper grades include glassine (silicone base paper) and super calendared, uncoated flexible packaging papers.

Digital Imaging Business (Cham, Canton Zug, Switzerland): A finishing plant is located in Cham Switzerland, in a 4000sqm industrial warehouse where the base paper from Condino or Carmignano mills are converted to produce 12 000 tons of digital imaging paper. The business employs 50 people.

Cham Paper Group sells its speciality paper business to Sappi Group

Cham Paper Group sells its speciality paper business to the South African Sappi Limited, one of the world's leading pulp and paper companies. The integration of the speciality paper business into the Sappi Group will open up new perspectives for the two high-performance plants of Cham Paper Group in Carmignano and Condino as well as for their employees and for the Digital Imaging team in Cham. The transaction is subject to the approval of anti-trust authorities. Following the divestment of the paper business, Cham Paper Group will focus on its real estate business. The group is pushing ahead the transformation of the «Papieri» area in Cham into a new, attractive urban quarter.

The Sappi Group, which is domiciled in Johannesburg and listed on the Johannesburg stock exchange, develops, produces and sells dissolving wood pulp, speciality, packaging and graphic paper, as well as biomaterials. It employs around 12,000 people with production facilities across 7 countries on 3 continents and customers in over 150 countries. It has focused its development in various areas of the speciality paper market. The integration of Cham Paper Group's speciality paper business into a strong, globally positioned Group will open up new opportunities for this business as regards procurement, market development, product innovation, expansion opportunities and staff development.

The Sappi Group, which is domiciled in Johannesburg and listed on the Johannesburg stock exchange, develops, produces and sells dissolving wood pulp, speciality, packaging and graphic paper, as well as biomaterials. It employs around 12,000 people with production facilities across 7 countries on 3 continents and customers in over 150 countries. It has focused its development in various areas of the speciality paper market. The integration of Cham Paper Group's speciality paper business into a strong, globally positioned Group will open up new opportunities for this business as regards procurement, market development, product innovation, expansion opportunities and staff development.

In recent months, the Cham Paper Group's Board of Directors has examined all strategic options for the company's future success following the relocation of the speciality paper production from Switzerland to Italy and the comprehensive modernisation of the plants in Carmignano and Condino. Although Cham Paper Group's profitable speciality paper business is well positioned today, it is still too small to develop its market position on its own in the long term. Accordingly, selling it to the Sappi Group is an optimal solution.

The sale of the speciality paper business requires a change in the corporate purpose of Cham Paper Group Holding AG. The shareholders may vote on the proposal at an Extraordinary General Meeting. The alteration of the company's purpose requires the approval of at least two-thirds of the votes represented at the General Meeting. In addition, the transaction is subject to the approval of anti-trust authorities. The transaction is expected to close in the first quarter of 2018.

Following the divestment of the speciality paper business, the company will focus on its real estate business and will operate under the name «Cham Group». The sale at an enterprise value of CHF 146.5 million will result (after deduction of bank debt, liabilities and cost) in an inflow of approximately CHF 125 million in cash to the Group. These financial resources increase the flexibility for the development of the «Papieri» project. For example, the resulting higher equity ratio means that a higher proportion of investment properties could be considered at the expense of the condominium ownership ratio. Real estate investments beyond the «Papieri» site are also possible.

The Board of Directors intends to make the Cham Group share an attractive dividend-bearing security for the long-term. A base dividend of at least CHF 6.00 per share will be proposed to the General Meeting of Shareholders as of the financial year 2017. The distribution is tax-free from capital reserves. As soon as the «Papieri» site yields regular income, which is likely to be the case from 2022 onwards, the dividend will be based on the actual profit generated.

Cham Paper Group

The Cham Paper Group is a leading manufacturer of coated speciality papers. Surface finishing lends papers properties that generate value added for its customers. The company, which was founded in 1657, has three sites, one in Switzerland (Cham) and two in Italy (Carmignano and Condino), and a global sales network.

The decision to focus on development and sales and discontinue paper manufacturing in Switzerland has made way for a new project on the factory site in the centre of Cham. The Cham Paper Group is developing an eleven-hectare quarter there called the Papieri site.

The Cham Paper Group (stock exchange symbol: CPGN) is listed on Switzerland's SIX Swiss Exchange.

Clearwater Paper Announces New Board Chair

Clearwater Paper Corporation (NYSE:CLW) has just announced that Beth Ford has been appointed as chair to the company's board of directors effective January 1, 2018.

Ms. Ford, the chief operating officer for Land O'Lakes Businesses, has served on the Clearwater Paper board of directors since 2013. As chief operating officer, Ms. Ford oversees Land O'Lakes' multi-billion dollar U.S. businesses, which include Purina Animal Nutrition, Land O'Lakes Dairy, and Winfield United, which provides crop inputs and agriculture technology solutions. In her 30 years in business, Ms. Ford has held senior and line leadership positions in seven companies across six industries, including roles at International Flavors and Fragrances, Mobil Corporation, PepsiCo and Pepsi Bottling Company, and Hachette Book Group and Scholastic, Inc.

Ms. Ford, the chief operating officer for Land O'Lakes Businesses, has served on the Clearwater Paper board of directors since 2013. As chief operating officer, Ms. Ford oversees Land O'Lakes' multi-billion dollar U.S. businesses, which include Purina Animal Nutrition, Land O'Lakes Dairy, and Winfield United, which provides crop inputs and agriculture technology solutions. In her 30 years in business, Ms. Ford has held senior and line leadership positions in seven companies across six industries, including roles at International Flavors and Fragrances, Mobil Corporation, PepsiCo and Pepsi Bottling Company, and Hachette Book Group and Scholastic, Inc.

"We greatly value the retail, supply chain, and operations insight Beth brings to us, which will help us improve our competitive position and succeed in the marketplace," said Linda Massman, president and CEO. "On behalf of the Clearwater Paper team, we extend our congratulations to Beth as our new board chair."

Ms. Ford will succeed Boh Dickey as chair. Mr. Dickey has been a Clearwater Paper board member since 2008 and chair since 2013. He is expected to retire from the company's board at the end of his current board term in May 2018 pursuant to the company's corporate governance guidelines.

"Boh has been a driving force in developing and guiding our strategy, positioning Clearwater Paper as one of the largest private label tissue manufacturers and an efficient paperboard manufacturer, serving our customers well over the years," added Massman. "I thank him for his numerous contributions and critical decisions that have helped make our company more successful."

With today's announcement, Clearwater Paper will be one of the few publicly-traded companies in the U.S. with women serving as the CEO and non-executive board chair.

ABOUT CLEARWATER PAPER

Clearwater Paper manufactures quality consumer tissue, away-from-home tissue, parent roll tissue, bleached paperboard and pulp at manufacturing facilities across the nation. The company is a premier supplier of private label tissue to major retailers and wholesale distributors, including grocery, drug, mass merchants and discount stores. In addition, the company produces bleached paperboard used by quality-conscious printers and packaging converters, and offers services that include custom sheeting, slitting and cutting. Clearwater Paper's employees build shareholder value by developing strong customer partnerships through quality and service.

Source: Clearwater Paper Corporation - http://www.clearwaterpaper.com/

Solenis to Increase Prices on all Alkaline Sizing Product Lines Globally

Solenis, a leading global producer of specialty chemicals, will increase prices by up to 20 percent on all alkaline sizing products globally, effective immediately or as customer contracts allow. The price increase is necessary due to the increase in certain raw material costs combined with a tightening overall global supply chain.

Solenis, a leading global producer of specialty chemicals, will increase prices by up to 20 percent on all alkaline sizing products globally, effective immediately or as customer contracts allow. The price increase is necessary due to the increase in certain raw material costs combined with a tightening overall global supply chain.

About Solenis

Solenis is a leading global producer of specialty chemicals for water intensive industries, including the pulp, paper, oil and gas, chemical processing, mining, biorefining, power and municipal markets. The company’s product portfolio includes a broad array of process, functional and water treatment chemistries as well as state-of-the-art monitoring and control systems. These technologies are used by customers to improve operational efficiencies, enhance product quality, protect plant assets and minimize environmental impact. Headquartered in Wilmington, Delaware, the company has 37 manufacturing facilities strategically located around the globe and employs a team of approximately 3,700 professionals in 118 countries across five continents. For additional information about Solenis, please visit www.solenis.com

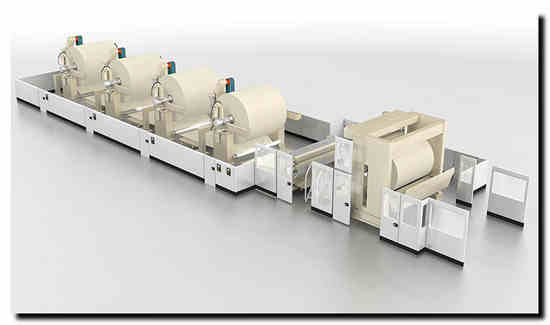

Valmet delivers new chipping line and chip handling system to Sappi's Saiccor pulp mill in South Africa

Valmet will deliver a new high capacity chipping line and chip handling system to Sappi Southern Africa (Pty) Ltd, Saiccor mill. The upgrade targets to increase the chipping capacity, to improve chip quality and minimize wood losses. The chipper will be delivered and installed at the end of 2018 and the start-up is planned for January 2019.

The order was included in Valmet's third quarter 2017 orders received.

Valmet chipping line and chip system

Valmet chipping line and chip system

"Valmet's high capacity drop feed chipper was found to be favourable for the new wood yard's current and future mill capacity requirement," says Ryno Eksteen, Senior Regional Project Manager at Sappi.

"Valmet's wood handling business continues to flourish in the South African market area. With our biggest drop feed chipper this project will be extremely important to us and we are delighted that Sappi once again trust our technology and capabilities. We look forward to working with the Sappi team," says Jussi Taskinen, Manager, R&D, Product Portfolio & Strategy at Valmet.

Details about the order

The order consists of a chipping line with a Camura GS1300 chipper and chip handling with storing and screening, including machinery, commissioning, training and start-up supervision. Mechanical installation of the chipping line is also carried out by Valmet.

About Sappi Saiccor mill

The Saiccor mill, situated 50 km south of the port of Durban in the province of KwaZulu-Natal in South Africa, is one of the production facilities for Sappi Specialised Cellulose. The mill has the capacity to produce approximately 800,000 tons of elemental chlorine free (ECF) dissolving pulp (DWP) per annum, mostly for export market. DWP is sold to converters to manufacture a wide range of consumer products, but in particular for viscose staple fibre (VSF) used in clothing and textiles.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2016 were approximately EUR 2.9 billion. Our 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

ANDRITZ successfully starts up rebuilt paper machine for Heinzel Group in Laakirchen, Austria

International technology Group ANDRITZ has successfully started up the rebuilt PM10 at Laakirchen paper mill for the Heinzel Group, Austria. The machine that originally produced SC paper was converted to a fluting and testliner machine producing basis weights ranging from 70 to 140 g/m² based on recycled fibers. With a design speed of 1,600 m/min and a working width of 7,500 mm, it is now one of the world’s most productive paper machines for fluting and testliners.

“We have implemented a comprehensive investment package for our paper mill in Laakirchen. The heart of this package is the PM10 rebuild. The new ANDRITZ technology enables production at the highest quality level. In addition to our PM11, which will continue producing paper for the high-quality SC market, the PM10 produces 450,000 t/y of fluting and testliners,” says Thomas Welt, Production Director at Laakirchen Papier AG.

Successful start-up of PM10 at the Laakirchen mill. © ANDRITZ

Successful start-up of PM10 at the Laakirchen mill. © ANDRITZ

In the stock preparation section, the ANDRITZ scope of supply comprises a complete OCC line with a capacity of 1,350 t/d, rebuild of the existing paper machine approach flow system, as well as sludge and reject handling. The pulping system with detrashing includes a 130 m³ FibreSolve FSR pulper, which is the largest low-consistency pulper ANDRITZ has ever installed in Europe.

The rebuilt paper machine features a PrimeFlow TW double-layer headbox with PrimeProfiler F consistency profiling system. This headbox enables best surface profiles at maximum production flexibility with the stiff separating lamella between the layers. The new PrimeForm TW gap former with a specially designed forming suction roll for higher dewatering capacity gently dewaters the web and ensures high retention rates. Forming shoes at both the top and bottom ensure optimized dewatering within a broad operating window. In combination with the PrimeFilm Sizer unit, high strength is achieved in the end product.

In the first drying group, PrimeRun Evo web stabilizers were installed to improve the runnability of the machine after the press section. PrimeRun Evo web stabilizers are high-vacuum boxes with three different vacuum zones in one box. Thus, the web can be removed carefully from the surface of the drying cylinder. In addition, PrimeRun Duo web stabilizers were installed in the existing pre-drying section and in the new after-drying section to enable an even web run throughout the drying section.

Instead of cast iron cylinders, PrimeDry Steel cylinders are used to achieve the targeted production capacities. They provide up to 7% more drying capacity compared to same-sized cast iron cylinders at the same operating pressure and thus enable either increased production or reduced energy consumption within the space available. In addition, a new air system including heat recovery for the rebuilt drying section was installed to provide energy-efficient paper production.

The new PrimeFilm Sizer applies surface starch to both sides of the paper web simultaneously to achieve the requested strength values. This starch application technology was installed due to the high speed of the machine. The PrimeAir Glide air-turn and the PrimeFeeder tail threading system result in gentle web turning and reliable and fast tail threading.

The scope of supply further includes the entire basic process engineering as well as the complete PrimeControl automation package.

This order once again confirms the strong business relationship between ANDRITZ and the Heinzel Group. ANDRITZ has already started up Europe’s largest new MG paper machine (PM2) successfully at the Pöls mill as well as a new black liquor recovery boiler plant.

The international Heinzel Group – with its affiliates Laakirchen Papier AG, Zellstoff Pöls AG, both in Austria, Raubling Papier GmbH, Germany, and AS Estonian Cell, Estonia – ranks among the largest producers of market pulp, corrugated paper, and magazine paper in Central and Eastern Europe. Containerboard has been part of the group’s portfolio since the beginning of 2016.

ANDRITZ PULP & PAPER is a leading global supplier of complete plants, systems, equipment, and comprehensive services for the production and processing of all types of pulp, paper, tissue, and cardboard. The technologies cover the processing of logs, annual fibers, and waste paper; the production of chemical pulp, mechanical pulp, and recycled fibers; the recovery and reuse of chemicals; the preparation of paper machine furnish; the production of paper, tissue, and cardboard; the calendering and coating of paper; as well as the treatment of reject materials and sludge. The service offering includes system and machine modernization, rebuilds, spare and wear parts, on-site and workshop services, optimization of process performance, maintenance and automation solutions, as well as machine relocation and second-hand equipment. Biomass, steam, and recovery boilers, as well as gasification plants for power generation, flue gas cleaning plants, plants for the production of nonwovens, dissolving pulp, and panelboard (MDF), as well as recycling plants are also part of this business area.

Lucart boosts production performance with a new Toscotec – supplied tissue rewinder at Laval sur Vologne mill, in France.

Lucart has recently started up a new tissue rewinder TT WIND-P supplied by the Italian machinery producer Toscotec at their facility in Laval sur Vologne – France.

The tissue rewinder model TT WIND-P features 2 unwind stands and handles parent rolls of 2900 mm width and 2600 mm diameter at the maximum speed of 1400 mpm. Toscotec’s machinery is equipped with a slitting unit of 150 mm min width, automatic control of all unwinding and rewinding operations and sectional drive system.

This turnkey project includes Toscotec’s proprietary automation and control system. This recently developed system is integrated into Toscotec’s rewinder technology and guarantees a significant increase in efficiency and productivity. Supervision during erection, commissioning and start-up was performed by Toscotec’s Service division YES – Your Expert Service.

The new "state-of-the-art" rewinder serves the PM9 tissue machine and represents another important collaboration between Lucart and Toscotec after the rebuilding of PM10 in late 2016.

Lucart’s sas President Mr. Alessandro Pasquini declared: “Toscotec has been working with us since 2008. They have grown to become a strong partner for Lucart and we are now cooperating on a number of interesting projects. This new rewinder at Laval sur Vologne mill has been performing well and meets our expectations.”

Lucart’s history goes back to the 1930s when the Pasquini family decided to set up a papermaking factory in Villa Basilica (Lucca). Today the Group’s total production capacity is over 300,000 tons/year with 10 paper machines and 58 converting lines.

Welcome to the 1st Annual Pulp Paper World Forum 2018

Today’s pulp and paper industry specialists are constantly being asked how, why and when on a variety of subjects. To ensure they stay ahead and on the forefront of their industry, next to the valuable constant of inter-company learning, it is exclusively through networking and panel discussions that the true sharing of knowledge can move the entire industry forwards.

Today’s pulp and paper industry specialists are constantly being asked how, why and when on a variety of subjects. To ensure they stay ahead and on the forefront of their industry, next to the valuable constant of inter-company learning, it is exclusively through networking and panel discussions that the true sharing of knowledge can move the entire industry forwards.

Pulp Paper World Forum 2018, is the arena where sharing of ideas and experiences from high-quality speakers and companies will bring something unique to the table.

According to the industry, these are the topics that matter

MAIN TOPICS

Innovation and Digitalization -. Industry 4.0

The pulp and paper industry faces a series of transformations driven by digital disruption. In all aspects of business, technology is transforming how the industry operates. While some are fearful, others have already embraced the opportunity to increase efficiency and satisfy growing customer demands whilst developing novel products, technologies and swiftly progressing toward a low-carbon bio-economy.

Service & Maintenance

It is a time of opportunity for the pulp and paper industry as better integration of digital technology leads to major business advantages like less product rework and lower energy use, safer and more efficient work environment, self-monitoring equipment that recommends on repairs, maintenance and ordering parts that has brought a much greater level of customer satisfaction that even before. This evolutionary innovation is bound to continue and while technology has made for tighter profit margins and shifting demands, there is vast potential and this is where specialist, partners, service and logistic providers are essential and will make the difference.

Improving Environmental Impacts – the EU 2020

Energy costs in the industry represent on average 17% or higher of the total production cost at the average mill, globally the pulp & paper industry ranks in the top five consumers of energy, however the continuous technological improvements can further reduce environmental impacts and optimize the use of esources such as raw materials, water, and energy.

Key drivers in the reduction of environmental impacts has been an improved process efficiency and reducing the reliance on fossil fuels and the move to biomass CHP plants and the use of residues for bio based products.

Ian Melin-Jones

Event Director

Contact: This email address is being protected from spambots. You need JavaScript enabled to view it.