Displaying items by tag: Glocell

GloCell offers New software tools

GloCell tools and services have now been widely accepted in the global pulp and paper market. Thanks to our innovative and forward looking customers we are happy to announce new products and services that enable pulp, paper and board makers to effectively find the best cost vs. quality for the grades they wish to produce.

We have also updated our reference list that contains already some of the most important companies in our genre. There are also more to join in near future.

We have also started co-operation for on-line services with Metso Automation and on-going possibility of combining our tools with Savcor Wedge still remain.

SoftaCellTM is providing easy to use software for pulp and paper business. Our fiber and raw material optimization covers the whole value chain from plantation forests to complicated fiber based products like multi-layer cardboards.

Our approach is a project where the main targets will be set jointly with the customer. The usual targets are around savings with the same quality or increased quality to produce added value for the customers.

In forestry we have delivered models about capability for wood users to pay for tree. In the models were included various sample mills and the optimal usage of wood in the regions selected.

In Pulp Mill product optimization the projects have included analysis of the benefits for pulp producers’ customers from improved pulps for different paper grades.

In paper making our references include furnish quality and cost optimizations for several paper makers. Projects have been done with paper manufacturers from specialty papers to common printing grades. We have just recently also done optimisations for board and other multilayer grades.

The typical savings are from 5 to 15€ per ton of paper produced, but even larger potentials have been shown.

Please check out the links that you are interested in below.

SoftaCellTM FIT for pulp sales

Glocell's Fiber value chain optimization

We have now a new presentation of what our approach is. This includes some first shots of the new optimization software that is available soon. Please see the presentation behind the link. Presentation!

We have now a new presentation of what our approach is. This includes some first shots of the new optimization software that is available soon. Please see the presentation behind the link. Presentation!

The approach includes possibility to optimize parts or the whole value chain from forest to paper and boardmaking.

Forestry

Evaluation of wood availability for planned or current useEvaluation of genotype and phenotype effects to pulp production

Raw material based quality positioning options for pulp producers

Pulp making

Evaluation of quality based on wood procurement possibilitiesPulp mill segregation of needed wood for the wanted outcome of mechanical and chemical pulps

Pulp mill process optimization for the needed quality and end user benefit outcome

Pulp sales tools

Paper and board making

Cost vs. quality optimization tool and service for paper and board gradesPulp quality selection tools for procurement purposes

On-line cost follow-up of on going production

Quality planning and trial run minimization

Presentation is included here.

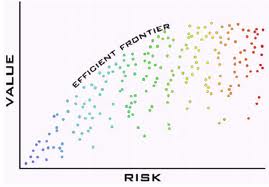

Glocell's Innovation portfolio optimization

Do you really have quantitative data on your development and innovation portfolio, or are you just making decisions based on qualitative opinions? There is a way to make innovation evaluation more accurate with Modern Portfolio Theory application.

Do you really have quantitative data on your development and innovation portfolio, or are you just making decisions based on qualitative opinions? There is a way to make innovation evaluation more accurate with Modern Portfolio Theory application.

Check out our approach presentation.

MPT has been recently criticized for its inability to understand actual market situations in investment field. As this criticism is well justified in investment banking, it has no relevance in innovation portfolio management. This is based on the nature of collecting data for the model as well as the natural predictability of future development. The approach is very suitable to companies’ innovation evaluation work when various predictions of the future need to be justified for improved decision making .

The answer to the R&D evaluation challenge is three fold. First we need to evaluate the used processes and adjust them to meet the data collection criteria. Second we need to collect all qualitative data into tools that enable variation of input. And third, we need to perform a portfolio analysis based on the data from multiple projects.