Displaying items by tag: GL&V

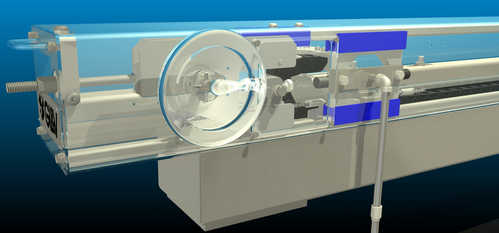

GL&V FlexTrim™ Tail Cutter Development

In 2014, GL&V initiated a development project to improve and modernize our wet end tail cutter equipment.

Features of the new design include:

- A totally enclosed and pressurized drive section that protects the motor and clutch assembly from the harsh mill environment. The drive section is also skid mounted and easily removable for off machine maintenance.

- Several control options.

- Optional travel speeds.

- Adaptable to any machine width.

Our new FlexTrim™ Tail Cutter represents two of GL&V’s core values: Flexibility & adaptability.

Four of these improved units have recently been sold, installed and commissioned and have provided GL&V with positive customer feedback.

For further details, please visit our website www.glvpulppaper.com

Kawanoe Zoki to offer GL&V Pulp and Paper’s BTF™ Headbox technology in China

GL&V Pulp and Paper is pleased to announce that Kawanoe Zoki, our long term partner in the pulp and paper market in Japan, is taking over responsibility for the BTF™ headbox technology in China.

Kawanoe Zoki has extensive experience in designing, building and marketing pulp and paper equipment in Asia, and has been a partner of GL&V for more than 20 years. Kawanoe Zoki has sold, designed, manufactured and successfully started up many BTF installations in Japan. They already have extensive experience in the Chinese pulp and paper marketplace with their tissue forming technologies.

There are now 190 BTF installations worldwide, including 44 in Asia, of which 25 are located in China. GL&V is pleased that Kawanoe Zoki will be continuing to offer customers in China the benefits of BTF Dilution Profiling headbox technology.

GL&V -GL&V Pulp and Paper Group designs and markets equipment used in various stages of pulp and paper production, from pulp preparation to sheet forming and finishing. GL&V serves the global market with spare parts, rebuilds, upgrades and optimization services for new and existing equipment. Our pulp and paper group is focused on innovation and provides technologies that generate energy and cost savings for our customers.

For further information, please contact:

GL&V - This email address is being protected from spambots. You need JavaScript enabled to view it. or visit our website www.glvpulppaper.com

Kawanoe Zoki - This email address is being protected from spambots. You need JavaScript enabled to view it. or visit our website www.kawanoe.co.jp/english/

Södra picks GL&V for fibreline upgrade at Mörrum

Södra Cell has appointed GL&V to supply a major upgrade of the softwood pulp line at its Mörrum mill.

Södra Cell has appointed GL&V to supply a major upgrade of the softwood pulp line at its Mörrum mill.

Two weeks ago Södra announced that its Board of Directors had granted SEK 700 million for a comprehensive refurbishment of the pulp mill at Mörrum.

GL&V will be responsible for screening and washing equipment in the unbleached area of the softwood pulp line.

Investing in a new screen room and brown-stock washing is fundamental for the development of the Mörrum mill.

"We have had a good and close co-operation with GL&V while planning this project and we are convinced it will continue in the execution phase", said Jörgen Lindström, Operations Engineer at Södra Cell Mörrum.

"The Mörrum mill will be equipped with what in our opinion is undoubtedly the industry's best technology. We focus on innovation and we are glad that Södra Cell, which itself is one of the industry's most innovative companies, has chosen to partner with us", commentedFredrik Björck, Sales Manager at GL&V.

GL&V is part of the GLV Group which has a total of 1,800 employees. In Sweden GL&V focuses on solutions for the pulp and paper industry through its technology centres in Stockholm and Karlstad.

GL&V News: BTF™ Headbox & Retrofit Start-Ups in China

GL&V recently began assembling BTF™ Headboxes and Retrofit Systems for the Chinese marketplace in China, using critical components manufactured in Canada and other parts manufactured in China by local supplier partners. Rigorous training and quality control systems were put in place to ensure that the resulting BTF products would meet GL&V quality standards. A total of 5 new headboxes and 4 retrofits have already been sold and manufactured with this new process. Several of these started up recently and are operating very successfully.

GL&V recently began assembling BTF™ Headboxes and Retrofit Systems for the Chinese marketplace in China, using critical components manufactured in Canada and other parts manufactured in China by local supplier partners. Rigorous training and quality control systems were put in place to ensure that the resulting BTF products would meet GL&V quality standards. A total of 5 new headboxes and 4 retrofits have already been sold and manufactured with this new process. Several of these started up recently and are operating very successfully.

Lee and Man, the second biggest paper company in China, installed and started up a BTF dilution control headbox retrofit on the base ply of their PM3 linerboard machine in September last year. Performance optimization trials were run in October and the installation met all performance guarantees. In addition to the expected improvements in the sheet CD profile, the mill also realized significant savings in chemical costs. Lee and Man have ordered two more BTF retrofit systems, one for their PM5, which will start up later this year, and one for their PM7, which recently started up successfully

in February.

Zao Zhuang Huarun started up four new BTF headboxes on their PM4 four-ply gypsum board machine in September 2012. Performance optimization trials were run in November and following successful testing, the customer released all performance guarantees. This customer already has two older BTF headboxes on their PM3 machine, now making a total of 6 BTF headboxes in this mill.

Zao Zhuang Huarun started up four new BTF headboxes on their PM4 four-ply gypsum board machine in September 2012. Performance optimization trials were run in November and following successful testing, the customer released all performance guarantees. This customer already has two older BTF headboxes on their PM3 machine, now making a total of 6 BTF headboxes in this mill.

GL&V to deliver 600 t/d OCC-line to Ukraine

GL&V Sweden AB has received an order for a new OCC line based on the innovative TamPulping™ process technology, designed to produce high quality pulp with a minimum of energy usage.

GL&V Sweden AB has received an order for a new OCC line based on the innovative TamPulping™ process technology, designed to produce high quality pulp with a minimum of energy usage.

The TamPulper™ two-layer pulper enables the pulper and coarse screening stations to be combined, significantly simplifying the process and reducing the connected power requirements. The atmospheric secondary stage TamPulper™ station also has proven to be much more reliable than pressurized style pulpers operating on highly contaminated OCC furnishes.

Apart from the new pulping station, the system includes other innovative GL&V technologies which contribute to the low energy consumption:

- Celleco Twister® and Slidepac® high consistency fine cleaners

- TamScreen™ multistage screens

- High consistency fed CDI disc filters

- The DD®6000 refiner with EquaFlow™ technology

GLV Announces the Recent Award of New Large-Scale Contracts Worth Close to $39M

GLV Inc. (TSX: GLV.A, GLV.B) announced today that it has been awarded new major contracts worth close to $39M. Among these contracts, the Water Treatment Group has obtained a $13.5M order from an Australian food processing company for a system that allows reusing up to 3 million litres of process water a day. It has also won two contracts totalling $9.7M for the delivery of water screening systems to Middle East companies operating in the energy and oil and gas sectors.

In addition, the Pulp and Paper Group has received orders totalling $15.5M from North American and European producers. Pursuant to these contracts, the Group will deliver solutions based on GLV’s technologies to increase productivity, machine reliability, product quality and new product manufacturing capability.

These contracts add to the numerous smaller-scale orders awarded to both groups over the last few months.

“The orders won since the beginning of the year attest to both groups’ ability to meet the diversified needs of a customer base present on five continents,” indicated GLV’s President and Chief Operating Officer Richard Verreault. “The water treatment industry remains dynamic and our teams are continuing their efforts to develop close business relations with customers in order to provide them with custom-made solutions meeting their expectations in terms of efficiency and operating costs. In the pulp and paper industry, the award of some of the latest contracts confirms the first signs we have been observing since last fall of renewed investment by pulp and paper manufacturers worldwide. Thus, the Pulp and Paper Group will continue to bank on the solidity of its proprietary product line, expertise and global network to take advantage of the business opportunities that should arise as companies resume their investments to upgrade their facilities.”

FOR INFORMATION

Investors

Marc Barbeau, CA

Executive Vice-President and Chief Financial Officer

Tel: 001 514 284-2224

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.

Media

Yves Doucet

Director, Communications

Tel: 001 514 284-7202

Email: This email address is being protected from spambots. You need JavaScript enabled to view it.