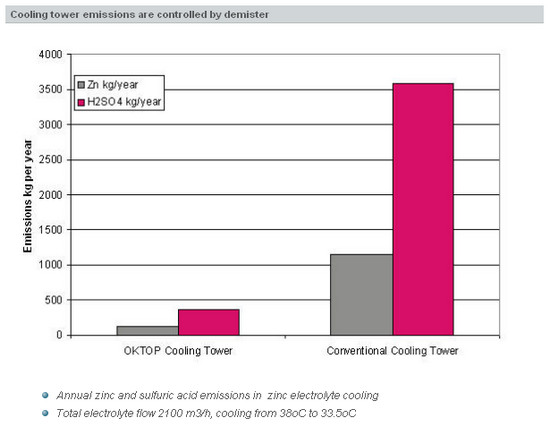

Outotec OKTOP® Cooling Towers enable lower emissions and larger cooling capacity than conventional cooling towers.

Outotec launches a new series of cooling towers for process solutions. The major benefits are increased cooling capacity as well as lower emissions to air.

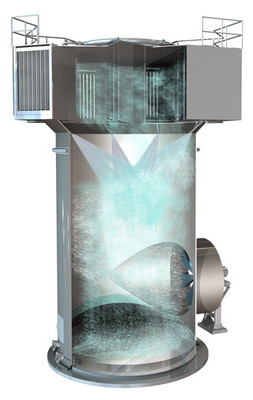

The towers are a result of several years of product development which have resulted in radically new structural geometry. The most important change is that the air flows out of demisters horizontally, not vertically like in conventional cooling towers. The speed in the demister is higher and there is more cooling air. In addition, drops are separated more efficiently. Consequently, the amount of harmful solution emissions is brought down to a completely new level.

The new structure also improves the cooling air flow distribution inside the tower. This minimizes the dead spots where the drops are not cooling.

Furthermore, the inflow of the air can be adjusted dynamically so that the out-flowing solution temperature can be controlled regardless the outside weather conditions.

More capacity in one tower

“Our technology is way superior to our competitors,” Process metallurgist Tuomas Hirsi says. “We can offer a better overall solution based on the customer’s process conditions and meet even the strictest environmental legislative requirements. By using advanced CFD modelling and our own standardized models, we can determine the optimum solution for every customer.”

By optimising the process and using the more efficient cooling towers there is no need for as many towers as there would be when using conventional technology. Less towers equals to less space, less piping, less energy and less running costs. Lower emission levels meet the emission limits for a long time in the future. Thus, investing in an OKTOP Cooling Tower pays itself back very quickly.

Excellent availability and easy maintenance

Another benefit of the new cooling tower is its easy maintenance, which has been paid special attention to. All regular maintenance work can be carried out from the upper deck safely and while the tower is still running. There are maintenance hatches where the pieces of equipment can be serviced and the nozzles can be changed without going inside the tower. The demister boxes can be separated and they can be washed without shutting the tower off. This ensures maximum availability of the plant and makes working with the towers as safe as possible.