Displaying items by tag: Aikawa

AFT – Winning with customers via the Lean Stream

AFT's rotor and cylinder plant in Varkaus, Finland is meeting customer needs like never before since the implementation of the Lean Stream project in 2013. Over the past four years, productivity and profitability have improved, work in progress and throughput times have been cut in half, and reliability of supply has increased to an all time high above 97%.

According to Antti Kettunen, Plant Manager and Team Leader: "With Lean Stream, almost no equipment changes were made to reach a record level of efficiency. The investment was in ideas and embracing all workers as managers."

According to Antti Kettunen, Plant Manager and Team Leader: "With Lean Stream, almost no equipment changes were made to reach a record level of efficiency. The investment was in ideas and embracing all workers as managers."

So what changed? Kari Ikäheimonen, HR Manager at AFT Varkaus explains: "We switched from a resource-based to a production model around customer orders, understanding and modifying the value stream from beginning to end. The magic began to happen when everyone at the factory could see the customer beside him or her at all times."

AFT’s Lean Stream won the 2014 Lean Act of the Year Award from the Lean Association of Finland in recognition for being a model in adapting traditional industrial processes to value streams centered on customers. This prize is designed to improve the competitiveness of the private and public sector in Finland.

The objective of Lean Stream is to always ensure an uninterrupted and faster flow of products throughout the process. Customer demands and manufacturing issues are discussed twice daily in 5-10 minute meetings that take place on the shop floor with foreman and employees. Continuous improvement is key and revolves around trust between personnel and management.

Kettunen adds: "AFT’s strengths include the ability to radically challenge traditional thinking, employees committed to continual change and ongoing development of operational processes, staff skills, and management systems.”

AFT is a global supplier specializing in stock preparation, screening, refining and paper machine approach flow. With over 110 years of experience in manufacturing and supplying tailored solutions, AFT helps to improve performance with trademarked advancements: Finebar - ultra low intensity refining, Powerwave - energy efficient screening, MaxiPulper - advanced pulping technologies, POM Systems and more.

AFT opens new manufacturing site in China

AFT Inc. has announced the opening of a new manufacturing facility in China -- Jiaxing AFT Manufacturing Co., Ltd. The facility is located in Zhejiang Province, west of Shanghai, on the Hangzhou Bay near an excellent transportation network of highways, railways, and shipping lanes.

AFT Inc. has announced the opening of a new manufacturing facility in China -- Jiaxing AFT Manufacturing Co., Ltd. The facility is located in Zhejiang Province, west of Shanghai, on the Hangzhou Bay near an excellent transportation network of highways, railways, and shipping lanes.

Jiaxing AFT Manufacturing will serve the dynamically growing pulp and paper market in China and joins the network of other AFT manufacturing centers in Canada, Finland, and South Korea.

Activities at the Chinese facility include the production of performance components (for screening and refining systems) as well as equipment rebuilds for screens, refiners and pulpers.

In addition to its performance components, AFT offers systems and equipment for fiber processing (virgin and recycled fiber) including screens, refiners, stock preparation, and paper machine approach flow.

According to company officials, the Chinese organization will be an area for investment over the next few years as capacity is added and capabilities of the site are expanded.

To support the new facility, a website www.aftzhongguo.com has been recently launched.

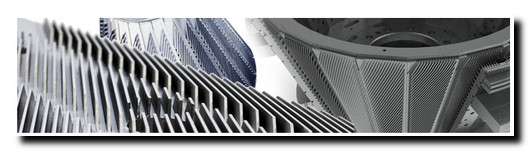

Refiner plate MiniSegment™ extends value, saves money for LC refining

AFT Finebar®, part of the global Aikawa Group, has developed the MiniSegment™ refiner plate – the latest advancement in diffusion bonded refiner plate technology. The MiniSegment allows mills to replace only the working surface of the refiner plate, reducing the overall cost of ownership.

AFT Finebar®, part of the global Aikawa Group, has developed the MiniSegment™ refiner plate – the latest advancement in diffusion bonded refiner plate technology. The MiniSegment allows mills to replace only the working surface of the refiner plate, reducing the overall cost of ownership.

The MiniSegment is installed on an Adapter Plate, which is bolted to the mounting surface using the existing refiner bolt holes. In addition to saving money by replacing only the fiber-contacting portion of the refiner plate, the MiniSegments weigh considerably less than a traditional plate, making them easy to position when bolting and safer to handle.

AFT Finebar MiniSegments can be applied to nearly any single disk, double disk, or Tridisk low consistency refiner.

Aikawa gathers forces to give papermakers a choice in stock preparation solutions

New organization under a single brand is driven by customer requests for alternatives to avoid being “boxed in” for key technologies

For many years, Aikawa Iron Works worked quietly to build its foundation as a premier supplier of stock preparation technologies in Japan. Its acquisitions of specialist companies such as AFT Screen Plates of Canada, Finebar of the USA, and POM Technology of Finland were conducted with little fanfare.

“Perhaps we have operated under-the-radar,” admits Masaki Aikawa, Chairman of the Aikawa Group. “But that has been our style. We put performance ahead of self-promotion.”

In pursuit of higher performance and recognition, the Aikawa Group is announcing a name change and a new, consolidated global organization. “This is in response to our customers’ requests,” Aikawa admits. “They want alternatives to the packaged offerings of the ‘Big Box’ major suppliers. They prefer the freedom to select the best single equipment, with the expertise to put systems together when required.”

The new organization is being consolidated outside of Japan under the umbrella of Aikawa Fiber Technologies (AFT), which is guided by Michael Stephens, President and a 35-year veteran of the pulp and paper industry.

Stephens says that AFT is being structured into teams to serve the three major customer groups for Aikawa outside Japan: screen manufacturers (original equipment manufacturers) who contract with AFT for manufacturing of screen cylinders, plates, and rotors; mills who order these engineered wear parts directly from the company; and mills looking for technical solutions for fiber processing, stock preparation, and machine approach applications.

“Each of these customer groups has unique needs that often times are addressed separately,” Stephens says. “But there are also occasions where customers need solutions that cross over from capital equipment to engineered wear parts to process/systems knowledge. When this happens, we don’t want to confuse our customers with separate interfaces or separate companies with different ways of working.”

According to Stephens, in the contract manufacturing segment, AFT produces more screen cylinders than any manufacturer in the world. Stephens explains, “Most of the OEMs are customers of ours and we give them preferred pricing based on volume. The focus here is on high-precision, low-cost manufacturing that is private-labeled for OEMs.”

The fiber processing and stock preparation solutions are a combination of Aikawa technologies and the technologies of the former POM Technology Oy of Finland, which Aikawa acquired. POM has a patented compact wet end technology for paper machines. Timo Koivisto, formerly the head of POM Technology, is responsible for AFT’s Process/Equipment Solutions team.

The transition from separate companies to a unified AFT organization is currently underway and will be completed by year’s end, according to Stephens. Key management decisions will be announced in the near future.

Aikawa honored with Sasaki Award from Japan TAPPI

Prestigious award presented annually to most outstanding technology development

Aikawa Iron Works, headquartered in Japan, was awarded the prestigious Sasaki Award for its developments of FINEBAR® refiner plate technology. The Sasaki prize is given once a year to the company demonstrating the most outstanding technology development.

Shinichiro Kondo, Chairman of the Board of Japan TAPPI, presented the award to Takeshi Kanazawa, Director Vice President of Aikawa Iron Works, at a ceremony on May 26, 2011.

In presenting the award, Aikawa was cited for “developing a refiner plate that not only saves refiner energy, but also improves paper strength and refiner plate life. This has contributed to the development of the industry’s refining technology and has also made a great contribution to the Japanese pulp and paper industry.”

The FINEBAR® patented design is manufactured using precise techniques which achieve extremely thin bars and fine grooves. The result is the ability to refine fibers in low-consistency applications with ultra-low intensity – saving energy and enhancing paper qualities.

FINEBAR® plates are manufactured, marketed, and supported outside of Japan by Aikawa’s subsidiary, AFT.