In 1928 our knife gate valve manufacturing started in close co-operation with nearby pulp and paper mills. Now it is time for the eighth knife gate valve generation, the MP, which is a result of market driven requirements and experienced engineering throughout the years. Stafsjö has introduced one new knife gate valve every year now the last three years. 2009 we introduced the slurry valve SLV, primarily for the mining business. 2010 we introduced our HL, a slim line version of our HG valve with through-going gate, and now 2011 the MP.

In 1928 our knife gate valve manufacturing started in close co-operation with nearby pulp and paper mills. Now it is time for the eighth knife gate valve generation, the MP, which is a result of market driven requirements and experienced engineering throughout the years. Stafsjö has introduced one new knife gate valve every year now the last three years. 2009 we introduced the slurry valve SLV, primarily for the mining business. 2010 we introduced our HL, a slim line version of our HG valve with through-going gate, and now 2011 the MP.

– We are proud to announce Stafsjö’s latest development for the Pulp & Paper Industry. The MP valve represents the new generation of shut-off valves which fully corresponds to today’s market demands such as bi-directionality, full bore and minimum maintenance, says Thomas Carlson, CEO of Stafsjö.

Product features

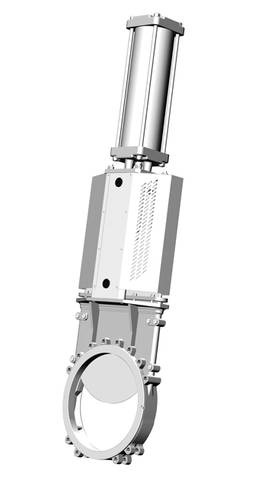

The MP is a bi-directional full bore valve which together with its special shut-off design makes it suitable for many different applications – it is a true Multi Purpose valve.

MP has a one piece body design in stainless steel. For operation reliability in applications with corrosive or clogging media the valve body comes with integrated purge ports as standard. The MP is also supplied with Stafsjö’s retainer ring system which can be combined with several seat materials and this makes it easy to optimize the valve to specific process conditions. It also offers smooth and cost-efficient maintenance. The valve has a gate support and casted bottom support cams to obtain bi-directional sealing. The gate support is available in different materials.

The top work consists of aluminium beams and stainless steel tie rods which gives good corrosion resistance and stability at maneuvering. Several actuator types are available to choose from as standard as well as accessories. All remote operated valves are supplied with gate guards in stainless steel.

Sealing principle

When the valve is operated from open to closed position, the gate effectively cuts through the media. This is facilitated by the inner cavity of the valve body and the bevel edged gate. In closed position the gate is pushed against the seat and the gate support ensure a bi-directional sealing together with the bottom support cams that stabilizes the gate.

The gland box is equipped with three layers of our TwinPackTM and a box bottom scraper, which gives high operation reliability and prevent the media from reaching surrounding environment.

Accessibility

Stafsjö is a recognised supplier of knife gate valves to process industries worldwide. Together with our sister company Ebro Armaturen and external sales partners we are able to provide fast deliveries, high quality service and support to local markets. We strive to be the most accessible, reliable and cost-effective supplier of knife gate valves.