Displaying items by tag: valmet

Valmet receives an order from Holmen for hardwood line rebuild at Iggesund mill in Sweden

Valmet will deliver equipment and services for a rebuild of the hard wood pulp line at Holmen's Iggesund mill in Sweden. The rebuild will cut variable costs and improve production stability. The work will be implemented during the second half of 2022.

The order is included in Valmet's orders received of the second quarter 2021. The value of the order will not be disclosed.

"We have a good experience in working with Valmet, since we have had their presses in our mill for many years. This rebuild will lower the load on the effluent and reduce variable costs, which will strengthen our competitiveness," says Johan Björkman, Project Manager, Iggesund.

"This rebuild is the first step towards a press-based bleach plant in the hard wood pulp line. The high outlet consistency makes the process easier to control and the volume of effluent will be less than for washers with lower discharge consistencies. Also, water and chemical consumption will be minimized. We are looking forward to a good co-operation in this project", says Mikael Gustafsson, Sales Manager, Valmet.

Valmet will deliver equipment and services for a rebuild of the hard wood pulp line at Holmen's Iggesund mill in Sweden.

Valmet will deliver equipment and services for a rebuild of the hard wood pulp line at Holmen's Iggesund mill in Sweden.

Technical information about Valmet's delivery

The scope of the Valmet delivery includes main machinery, basic engineering and erection. In the first stage, a vacuum filter will be replaced with a new TwinRoll press and in a second phase, remaining filters in the bleach plant will be replaced with TwinRoll presses.

About Holmen and Iggesund mill

Holmen’s business is built around forest ecocycle and renewable products. The business areas are forest, renewable energy, wood products, paperboard and paper. With a workforce of 3,300 people they generate sales of around SEK 16 billion and the shares are listed on Nasdaq Stockholm, Large Cap.

Holmen's Iggesund mill is one of the most advanced, fully integrated pulp and paperboard mills in the world. The mill has traditions dating back to 1685. Exclusive packaging for perfume, chocolate, wine and spirits are examples of applications. The mill has a production capacity of 340,000 tonnes per year and 800 employees.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2020 were approximately EUR 3.7 billion. Our 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Valmet has completed the acquisitions of EWK Umwelttechnik and ECP Group to strengthen its environmental systems business

Valmet has completed the acquisition of EWK Umwelttechnik GmbH and ECP Group Oy following the agreements that were announced on June 10. EWK Umwelttechnik is a German company manufacturing and supplying air emission control systems and after-installation services. ECP Group is a manufacturer and maintainer of electrostatic precipitators (ESP), focusing on power plants and pulp and paper industry, in Finland.

EWK Umwelttechnik and ECP Group will be included in Valmet’s financial reporting for the first time in Valmet’s third quarter financial reporting 2021.

The acquisition of EWK Umwelttechnik

The acquired business of EWK Umwelttechnik becomes a part of Valmet’s Pulp and energy business line. EWK Umwelttechnik’s offering of emission control technologies includes electrostatic precipitators, wet absorbers, catalytic and heat recovery systems, and wastewater purification products. The company serves multiple customer segments, including wood-based panelboard, glass, mineral wool, and steel industries. The net sales of EWK Umwelttechnik were approximately EUR 22 million in 2020. The company employs approximately 50 employees mainly in Kaiserslautern, Germany.

The acquired business of EWK Umwelttechnik becomes a part of Valmet’s Pulp and energy business line. EWK Umwelttechnik’s offering of emission control technologies includes electrostatic precipitators, wet absorbers, catalytic and heat recovery systems, and wastewater purification products. The company serves multiple customer segments, including wood-based panelboard, glass, mineral wool, and steel industries. The net sales of EWK Umwelttechnik were approximately EUR 22 million in 2020. The company employs approximately 50 employees mainly in Kaiserslautern, Germany.

“The acquisition was completed as planned. Combining Valmet’s and EWK Umwelttechnik’s emission control offerings expand the solutions we can provide our customers and widens the industries that our technologies cover. This creates new business opportunities for our environmental systems business. EWK Umwelttechnik has a very skilled team and I am happy to warmly welcome the 50 professionals to be part of Valmet,” says Bertel Karlstedt, Business Line President, Pulp and Energy, Valmet.

“I am satisfied that the closing process has been completed successfully. EWK Umwelttechnik has a long history and our strengths are the flexibility of our solutions and closeness to customers. Joining Valmet is a start of a new chapter in our history. We bring new technology and industry competences to Valmet and I’m convinced that together we will be able to serve our current and future customers with a more comprehensive technology offering and service presence globally,” says Peter Ohlenschläger, CEO of EWK Umwelttechnik GmbH.

The acquisition of ECP Group

As of July 1, 2021, ECP Group is known as Valmet Environment Oy. The acquired business will be integrated into Valmet EMEA organization, to enhance energy and recovery services. The offering acquired from ECP Group consists of manufacturing and modernizing electrostatic precipitators as well as providing services, such as inspections, annual maintenance, spare parts and performance improvements. The net sales of ECP Group were approximately EUR 6 million in 2020. The company, founded in 2002, is headquartered in Vantaa, Finland, and employs around 20 employees.

“Valmet Environment complements our competences in improving and maintaining emission control processes in the pulp, paper and energy industries. The demand for better air emission control is increasing as emission regulations are tightening in our customer industries, and our customers look for more sustainable technology. Now we are able to better serve our customers’ needs in flue gas cleaning. This is a true step change, and we are excited to welcome experienced and committed members to our team,” says Minna Saarelainen, Director, Energy Sales and Services Operations, Valmet.

“Especially over the past five years, we have been able to serve our customers in energy, pulp and paper industries with new, broader service and modernization solutions both domestically and abroad. Joining Valmet enables us to develop and strengthen our expertise in ESP technology. As part of Valmet, we are taking a major leap forward as we will be able to serve our customers in an even stronger, more international and customer-oriented manner,” says Tapani Stipa, CEO of ECP Group.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2020 were approximately EUR 3.7 billion. Our 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Valmet receives the ninth tissue line order from Hayat Kimya in Russia

Valmet will supply the ninth tissue line delivery, including an extensive automation package, to Turkish tissue producer Hayat Kimya. The company has decided to invest in a new tissue machine at their new mill in Russia, with a target to meet the increasing demand for their high-quality tissue products. The new line will add 70,000 tons of tissue to their current production of facial, toilet and towel tissues. The start-up is planned for the end of 2022.

The order is included in Valmet’s orders received of the second quarter 2021. The value of the order will not be disclosed.

Hayat Kimya has previously installed seven Valmet Advantage DCT 200TS tissue production lines to its mills in Turkey, Russia and Egypt, and is currently installing the tissue machine TM9 at its new site in Russia. Hayat Kimya is constantly utilizing the latest technology to reach the highest efficiency and lowest possible energy consumption.

Hayat Kimya has previously installed seven Valmet Advantage DCT 200TS tissue production lines to its mills in Turkey, Russia and Egypt, and is currently installing the tissue machine TM9 at its new site in Russia. Hayat Kimya is constantly utilizing the latest technology to reach the highest efficiency and lowest possible energy consumption.

“Our ambition is to continuously improve our performance with each installation, and the Advantage DCT technology is certainly supporting that target. Together with Valmet, we have established an efficient way of working and have been able to reach very smooth and fast start-ups. Ever since the start-ups, we have been running the machines at constant high speed and efficiency,” says Lütfi Aydin, Director, Paper Group, Hayat Kimya.

“We are proud to have had the opportunity to deliver nine Advantage DCT machines in a row to Hayat Kimya. That is definitely a proof that the technology is reliable, efficient, easy to use and meets expected production and product quality targets. During the years, we have developed both good technical performance and team collaboration, so we are excited to continue the journey to also make this new project a success,” says Björn Magnus, Sales Director, Tissue Mills business unit, Paper business line, Valmet.

Technical information

The new tissue machine TM10 will have a width of 5.6 m and a design speed of 2,100 m/min.

The raw material to be used in the tissue production will be virgin fiber. The new production line is optimized to save energy and to enhance the quality of the final product.

Valmet’s scope of delivery will comprise a complete tissue production line featuring stock preparation systems and a Valmet Advantage DCT 200 TS tissue machine. The machine will be equipped with an OptiFlo headbox and a cast alloy Yankee cylinder. It will also be featured with the Advantage tissue technology including ViscoNip press with Valmet Black Belt R, an AirCap Heli hood and air system prepared for co-generation, WetDust dust system, sheet transfer system and a SoftReel L reel. The stock preparation line will consist of OptiSlush pulpers, OptiFiner conical refiners and OptiScreen machine screens.

Furthermore, the delivery will include an extensive Valmet automation package with Valmet DNA machine controls, drive controls, process controls and machine monitoring, as well as Valmet IQ quality controls with IQ Fiber and IQ Softness sensors, MD Controls and IQ Dilution CD Controls. Complete engineering, installation supervision, training, start-up and commissioning as well as a spare parts package are also included in the delivery.

Information about Hayat Kimya

Hayat Kimya A.S. is part of the Hayat Group. The Hayat Group primarily operates in the home care, hygiene and tissue categories for the consumer goods industry. Hayat has continued to invest significantly since their entrance into the tissue category 14 years ago and today the Group carries "The Largest Tissue Manufacturer of Africa, Middle East and Eastern Europe" title with 490,000 tonnes production capacity/year.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2020 were approximately EUR 3.7 billion. Our 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Valmet to supply two more OptiConcept M container board making lines to Zhejiang Shanying Paper in China

Valmet will supply two OptiConcept M container board making lines with extensive packages of automation, services and industrial internet applications to Zhejiang Shanying Paper in Jiaxing City, Zhejiang province, China.

The orders are included in Valmet's orders received of the second quarter 2021. The values of the orders will not be disclosed.

The new board making lines PM 16 and PM 17 continue the expanding of Zhejiang Shanying Paper’s business in Zhejiang area. The start-ups are scheduled from the end of 2022 to early 2023.

These deliveries at Jiaxing Mill will already be Valmet’s 11th and 12th OptiConcept M board making line deliveries to Zhejiang Shanying Paper. The 10 earlier machines were or will be delivered to customer’s different sites. The latest one (PM 53) was published earlier this year.

These deliveries at Jiaxing Mill will already be Valmet’s 11th and 12th OptiConcept M board making line deliveries to Zhejiang Shanying Paper. The 10 earlier machines were or will be delivered to customer’s different sites. The latest one (PM 53) was published earlier this year.

“Our cooperation with Valmet has been excellent, and it is based on mutual trust. We are really happy about the already started-up machine lines of Huazhong PM 21 and PM 23. This was a decisive factor when we were choosing the supplier for PM 16 and PM 17. We are expecting to have excellent support for the start-up and the line optimization after the start-up with the extensive automation package,” says Wu Ming Wu, Chairman and CEO of Shanying International.

Technical information about Valmet’s delivery

Valmet's delivery for the both machines will include a high-speed, multi-layer container board making line from broke collection to a reel and winders. The delivery will also include board machine process ventilation systems. The wide automation package includes Valmet DNA automation system for process and machine controls as well as runnability and condition monitoring and Valmet IQ quality management system. The delivery will also include comprehensive Maintenance Master Data, Valmet Paper Machine Clothing, spare parts and consumables packages.

For a period of two years, the start-up and the further optimization of PM 16 will be supported remotely from Valmet Performance Center. Valmet Industrial Internet solutions will help the optimizing of raw material and quality and help the operator to optimize the use of fabrics. They can also be used to predict and avoid production losses and increase the machine reliability, and with a solution called Dynamic Centerline Advisor, the operator can find the optimal setpoint and running conditions for processes. Virtual Mill, which can be used e.g. for personnel training, consists of full digital design twin of the board machine.

About the customer Zhejiang Shanying Paper

Zhejiang Shanying Paper founded in 2002, is part of Shanying International Holding. The company has several packaging paper and newspaper production lines producing box board paper, high-strength fluting paper, card paper, newspaper and other products. The production lines use domestic and foreign recycled fibers.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2020 were approximately EUR 3.7 billion. Our 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Valmet delivers recycled fiber lines for Umka Cardbord Mill rebuild in Serbia

Valmet will supply recycled fiber lines for Umka Cardboard Mill rebuild in Serbia. The order is a continuation of Valmet’s board machine rebuild delivery, which will be started up during the second half of 2021. The main target of the rebuild is to increase the customer’s production capacity and improve end-product quality. The recycled fiber lines are scheduled to start-up during the first half of 2022.

The order was included in Valmet’s orders received of the first quarter 2021.

The order was included in Valmet’s orders received of the first quarter 2021.

“We are delighted that an end-to-end solutions provider like Valmet is supplying us with the recycled fiber lines for our cardboard mill rebuild. Umka has an 82-year long history and with the ability to increase our capacity to over 200,000 tons, while also improving our recycled cardboard products, this equipment perfectly positions us for continued success in the future,” says Milos Ljusic, Umka’s Managing Director.

Valmet’s delivery will include substantial changes to the recycled fiber lines for Umka’s paper machine PM 1. These include an Old Corrugated Containers (OCC) line with reject handling and a rebuild of two Deinked Pulp (DIP) lines.

“Together with the customer, we built a solution that will help Umka increase recycled fiber lines capacity, reduce maintenance, and improve end-product quality. We’re happy to be able to provide services, technology, and the industry expertise as an end-to-end partner for Umka,” says Hanna Jokinen, Director, Capital Business, Paper business line, Valmet.

About the customer

Umka Cardboard Mill has been a part of KappaStar Group since its privatization in 2003. The mill’s production capacity is currently 130,000 tons per year. Umka exports over 83% of its production to over 30 European countries as well as to markets in North America, Middle East and Central Asia. The most important export markets are Poland, Hungary, Romania, Italy, Czech Republic, and Russia. Umka’s cardboard is widely used in the manufacturing of cardboard packaging for the food, confectionery, pharmaceutical, chemical, tobacco, textile, and automotive industries, as well as for spare parts production within the machine industry. It is also used for lamination in the manufacture of transport packaging.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2020 were approximately EUR 3.7 billion. Our 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Valmet to deliver two automated paper testing laboratories for Brigl & Bergmeister’s paper mills

Valmet will deliver two Valmet Paper Labs, automated board and paper testing laboratories for Brigl & Bergmeister’s paper mills in Niklasdorf, Austria and Vevče, Slovenia. Valmet Paper Labs deliver accurate and rapid measurement results that are used to monitor and control the quality of the specialty papers produced by the two mills.

The order is included in Valmet's orders received of the second quarter 2021. The value of the order will not be disclosed. Both analyzers are scheduled to be delivered during the fourth quarter 2021.

“The original motivation for these investments was the improvement of the quality of our products. The Valmet Paper Lab will give us the opportunity to either increase the frequency of the standard quality measurements, and on the other hand, to reduce the regular manual work in order to have more time for special quality measurements,” says Eugen Habsburg-Lothringen, Head of Technology, Brigl & Bergmeister.

“We have been collaborating with Brigl & Bergmeister for a long time and they already have our automation and quality control systems as well as analyzers and measurements in their mills. And now, the end-product quality measured by Valmet Paper Labs supplements our offering and is a good continuation of our cooperation,” says Markku Merra, Sales Manager, Automation, Valmet.

The two Valmet Paper Labs will be delivered for Brigl & Bergmeister’s mills in Austria and Slovenia.

The two Valmet Paper Labs will be delivered for Brigl & Bergmeister’s mills in Austria and Slovenia.

Technical details about the delivery

Valmet’s delivery includes two size L Valmet Paper Labs, modular and scalable automated board and paper testing systems. With the widest selection of industry-standard tests on the market, they can measure all the important quality properties from the end-product. The testing system is based on several decades of automated paper testing experience with over 300 units delivered to paper and board mills around the world. The delivery scope also includes start-up and customer training.

Valmet Paper Lab provides an easy-to-learn and intuitive tool for paper and board property testing which together with Valmet’s Industrial Internet remote support can take the automated laboratory’s performance to a new level.

Information about the customer Brigl & Bergmeister

Brigl & Bergmeister produces sustainable, technical specialty papers for the beverage, food and consumer goods industries. Globally, the company is considered a leading manufacturer of label papers and delivers paper for around 100 billion labels annually to its globally active customers. Both Niklasdorf mill in Austria and Vevče mill in Slovenia produce specialty papers, such as label papers and food packaging.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2020 were approximately EUR 3.7 billion. Our 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Valmet to supply a major pulp and board technology delivery to Klabin in Brazil

Valmet will supply a large pulp and paper technology delivery to Klabin in Brazil. The order consists of a paperboard making line (PM 28), a complete new fiberline including a new Continuous Cooking G3, and a new bleached chemi thermo mechanical pulp (BCTMP) line, all with extensive scopes of automation and Valmet Industrial Internet solutions. The start-ups of PM 28, the BCTMP line and the fiberline are scheduled for the second quarter of 2023.

The orders are included in Valmet's orders received of the second quarter 2021. The values of the orders will not be disclosed. The delivery value of an order similar to PM 28 is typically around EUR 240-270 million, and the combined value of an order similar to the delivery of the fiberline and BCTMP line is typically around EUR 80-90 million.

These orders are part of the second phase in Klabin’s large investment project (PUMA II). Valmet’s delivery for the first phase announced in 2019 included the kraftliner machine (PM27) and the fiberline with Continuous Cooking G3. In this second phase, the BCTMP and fiber lines will be integrated with the new board making line PM 28, which will be a so-called flex machine. The machine will produce a large variety of board grades from kraftliner to coated boards such as folding box boards (FBB) and liquid packaging boards (LPB) with a reservation to add bio-barrier grades to the portfolio in the future. This combination will increase Klabin’s flexibility and reduce its exposure to market volatility.

These orders are part of the second phase in Klabin’s large investment project (PUMA II). Valmet’s delivery for the first phase announced in 2019 included the kraftliner machine (PM27) and the fiberline with Continuous Cooking G3. In this second phase, the BCTMP and fiber lines will be integrated with the new board making line PM 28, which will be a so-called flex machine. The machine will produce a large variety of board grades from kraftliner to coated boards such as folding box boards (FBB) and liquid packaging boards (LPB) with a reservation to add bio-barrier grades to the portfolio in the future. This combination will increase Klabin’s flexibility and reduce its exposure to market volatility.

“Over the last year, we have evaluated trends and market conditions to ultimately reach this decision of PM 28. The packaging board segment offers a huge growth potential, driven primarily by the potential substitution of single-use plastics with more sustainable options. We see an opportunity to create even more value for Klabin, reinforcing our business model, which is integrated, diversified and flexible. After the ramp-up of PM 28, Klabin is set to become one of the leading virgin fibers coated boards and kraftliner producers in the world,” says Francisco Razzolini, Director of Industrial Technology, Innovation, Sustainability and Projects and Pulp Business Officer at Klabin.

“Valmet was chosen a key partner for Klabin’s new PM 28, which will produce highly demanding coated board grades, because of our strong expertise and technical advantages. In the first phase of the project with PM 27, the cooperation between Valmet’s and Klabin’s teams has been excellent. I am proud to say that we, Valmet and Klabin, have managed the PM 27 project very well in these challenging and exceptional times. PM 27 will be started up in the near future,” says Jari Vähäpesola, President, Paper Business Line, Valmet.

“For the first phase of the project we delivered a new Continuous Cooking G3 technology that is tailored for southern hardwood. This second phase is a natural continuation in the utilization of our leading technologies. Our BCTMP technology offers excellent raw material efficiency and high bulk which enables sustainable light-weighted carton board production,” says Bertel Karlstedt, President, Pulp and Energy Business Line, Valmet.

“The paperboard segment has a big growth potential and once again Valmet and Klabin are partners to develop and introduce together high-efficiency, sustainable solutions. In this project, we are providing state-of-the-art technologies to produce high quality kraftliner and coated boards supporting Klabin’s strategic targets in this market. The industrial internet solutions embedded in the delivery will enable Klabin to move faster towards its’ sustainability and productivity targets,” adds Celso Tacla, Area President, South America, Valmet.

Technical information about the delivery

Valmet’s delivery will consist of equipment for stock preparation and approach flow systems as well as a complete three-ply coated board making line (PM 28) from headboxes to reel, followed by a winder with automated transfer rails and roll handling systems. The delivery also includes extensive packages for air systems for the machine, a hall ventilation system as well as a wet end chemical system, and surface starch and coating color preparation with supply systems for a sizer and coating stations. The machinery will be delivered installed.

The automation delivery includes Valmet DNA automation system for process and machine controls and Valmet IQ quality control system. A large Valmet Industrial Internet package with Valmet Performance Center services, a large combination of advanced monitoring and prediction applications, advanced process controls and training simulators with Valmet Virtual Mill will be included in the delivery, as well as Valmet Paper Machine Clothing package for start-up for all machine clothing positions.

The 9,000-mm wide (wire) machine will produce high quality kraftliner, liquid packaging board and folding box board grades with a design basis weight range of 150-350 g/m2. The design speed of the machine will be 1,200 m/min and the annual capacity 460,000 tonnes.

Technical information about the cooking fiberline and BCTMP line delivery

The fiberline is designed to flexibly produce eucalyptus hardwood pulp or southern pine softwood pulp. The design capacity for eucalyptus pulp is 1.000 tonnes/day and for pine pulp is 800 tonnes/day. The fiberline delivery includes a Continuous Cooking G3 with ImpBin technology for steaming and impregnation of the wood chips. This two-vessel system provides excellent pulp quality with very low reject content. The washing utilizes Valmet TwinRoll press technology for easy to maintenance and delivers high washing efficiency, low energy consumption and high availability.

“We are very proud to participate in this new phase of the Klabin Ortigueira unit expansion project. In the first phase, Klabin acquired from Valmet the first unit of our new continuous cooking technology, called G3 (Generation 3). The confirmation of this second line with the same technology reinforces Klabin's confidence in Valmet technology, delivery capacity and especially our ability to innovate and improve processes and equipment,” says Fernando Scucuglia, Director, Pulp & Energy, South America Area, Valmet.

The new 400 tonnes per day BCTMP line includes impregnation system, high consistency refining stage, bleaching system, low consistency refining, screening, dewatering and washing. The BCTMP solution was tailored as a joint effort by Valmet and Klabin based on work done by respective technology centers. It is designed to provide high yield, low energy consumption and excellent pulp quality for the new paper machine.

The delivery for cooking & fiberline and BCTMP line will be supported by a large Valmet Industrial Internet package with Valmet Performance Center services, advanced monitoring and prediction applications, Advanced Process Controls and Training Simulators.

Information about Klabin

Klabin S.A. is the leading packaging paper producer and exporter in Brazil, the only company offering one-stop shop solutions in hardwood, softwood and fluff pulp, and the leader in corrugated board packaging and industrial bags. The company was founded in 1899 and operates 24 industrial plants of which 23 in Brazil and one in Argentina.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2020 were approximately EUR 3.7 billion. Our 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

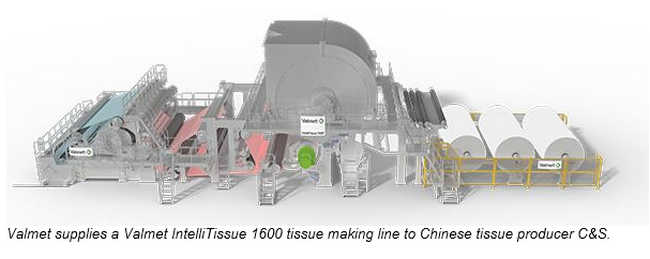

Valmet to supply the 12th tissue making line to C&S in China

Valmet supplies a Valmet IntelliTissue 1600 tissue making line to Chinese tissue producer C&S. The new line will be installed at the company’s mill in Tangshan, China. The start-up is scheduled for the first quarter of 2022.

The order was included in Valmet’s orders received of the first quarter 2021. The value of the order will not be disclosed. However, a project of this size and scope is typically valued at around EUR 5-10 million.

Valmet IntelliTissue machines belong to the small and medium size tissue machines that were integrated to Valmet’s offering when the company acquired PMP from Poland in 2020. Thanks to a long-term customer relationship, this order will be Valmet’s twelfth IntelliTissue tissue making line delivery to C&S.

“The target for our investment is to expand C&S’ share on the Chinese tissue market. We have decided to go for the IntelliTissue technology and execute the project together with Valmet due to their excellent references implemented worldwide,” says Tiande Lin, Director of Technology Center, C&S.

“This solution is a perfect match to the customers’ expectations. Valmet’s IntelliTissue technology ensures low energy consumption and high tissue quality thanks to state-of-the-art technology. The machines are responding to the needs of the customers in developing markets who see the possibility to grow their business not only by increasing the capacity, but also by lowering the production costs,” says Harrison Zhang, Vice General Manager of SMM (Small and medium size machinery), Changzhou, Paper business line, Valmet.

About C&S

C&S is a household paper manufacturing company in China and it is listed in Shenzhen stock exchange. The company has six production bases in Jiangmen and Yunfu of Guangdong, Chengdu of Sichuan, Jiaxing of Zhejiang, Xiaogan of Hubei and Tangshan of Hebei, with a sales network radiating to six biggest areas of east, south, west, north and middle of China, Hong Kong and Macao. C&S is selling its products to the overseas markets such as Southeast Asia, Middle East, Australia, and Africa.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2020 were approximately EUR 3.7 billion. Our 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Valmet signs an extensive Industrial Internet services agreement with ARAUCO for new pulp production line in Chile

Valmet and ARAUCO have signed an agreement to jointly develop the Arauco Mill Line 3 in Chile to become the world’s most autonomous pulp mill. Valmet will supply its Industrial Internet Solutions (VII Solutions) comprised of Mill Wide Optimization applications, advanced prediction and monitoring applications as well as expert services. The target is to improve the overall efficiency and profitability of the entire mill by coordinating and optimizing across process islands. The expert support is given both onsite and remotely through Valmet Performance Centers in South America and the Nordics.

The Arauco Mill Line 3, located in the Bio Bío Region in Chile, is currently being built as the MAPA project, a major investment to expand ARAUCO’s current pulp production capacity. As announced in 2018, Valmet delivers pulp drying and baling, recovery boiler and biomass boiler to the MAPA project.

“Since we started the MAPA project in 2011, we have wanted that the project represents a real contribution to the territory and is also in line with the environmental standards required today. From the beginning, this project comprised a broad investment program in technology, energy efficiency and big data, among others, which will make the processes much more efficient. Our partnership with Valmet represents another step in the sustainable development of the project. We believe that it is essential to have a world-class ally that guarantees the standards and the best technology available in the market today,” says Charles Kimber, Senior Vice President, People and Sustainability, ARAUCO.

“This is a true partnership, where we have jointly tailored the solution to best suit the ARAUCO’s needs. With this partnership it will be possible to maximize the production of the mill and move towards an autonomous mill. In this project we utilize our solid process and automation know-how and combine our strong local presence in South America with our global resources. Our common target with ARAUCO in the first phase is to secure successful commissioning of the MAPA project, fast start-up, ramp-up curve and improve the overall efficiency and profitability of the mill for the years to come,” says Félix Hernaiz, General Manager, Andes Region, Valmet.

Valmet will supply Industrial Internet solutions for Arauco Mill Line 3 onsite and remotely from Valmet Performance Centers in South America and the Nordics.

Valmet will supply Industrial Internet solutions for Arauco Mill Line 3 onsite and remotely from Valmet Performance Centers in South America and the Nordics.

Technical information about the agreement

The contract includes several Valmet Mill Wide Optimization applications which provide a completely new way to improve mill profitability. The Mill Wide Optimization applications use process flowsheet optimization to automate mill level decisions and coordinate process area actions by generating production and quality plans for each mill area to help increase production and reduce costs. Additionally, Valmet will deliver optimization, advanced monitoring and prediction applications for selected process areas focusing on the pulp dryer and power and recovery boilers. Optimizations are based on Valmet’s kappa, brightness and alkali analyzer measurements.

Valmet also delivers expert support onsite and remotely from Valmet Performance Centers in South America and the Nordics. A Valmet expert will be daily at the mill and Valmet specialists will visit the mill several times a year to evaluate the performance. A comprehensive Data Discovery service will be implemented during the five-year contract period.

“This agreement combines Mill Wide Optimization, Advanced Process Controls (APC), analytical applications and remote services from Valmet Performance Center. We are using Valmet Customer Portal as our digital collaboration space to provide easy access to the advanced applications and the Valmet expert team,” says Jari Almi, Vice President, Industrial Internet, Valmet.

Valmet Industrial Internet solutions in a nutshell

In early 2020, Valmet introduced a full range of new, data-driven Industrial Internet solutions to pulp, board, paper, tissue and energy producers. The Valmet Industrial Internet (VII) solutions combine advanced monitoring and prediction applications, Advanced Process Controls (APC), dynamic process simulators and remote services from Valmet Performance Centers into comprehensive solutions that provide tangible benefits to customers.

The purpose is to efficiently utilize data and Valmet’s expertise to reduce energy consumption, improve chemical and environmental efficiency, optimize pulp and paper quality, increase process reliability, maximize production and enable efficient management of the customer’s equipment fleet.

About the customer ARAUCO

ARAUCO is a global forest product company. The company operates in the forestry, pulp, lumber, plywood, composite panels, millwork, and renewable energy businesses. The company has a revenue of about USD 5 billion. The company operates altogether 42 sawmills, panel mills and pulp mills in North America, South America, Europe and South Africa.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2020 were approximately EUR 3.7 billion. Our 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

For further information, please contact:

Samuli Lehtonen, Director, Performance Optimization, Valmet, tel. +358 50 583 6281

Marcus Oliveira, Regional Sales Manager, South America, Valmet, tel. +55 15 997814768

The new Valmet Fiberline Analyzer fulfills all major process control needs in the pulp mill

Valmet introduces the new Valmet Fiberline Analyzer to enable pulp makers to improve total pulp quality management, boost process stability and gain major savings in chemical costs from the digester blow line right up to final pulp storage.

The Valmet Fiberline Analyzer includes the major advances in measuring technology gained through four generations of Valmet Kappa Analyzers. It measures pulp lignin content and brightness in addition to enhanced fiber and shive property measurements using the latest high-definition imaging techniques. Measurement data from automatically extracted pulp samples, in addition to inline sensor information can be combined with real-time production targets to provide setpoints for chemical controls from the digester to final bleaching stages.

“This is the most robust analyzer solution we have ever developed for the pulp mills and it provides a very good basis for advanced process control,” says Kari Lampela, Business Manager, Automation business line, Valmet.

Valmet Fiberline Analyzer

Valmet Fiberline Analyzer

Application specific measurements and controls

Built-in controls can provide external setpoints to the chemical dosage controllers using easily understood function blocks to perform filtering and calculations. For softwood pulps, the basic controller uses a Kappa factor control modified with predictive feedback taking Kappa/brightness, shive content and COD (Chemical Oxygen Demand) into account.

Valmet Fiberline Analyzer can also separately measure lignin and hexenuronic acid (HexA) to provide significantly improved control of the complex chemistry of cooking and delignification, especially with hardwood pulps. These measurement and control capabilities, coupled with the analyzer’s unique ability to accurately measure final brightness, close the loop for true fiberline process optimization and quality control.

User-friendliness and remote support

The analyzer requires minimal maintenance and features chemical based self-cleaning for trouble free operation. With the built-in touch screen display, all analyzer operating parameters, operating sequences and diagnostics together with operating instruction are all instantly available. Remote configuration and operation as well as Valmet Industrial Internet (VII) capabilities provide the possibilities of remote specialist support and assistance from Valmet around the world.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2020 were approximately EUR 3.7 billion. Our 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com