Conventional, oil-based release technology has served well to control sheet adhesion on the Yankee dryer, provide lubrication for creping and cleaning blades, and remove excess coating from the dryer surface. However, oil-free technology is now available that provides advantages over traditional release technology

There are two main directions in developing oil-free release aids: plasticization of the coating to improve crepe density and control hard edge buildup, and replacing oil-based release aids with a cost effective, oil-free alternative. This paper recounts recent findings in tailoring oil-free release aids for plasticizing and release properties.

Oil-based vs. oil-free release technology

Let’s start with a brief description of how traditional, oil-based release agents interact with adhesives. Yankee coatings are generally composed of two components: adhesives and release agents. A number of tissue manufacturers use a third component, a coating modifier; but for our purposes, we’ll restrict this discussion to two component systems. Adhesives (responsible for holding the sheet against the Yankee during creping) are polymers- natural or synthetic- that crosslink on the Yankee surface. Left to themselves, adhesives would hold the sheet so strongly against the Yankee that it would be difficult, if not impossible, to control creping without causing sheet holes and breaks. This is where release agents come in. Release agents interfere with the integrity of the polymer matrix on the Yankee surface. Oil-based release agents create pockets of “dead space” in the matrix by inserting droplets of oil in between adhesive molecules. These droplets help to prevent too much crosslinking of the adhesives, which is good. However, the droplets tend to weaken the matrix so much that the coating tends to be stripped off the dryer when the ratio of release to adhesive is slightly out of balance.

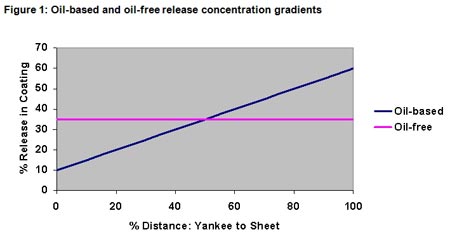

Typically, adhesives and release agents are applied to the Yankee surface by a low pressure shower. The concentration of the adhesive and release (taken together) is typically less than 1%. Before the coating matrix can form on the Yankee surface, the carrier water must be evaporated. As the carrier water is evaporated, the volume of coating on the dryer decreases and adhesive molecules come closer together and start to associate with each other. Consequently, the adhesive portion of the coating becomes more compact as the coating dehydrates. The release agent, on the other hand, is an emulsion of oil in water. The oil does not compact during coating dehydration. In fact, it expands on heating, migrating away from the dryer surface. Because the release oil expands while the adhesive compacts, a concentration gradient of release oil in the coating matrix develops. More release oil is present in the upper layer of the coating matrix; less is present in the harder layer near the dryer surface. Figure 1 shows a hypothetical concentration gradient of an oil-based release in the coating matrix between the dryer surface and the sheet. A potential problem with having a concentration gradient of release oil in the coating is the coating remaining on the dryer after creping can be quite hard. Under the right conditions, it can become quite difficult to control the buildup of hardened coating on the dryer, especially just outside the sheet edge. “Edge buildup” is a potentially serious problem, often associated with sheet breaks and/or heavy blade wear.

Oil-free release agents use a different approach to modifying the coating on the Yankee dryer. Instead of interfering with the ability of adhesive molecules to bond by inserting dead space in the coating matrix, oil-free plasticizers associate with adhesive molecules but do not crosslink with them the way another adhesive molecule would. Let’s first define the term “plasticizer”. A plasticizer acts to make something more pliable or flexible- more “plastic”. Since plasticizers associate intimately with the adhesive in the coating matrix, the net effect is to make the entire matrix more flexible. Creating a flexible coating matrix is the goal of any “soft” coating program.

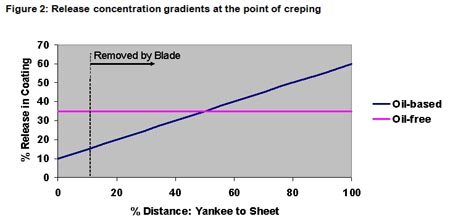

Looking again at Figure 1, we see that there is essentially no concentration gradient of oil-free release in the coating matrix. Both the oil-free release and the adhesive portions of the coating matrix compact during dehydration. That means the oil-free release has no “driving force” to concentrate in one portion of the coating, leaving a uniform amount of oil-free release throughout the Z-direction of the matrix. This lack of a concentration gradient is especially important when we consider what happens at the creping and cleaning blades. Sheet softness is built in the soft part of the coating matrix. It is here that the creping blade deforms both the coating and the sheet, which is the basis of creping. But what happens to the coating that is left on the dryer after the creping and cleaning blades have removed the softer part of the coating? It is here that Yankee protection is built. It is also here that an excessively hard residue can be developed which interferes with machine runnability and blade wear.

Figure 2 shows the hypothetical difference between the concentrations of oil-based and oil-free release agents in the harder portion of the Yankee coating matrix- the fraction that is not removed by the creping and cleaning blades. In this example, the average concentration of oil-based release in the cured portion of the coating is 15%, while that of the oil-free is 35%. The difference can lead to a dramatic difference in pliability of the coating left on the dryer.

Now that we have a basic understanding of how non-oil release agents work, it’s time to decide whether to focus on plasticizing or release

Plasticizing vs. release

Strictly speaking, when dealing with oil-free release agents the question is not “either/or” regarding plasticizing and release. It is rather a question of degree. The reason is there is an inverse relationship between plasticizing and release properties. There are four key factors in determining where a particular release fits on the curve of plasticizing vs. release:

- The type of base polymer used

- The molecular weight of the base polymer

- The type and degree of modification of the polymer

- The emulsification package

By working with these key properties, it is possible to create oil-free release agents that give strong release- much stronger than oil-based release agents on an actives basis- and some plasticization. It is also possible to create highly plasticizing release aids that have less aggressive release properties. However, even highly plasticizing release aids can be more efficient than oil-based release agents.

Advantages of plasticizing release

There are two essential characteristics of plasticizing release agents: they are “soft” polymers that associate intimately with creping adhesives and they compact along with creping adhesives during coating dehydration. These two aspects give the following benefits

A softer, thicker, more even coating. Because the plasticizer does not strip the adhesive off the dryer, the coating matrix actually gains in bulk. This is helpful in dealing with moisture streaks that interfere with proper coating buildup on the dryer.

More even creping. Unlike oil-based release agents that form discrete droplets in the coating matrix, the plasticizers associate intimately with the creping adhesive on the dryer. This leads to fewer “pockets” of coarser crepe in the sheet. Virtually all plasticizing release trials to date have shown a significant improvement in MD and CD creping uniformity.

Finer creping. Because plasticizing release aids don’t strip the adhesive from the dryer, the soft part of the Yankee coating (where creping takes place) tends to be softer, which usually gives an extra 10 crepe bars per cm in crepe density.

Less hard edge buildup. Having a relatively large fraction of release aid in the hard part of the Yankee coating helps to keep the coating left on the dryer flexible and easier to manage.

Case history 1: Removing edge buildup

A mill in the Middle East suffered from hard edge buildup, causing them to change creping blades every 1-2 hours due to edge blade wear. Figure 3 is a photograph of the tending side of the Yankee; the edge buildup was several centimeters wide, and could not be removed under normal operating conditions. A hard creping adhesive was chosen because of the machine’s operating speed (1750 m/minute) and the desire to protect the Yankee. Figure 4 is a photograph of the same area after introducing a plasticizing release; the edge buildup was brought under control. As is typical with plasticizing release applications, there was a significant reduction in creping adhesive use. In this case, the reduction was 37.5%. There was also an increase in creping density: the crepe bar count increased from 65 to 75 per cm.

Case history 2: Controlling blade wear

A mill in Southeast Asia suffered from severe edge wear of the creping blade and uneven roll building. Replacing the previous creping program with a hard, moisture tolerant coating and a plasticizing release gave significant improvements in blade wear, roll building, and creping. Figure 5 shows typical pre-trial blade wear of >5 mm at the edges. Figure 6 shows even blade wear at the same blade life. In addition, crepe density increased from 45 to 60 bars/cm. All this was achieved with a reduction of 24% in creping adhesive use.

Case history 3: Oil replacement

A mill in Southeast Asia was interested in reducing their creping program cost. Replacing the oil-based release aid with an oil-free plasticizer allowed the mill to enjoy a release aid program cost reduction of >20% while improving the evenness of the Yankee coating and maintaining handfeel, crepe density, roll building, and sheet specifications.

Conclusion:

Certainly, oil-based release agents have served tissuemakers well for decades. However, there are now alternate, oil-free release technologies that provide real advantages over conventional release agents. Plasticizing releases allow the tissuemaker to soften the Yankee coating without stripping it; improving creping, roll building, blade wear, and controlling problematic Yankee coating buildup. Oil replacement releases offer significant program savings over their oil-based counterparts.