Ian Melin-Jones

Unboxing - this year's theme for international packaging design competition PIDA

For the fourteenth consecutive year, BillerudKorsnäs organizes the international packaging design competition Packaging Impact Design Award (PIDA). Together with approximately 200 students from leading design universities in Sweden, Germany, France and England, the packaging phenomenon unboxing will be challenged.

Unboxing, the moment when a packaging is opened for the first time, is not only the consumer's first encounter with a product, but also increasingly critical for a brand's ability to make a first personal, and through social media, global impression. The possibility of differentiation through unboxing is the theme of the 2018 edition of BillerudKorsnäs design contest PIDA.

However, the brief to the contestants is more far-reaching than just embracing the first impression. It is about creating a sustainable, innovative and functional packaging concept with a unique unpacking experience that differs from the conventional solutions we see in stores and e-commerce today.

"During the fourteen years we have worked with PIDA, the competition has succeeded in becoming an international institution and one of the most important meeting places for new generation packaging designers and the established industry with brand owners, converters and design agencies. PIDA is a way for us to push forward the development of sustainable packaging design and this year we want to challenge conventional packaging solutions by bringing unboxing to a new level where it can reach its full potential in terms of creativity, sustainability and innovation,"says Lena Dahlberg Manager Carton Solution at BillerudKorsnäs.

Three competitions and new international "public award"

The competition brief was sent to the participants during January and the concept presentation/announcement of winners will occur at three separate events; in Stockholm on May 22 for Swedish and English students, in Paris on June 21 for French students and in Ludwigsburg on November 8 for German students. A novelty this year is the addition of an international award, the Peoples Choice Grand Final Award, where the public is invited to designate a total winner via Facebook. The nomination of the respective winners from England, France, Sweden and Germany starts after all regional competitions have been settled, and the entry that receives the most likes and shares is then named as the total winner of Peoples Choice Grand Final Award.

About PIDA

BillerudKorsnäs Packaging Impact Design Award (PIDA), has been organized annually since 2005 in collaboration with leading colleges and universities in France, Germany and Sweden. The goal with the competition is to put the packaging at the center and show how significant packaging is for both the product and the environment. Every year, approximately 200 design students participate in the competition, which is an integral part of the education. Read more about PIDA at http://pida.billerudkorsnas.com/ and https://www.facebook.com/PIDAcommunity/

BillerudKorsnäs provides packaging materials and solutions that challenge conventional packaging for a sustainable future. We are a world-leading provider of primary fibre based packaging materials and have customers in over 100 countries. The company has 8 production sites in Sweden, Finland and the UK and about 4300 employees in over 13 countries. BillerudKorsnäs has an annual turnover of about SEK 22 billion and is listed on Nasdaq Stockholm. www.billerudkorsnas.com

Toscotec’s TT SYD-18FT is running efficiently for reconstituted tobacco production at Fujian Jinmin, China.

Toscotec’s steel Yankee dryer TT SYD-18FT was successfully fired up at Fujian Jinmin Reconstituted Tobacco Development Co., Ltd., a subsidiary of China National Tobacco Corporation, at its Luoyuan mill, Fujian, China. The TT SYD reached top performance immediately after start-up at the end of March.

The advantages of TT SYD can benefit all grades and types of paper, not least reconstituted tobacco paper. After Toscotec’s successful reconstituted tobacco application in the U.S., the Chinese reconstituted tobacco paper producer Fujian Jinmin is now operating a big diameter TT SYD, which guarantees top drying efficiency at the lowest possible consumption cost.

From the delivery of the first TT SYD in 2000 throughout 18 years of successful and safe applications and two generations of design, this achievement further reinforces Toscotec’s position as the number one supplier of steel Yankee dryers worldwide. The number of TT SYD sold in five continents around the globe has recently reached more than 200 units, way ahead of the competition. Based on its ever-growing experience, Toscotec has constantly been upgrading its design and it is currently in the process of honing the third generation of TT SYD.

Archroma to highlight eco-advanced solutions for enhanced packaging and paper at TAPPI’s papercon 2018

Archroma, a global leader in color and specialty chemicals, will be at TAPPI’s PaperCon 2018 to highlight Archroma’s solutions and expertise to enhance both the optical and functional properties of board and paper – with a special focus on sustainability.

- Visit Archroma at TAPPI’s PaperCon 2018, Booth #923, Charlotte Convention Center, Charlotte, NC, USA, April 15-18, 2018

- Meet OBA expert Andrew Jackson presenting new Leucophor® ACK at TAPPI’s PaperCon New Technology Showcase on April 17, 2018

- Join the Archroma team at the TAPPI’s 14th Annual Runnability 5k Fun Run/Walk on April 18, 2018

Archroma is at TAPPI’s PaperCon 2018, Booth #923. (Photo: Archroma)

Archroma is at TAPPI’s PaperCon 2018, Booth #923. (Photo: Archroma)

With a one million square foot facility in Martin, South Carolina, the company is one of only a few specialty chemical and dye manufacturers in the US dedicated to serving the paper and textile industry.

Archroma strongly believes, based on its extensive experience in packaging and paper solutions, that sustainability can generate innovation, performance and can even lead to cost reductions for customers.

Visitors at Booth #923 will be able to explore solutions for:

Eco-advanced brightness and whiteness from concentrated Leucophor® liquids

Archroma will take the opportunity of TAPPI’s PaperCon to introduce its new patented disulfonated fluorescent whitening agent (FWA), Leucophor® ACK liquid, to North American papermakers. Bringing a new ecological focus to the field of FWA, Archroma’s ultra-concentrated Leucophor® ACK liquid is free of urea and other additives that increase nitrogen load and COD in back- and wastewaters, while its higher actives content brings advantages of fewer deliveries, reduced freight costs, lower greenhouse gas emissions and better use of storage capacity. Leucophor® ACK liquid enables brilliant whiteness in stock and coating applications, and complies with major international eco-labels.

New patented, urea-containing alternative, Leucophor® ACS liquid, retains the advantages of fewer deliveries, reduced freight costs, better use of storage capacity and a lower carbon footprint.

- Leucophor® ACK liquid has been selected for the TAPPI’s PaperCon New Technology Showcase program. Archroma’s global OBA expert Andrew Jackson will deliver a short presentation of the technology on Tuesday, April 17, 2018 around 12:00pm.

Stronger, more sustainable packaging and paper – Cartastrength® & Cartaseal®

Archroma offers a unique system combining: 1) Its Cartastrength® process chemicals to increase the stability of corrugated fiberboard and allow manufacturers to achieve high levels of dry strength with lower amounts of fresh fibers; and 2) the coatings from its Cartaseal® range including fluorine-free alternatives to wax water barriers that facilitate recycling by breaking down during repulping without the need of further additives.

Archroma will present at the booth the latest addition to the range, Cartastrength® HWM liq, which provides high performance wet strength in particular to tissue paper, whist coming in high solids form for low shipping and storage costs. Cartastrength® HWM liq is FDA compliant and displays lower AOX (Adsorbable organic halides) than typical Grade 1 products.

Prevention of stickie and pitch contamination. Pulp & paper deposit control – Cartaspers®

Pitch and stickies are the result of natural resin residues and other adhesive material found in wood fibers and in address labels or self-sealing envelopes. Both can seriously compromise recycled papermaking by clogging up machinery and causing unwanted agglomerations and deposits.

Archroma’s Cartaspers® polymers can solve that problem in different ways. The latest innovation in the range, Cartaspers® PLH liquid, is a single-product breakthrough enabling easy and highly-effective control of pitch and stickies deposition especially in soft water pulp and papermaking environments. Pulp mill tests already report easier application, better performance and significant cost savings compared to alternative deposit control systems.

Cartaspers® is a replacement for talc-based products; it is a liquid form solution offering both consistent quality and easier application than talc. Easy to use and effective in a wide variety of environments, our deposit control polymers reduce downtime, improve end-product quality and bring a host of other economic and ecological advantages.

Eco-advanced, high performance oil and grease barrier for food packaging – Cartaguard®

When applied to products such as fast food boxes and wrappers, pet food packaging, molded pulp plates and boxes containing bouillon cubes, Archroma’s Cartaguard® KST & KMP coatings provide strong and long-lasting barrier against grease and water.

The series includes an additive that has been optimized for the production of molded pulp packaging and can be added to thick stock.

These cationic fluoropolymers have been approved for food contact both by the American FDA and Germany’s Federal Institute for Risk Assessment (BfR).

Supporting the next generation of papermakers

Last but not least, Archroma is a proud official sponsor of the TAPPI’s 14th Annual Runnability 5k Fun Run/Walk that will take place on Wednesday, April 18th, 2018. The event aims at helping bright students achieve a future career in the pulp and paper industry. All proceeds will go to supporting TAPPI’s Scholarship Funds.

“At Archroma, we deliver innovative colors and chemicals to safely enhance your products and brands, while respecting the planet. As we like to say: It’s our nature! We strive to show customers how we can develop creative solutions together and reduce the environmental impact of their products and production processes,” comments Robin McCann, Head of Sales, North America, Packaging & Paper Specialties, at Archroma.

Leucophor®, Cartastrength®, Cartaseal®, Cartaspers® and Cartaguard® are trademarks of Archroma registered in many countries.

© 2018 Archroma

About Archroma

Archroma is a global color and specialty chemicals company headquartered in Reinach near Basel, Switzerland. It operates with 3,000 employees over 35 countries and with 24 production sites. Its three businesses – Brand & Performance Textile Specialties, Packaging & Paper Specialties, and Coatings, Adhesives & Sealants – deliver specialized performance and color solutions to meet customers’ needs in their local markets, touching and coloring people’s lives every day, everywhere.

Archroma is passionate about delivering leading and innovative solutions, enhancing people’s lives and respecting the planet. The company is committed to challenging the status quo in the deep belief that it can make its industry sustainable; an approach reflected in its innovations, world-class quality standards, high service levels and cost-efficiency. Products enhanced, colors enhanced, performance enhanced – “Life enhanced”.

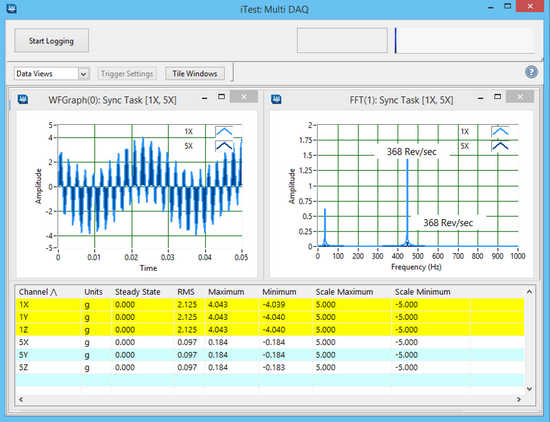

ITM Announces Newest Release of Engineering Measurement Platform, iTestSystem

Integrated Test & Measurement (ITM), a leading provider of structural test and measurement engineering software, test and monitoring systems, and related services, announces the latest release of its software platform, iTestSystem. Specifically designed for use with National Instruments (NI) cDAQ hardware, the iTestSystem software suite enables test engineers to organize, acquire, view and analyze important engineering data.

This latest release contains a number of enhancements including support for additional data acquisition hardware along with advanced event triggering functionality. These and other enhancements give engineers a tool to collect, analyze and trend data from sensors connected to their products and processes enabling them to predict failures, evaluate operating conditions and determine vibration levels.

iTestSystem v16 New Features & Enhancements:

- Automated Data Collection / Trending

- Expanded Data Acquisition Hardware Support

- Automated Data Analysis

- Enhanced Tools for Data Viewing & Analysis

- New Data Management and Email Notification Services

iTestSystem Platform Manager, Chase Petzinger comments:

“Our newest release of iTestSystem software contains a number of customer-driven enhancements and new functionality across the board. Of note is an advanced triggering feature in MultiDAQ (iTestSystem’s data acquisition application) that will help ensure comprehensive data collection. As a key unattended testing component, MultiDAQ is configured to collect data at regular intervals. Our newest release takes this a step further by triggering data capture when certain conditions are met and only during times when the system is active. This ensures that anomalies and other key events are captured and made available to the test engineer without wasting disk space.”

Information

A complete list of software features and specifications, along with other ITM products and services, is available by calling 1-844-837-8797, e-mailing This email address is being protected from spambots. You need JavaScript enabled to view it. or on the web at itestsystem.com.

About ITM

Headquartered in Milford, OH (USA), Integrated Test & Measurement, LLC (ITM) focuses on three vertical spaces: Industrial Monitoring, Testing Services, and Configuration-based Test Software, iTestSystem. Founded in 2001, ITM helps companies reduce costs and improve efficiencies in product development, manufacturing, and production activities. Today, ITM provides software development, structural and mechanical testing services, industrial monitoring, strain gauging, and data analysis solutions to clients on six continents. For more information on ITM, iTestSystem and ITM’s other products and services visit itestsystem.com

Voith BrokeGo: Efficient transport of waste paper

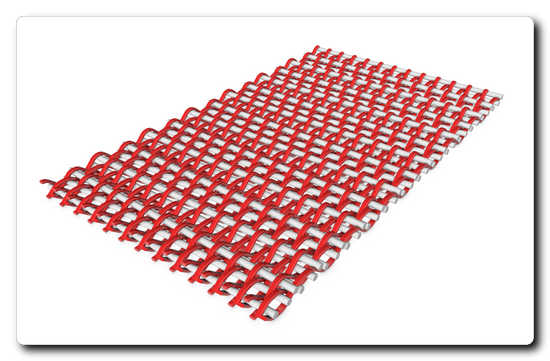

With BrokeGo, Voith has developed a reliable fabric for broke conveyors which quickly and safely removes broke following a web break. The strong and highly wear-resistant belt transports the broke directly to a pulper for further processing.

The ribbed surface of the Voith BrokeGo stops the paper slipping from the belt. The underside is made from wear-resistant material, which results in a longer service life.

The ribbed surface of the Voith BrokeGo stops the paper slipping from the belt. The underside is made from wear-resistant material, which results in a longer service life.

Web breaks cannot always be avoided. Generally, the broke paper drops into an area underneath the machine. To remove this broke efficiently and safely, Voith has developed BrokeGo, which is suitable for all paper grades. The ribbed upper surface stops the paper slipping from the belt. The underside is made from wear-resistant material, which results in a longer service life.

BrokeGo needs to have very different properties from the dryer fabrics that are often used as conveyor belts in the broke conveyor. BrokeGo was specially developed to meet the specific requirements of paper transport after web breaks in particular.

About Voith Paper

Voith Paper is a Group Division of Voith and the leading partner and pioneer in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-conserving products to reduce the use of energy, water and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

About Voith

Voith is a global technology group. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, Voith today has more than 19,000 employees, sales of €4.2 billion and locations in over 60 countries worldwide and is thus one of the largest family-owned companies in Europe.

Voith and SEPAC: Successful partners in yet another tissue machine start-up in Brazil

Voith Paper, world leader in innovation for the paper industry, completed the successful start-up of the TM 6 XcelLine machine at SEPAC, a company headquartered in the Brazilian state of Paraná that is among the country’s five largest manufacturers of tissue paper for sanitary purpose. Installed in the company’s Mallet plant in Paraná, the TM 6 machine went into service at the end of 2017 and produced paper within the necessary quality specifications from the very first day. The machine is capable of producing nearly 110 metric tons of paper per day and has a design speed of 2,000 meters per minute.

Voith’s scope of supply covered the entire tissue machine, which was fitted with a MasterJet Pro T headbox, a CrescentFormer, a NipcoFlex T shoe press, an EvoDry Y steel Yankee cylinder, a high-efficiency EcoHood T hood and a MasterReel winder. The project also included the ancillary systems, automation systems, as well as installation supervision, commissioning and complete start-up assistance.

Voith’s scope of supply covered the entire tissue machine, which was fitted with a MasterJet Pro T headbox, a CrescentFormer, a NipcoFlex T shoe press, an EvoDry Y steel Yankee cylinder, a high-efficiency EcoHood T hood and a MasterReel winder. The project also included the ancillary systems, automation systems, as well as installation supervision, commissioning and complete start-up assistance.

The project’s main features are the NipcoFlex T shoe press and its 4.8 meter steel Yankee cylinder, which besides ensuring greater speed and quality, enables SEPAC’s machine to consume up to 20 percent less thermal energy.

The project is part of the growth strategy pursued by SEPAC, a company focused on manufacturing tissue paper from virgin cellulose fibers, and will increase its annual production capacity to approximately 180,000 tons, making it one of the country’s largest tissue manufacturers. SEPAC’s growth strategy began in 2007, with the purchase of its TM 3 from Voith. Over the last ten years, Voith has supplied four tissue machines to SEPAC – a clear demonstration of the successful partnership built on trust and respect that the companies have developed over the period.

About SEPAC

Sepac is one of Latin America’s largest tissue paper producers, with 40 years of experience in the domestic and international markets. Headquartered in the state of Paraná, the company is a market leader in the segment of tissue paper for sanitary purposes in Brazil’s South Region. Its state-of-the-art manufacturing facilities in Mallet (located in the Brazilian state of Paraná) and its successful distribution network reinforce the company’s significant growth potential. Sepac’s towels, napkins and toilet papers are marketed in all regions of Brazil and the Mercosur countries under the Duetto, Paloma, Maxim and Stylus brands.

In 2017, Sepac also joined the personal care segment with the launch of its BabyBoo disposable diapers brand. The operation is initially focused on the special and value segments with the BabyBoo “Fases” and BabyBoo “Dia a Dia” lines, which are distinguished by their attributes of absorption, comfort and anatomical shape.

About Voith Paper

Voith Paper is a Group Division of Voith and the leading partner and pioneer in the paper industry. Through constant innovations, Voith Paper is optimizing the paper manufacturing process, focusing on developing resource-conserving products to reduce the use of energy, water and fibers. Furthermore, Voith Paper offers a broad service portfolio for all sections of the paper manufacturing process.

About Voith

Voith is a global technology group. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, Voith today has more than 19,000 employees, sales of €4.2 billion and locations in over 60 countries worldwide and is thus one of the largest family-owned companies in Europe.

Metso to acquire the valve automation division of India based Rotex Manufacturers and Engineers Pvt. Ltd

Metso has signed an agreement to acquire the valve automation division of the India-based valve technology company Rotex Manufacturers and Engineers Pvt. Ltd (RMEPL). The company has a market-leading position in India in the actuator business and an advanced offering of switches, process valves, and valve automation products and solutions.

The acquired division's sales in the last fiscal year ending March 31, 2018, were approx. INR 1,550 million (EUR 19 million) and it employs approximately 275 people. It has two manufacturing facilities in the Mumbai area and sales offices in Mumbai, Vadodara, Kolkata and Pune.

Rack & Pinion actuator is a competitive solution which can be used in several applications and industries

Rack & Pinion actuator is a competitive solution which can be used in several applications and industries

The acquisition will complement Metso's actuation and valve automation offering and enable a full range of actuators for all major valve markets and a broader offering of limit switches for mid-market applications. It also introduces new products to Metso's process-valve portfolio for the oil and gas, pulp and paper, mining, water treatment and other process industries.

"This acquisition represents an important strategic step for Metso's valves business. It expands our offering for the current customer segments, especially outside North America, and increases our presence in attractive new industries and application areas," says John Quinlivan, President, Valves business area, Metso. "In addition, the acquisition strengthens our capacities and our presence in the important Indian market."

"We are confident that RMEPL's capabilities and technological solutions will align perfectly with Metso's offering and global valve network. This acquisition will benefit our customers and employees who have been the most important asset of the Rotex Group," says Amit Shah, Managing Director, RMEPL.

Closing of the acquisition is estimated to occur in July 2018 subject to satisfaction of customary closing conditions. The parties have agreed to not disclose the value of the transaction.

About Rotex Manufacturers and Engineers

Rotex Manufacturers and Engineers is part of the privately-owned Rotex Group. It produces actuators, limit switches, valve automation components and valves. Its customers include major original equipment manufacturers (OEMs) of valves, engineering, procurement and construction (EPC) companies, and mainly India-based major end customers in the oil and gas and power industries. Rotex Group will continue to retain full ownership in other businesses, including solenoid valves, positioners, electro-hydraulic controls for actuators, and its German subsidiary, Magwen valves.

Metso is a world-leading industrial company offering equipment and services for the sustainable processing and flow of natural resources in the mining, aggregates, recycling and process industries. With our unique knowledge and innovative solutions, we help our customers improve their operational efficiency, reduce risks and increase profitability. Metso is listed on the Nasdaq Helsinki in Finland and had sales of about EUR 2.7 billion in 2017. Metso employs over 12,000 people in more than 50 countries. metso.com

Twin Rivers Paper Announces Agreement to Acquire Pine Bluff, Arkansas Paper Mill from Mondi Group

Twin Rivers Paper Company LLC has just announced that it has entered into a definitive agreement to acquire the paper mill located in Pine Bluff, Arkansas owned by Mondi Group. Twin Rivers, headquartered in Madawaska, Maine, produces specialty packaging, label, publishing, and technical specialty papers as well as dimensional lumber. It is owned jointly by Atlas Holdings LLC and Blue Wolf Capital. The acquisition is anticipated to be completed in Q2 2018. Terms were not disclosed.

The mill to be acquired under this agreement produces Multiwall, Converting and Grocery Bag grade unbleached kraft papers serving a variety of food, agricultural, and industrial applications. With basis weights between 40# and 78#, the mill has a capacity in excess of 140,000 US short tons.

The mill to be acquired under this agreement produces Multiwall, Converting and Grocery Bag grade unbleached kraft papers serving a variety of food, agricultural, and industrial applications. With basis weights between 40# and 78#, the mill has a capacity in excess of 140,000 US short tons.

“Twin Rivers is a nimble, high quality, integrated forest products company that is well positioned as a market leader in the packaging, publishing, label and technical specialties markets,” said Bob Snyder, Chief Executive Officer of Twin Rivers. “The addition of the Pine Bluff mill is consistent with the evolution of our company and fully complements our overall mill system, product offerings and strategic direction.”

“We are very pleased with the opportunity to add this facility and its valued associates to our company,” said Ken Winterhalter, President of Twin Rivers. “The proposed transaction will provide a logical grade-line extension to our current offerings and is

evidence of our ongoing commitment to enhance the value we provide to our customers.”

“With this agreement and its recent acquisition of Burrows Paper, Twin Rivers continues to strengthen its hold atop the marketplace,” said Tim Fazio, Co-Founder and Managing Director of Atlas Holdings. “This is an exciting step for the business and we look forward to welcoming the team in Pine Bluff to the Twin Rivers family.”

“We are excited to add Pine Bluff to the Twin Rivers portfolio,” said Adam Blumenthal, Managing Partner of Blue Wolf Capital. “The strategic acquisition positions the company well to grow with and better serve its customers and other stakeholders.”

Clemens Willee, CEO Packaging Paper, Mondi Group, said, “We believe that the interests of the mill and its employees are better served by the new owners where there is a closer long-term strategic alignment.”

About Twin Rivers Paper Company

Twin Rivers Paper Company, headquartered in Madawaska, Maine, is an integrated specialty paper company that produces specialty packaging, label, publishing, and technical specialty papers as well as dimensional lumber. Targeting its manufacturing capabilities to specific market segments, Twin Rivers creates competitive advantages through nimble innovation

and product development, service excellence and an unfailing commitment to quality. The company’s brands include Acadia® packaging products, Alliance® label products, and Pharmopaque® pharmaceutical papers. Twin Rivers is owned jointly by Atlas Holdings LLC and Blue Wolf Capital. For more information, visit

About Mondi Group

Mondi is a global leader in packaging and paper, employing around 26,000 people in over 30 countries. We are fully integrated across the packaging and paper value chain - from managing forests and producing pulp, paper and plastic films, to developing and manufacturing effective industrial and consumer packaging solutions. Sustainability is embedded in everything we do, with clearly defined commitments across 10 action areas. We delight our customers with our innovative and sustainable packaging and paper solutions.

Our major operations are in central Europe, Russia, North America and South Africa. In 2017,

Mondi had revenues of €7.1 billion and a return on capital employed of 19.7%.

Mondi has a dual listed company structure, with a primary listing on the JSE Limited for

Mondi Limited under the ticker MND and a premium listing on the London Stock Exchange for Mondi plc, under the ticker MNDI. We are a FTSE 100 constituent, and have been included in the FTSE4Good Index Series since 2008 and the JSE's Socially Responsible Investment (SRI) Index since 2007.

Valmet to supply automation technology to PT. Buana Megah in Indonesia

Valmet will supply automation technology to PT. Buana Megah's PM3 board machine in Pasuruan, East Java, Indonesia. Valmet's delivery includes Valmet DNA automation system, Valmet IQ quality control system and consistency transmitters. The order is included in Valmet's first quarter of 2018 orders received. The delivery is scheduled to take place in the third quarter of 2018.

The board machine will have an annual capacity of 62,780 tons of board. It will produce board and liner. The production is expected to start up in the end of 2018. With Valmet's automation solution for process and quality control and consistency transmitter technology, the mill will be able to optimize machine performance and achieve the set high-quality goals.

The board machine will have an annual capacity of 62,780 tons of board. It will produce board and liner. The production is expected to start up in the end of 2018. With Valmet's automation solution for process and quality control and consistency transmitter technology, the mill will be able to optimize machine performance and achieve the set high-quality goals.

"Valmet is capable of offering a complete automation package, including all process controls with Valmet DNA, quality control with Valmet IQ and consistency transmitters. Our long tradition of innovative automation solutions and professional project management are in our favor," says Pete Teh, Country Manager, Indonesia, Automation, Valmet.

Information about Valmet's delivery

Valmet's delivery comprises of Valmet DNA automation system with total of 2,150 I/Os and a Valmet IQ quality control system including a scanner with basis weight and moisture measurements as well as a standalone moisture measurement. Four Valmet Microwave Consistency Transmitters (Valmet MCA) and 14 Valmet Blade Consistency Transmitters (Valmet SP) ensure better measurements and controls. This comprehensive automation package will enable the mill to optimize its processes and achieve premium end-product quality.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2017 were approximately EUR 3.1 billion. Our more than 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more http://www.valmet.com

APP successfully starts up Toscotec’s Prodergy tissue machine at its Perawang mill.

Toscotec’s new Prodergy tissue machine fires up at APP Group’s Perawang mill, in Indonesia. This start-up is part of a major APP order of Toscotec’s Prodergy machines, to be installed at APP Indonesian paper mills.

PRODERGY is Toscotec’s leading innovation: an AHEAD-2.0L tissue machine, 5.6 m width, 2,000 m/min operating speed, featuring a second generation TT SYD-22FT and steam-heated hoods. Toscotec’s 22 ft diameter steel Yankee dryer constitutes a world record: the biggest steel Yankee dryer ever manufactured worldwide for tissue application. This breakthrough equips Toscotec with a significant advantage in terms of technological innovation. Prodergy’s unprecedented drying efficiency is threefold, combining the benefits of the largest diameter TT SYD ever delivered worldwide, an efficient press configuration and steam-heated Yankee hoods. Each element of Prodergy’s drying equation contributes to the best possible energy efficiency of the tissue making process. The exclusive use of steam energy throughout the entire drying process ensures significant cost reduction compared with gas energy drying. The design of the TT SYD 22ft and the steam-heated Yankee hood system with multiple energy recovery stages deliver the highest dryness rate with minimum consumptions. The press configuration guarantees the highest possible degree of mechanical dewatering before entering the energy-based drying section of the AHEAD-2.0L.

Toscotec’s Sales Director Marco Dalle Piagge affirmed, “We are extremely proud of this incredible achievement. The first 22 ft TT SYD ever manufactured and delivered worldwide, and installed on a top performance tissue making line. We are making history and we expect Prodergy to set a new record for energy efficiency in tissue”.