Displaying items by tag: acelli paper

A.Celli and SINAMICS upgrade: stepping into the future!

Two Paper Rewinders E-WIND® P100 for Liensheng Paper (Shanying Group)

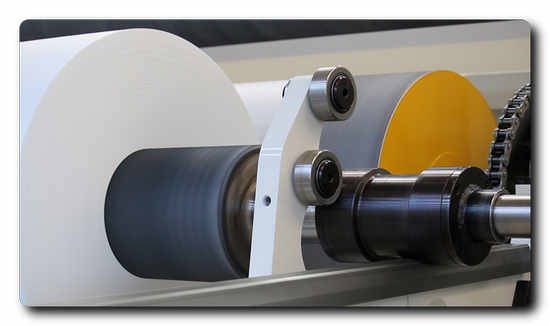

A.Celli Paper is pleased to confirm its ongoing and valuable collaboration with the Chinese group Shanying Huazhong Paper Industry Co., Ltd., enshrined in the agreement for the supply of two latest generation E-WIND® P100 rewinders, for the mill located in Zhangzhoi City, in Fujian province, China.

The E-WIND® P100 Paper Rewinders, highly developed in terms of design, will have a paper width of 6660 mm and will guarantee a maximum production speed of 2500 mpm (operating speed).

They are combined with sophisticated technological innovations including:

- Innovative Slittomatic® double motor cutting unit positioning system;

- Web-in technology, the automatic system that maximises the management of positioning cutting units without the need to break the web, with considerable time and safety savings for operators;

- Jumbo roll parking station and shuttle (mobile trolley on rail) for their handling.

These two rewinders have been selected by the Chinese group to process medium board paper, with basis weight range from 80 up to 160 gsm.

Liansheng Paper had already purchased two other rewinders, with the same width, in 2016 and Shanying Group, of which the paper mill is part, bought two large-width paper rewinders (8 meters) from A.Celli last year.

An important new confirmation of a consolidated partnership between Shanying Group and A.Celli, which underlines the success of the paper rewinders A.Celli E-WIND®.

Shan Don Sun Honghe Paper Industry Co., Ltd and A.Celli Paper for a new E-WIND® P-100 paper rewinder

The Chinese customer has confirmed its trust in the A.Celli Group, signing a new contract for the order of the E-WIND® P-100 paper rewinder, whose delivery is scheduled for July 2019.

The new rewinder is destined to the Shandong plant and will be installed downstream of the PM36 and PM37 paper lines; it has the design speed of 2500 mpm, with the mother roll width of 6660 mm and will be dedicated to the production process of Medium Liner Board paper. This product, having the weight range between 60 and 110 gsm, requires extremely precise control of the web tension and of the process stability. It is equipped with the Slittomatic Web-in automatic system, which allows the slitting units to be positioned without breaking the sheet, with considerable time savings.

The partnership between A.Celli and Shan Don Sun Honghe Paper Industry, about rewinders, dates back to the mid-2000s and was consolidated in 2014 with the supply of three E-WIND® P-100 rewinders, similar to the one sold recently in features and with the same paper format.

Another success for A.Celli: the commissioning of a winder and rewinder in Poland!

A Stream winder and Rapid rewinder have been installed with success!

A.Celli Nonwovens has proven once again to be a benchmark company in the global market of non-woven fabric with the installation of a winding and rewinding system for Spunlace products at the plants of Novita S.A. in Poland, and the commissioning of the system on February 7th.

Novita S.A. has operated on the non-woven fabrics market for over 40 years, offering high-quality hygiene, industrial, medical and home products created by applying the best technologies to its production processes of which A.Celli machines now form a part.

In detail, A.Celli supplied:

– a Stream winder of 3600 mm that handles reels up to 2500 mm in diameter, with basis weights from 25 to 100 gsm and designed specifically for carded products. It is highly reliable and requires minimum maintenance, and has a maximum operating speed of 350 m/min;

– a Rapid Rewinder of 3600 mm, calibrated for reels up to 1200 mm in diameter, with basis weights from 25 to 100 gsm and an operating speed of 800 m/min. It is equipped with the “DSS” (defect stop system) that monitors the reel and signals any defects to be removed. The system also has a second metal detector installed on the rewinder for the purpose of avoiding metallic contamination. An automatic shaft handling unit for management of the shafts and positioning of the cardboard cores was also supplied with the rewinder.

iDEAL® forged YD: a new state-of-the-art Yankee has been shipped to Mexico

More and more affirmations for the A.Celli’s forged steel patented solution.

A.Celli Paper is pleased to announce the delivery of another iDEAL® Forged_YD new generation Yankee.

Particularly, we are talking about a valuable collaboration with the Mexican customer Grupo Corporativo Papelera, sealed with an agreement for the supply of a new generation iDEAL® Forged_YD – 16” Yankee Cylinder for the El Tepetloxto plant, in Mexico.

iDEAL® forged YD is the new production technology, conceived and patented by A.Celli Paper, which allows us to make cylinders with a seamless shell, starting from a single piece of steel that is shaped and worked with hot forging and rolling systems.

The result is a homogenized and high-quality manufacturing material structure.

A.Celli Paper iDEAL® forged YD: the future of Steel Yankee Dryers!

Two 8-metre Paper Rewinders for Shanying Huazhong Paper Industry Co., Ltd

A.Celli Paper is pleased to confirm its ongoing and valuable collaboration with the Chinese group Shanying Huazhong Paper Industry Co., Ltd., enshrined in the agreement for the supply of two latest generation E-WIND® P100 rewinders, for the mill located in Jingzhou District, China.

The E-WIND® P100 Paper Rewinders, highly developed in terms of design, will have a paper width of 7960 mm and will guarantee a maximum production speed of 2500 mpm (design speed).

They will be able to accommodate large reels on the unwinder, with diameters up to 3800 mm and weighing about 65 t.

In addition, they are combined with sophisticated technological innovations including:

- Web-in technology, the automatic system that maximises the management of positioning cutting units without the need to break the web;

- Built-in spool-parking.

The machines, with start-up scheduled for the third quarter of 2019, will allow the Chinese group to process high-quality flat-paper and test-liner paper of the lowest grammage (from 50 to 110 gsm).

This new investment by Shanying Huazhong Paper Industry is further confirmation of how technologically reliable and evolved Paper A.Celli E-WIND® Rewinders can prove to be, and now A.Celli Paper is considered a valuable and expert partner, able to constantly support its customers, building and cultivating important professional relationships.

iDEAL® forged YD: another new-generation Yankee has been shipped

A further confirmation for the A.Celli Group after the presentation of the patent during the “iT’s Tissue 2018” event

At the end of last December, a new 15’ iDEAL® Forged YD was shipped to the customer PartexTissue Ltd, in Bangladesh.

The latest generation Yankee is an integral part of the project for a complete turnkey plant consisting of an iDEAL-1800 Tissue Machine, a E-WIND T100 rewinder with three unwinders and the A.Celli R-WAY roll handling system.

The customer has chosen a highly innovative A.Celli product, the iDEAL® forged YD, created using the new patented technology that involves the production of the dryer cylinder shell starting from a single piece of steel shaped and worked with forging and hot rolling systems.

From this particular process a homogeneous material is obtained; the unique seamless structure allows greater variation in operating pressure and definitively eliminate the risk of welding failures.

Innovation, safety, efficiency, the A.Celli Group’s basis of research.

A.Celli Paper and Global Hygiène for a turn-key tissue plant project

A.Celli Paper is pleased to begin a valuable collaboration with the French company for the supply of a complete tissue production plant.

Global Hygiène has chosen to rely on A.Celli Paper technology for the order of a complete turnkey plant to be installed in Charavines, in southeastern France.

The French company has secured the A.Celli technological excellence, from the stock preparation to the roll handling system.

The new iDEAL®1800S machine will have a 2850 mm format and an operating speed of 1800 mpm. The project also includes an E-WIND® T100 rewinder and a R-WAY® roll-handling system.

The Yankee supplied is the forged one of the latest A.Celli generation and has a diameter of 15’.

Luc Brami, CEO of Global Hygiène, said that the production of Charavines, estimated in 30.000 t/y, will cover the needs of the two Global Hygiène group’s converting plants, in Auxonne and Vern d’Anjou, consolidating the company’s leadership position in the market for hygienic products.

As usual A.Celli has given its total availability in experience and professionalism to the customer, with a full spirit of partnership.

The delivery is expected for the fourth quarter of 2019.

A.Celli Rebuilding: Shaniv Paper Industries Tissue Machine TM1 launched

In early October, the Customer Service team at A.Celli Paper launched the Tissue Machine TM1 of Shaniv Paper Industries Ltd, the second largest Israeli paper manufacturer for home use.

The operation consisted in the supply of a new reel, an innovative DCS system, a set of more efficient motors, renewed roller equipment and the relative drives. The dryer roller (Yankee Dryer) was also insulated by shielding the heads with a layer of coating.

The operation, completed by a team of qualified technicians, allowed the machine to reach the speed of 1500 mpm for the production of high quality tissue paper.

The ambitious project was carried out in full compliance with the client's expectations, which complimented the team of A.Celli Paper for the excellent work performed.

The technicians will also accompany the customer's operators during this first post-start phase, for a brief period of baby sitting based on the well-known spirit of partnership that has always distinguished the A.Celli Group.

A new A.Celli E-WIND® T80S rewinder for Fapajal

Portuguese Producer chooses A.Celli Paper for its new investment

It is with extreme satisfaction that A.Celli Paper S.p.A. announces the start of a precious collaboration with Fapajal – Fábrica De Papel Do Tojal, S.A. through the agreement for the supply of a latest-generation E-WIND® T80S rewinder for the production of tissue.

A.Celli Paper E-WIND® T80S is a modular and fully automated rewinder, running at 1000mpm, with built-in electrical cabinets, capable of managing products that involve a specific volume, diameter and cutting format while also guaranteeing extra capacity during production peaks.

It is customisable, plug-and-play, perfectly adaptable and compatible with any standard rewinding system or complete line in the tissue sector.

Yet another confirmation for A.Celli Paper technology that is even more present and is capable of meeting the needs of different customers, promptly answering the motley production variables with flexibility.

COMPANY PROFILE

Fapajal has a paper-making tradition dating back to 1755 and is currently focussed on producing tissue paper. Headquartered in São Julião do Tojal, Loures, the Company relies on the contribution of over 150 employees and approximately 50 outsourced employees.