Displaying items by tag: abb

ABB delivers machine modernization plan for one of the world’s most advanced pulp and board mills

Major upgrade with ABB Ability ™ System 800xA drives and quality control solutions underway for enhanced operations at Iggesund Paperboard

Global technology company ABB is leading a major installation of new drives, control systems and quality control solutions (QCS) for Iggesund Paperboard in Sweden, driving increased safety, higher availability and more stable operations for the board mill.

ABB will deliver a comprehensive maintenance and upgrade project in several stages during 2021, with total supplier responsibility for Iggesund’s two board machines, which are part of one of the world’s most advanced, fully-integrated pulp and board mills. The machines produce premium quality board for consumer and customized luxury packaging, as well as safe, durable medical packaging.

The strategy minimizes the impact on daily operations to the lowest possible downtime on each machine. ABB has created an evolution path to ensure that older Smart Platform system architecture is replaced by the latest Network Platform technology in the most straightforward, cost-efficient way.

A step-by-step electronics upgrade is underway on measuring frames as part of QCS on the two machines. Each frame will be equipped with the latest generation of ABB's moisture sensors, the High-Performance Infrared Transmission (HPIR-T). Moisture is an important quality parameter if the board is to retain its properties in subsequent product conversion steps.

Functions to enable a safer working environment for operators and other personnel, including double-channel emergency stops, a modern start warning system and safe speed monitoring of the machines, are integrated within the drive and automation solution.

To secure the future of production, ABB is supporting the modernization of 150 drive systems with the ABB Ability ™ System 800xA automation and control system and frequency converters from the new ACS880 multidrive system family. ABB Ability™ System 800xA, ranked by the ARC advisory group as the world’s #1 distributed control system (DCS) platform over the last 21 years.

“We will now benefit from a more modern control and drives system that is dimensioned for higher speeds, increased logging possibilities, better fault diagnostics and higher safety,” said Mikael Larsson, Project Manager at Iggesund Paperboard. “We are building for the future and will be able to continue to meet the high demands of our customers.”

“With an upgraded drive, automation and quality control system, Iggesund Paperboard will experience higher availability and utilization rate of the machines, which will produce paperboard of the right quality in stable processes,” said Björn Jonsson, Head of Process Automation in Sweden, ABB. “This more predictable process operation will contribute to lower maintenance costs, higher availability and safety.

“ABB has the solutions, project expertise and experience to deliver on plans such as this with sharpness and guaranteed quality. On top of the product-based design and commissioning, we’re also supporting Iggesund with training staff on the systems.”

ABB (ABBN: SIX Swiss Ex) is a leading global technology company that energizes the transformation of society and industry to achieve a more productive, sustainable future. By connecting software to its electrification, robotics, automation and motion portfolio, ABB pushes the boundaries of technology to drive performance to new levels. With a history of excellence stretching back more than 130 years, ABB’s success is driven by about 105,000 talented employees in over 100 countries. www.abb.com

Process Automation: ABB’s Process Automation business is a leader in automation, electrification and digitalization for the process and hybrid industries. We serve our customers with a broad portfolio of products, systems, and end-to-end solutions, including our #1 distributed control system, software, and lifecycle services, industry-specific products as well as measurement and analytics, marine and turbocharging offerings. As the global #2 in the market, we build on our deep domain expertise, diverse team and global footprint, and are dedicated to helping our customers increase competitiveness, improve their return on investment and run safe, smart, and sustainable operations.

ABB delivers first-of-its-kind winder safety system for New Zealand paper mill

Oji Fibre Solutions selects ABB to install automation and winder systems to improve operator safety at Penrose Mill in Auckland

Oji Fibre Solutions, a leading producer of market pulp, paperboard and fiber-based packaging, has appointed ABB to supply a specially-designed winder safety system – the first of its kind in New Zealand – as well as a winder drive control system and DCS880 drives. With the mill’s existing winder equipment installed more than 30 years ago, the upgrade will help Oji Fibre ensure safe and efficient future operations, in line with recently updated safety requirements* .

The new system features a range of winder safety improvement steps and devices including mechanical guarding (perimeter personnel access control via a retractable fence that keeps operators away from the danger zone), electrical controls (power interlocks), hydraulic controls (with redundancy), optical (safety light curtains) and safe speed monitoring. The creation of safety zones allows operation in one zone to continue when another zone is infringed, improving uptime at the mill.

The automation of manual tasks – such as hands-free threading, set change with automatic sheet cut off, automatic gluing or auto-measuring slitters - also reduces the risk of injury and failure by eliminating hands-on tasks. All of these automatic upgrades both increase winder throughput and remove the operator from exposure to potential hazards. The improved features are all supported by a new operator control panel with safety programmable logic controller (PLC) and new human-machine interface (HMI).

The automation of manual tasks – such as hands-free threading, set change with automatic sheet cut off, automatic gluing or auto-measuring slitters - also reduces the risk of injury and failure by eliminating hands-on tasks. All of these automatic upgrades both increase winder throughput and remove the operator from exposure to potential hazards. The improved features are all supported by a new operator control panel with safety programmable logic controller (PLC) and new human-machine interface (HMI).

Penrose Mill, which has an annual output of more than 85,000 tons of containerboard liner uses recycled sources collected by Oji Fibre’s Fullcircle recycling service. Finished products are supplied mainly to the New Zealand, Australian and Asian markets.

“Our focus was to supply the equipment while simultaneously designing a safety system that would allow Oji Fibre to operate effectively to safely meet its customer requirements,” said Shane Archer, Local Division Manager, Process Industries, ABB New Zealand.

“These measures also had to be benchmarked against national and international standards. We are proud to have redesigned and rebuilt Oji Fibre’s safety system in line with New Zealand’s latest requirements, making operations safer, more intelligent and more productive.”

The investment with ABB will further future-proof the Oji Fibre site, which has taken steps to diversify its packaging portfolio in recent years. ABB will also complete all factory acceptance tests and commissioning remotely.

For further information please visit: https://new.abb.com/pulp-paper/abb-in-pulp-and-paper/products/paper-machine-drives

* The new system complies with the latest ISO13849-1 safety-related parts of control systems requirements

ABB (ABBN: SIX Swiss Ex) is a leading global technology company that energizes the transformation of society and industry to achieve a more productive, sustainable future. By connecting software to its electrification, robotics, automation and motion portfolio, ABB pushes the boundaries of technology to drive performance to new levels. With a history of excellence stretching back more than 130 years, ABB’s success is driven by about 105,000 talented employees in over 100 countries. www.abb.com

Process Automation: ABB’s Process Automation business is a leader in automation, electrification and digitalization for the process and hybrid industries. We serve our customers with a broad portfolio of products, systems, and end-to-end solutions, including our #1 distributed control system, software, and lifecycle services, industry-specific products as well as measurement and analytics, marine and turbocharging offerings. As the global #2 in the market, we build on our deep domain expertise, diverse team and global footprint, and are dedicated to helping our customers increase competitiveness, improve their return on investment and run safe, smart, and sustainable operations.

ABB partners with ACA Systems to offer new online porosity sensor for paper mills

ABB boosts portfolio with ACA Permi sensor, which provides online air permeability measurements and acts as early warning system for unwanted process changes

ABB has entered into a partnership with ACA Systems, the leading supplier of porosity sensors, to offer paper mill customers a proven technology that stabilizes the process to enable excellent roll quality when measuring online porosity. The single point ACA Permi sensor uses a continuous air flow method that is 50 to 100 times faster than other systems available on the market to reduce air permeance variations, enabling better product quality, optimized energy usage and reduced raw material costs.

The multiple advanced calibration features improve the accuracy of the measurements while also enabling faster grade changes, improving overall runnability. This accuracy means that the level of fines can be better controlled while monitoring the direct effect of refining, retention, broke addition and vacuum levels.

The multiple advanced calibration features improve the accuracy of the measurements while also enabling faster grade changes, improving overall runnability. This accuracy means that the level of fines can be better controlled while monitoring the direct effect of refining, retention, broke addition and vacuum levels.

When stabilized air permeability is at the desired level, the roll is considered highest quality. In contrast to laboratory measurements that take 5 to 10 points from the produced roll, ACA Permi measures more than 10,000 points in real time and makes a sophisticated, statistical analysis on the quality of the roll.

Under the partnership, ABB will supply the user-friendly ACA Permi to customers as the porosity option within its own portfolio. It is designed to be used in paper mills with requirements for online porosity measurement as a standalone solution or as part of the quality control systems (QCS) package.

It serves ABB’s L&W installed base by providing a replacement for the soon-to-be obsolete Porolog while augmenting the current QCS offering with the industry-leading porosity measurement that is easily integrated into the QCS for data, display and control. When combined with QCS, it can leverage the ABB Ability™ Quality Management System with its System 800xA backbone. It also has potential to be installed and used with ABB’s remote support.

“Our customers have reported faster grade change times of between 15 percent and 50 percent when controlling the roll quality with ACA Permi. This is a major benefit for operators focused on minimizing production loss and maximizing return on investment, ” said Vesa Kukkamo, CEO of ACA Systems.

“Our customers have reported faster grade change times of between 15 percent and 50 percent when controlling the roll quality with ACA Permi. This is a major benefit for operators focused on minimizing production loss and maximizing return on investment, ” said Vesa Kukkamo, CEO of ACA Systems.

The sensor offers a wide measurement range that usually requires one single calibration, so there is typically no need to change parameters or physical parts for various grades. Plus, the automatic cleaning cycle and smart construction make for easy maintenance and installation. The measurement signal is also compatible with all mill-wide systems and cloud services.

“ACA was strategically chosen for its leadership position, attained through extensive expertise in this space, and abilities to provide continuous measurement and strong service capability. The ACA Permi delivers more accurate, faster measurement results and therefore a higher quality output, which we know is crucial for our customers,” said Ad de Brouwer, Product Manager at ABB.

ACA Permi’s unique measurement head design, tailored with special coatings for challenging applications such as decor paper, provides excellent contact with the web and eliminates the leakage of air, dust and other disturbances. Both vacuum and air blow methods are available, resulting in a very high correlation between the ACA Permi and any lab standard.

The sensor suits a wide range of paper grades, including sack paper, MG-kraft paper, cigarette paper, security paper, decor paper, photo base paper, thermal paper, carbonless paper, saturating paper and base paper before coating.

ABB (ABBN: SIX Swiss Ex) is a leading global technology company that energizes the transformation of society and industry to achieve a more productive, sustainable future. By connecting software to its electrification, robotics, automation and motion portfolio, ABB pushes the boundaries of technology to drive performance to new levels. With a history of excellence stretching back more than 130 years, ABB’s success is driven by about 110,000 talented employees in over 100 countries. www.abb.com

ABB is a trusted partner and leading supplier to the pulp and paper industry, offering deep expertise and a comprehensive portfolio of integrated digital solutions, automation and electrification systems, industry-focused products and comprehensive services to help our customers optimize all phases of the papermaking process. We are committed to serving packaging, paper, tissue and pulp producers to help drive availability, performance, cost and quality improvements. Active worldwide, ABB has over 1000 pulp and paper professionals who serve customers in over 50 countries. www.abb.com/pulpandpaper

ACA Systems Oy , a privately-owned technology company founded 1986 in Polvijärvi Finland, is specialized in developing, manufacturing and selling high technology instrumentation for the paper, board and other industries globally.

Today we offer from manufacturers to finishing converters comprehensive services, high quality measuring equipment solutions as well as modern data handling platforms. Our heritage has been always to provide information that can lead to more stable processes and better product quality as well as production cost reduction. Our people are dedicated to support customers and develop new instrumentation based on the needs of the industry. www.aca.fi

ABB completes large-scale remote commissioning of winder drives for major paper producer in India

Paperboard and specialty paper producer ITC achieves greater uptime, improved reliability and better runnability through major upgrades completed in a short timeframe

ABB has completed a large-scale remote commissioning of winder drives, upgrading and commissioning PM5 installations at ITC’s Paperboards and Specialty Papers Division mill in south-central India.

This project included upgrading the mill’s complete winder drive system to ABB’s latest ACS880 drives, AC motors, AC800M controller and process panel, as well as ensuring that all new assets were fully commissioned and ready for operation.

Following studies of the existing machine, detailed task planning, and numerous checks on the safety aspects of every task, ABB’s domain expertise helped the team complete the commissioning in just three days.

ABB has completed a major winder drive system upgrade with remote commissioning

ABB has completed a major winder drive system upgrade with remote commissioning

ITC engineers conducted a series of installations, hardware and I/O checks, and reporting of field challenges. Team feedback indicated the user-friendly ABB system assisted with this site work.

As a result of the drives upgrade, ITC will benefit from more accurate winder controls, including inertia compensation calculation, loss compensation, accurate load share and tension, while also experiencing higher operating speeds, with improved uptime and reliability.

Initial feedback from ITC reported improved runnability and reliability, while devising a solution for remote commissioning helped to reduce unnecessary downtime.

“Our ABB team mobilized quickly and used its remote expertise to complete this large-scale commissioning project, overseeing all drive parameterization, controller and human-machine interface (HMI) programming, testing and commissioning,” said Sanath Kumar, Global Product Manager for Paper Machine Drives and Vice President and Head of Engineering for Process Industries, ABB India.

“For any paper producer, the winder is a critical machine, which directly affects production. Any delay or malfunction will completely stop paper production processes. Remote commissioning during a planned maintenance timeframe was essential to maximize uptime for ITC and avoid unnecessary production losses.”

ABB (ABBN: SIX Swiss Ex) is a leading global technology company that energizes the transformation of society and industry to achieve a more productive, sustainable future. By connecting software to its electrification, robotics, automation and motion portfolio, ABB pushes the boundaries of technology to drive performance to new levels. With a history of excellence stretching back more than 130 years, ABB’s success is driven by about 110,000 talented employees in over 100 countries. www.abb.com

New ABB Weight Virtual Measurement reduces sheet break recovery time and boosts mill profitability

Step change for modern mill transformation as new online measurement enables more efficient and cost-effective management of start-up events

ABB has just launched Weight Virtual Measurement, an ABB Ability™ Performance Service that allows paper, packaging and tissue manufacturers to recover quickly from sheet breaks. It works by reducing the amount of off-spec paper produced directly after sheet breaks and during the subsequent start-up period, potentially saving thousands of dollars each year.

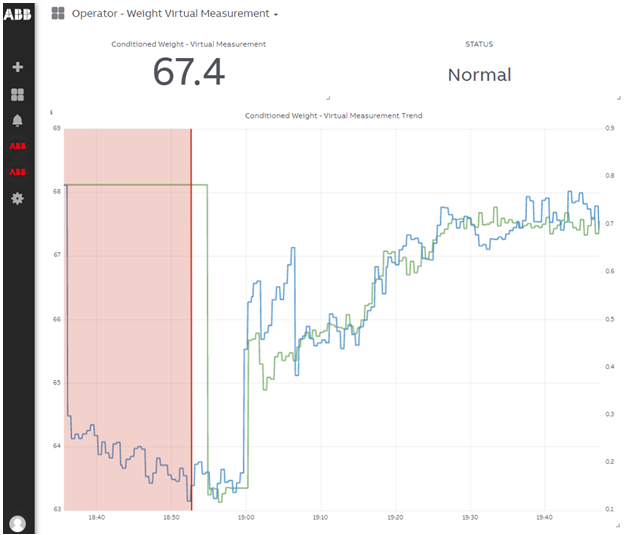

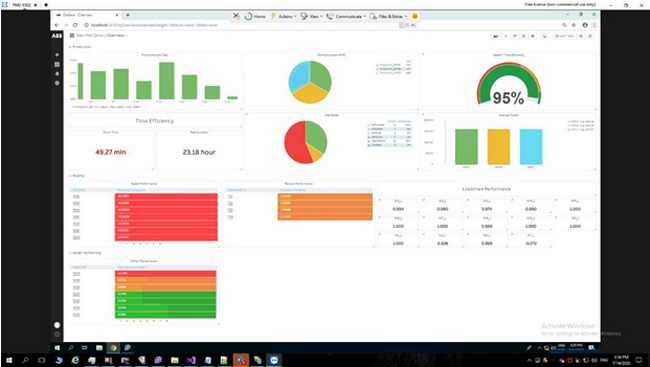

Dashboard comparison showing results of using or not using Weight Virtual Measurement

Dashboard comparison showing results of using or not using Weight Virtual Measurement

The new digital solution uses inputs that affect product weight - such as stock flow, consistency, first pass retention and machine speed - to provide an online conditioned weight measurement during a sheet break event when the Quality Control System (QCS) weight sensor cannot provide a measurement since there is no paper to be measured.

By providing operators with a continuously optimized, machine-learning generated measurement model, or ‘soft sensor’, Weight Virtual Measurement helps reduce downtime, improve grade change times and decrease the time to achieve on-spec paper. Operator displays combine various inputs and highlight when the Virtual Measurement is available in the absence of the QCS measurement. Operators can view the current status and work with a choice of adjustments to get back on target.

Operators took action to get the weight back on target using the virtual measurement

Operators took action to get the weight back on target using the virtual measurement

“Our new Weight Virtual Measurement solution is unlike any other in that it combines deep industry expertise with advanced analytics, machine-learning technologies, proprietary modelling and auto-calibration techniques to create an accurate and robust virtual sensor,” said John Schroeder, Global Product Manager for ABB Ability™ applications for pulp and paper. “This will enable mills to make more strategic decisions such as balancing the cost options of getting their production up and running faster versus delaying putting the paper on the reel to avoid compromising their paper quality.”

Weight Virtual Measurement joins the ABB Ability™ Performance Service suite that includes other Virtual Measurement features for pulp and paper mills, all of which do not require an ABB DCS or QCS for implementation. It is delivered via ABB Ability™ Collaborative Operations, a service delivery model that connects production, headquarters and ABB personnel with remote access to ABB digital technologies, data analytics and domain expertise, and incorporates ongoing performance monitoring and analysis of the online calculated weight.

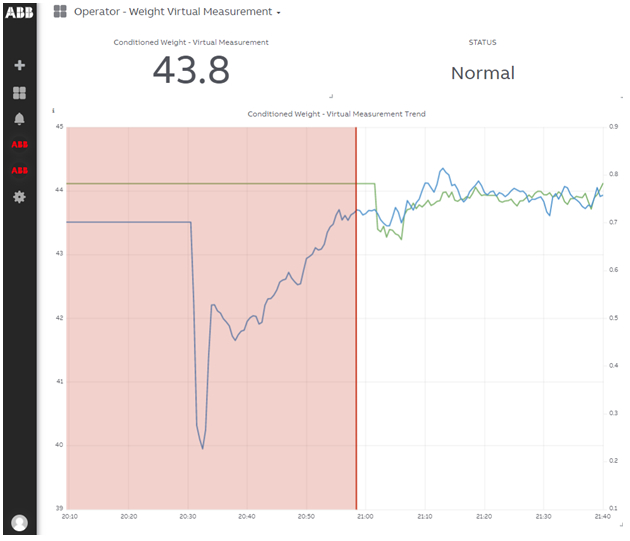

Weight Virtual Measurement helps to shorten time of sheet break and minimize recovery time

Weight Virtual Measurement helps to shorten time of sheet break and minimize recovery time

For more information about the solution go to: https://new.abb.com/pulp-paper/abb-in-pulp-and-paper/service/advanced-services/performance-services-for-paper-mills/weight-virtual-measurement

ABB is a trusted partner and leading supplier to the pulp and paper industry, offering deep expertise and a comprehensive portfolio of integrated digital solutions, automation and electrification systems, industry-focused products and comprehensive services to help our customers optimize all phases of the papermaking process. We are committed to serving packaging, paper, tissue and pulp producers to help drive availability, performance, cost and quality improvements. Active worldwide, ABB has over 1,000 pulp and paper professionals who serve customers in over 50 countries. www.abb.com/pulpandpaper

ABB (ABBN: SIX Swiss Ex) is a leading global technology company that energizes the transformation of society and industry to achieve a more productive, sustainable future. By connecting software to its electrification, robotics, automation and motion portfolio, ABB pushes the boundaries of technology to drive performance to new levels. With a history of excellence stretching back more than 130 years, ABB’s success is driven by about 110,000 talented employees in over 100 countries. www.abb.com

Södra Cell chooses ABB to supply new Quality Control System for eco-friendly, specialty pulp mill in Sweden

Fully integrated solution will enhance product quality through improved control of production changes

Leading Swedish pulp manufacturer Södra Cell has appointed ABB to supply and install a new, state-of-the-art Quality Control System (QCS) at its specialty mill in Mörrum, southern Sweden, which produces paper pulp and hardwood dissolving pulp for customers throughout Europe. Delivery is planned for October 2020.

The QCS order includes new sensors for a range of quality parameters including basis weight and moisture content plus multivariable cross direction (MCD) control. The system also benefits from the ability to interface directly with Södra Cell’s existing, third-party headbox actuators. A 12-month service contract provides comprehensive technical back-up after installation.

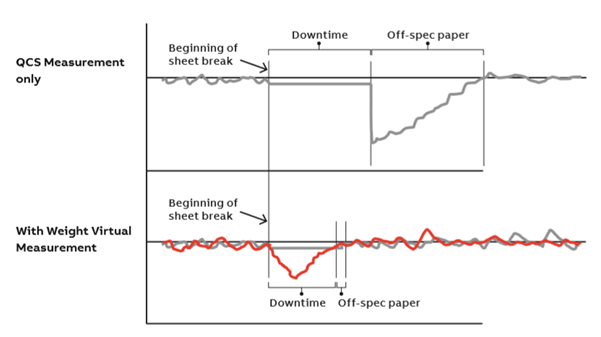

An example of an ABB Network Platform for on-line high-performance measurement scanning

An example of an ABB Network Platform for on-line high-performance measurement scanning

To meet the customer’s main objective of changing production rates without disturbing pulp quality, the QCS incorporates coordinated speed change control. This features an operator interface that provides information about all the supervisory and regulatory loops, including the status of the individual actuator ramps. Through its ease of use, this control encourages higher utilization than with conventional systems, leading to fewer sheet breaks, less downtime and an overall increase in average speed and production.

“Our existing, productive relationship with ABB, and their honest, consultative approach were critical to this order,” said Lennart Willander, Production Manager Pulp Dryer 1, Södra Cell Mörrum. “We look forward to continuing our strong relationship moving forward.”

“This order demonstrates ABB’s expertise in measurement and control throughout the value chain,” said Steve St. Jarre, Head of Business Development, Pulp and Paper, Process Industries, ABB. “We were able to advise the customer fully on the benefits of an integrated QCS that could interface with existing actuators versus a measurement system alone. We are confident that this will result in the desired improvements in productivity and product quality.”

QCS operator interface in use

QCS operator interface in use

In addition to producing dissolving pulp – which, when used as a cotton substitute in fabric fiber production, reduces dependence on pesticides – Södra Cell’s eco-friendly Mörrum mill also contributes green electricity and district heating to homes in the locality of Karlshamn, as a result of major investments in efficient energy management.

Södra is Sweden’s largest forest-owner association, with 52,000 forest owners as its members. Södra is also an international forest industry Group, with operations based on processing its members’ forest products.

ABB is a trusted partner and leading supplier to the pulp and paper industry, offering deep expertise and a comprehensive portfolio of integrated digital solutions, automation and electrification systems, industry-focused products and comprehensive services to help our customers optimize all phases of the papermaking process. We are committed to serving packaging, paper, tissue and pulp producers to help drive availability, performance, cost and quality improvements. Active worldwide, ABB has over 1000 pulp and paper professionals who serve customers in over 50 countries. www.abb.com/pulpandpaper

ABB (ABBN: SIX Swiss Ex) is a leading global technology company that energizes the transformation of society and industry to achieve a more productive, sustainable future. By connecting software to its electrification, robotics, automation and motion portfolio, ABB pushes the boundaries of technology to drive performance to new levels. With a history of excellence stretching back more than 130 years, ABB’s success is driven by about 110,000 talented employees in over 100 countries. www.abb.com

Grupo Gondi expands automated paper testing to include second ABB solution at its Monterrey, Mexico mill

L&W Autoline will be a key differentiator for Grupo Gondi customers seeking the highest quality

ABB has been chosen to supply leading Mexico packaging paper producer Grupo Gondi with a robust and reliable automated paper testing solution for its greenfield site in Monterrey, Mexico.

The comprehensive order—which focuses on improving quality and efficiency at the mill—includes L&W Autoline, with a wide range of testing modules and sample trimmer and L&W benchtop testing instruments. Engineering and installation of the project is planned for completion in Q3 2020.

Grupo Gondi became the first paper producer in Mexico to commission automated paper testing with the L&W Autoline installation at its Guadalajara mill in 2013, emphasizing the company’s commitment to achieving high quality outputs.

The new order for the Monterrey mill in northeast Mexico will continue to improve efficiency and reduce costs for the company, reducing dependence on manual testing and allowing resources to focus on optimizing product quality.

“Our previous experience of L&W Autoline and ABB’s excellent service made ABB an obvious choice for this contract,” said Felix Rocha, Paper Mills Director, Grupo Gondi. “We are confident that this order will provide us with rapid, reliable feedback on product quality across the business, ensuring the highest quality of output.”

“Having worked with Grupo Gondi to commission the first automated paper testing solution in Mexico, we have now built on our relationship to contribute to the company’s focus on consistently high-quality product,” said Per Sandstrom, Head of Lab and Process Testing Measurements, Pulp & Paper, Process Industries, ABB. “Automated paper testing will benefit the mill by enabling the prompt identification and resolution of issues that can compromise quality, helping to maximize on-spec output.”

By rapidly gathering information and highlighting off-spec data, L&W Autoline measures paper properties, identifies problem areas and allows papermakers to tune processes promptly, 24 hours a day, 365 days a year to optimize product quality. Reports and visualizations provided to operations and engineering personnel both locally and remotely in real time ensure the fulfillment of production targets and quality specifications.

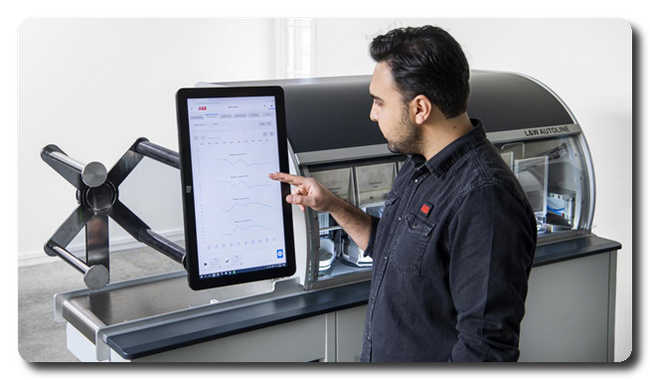

Technician working with the L&W Autoline user interface

Technician working with the L&W Autoline user interface

Grupo Gondi is the leading company in paper and cardboard packaging, with 65 years of experience in the Mexican market. Currently, Grupo Gondi employs over 7,500 people, with 15 converting plants and 6 recycled paper machines in operation for a current paper production of 650,000 tons per year. With the new paper machine at Monterrey, the Group will increase its capacity to over 1 million tons per year.

Gondi’s packaging solutions carry products from its clients to more than 190 countries worldwide, supported by certified processes and international regulations, offering high quality products and services to the market, with the support of the Gondi Paper and Packaging Investigation Center (CIPEG, for its initials in Spanish), which on a daily basis researches for innovational contributions to the success of its clients.

ABB is a trusted partner and leading supplier to the pulp and paper industry, offering deep expertise and a comprehensive portfolio of integrated digital solutions, automation and electrification systems, industry-focused products and comprehensive services to help our customers optimize all phases of the papermaking process. We are committed to serving packaging, paper, tissue and pulp producers to help drive availability, performance, cost and quality improvements. Active worldwide, ABB has over 1000 pulp and paper professionals who serve customers in over 50 countries. www.abb.com/pulpandpaper

ABB (ABBN: SIX Swiss Ex) is a leading global technology company that energizes the transformation of society and industry to achieve a more productive, sustainable future. By connecting software to its electrification, robotics, automation and motion portfolio, ABB pushes the boundaries of technology to drive performance to new levels. With a history of excellence stretching back more than 130 years, ABB’s success is driven by about 110,000 talented employees in over 100 countries. www.abb.com

ABB L&W Tearing Tester adds full automation and digital connectivity for safer, faster strength measurement

Newest paper lab testing instrument offers more streamlined and user-friendly operation across grades with accurate, repeatable results

ABB has just launched its market-leading L&W Tearing Tester with enhancements to ease operator use and safe handling, expand on tearing resistance testing capabilities and improve digital connectivity.

Paper mills already recognize the instrument for safely and accurately measuring tearing resistance on all paper grades and its unique automation, digitalization and safety features. Tearing resistance is a crucial determinant of product toughness and machine runnability and can help mills characterize pulp to determine if refining and reinforcement fibers are optimized.

ABB’s L&W Tearing Tester, which uses a pendulum to further tear a pre-cut sample, helps mills achieve tearing strength results faster with automatic clamping and notch cutting of the sample piece as well as automatic pendulum release, catch and retraction. Plus, testing for different grades is now faster than ever with interchangeable weights for the instrument’s one pendulum.

Lab technicians will benefit from a user-friendly touchscreen and more ergonomic-friendly operation. They will also be better protected with the two-hand operation requirement, avoiding contact with moving parts and the blade, and a unique pendulum safety guard that minimizes the risk of injury without interrupting the pendulum swing or slowing the test.

Th e instrument interfaces with ABB’s L&W Lab Management System, a web-based automated data acquisition and lab reporting solution that helps halve lab procedure times. With its capability to connect to ABB Ability™ Manufacturing Execution System for pulp and paper, manufacturers gain visibility of data across the mill and the entire enterprise to ensure consistent product quality.

“All mills aim for the best possible product toughness and machine runnability, and yet many struggle with measurement challenges – such as reliability or repeatability – associated with ageing equipment that could affect improvement opportunities,” said Per Sandstrom, Head of Lab and Process Testing Measurements for ABB Pulp & Paper.

“The new ABB L&W Tearing Tester is the only instrument on the market that combines the best modern automation, digitalization and safety advancements to deliver accurate and repeatable tearing strength results to help expedite quality and machine optimization.”

As the worldwide market leader for paper testing technical support, with local service organizations in all markets, ABB provides a comprehensive support network for the L&W Tearing Tester using L&W-specific calibration devices that are regularly certified with traceable calibration from global certification institutes.

For further information on ABB L&W Tearing Tester, please visit: https://new.abb.com/pulp-paper/abb-in-pulp-and-paper/products/lorentzen-wettre-products/laboratory-paper-testing/paper-strength-testing/l-w-tearing-tester

ABB supplies electrical package and drives automation to new Grupo Gondi mill in Monterrey, Mexico

On completion, PM7 will be the largest containerboard machine in Mexico, and among the most modern in the world

ABB has supplied and commissioned a full electrical solution for major packaging paper producer Grupo Gondi at its greenfield site in Monterrey, Mexico.

The project includes switchgear, transformers, motors, drives, and automation for the paper machine drive system with the industry’s leading distributed control system, ABB Ability™ System 800xA.

The highly robust solution focuses on quality and efficiency, and ABB will also supply a specialty instrumentation package to enable Gondi to optimize operations while maintaining low energy costs. Commissioning of the project is close to completion, with startup of the paper machine scheduled this month, September 2020.

ABB worked with Grupo Gondi’s trusted local partner, Grupo BTO, on the supply of the electrical and drives automation system. This collaboration ensures the best lifecycle support for the systems long after start-up is completed.

ABB drive systems for paper machines

ABB drive systems for paper machines

“Given the importance of this project, working with a reliable and experienced supplier that guaranteed meeting stringent paper machine specifications was crucial,” said José Iribarne, Project Director, Monterrey Mill, Grupo Gondi. “ABB also has solid resources for support and maintenance in Mexico, and we look forward to working with them to ensure ongoing success.”

“This landmark project with Grupo Gondi strengthens our position as a leading supplier of end-to-end solutions to the pulp and paper industry in Mexico,” said Steve St. Jarre, head of business development, Pulp and Paper, Process Industries, ABB. “Our comprehensive portfolio allows us to align solutions with customer needs and provide integrated, digital solutions backed by global expertise gained from more than 100 years of industry experience.”

Grupo Gondi is the leading company in paper and cardboard packaging, with 65 years of experience in the Mexican market. Currently, Grupo Gondi employs over 7,500 people, with 15 converting plants and 6 recycled paper machines in operation for a current paper production of 650,000 tons per year. With the new paper machine at Monterrey, the Group will increase its capacity to over 1 million tons per year. Gondi’s packaging solutions carry products from its clients to more than 190 countries worldwide, supported by certified processes and international regulations, offering high quality products and services to the market, with the support of the Gondi Paper and Packaging Investigation Center (CIPEG, for its initials in Spanish), which on a daily basis researches for innovational contributions to the success of its clients.

Grupo BTO was established in 2000 to provide complete automation and electrification solutions for its customers throughout Mexico, mainly in process industries. BTO is certified as a Value Provider Technical Distributor of ABB, and BTO and ABB have been successfully working in partnership for the last 20 years.

New ABB Ability™ digital solution continuously monitors paper machine drive health to prevent failures and boost productivity

Pioneering solution uniquely offers continuous monitoring of paper machine drives’ performance for near real-time insights that diagnose problems, optimize performance and save mills money

ABB has just launched the Paper Machine Drives Performance, a pioneering digital data analysis solution providing pulp and paper manufacturers with detailed insights into their drive system health to improve runnability and reliability, reduce sheet breaks and ultimately improve paper quality.

Paper Machine Drives Performance is the only continuous monitoring, drive-specific digital service that leverages a digital twin to better model and evaluate system drive control performance. Applying an advanced calculation engine to critical system data permits near real-time performance monitoring for web tension, speed control, draw and load share. This in turn enables drive system control optimization, faster troubleshooting and more informed asset decisions.

The system also provides advance warnings of potential failures and maintenance alerts, which enable mills to undertake predictive maintenance, reducing unplanned downtime and higher maintenance costs.

“Customers are always seeking better ways to understand their drive system health while efficiently identifying the root cause of any issues,” said Sanath Kumar, Global Product Manager for Paper Machine Drives, ABB. “Our new solution is the only available offering that specifically monitors paper machine drive control performance to provide near real-time detail on performance status, plus predictive alerts and root cause insights to optimize control and leverage predictive maintenance strategies.”

Removing the need for manual data collection, Paper Machine Drives Performance leverages the ABB Ability™ platform to collect and analyze a breadth and depth of data that would otherwise be unachievable. Part of the ABB Ability™ Performance Service for paper mills family, the service follows ABB’s proven ‘diagnose, implement, sustain’ methodology, helping grow and optimize performance and is delivered via ABB Ability™ Collaborative Operations.