International technology group ANDRITZ will be presenting its innovative technologies for sustainable paper production at MIAC 2021, booth #71, in Lucca, Italy, from October 12 to 15, 2021.

The ANDRITZ experts are looking forward to presenting the latest innovations and developments in the following areas:

- In fiber preparation, ANDRITZ will present its latest Prime technologies for enhanced fiber quality with economical use of resources, for example the PrimeFilter D, the cutting-edge technology in thickening and fiber recovery.

- For the tissue, paper and board industry, ANDRITZ will show its capabilities in the area of rebuilds, complete lines, and services with focus on sustainability and cost-efficiency, for example steel Yankees – giants up to 26 ft. in diameter – that enable energy-efficient drying at 8-10% better machine performance compared to cast-iron Yankees.

- The experts at ANDRITZ Fabrics and Rolls provide tailor-made roll covers, spreader rolls, shoe press belts and paper machine clothing solutions like the new StrataPress felt technology – a game-changing combination of materials, to deliver high sheet quality and reduced energy consumption at given machine speeds – or ANDRITZ’s durable, high temperature and contamination resistant MasterDry dryer fabrics that are specifically designed for extended fabric running times.

- The ANDRITZ service team will show ways of increasing the reliability, efficiency, and availability of process equipment regardless of the OEM, including service highlights like Yankee coating and on-site assembly.

- In the pumps business, ANDRITZ will show its broad pumps portfolio for all industrial applications and processes in the pulp and paper industry, including topics like model tests and after-sales service.

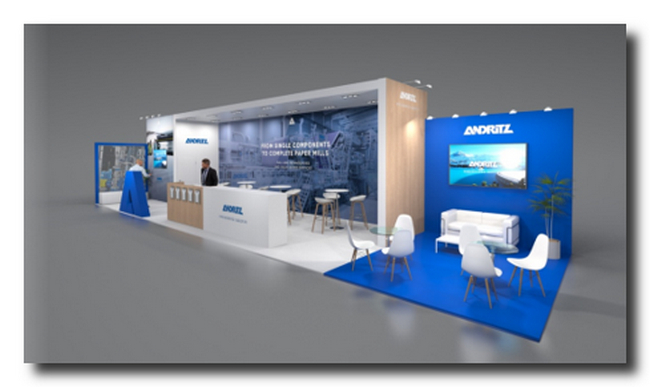

ANDRITZ will present its latest innovations for state-of-the-art paper production and value-added services at MIAC 2021 (booth no. 71). “Photo: ANDRITZ”.

ANDRITZ will present its latest innovations for state-of-the-art paper production and value-added services at MIAC 2021 (booth no. 71). “Photo: ANDRITZ”.

In conference speeches, ANDRITZ experts will also be presenting the latest solutions for efficient, sustainable paper production:

- Guido Lenzi, Sales Manager ANDRITZ Novimpianti, will be speaking about ANDRITZ’s solutions for upgrade of combustion systems to save resources and costs.

- Vincenzo Melilli, Senior Manager Technology and R&D Paper and Board ANDRITZ, and Mario Bernasconi, Senior Sales Manager Paper and Board ANDRITZ, will be introducing ANDRITZ’s cost-efficient technologies for sustainable paper and board production, including the world’s fastest kraftliner shoe-blade Gapformer and a 2,000 kN/m shoe press.

ANDRITZ is looking forward to meeting you in Lucca! Visit https://www.miac.info/en/preregister/ to register free of charge for the event or contact us at This email address is being protected from spambots. You need JavaScript enabled to view it..

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,700 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.