Displaying items by tag: spraying systems co.

New Catalog Features Air Nozzles and Systems to Improve Drying and Blow-off Efficiency

A new catalog featuring WindJet® compressed air nozzles and WindJet air knife packages powered by regenerative blowers for drying and blow-off has been released by Spraying Systems Co. The catalog takes an in-depth look at how air nozzles can reduce use of compressed air by as much as 92% and perceived noise up to 60% compared with open pipe. Also detailed is how compressed air use can be eliminated completely and replaced with air knives and quiet, dependable blowers.

A new catalog featuring WindJet® compressed air nozzles and WindJet air knife packages powered by regenerative blowers for drying and blow-off has been released by Spraying Systems Co. The catalog takes an in-depth look at how air nozzles can reduce use of compressed air by as much as 92% and perceived noise up to 60% compared with open pipe. Also detailed is how compressed air use can be eliminated completely and replaced with air knives and quiet, dependable blowers.

The catalog includes a section on blowing and drying operation optimization and provides helpful information on effective coverage, sound level and lineal and specific impact force.

Operating principles and usage guidelines are provided for air nozzles, low-flow air knives, air amplifiers and air knife packages to help readers understand the best applications for each product type.

Detailed performance information on dozens of WindJet products is also included. Material options, dimensional drawings and performance-enhancing tips for each product are provided.

Please click the banner to download the catalog

New TankJet® 55 Fluid Driven Tank Cleaner for Tanks/Barrels/Drums up to 5’ (1.5 m) in dia.

TankJet 55 tank cleaner is now available from Spraying Systems Co. The powerful TankJet 55 operates at low flows and fast cycle times enable cleaning of multiple tanks, barrels and drums in minutes. It is easy to use and can be repaired in the field.

TankJet 55 tank cleaner is now available from Spraying Systems Co. The powerful TankJet 55 operates at low flows and fast cycle times enable cleaning of multiple tanks, barrels and drums in minutes. It is easy to use and can be repaired in the field.

TankJet 55 is compact and fits in openings as small as 1-3/4" (44.5 mm). The durable tank cleaner is constructed of 316L stainless steel with carbon-filled PTFE seals. Two models are available: standard models for faster rotation and shorter cycle times and slow, rotational models which allow excellent dwell time for cleaning tougher residues.

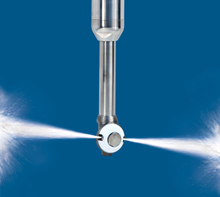

The fluid-driven, turbine-driven TankJet 55 cleans using narrow angle full cone sprays rotating in multiple axes for 360° coverage.

TankJet 55 is suitable for many applications including cleaning 59 gallon (223 l) barrels, 55 gallon (208 l) drums and small tanks, containers and totes.

Ways to Optimize Spray Operations and Reduce Operating Costs

White Paper Series Addresses Ways to Optimize Spray Operations and Reduce Operating Costs

A new white paper series, published by Spraying Systems Co., focuses on ways to increase efficiency and quality while dramatically reducing costs in cooling, cleaning, coating, moisturizing and other spray operations. The series details how to make changes that provide a fast return on investment. There are five white papers in the series:

• Change the Way You Spray to Minimize Clogging provides an in-depth look at the most common causes of clogging and offers ways to minimize or eliminate it from most spray operations.

• How to Reduce Compressed Air Consumption in Drying and Blow-Off Applications explains how to reduce compressed air consumption up to 92% in many operations and how to eliminate it in other operations by using regenerative blowers and air knives.

• How to Reduce Water Consumption in Cleaning, Cooling and Moisturizing Operations describes simple changes that can slash water use by millions of gallons a year.

• How to Pre-empt a Significant Profit Drain: Nozzle Wear delves into the causes of nozzle wear, provides specific steps to help detect and minimize wear and discusses best practices for spray nozzle maintenance.

• Change the Way You Spray: Seven Changes You Can Make that Will Reduce Costs Immediately offers detailed information on ways to improve sanitation operations, minimize chemical use in cleaning application and reduce downtime and labor costs through automation.

The free white paper series is available for download at www.spray.com/whitepapers.

Spraying Systems Co. is the global leader in spray technology. It has the broadest product range in the industry, ten manufacturing facilities and sales offices in more than 85 countries. Spray nozzles, turnkey spray systems, custom fabrication and research/testing services comprise the 70-year-old company’s offering. More information is available at www.spray.com or by contacting the company directly at 1-630-665-5000.

Spraying Systems Co. Launches New Website

Spraying Systems Co. announces the launch of their redesigned website, www.spray.com. The updated site features a wide range of spray technology including spray nozzles, automated spray systems, spray injectors, manifolds and testing/modeling services. New and improved navigation menus and advanced search features make it easy for visitors to find information of interest based on their market, application or product use.

Spraying Systems Co. announces the launch of their redesigned website, www.spray.com. The updated site features a wide range of spray technology including spray nozzles, automated spray systems, spray injectors, manifolds and testing/modeling services. New and improved navigation menus and advanced search features make it easy for visitors to find information of interest based on their market, application or product use.

Other additions to the site include an extensive video library of product demonstrations and simulations, an expanded literature section complete with foreign language catalogs and new results-based case studies documenting process improvements and cost savings that customers have achieved using the company’s products.

Visitors will also find timesaving tools that assist with flow rate, spray coverage and pressure drop calculations.

“Spray.com is a content-rich site with information that can help visitors optimize their spray operations,” says Jennifer Burr, Electronic Media Manager at Spraying Systems Co. “The site is easy-to-navigate and visitors have multiple search options. Within one or two clicks, they’re able to find the content of interest.”

TankJet® 9 Rotating Nozzles Effectively Rinse Tanks

Powered by the flow of the cleaning liquid, TankJet 9 tank cleaning nozzles from Spraying Systems Co. provide reliable, effective rinsing. The flat spray nozzles mounted in a rotating spray head operate effectively in any position – vertical or horizontal.

Powered by the flow of the cleaning liquid, TankJet 9 tank cleaning nozzles from Spraying Systems Co. provide reliable, effective rinsing. The flat spray nozzles mounted in a rotating spray head operate effectively in any position – vertical or horizontal.

TankJet 9 is suitable for clean-in-place and sanitary applications and can also be used for chemical distribution and passivation. The unit is ideal for cleaning brewery tanks, chemical containers, drums/kegs, food processing tanks, pharmaceutical tanks and wine barrels/vats.

Three versions are available. TankJet 9-A produces two flat side sprays for 2 x 175° coverage for use in tanks up to 6' (1.8 m) in dia.; TankJet 9-B produces six flat sprays for 360° coverage for use with tanks up to 12' (3.6 m) in dia. and TankJet 9-C produces six flat sprays for 360° coverage for use with tanks up to 16' (4.8 m) in dia.

Air Knife Drying Packages Eliminate Compressed Air Use in Drying and Blow-Off

WindJet® Air Knives powered by energy-efficient regenerative blowers provide excellent performance in drying and blow-off operations and eliminate the need for costly compressed air. Operating costs can be reduced by as much as 95 percent when the packages are used in a wide range of operations including debris and dust blow-off, removal of excess water and moving products.

WindJet® Air Knives powered by energy-efficient regenerative blowers provide excellent performance in drying and blow-off operations and eliminate the need for costly compressed air. Operating costs can be reduced by as much as 95 percent when the packages are used in a wide range of operations including debris and dust blow-off, removal of excess water and moving products.

WindJet Air Knives feature a unique 1/8" leading edge along the length of the knife to direct a consistent and controlled air stream that retains its integrity further downstream and eliminates spotting and blotching. The air stream produced by the knives entrains ambient air to increase the total volume of air and maximize drying and blow-off efficiency.

Unlike other blower types, the regenerative blowers included with the packages are rugged, reliable and require infrequent, minimal maintenance. Plus, no sound enclosure is needed because the blowers provide low noise operation.

Each air knife package is customized for the application. Air knives are available in lengths from 6” to 36” and two air slot sizes, .040” and .060”. Regenerative blower assemblies are available from 5.5 to 30 HP. Packages include pressure relief valve, pressure gauge, air inlet filter, filter monitoring gauge, vibration dampener, fittings and mounting adapter.

Automated Tank Cleaning: Myth or Fact?

Learn How to Get Tanks Cleaner in Less Time and Lower Operating Costs

The benefits of automated tank cleaning are generally well understood -- reduced manual labor and more consistent cleaning; however, there are many aspects of automated tank cleaning that are widely misunderstood and prevent people from automating or achieving optimal results. This webinar will take a look at seven common myths about automated tank cleaning. You'll learn about why most of the perceived obstacles to automation aren't really obstacles at all and how to optimize cleaning efficiency while using less chemicals and water.

Myths addressed:

Automated cleaning isn't powerful enough to clean my tanks.

The payback on automating tank cleaning is too long.

I can't automate due to obstructions in my tank.

The residue in my tank is prone to sparking so automation is out of the question.

My tanks are too big/too small for an automated solution.

I won't be able to verify that my tanks are completely clean if I automate.

I'll still need hot water to remove residue even with an automated tank cleaner.