Displaying items by tag: Kelheim Fibres GmbH

Kelheim Fibres to present new research results at Zellcheming

Once again Kelheim Fibres will attend this year’s ZELLCHEMING general meeting and Expo. Dr. Ingo Bernt, a member of the R&D team of the Bavarian fibre specialist, and Dr. Rene Eckhart from the TU Graz will give a lecture on the results of the latest research into the effects of flat viscose fibres in papers, while other members of Kelheim Fibres are available in hall 2, booth nr 207, for further discussions. There is also the possibility to learn more about Kelheim’s most recent “paper fibre”, the newly developed Leonardo.

Kelheim Fibres continues to pursue the strategy of expanding its activities fin the paper making industry. Kelheim’s speciality fibres have been used in papers for several decades, but recently numerous new developments have led to a multitude of new possible applications in this sector. In addition to interesting functionalities Kelheim’s viscose fibres offer two particular benefits: they are easy to incorporate in the papermaking process – as they are manufactured from cellulose, the same raw material used for paper – and they are an environmentally friendly alternative to other additives, as they consist of a 100% renewable resources and are completely biodegradable.

Kelheim Fibres GmbH presents Leonardo

Kelheim Fibres: first step of a 4-stage investment package authorized!

The shareholders of Kelheim Fibres GmbH have approved the first stage of a new, 4-stage investment package. This was announced by the C.E.O. of Kelheim Fibres GmbH, Dr. Haio Harms, during festivities to mark the 75th anniversary of the fibre manufacturer.

At the festivities, staged under the motto “75 years – a bridge from yesterday to tomorrow,“ which were intended to focus particularly on the future development of the Kelheim fibre-producing location, amongst other issues, Harms emphasized those positive signals seen on the site in the past few years: the willingness to invest in new processes, in innovation and new products, had made it possible to continue to expand the company’s technological edge and to strengthen its market position.

He confirmed that more than 100 million Euros had already been invested in the location between 2004 and 2009.

In the first stage of the so-called UEK Programme („Umweltverbesserung (environmental improvement), effizienz-steigernde Erneuerung (efficiency-enhancing renewal) and Realisieren von Kapazitätsreserven“ (realization of capacity reserves) an investment volume of around 25 million Euros are to be spent on refurbishing an existing spinning line with state-of-the-art technologies. This will allow removal of the majority of process exhaust air directly at source.

An additional environmental measure includes investing in a new, combined evaporation and calcination plant, which will cut consumption of steam currently needed in this area by 75%.

At the same time, these improvements also eliminate certain bottlenecks in production, enabling an increase in production capacity at Kelheim Fibres as of the second quarter of 2012 to an annual fibre capacity of 91,000 tons.

In the following years, three further stages “UEK 2 to 4“ – each involviing an investment of around 25 million Euros – are planned for modernisation of the remaining spinning lines, thus enabling a capacity of around122,000 tons/annum to be reached.

This increase in production volume will enable Kelheim Fibres to alleviate the competitive disadvantage resulting from producing in Germany with the increased infrastructure costs this entails (such as energy, safety, incidental wage costs, environment, administration, etc.) via higher quantities – to maintain the competitive edge of Kelheim’s Fibres in an international environment.

Competence in Paper: Kelheim Fibres expands in-house Technical Centre

Kelheim Fibres, the world’s leading manufacturer of viscose specialities, has extended its in-house technical centre for paper making.

Research and development are key points for the producer of functional and tailor-made speciality fibres. The development work focuses not only on the development of new fibres but also on the potential end products made out of them.

A range of in-house pilot plants and technical equipment allow Kelheim Fibres to simulate their customers’ processes and to duplicate the properties of the end product. In this way they have been able to develop a broad understanding for the customer’s needs.

For the development of viscose fibres for speciality papers and wet laid products, Kelheim Fibres makes intensive use of its own in-house technical centre for paper production.

To meet the growing demand in this area, the technical centre has now been extended.

The new pilot plant has inclined wire technology and it is possible to process all types of fibre, pulp and – if required – to include different additives in papers with weights from 20–200g/m². The new inline dryer also enables the production of larger samples.

Using this new technical centre Kelheim Fibres is able to rapidly verify the results of the fundamental research carried out in cooperation with the Institute for Paper, Pulp and Fibre Technology at the Graz University of Technology and transform the theories developed into innovative paper products. The new Paper Competence Centre is also available for Kelheim Fibres customers′ own trial work.

Test runs on big production plants are expensive and disrupt regular production campaigns. With the new pilot plant customers can take the first steps in developing innovative papers – and engineer these new products in close cooperation with Kelheim’s R&D fibre experts.

Fibre Solutions for Recycling Paper

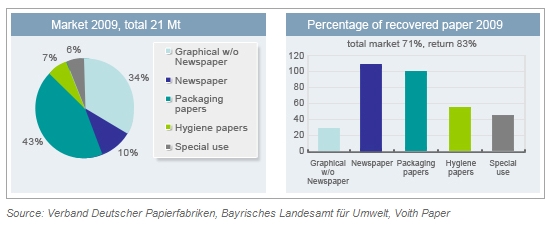

Worldwide there is an expected rapid growth of paper as in the past paper demand grew more rapidly than Gross National Product and has been unaffected by the often predicted “paperless office”. Covering this huge demand only by using fresh fibre pulp would lead to en overexploitation of forest resources. Therefore it has mainly to be covered by recycling of used paper products.

Even though 80% of used paper is collected still only 70% of it is recycled even though recycling is economically very attractive. 30% of paper is still made out of virgin fibres.

Why don′t we recycle all of the paper we collect? During the recycling process paper is ground. Its fibres are shortened and hence the stability of the paper is reduced making it unsuitable for many applications. We have to consider that “70% recycled” also means 50% has been recycled more than once, leading to a further deterioration in performance. To compensate this 30% of fresh fibres are added to the paper. Particularly graphical papers have a very low content of recovered material.

With our viscose fibres we were able to achieve an increase of paper quality demonstrated by e.g. higher double fold numbers and tear lengths by adding only 2–3% of our short cut viscose fibres to the pulp. With these short cut fibres it is possible to use nearly 100% of the cheaper recycled pulp. Instead of adding 20–30% of fresh fibre pulp there is only a need to add 2–3 % of viscose fibres such as Bellini.

This means that resource consumption can be reduced by up to 90%. Furthermore savings can be made on the raw material price because adding 2–3 % of viscose fibres is still cheaper than adding 20–30% of virgin pulp.

Kelheim Fibres present Viscose specialities with added functionality at INDEX

The Bavarian manufacturer of speciality viscose fibres has been firmly established in the nonwovens industry as a supplier of unique fibre solutions for many years.

Therefore Matthew North, Commercial Director at Kelheim Fibres, is more than happy to present an extended range of new products at this year's INDEX in Geneva. Kelheim's fibre specialists are particularly proud of their new fibres with added functionality.

"We have developed the first viscose fibre with ion exchange properties. Incorporated in special papers or nonwovens it can filter destructive acids out of all kinds of liquids - or provide a better taste of hot beverages when used as water softener in tea or coffee pads.", he explains about Poseidon, one of Kelheim's new fibres.

Poseidon's sister fibre, Deep-Dye, is a cationically activated viscose fibre which stands out thanks to its particularly high dye absorption capacity. Deep-Dye also does an outstanding job in filters, used for example for the decolouration of waste water from dyehouses.

In addition to Poseidon and Deep-Dye - and also of major interest for the nonwovens industry - there are extra absorbent new viscose specialities that offer a number of benefits not only for the end product but also for further processing thanks to their different added functionalities, including high levels of dispersability.

"These new fibres are the result of our consistent strategy of developing innovative speciality fibres. Specialities will gain even more importance in the future. They make the difference: they can give a product new added properties or they can make further processing more efficient - and therefore more cost-effective.", says Matthew North.

At the same time, he is convinced that innovative fibres form the basis for further developments in the future: "The market for tailor-made fibres - fibres that are precisely engineered to meet the specific requirements of the customer, will grow." Kelheim's R&D team is well prepared to meet this challenge. They work together with an international network of scientists and have their own on-site testing facilities and pilot plants, including, for example, a technical centre for paper applications. In this way Kelheim is able to find the answers to very specific requirements of its customers.

In addition to the new fibre specialities from Kelheim their established brands Danufil®, Galaxy® and Viloft® nonwoven will be an important subject at INDEX, as Kelheim Fibres has been the world's leading supplier of viscose specialities for tampon and hygiene fibres for many years. Different cross sections and a wide range of special fibre properties are the characteristics of Kelheim's broad range of products. Beyond that, Kelheim Fibres has made itself a name as the only European manufacturer of viscose short cut fibres for paper applications.