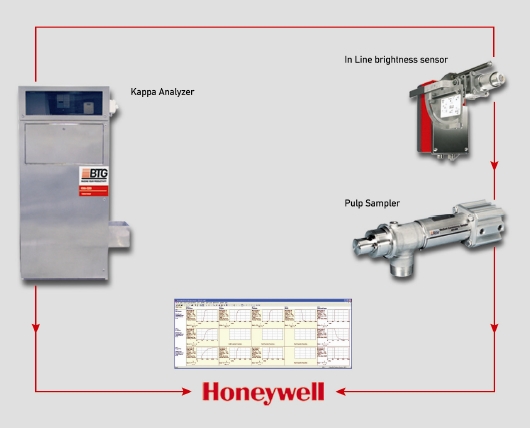

An enhanced Pulp mill solution, which reduces chemical consumption and quality variations and increases operator effectiveness, also requires modern communication with the instrumentation. BTG’s field sensors and analyzers are the window to your process and enable Honeywell’s Profit Controller® to provide best-in-class Advanced Process Control performance.

Therefore, BTG releases a new PLC and computer interface for new and existing KNA kappa analyzers. The new PLC utilizes connection to today’s most common field bus systems and allows four bus modules at one time. These include: Profibus DP, DeviceNet, CANopen, MODBUS, CS31, RCOM, Ethernet TCP/IP, PROFINET and EtherCAT. An OPC server is also provided.

Enhanced user-designated screens, graphics and diagnostics make this the most easily accessible kappa analyzer on the market. The computer interface for mill operators, instrument technicians and process engineers is Windows 7 based.

As of January, 2011 all new BTG kappa analyzers are delivered with this enhanced performance. Upgrade kits for mills, owners of the KNA-5200, will be available to take advantage of today’s new connection and communication technology.