Super User

Sappi Europe announces price rises for its Woodfree paper grades

Sappi Europe continues to face increasing costs to its Graphic Paper business, related to energy costs as well as raw material cost rises due to availability challenges. It is forecast that this volatile environment will persist for now due to the current uncertain political and economic climate. Accordingly in order to maintain profitability and keep its mills running full, Sappi will implement a further price increase of 10% to its Woodfree paper grades effective for deliveries from early April latest beginning May depending on the market. This will be in addition to the previously announced increases.

The business climate remains extremely challenging for everyone, and Sappi appreciates all its customers support in these difficult times.

The business climate remains extremely challenging for everyone, and Sappi appreciates all its customers support in these difficult times.

The local Sappi sales offices are in touch with customers to discuss the detailed implementation.

About Sappi

Sappi is a leading global provider of sustainable woodfibre products and solutions, in the fields of Dissolving pulp, Printing papers, Packaging and speciality papers, Casting and release papers, Biomaterials and Bio-energy. As a company that relies on renewable natural resources, sustainability is at our core. Sappi European mills hold chain of custody certifications under the Forest Stewardship Council™ (FSC™ C015022) and the Programme for the Endorsement of Forest Certification (PEFC/07-32-76) systems. Our papers are produced in mills accredited with ISO 9001, ISO 14001, ISO 50 001 and ISO 45 001 certification. We have EMAS registration at 5 of our 10 mills in Europe.

Sappi Europe SA is a division of Sappi Limited (JSE), headquartered in Johannesburg, South Africa, with 12,500 employees and 19 production facilities on three continents in nine countries, 37 sales offices globally, and customers in over 150 countries around the world.

Learn more about Sappi at www.sappi.com.

Toscotec continues expansion at Lucca headquarters in Italy.

Toscotec continues the expansion of its covered production area with the inauguration of a new building - Workshop 9 - at its headquarters in Lucca, Italy. The new workshop is primarily dedicated to equipment loading and logistic operations, and it frees up space for the increasing manufacturing and pre-assembly activities at the facility. This addition testifies to Toscotec’s growth as a prominent supplier of advanced, energy efficient technology for the tissue and paper industry and global leader of turnkey tissue projects.

Alessandro Mennucci, CEO of Toscotec, says, “In our vision, sustained growth and tangible improvements in carbon reduction go hand in hand. While pursuing technological innovation for the decarbonisation of the paper making industry, Toscotec also strives to enhance its environmental performance and achieve maximum efficiency at its production sites.”

Toscotec’s production base in Lucca covers an area of more than 65,000 square meters which is devised for maximum manufacturing efficiency. Inspired by lean production, the site’s new layout has been designed to serve a fully integrated and compact logistic flow. Driven by a strong commitment to constantly improving the sustainability of its operations, Toscotec has streamlined material handling processes and has accomplished a significant reduction of energy consumptions and carbon footprint.

For more information, please contact:

Giulia Fabbri, Global Marketing & Communications Manager, This email address is being protected from spambots. You need JavaScript enabled to view it.

Metsä Board launches a state-of-the-art Excellence Centre to accelerate paperboard and packaging innovation

Growing consumption and demand for more sustainable packaging is boosting the need for new innovations. To develop solutions for packaging today and into the future, Metsä Board, part of Metsä Group, has started up operations in its new Excellence Centre at the unique bioeconomy site in Äänekoski, Finland.

The centre, with its cutting-edge technology for R&D, packaging design and paperboard and packaging performance, aims to accelerate material and packaging innovation and provide a collaboration platform for customers and technology partners globally.

“As the amount of packaging continues to grow, new, sustainable solutions are needed to replace fossil-based materials and ensure circularity. The Excellence Centre concept enables paperboard and packaging solutions that look at the entire value chain, and not just at its separate parts. With the material knowhow, competence and tools now available, we can optimise performance throughout the packaging lifecycle”, says Mika Joukio, CEO of Metsä Board.

Metsä Board Excellence Centre

Metsä Board Excellence Centre

The Excellence Centre, which covers a total of 1,500 square meters, includes R&D facilities, a packaging design studio, a customer feedback centre and a state-of-the art laboratory providing more than 100 different measurement methods and analytics. The centre also features a virtual store and a computer-aided engineering (CAE) tool to allow sophisticated simulation and analysis of packaging performance.

Metsä Board’s Excellence Centre brings together Metsä Board’s own competencies and deep expertise in fibre-based solutions with that of various experts and partners, such as material suppliers, technology providers, start-up companies, universities and research companies. Virtual collaboration workshops have also been developed to enable joint development and co-creation if physical meetings are not possible.

“Renewable and recyclable fresh fibre paperboard can be utilised for packaging in many ways. Fibre-based packaging has a lot to offer, and together with our partners and the new Excellence Centre, we are able to explore the possibilities even more comprehensively. I am excited about the opportunities this will bring for today and the future,” says Metsä Board’s CEO Mika Joukio.

Äänekoski’s world-unique bioeconomy ecosystem includes a next-generation bioproduct mill, a paperboard mill, plywood mill, the Pro Nemus visitor centre, and a textile fibre demo plant.

Metsä Board

www.metsaboard.com

Metsä Board is a leading European producer of premium fresh fibre paperboards and forerunner in sustainability. We produce premium lightweight folding boxboards, food service boards and white kraftliners for consumer goods packaging as well as retail-ready and food service applications. We work together with our customers on a global scale to innovate solutions for better consumer experiences with less environmental impact. The pure fresh fibres Metsä Board uses are a renewable resource, traceable to origin in sustainably managed northern forests. We aim for completely fossil-free mills and raw materials by 2030.

The global sales network of Metsä Board supports customers worldwide, including brand owners, retailers, converters and merchants. In 2019, the company’s sales totalled EUR 1.9 billion, and it has approximately 2,400 employees. Metsä Board, part of Metsä Group, is listed on the Nasdaq Helsinki.

Metsä Group

www.metsagroup.com

Metsä Group is a forerunner in sustainable bioeconomy utilising renewable wood from sustainably managed northern forests. Metsä Group focuses on wood supply and forest services, wood products, pulp, fresh fibre paperboards and tissue and greaseproof papers.

In 2019, Metsä Group’s sales totalled EUR 5.5 billion, and it employs approximately 9,300 people. Metsäliitto Cooperative is the parent company of Metsä Group and is owned by approximately 100,000 Finnish forest owners.

As a provider of solutions to the EU’s strategic dependencies, the pulp & paper sector must be allowed to ‘keep the lights on’

Cepi, the European paper industry association, and its members across Europe have responded decisively in face of the unjustified military aggression against Ukraine and in a spirit of solidarity with the people in Ukraine at this difficult time. We support EU leaders in their defence of international law, human rights and democratic values.

Europeans see our products as essential goods. But to provide them and maintain business as usual has proven difficult. Our sector is particularly hit by the spike in energy prices. At the time of writing, many paper mills across of Europe were forced to stop production or to introduce temporary downtimes. This situation puts at risk the jobs of over 4 million people who are employed in the European forest-based value chain.

The supply chain shortages could have major implications for the pulp and paper industry. Products of all kinds made of pulp and paper, including packaging and essential hygiene products, are in danger of disruptions. This includes the transport and delivery of food and pharmaceuticals, including to the populations which need it the most in the face of the multiple current crises.

The supply chain shortages could have major implications for the pulp and paper industry. Products of all kinds made of pulp and paper, including packaging and essential hygiene products, are in danger of disruptions. This includes the transport and delivery of food and pharmaceuticals, including to the populations which need it the most in the face of the multiple current crises.

The Versailles Declaration has called for the protection of critical infrastructure, we are now calling for our sectors[i] to be recognised as essential suppliers in several critical European value chains and to be eligible for state aid and preferential gas deliveries. This will ensure continuity of vital supplies to society during the double energetic and security crisis, and as the EU is still recovering from the Covid-19 health crisis.

Reasons for further diversification of gas supplies, as called for by the EU Commission and several Member States are well understood, and supported, by our sector. Over the past decade, we have been leading in terms of investments in the transition to a greener and more efficient energy model. But it is important that new restrictions are applied in a pragmatic and fair way, and with deep respect to the fundamental role of different economic sectors.

A plan to wean ourselves off Russian gas and oil as a feedstock for manufacturing should be backed by the necessary national and European resources. Wood-based materials clearly are such a resource, and many connected sectors are already starting to tap into our readily available substitutes. In addressing Europe’s strategic dependencies, Heads of State and Government have also underlined the importance of critical raw materials; wood-based materials are a key enabling raw material. Pulp and paper and their derivatives hold potential as circular, sustainable and home-grown substitutes for those fossil materials impacted by the crisis. This includes a number of plastic-based products, but also textiles, packaging, and even electric car batteries. By replacing CO2-intensive materials with wood-based products we reduce EU emissions by 10%, or 410 Mt CO2 equivalent per year.

As we did in past times of crisis, we will strongly support the work of the EU institutions and national governments with our reiterated commitment to invest in Europe’s energy future and growth model, and by providing regular updates on the evolution of the paper and pulp sector economic situation.

[i] NACE codes 17, 18 and 02.10

About Cepi :

Cepi is the European association representing the paper industry. We offer a wide range of renewable and recyclable wood-based fibre solutions to EU citizens: from packaging to textile, hygiene and tissue products, printing and graphic papers as well as speciality papers, but also bio-chemicals for food and pharmaceuticals, bio-composites and bioenergy. We are a responsible industry: 86% of our raw materials are sourced from within the European Union and 78% of the wood comes from certified forests, 92% of the water we use is returned in good condition to the environment. We are the world champion in recycling at the rate of 73.9%. At the forefront of the decarbonisation and industrial transformation of our economy, we embrace digitalisation and bring 18.5 billion value addition to the European economy and €4.5 billion investments annually.

More information about our sustainability performance here.

Through its 18 national associations, Cepi gathers 495 companies operating 895 mills across Europe and directly employing more than 180,000 people.

Valmet to supply a fiber furnish analyzer to Arctic Paper Kostrzyn S.A. in Poland

Valmet has received an order from Arctic Paper to supply a Valmet Fiber Furnish Analyzer (Valmet MAP Q) with services to its Kostrzyn plant located in the western part of Poland.

The order is included in Valmet's orders received of the first quarter 2022. The value of the order will not be disclosed. The solutions will be delivered in the second quarter of 2022.

Due to the planned investment Arctic Paper Kostrzyn S.A. will be able to improve the quality of paper production and further improve the production efficiency.

“We are very pleased to cooperate with Arctic Paper, as they are strongly aware on the environmental issues. Our solution will help them to minimize the environmental impact and use raw materials efficiently while improving the quality of their end-products,” says Markku Merra, Sales Manager, Automation Business Line, Valmet.

Technical information about the Valmet Fiber Furnish Analyzer

Valmet Fiber Furnish Analyzer (Valmet MAP Q) provides paper, board, and tissue makers with fast and precise online updates of key fiber and papermaking furnish properties. It represents the state-of-the-art online fiber analysis, building upon continuous advancements by Valmet over the past forty years. One of the key benefits of the Valmet Fiber Furnish Analyzer is the increased energy efficiency and refiner segment life while maintaining the highest pulp quality.

About the customer Arctic Paper Kostrzyn

Arctic Paper Kostrzyn is the largest producer of offset paper in Poland manufacturing uncoated woodfree paper for general printing use such as books, brochures and documents, but also modern papers for high-speed inkjet technologies.

Arctic Paper Kostrzyn belongs to Arctic Paper S.A., a leading European producer of high-quality graphic paper, listed on the stock exchanges in Warsaw and Stockholm employing 1,200 people in three mills: Kostrzyn nad Odrą (Poland), Munekdals and Grycksbo (Sweden).

For further information, please contact:

Markku Merra, Sales Manager, Austria & CEE, Automation business line, Valmet, tel: +43 664 1436307, This email address is being protected from spambots. You need JavaScript enabled to view it.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2021 were approximately EUR 3.9 billion. Our more than 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward – every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

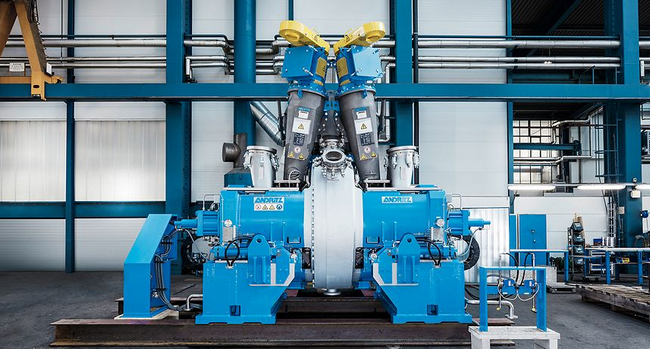

ANDRITZ to supply high-capacity P-RC APMP line to Jiangxi Five Star Paper, China

International technology group ANDRITZ has received an order from Jiangxi Five Star Paper Co., Ltd., China, to supply a high-capacity, chemi-thermomechanical pulping system.

Start-up is planned for 2023.

ANDRITZ will install its well-proven P-RC APMP (Pre-Conditioning Refiner Chemical Alkaline Peroxide Mechanical Pulp) technology to achieve optimum pulp quality at lowest energy consumption. The pulp will be used to produce folding boxboard (FBB) from eucalyptus wood chips as raw material. With a capacity of 1,500 admt/d the new fiberline will be the largest system worldwide based on a single-line concept with only one HC refiner as the heart of the process.

High-capacity and high-performance refining with the ANDRITZ TX68 refiner © Croce

High-capacity and high-performance refining with the ANDRITZ TX68 refiner © Croce

ANDRITZ will supply the main equipment – from chip washing to the storage tower – featuring the following highlights:

- MSD Prime Impressafiner, type MSD600, for wood chip maceration to enable optimum chemical impregnation

- TX68 twin refiner – the world’s largest high-consistency (HC) refiner – including an advanced feeding system for continuous high throughput, consistently high pulp quality and lowest energy consumption.

- Three ANDRITZ COMPACT PRESS units to enable high discharge consistency and superior washing efficiency after bleaching

- Several PrimeScreens X with an innovative PrimeRotor for top performance in primary and reject screening at minimum energy consumption

The scope of supply also includes the basic engineering as well as supervision of mechanical installation, commissioning and start-up.

Jiangxi Five Star Paper is specialized in the production of specialty paper. It has been part of Quzhou Wuzhou Special Paper Co. Ltd., one of China’s largest food wrapping paper producers, since 2015.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. The global product and service portfolio is rounded off with plants for power generation, recycling, the production of nonwovens and panelboard, as well as automation and digital solutions offered under the brand name of Metris. The publicly listed group today has around 27,800 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power production, flue gas cleaning plants, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area.

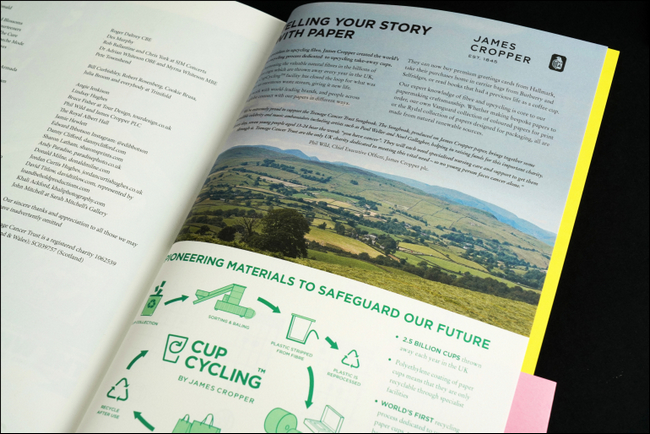

James Cropper collaborates with teenage cancer trust on charitable song book

With contributions from the likes of Paul Weller and Noel Gallagher, specialist papermaker, James Cropper, has collaborated with Teenage Cancer Trust in the creation of a fundraising song book.

Produced with artist Pete McKee, the book features 19 songs which have been performed on stage at Teenage Cancer Trust events over the past 20 years.

The handwritten lyric contributions come from an all-star line-up of artists including Amy Macdonald, Kasabian, Suede, Blossoms, The Cure and many more. Each song is accompanied by an interpretative design produced by Pete McKee, forming an exclusive collection of McKee artworks not available elsewhere.

The song book also features lyrics from cancer survivor, and singer of Ishmael Ensemble, Holly Wellington, who was helped by Teenage Cancer Trust. Her song ‘Empty Hands’ was written about her cancer experience and Wellington also wrote the foreword to the book.

Available now, the song book launched as Teenage Cancer Trust’s iconic Royal Albert Hall fundraising concert returned to the venue to celebrate its 20th event, after three years away.

James Cropper CEO, Phil Wild is on the Advisory Board for the charity and is a strong advocate of Teenage Cancer Trust. To support the song book’s fundraising ambitions, the Cumbrian based papermaker contributed all the premium upcycled paper used in the production of the book.

Phil Wild, Chief Executive Officer at James Cropper plc says: “Every day, seven young people aged 13-24 hear the words “you have cancer”. They will each need specialised nursing care and support to get them through it. The Teenage Cancer Trust is the only UK charity dedicated to meeting this vital need – so no young person faces cancer alone.

“We’re extremely proud to support this project. Produced with James Cropper paper, the song book brings together some incredible celebrity and music ambassadors, all helping in raising funds for this important charity.”

The song book, whose pages are made with innovative CupCycling technology that gives disposable cups a valuable second life, is available now via www.petemckee.com and will retail at £25, with all profits going to support Teenage Cancer Trust.

About James Cropper

James Cropper is a prestige paper innovator based in the English Lake District, supplying distinct, custom-made paper products to many of the world’s leading luxury brands, art galleries and designers.

Throughout 176 years of high-quality paper production, the business has been carefully stewarded and nurtured by six generations of the Cropper family and is renowned globally for individual expertise in colour and fibre innovation.

https://www.jamescropper.com/tailor-made

About James Cropper COLOURFORM™

Blending technological solutions and innovative design with a growing eco-conscious consumer mind-set, COLOURFORM is a thermoformed, moulded fibre packaging solution, offering a full service direct to brands.

COLOURFORM is no stranger to innovation. The moulded-fibre packaging company has been born from a group with tremendous heritage, who continually looks to the future with its innovation and progressive thinking. Coupled with the creative capability to go head-to-head in the design stakes with undesirable plastics, COLOURFORM is meeting the needs of complex and high-end design, while blazing a trail for sustainable luxury packaging in the future.

https://www.jamescropper.com/Colourform

About Teenage Cancer Trust

Every day, seven young people in the UK aged 13 to 24 hear the words "you have cancer" Teenage Cancer Trust puts young people in the best possible place, physically, mentally and emotionally, for their cancer treatment and beyond

We do it through our expert nurses, support teams, and hospital units. And we're the only UK charity dedicated to providing this specialised nursing care and support

Teenage Cancer Trust is a registered charity: 1062559 (England & Wales), SC039757 (Scotland).

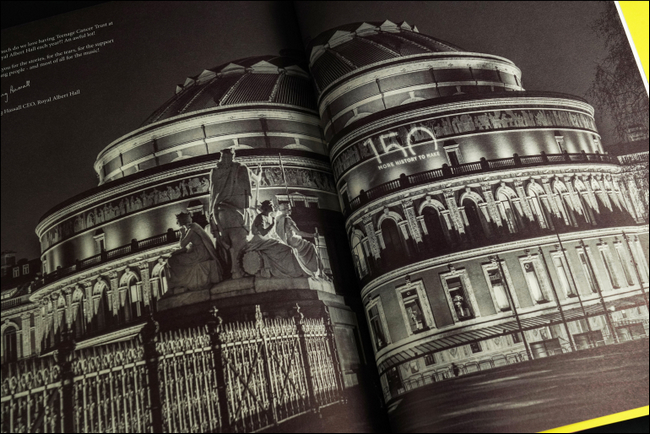

About Teenage Cancer Trust at The Royal Albert Hall

2020 would have marked the 20th year of Teenage Cancer Trust’s phenomenally successful series of music and comedy events at The Royal Albert Hall, which were started by Roger Daltrey CBE. The gigs were to also help celebrate the 30th anniversary of Teenage Cancer Trust.

Some of the biggest names in entertainment have now raised more than £30 million for Teenage Cancer Trust’s specialist nurses, hospital wards and support teams that help young people through the toughest times of their lives.

Over the past 20 years, audiences at Teenage Cancer Trust’s annual gigs have witnessed some extraordinary, once in a lifetime shows, from Noel Gallagher and Damon Albarn performing together for the first time ever in 2013, Sir Paul McCartney in 2012, plus the likes of Oasis, Muse, Ed Sheeran, Florence + The Machine and many more.

There have been many legendary moments. Sir Paul McCartney was joined on stage in 2012 for the Beatles’ ‘Get Back’ by Roger Daltrey, Ronnie Wood and Paul Weller – marking a Beatle, Rolling Stone and The Who joining forces.

Muse played in 2008, their only show in the UK that year apart from two sold out Wembley Stadiums. They called it, “one of the best gigs of our lives.” The Cure played a three-hour set on two consecutive nights in 2014, bringing the house down with 45 songs.

PulPaper 2022 enables networking in June

About 250 exhibitors will participate in the leading international event for the forest industry, PulPaper 2022. The program consists of the PulPaper Conference, the new Green Economy Business Summit, and a wide range of presentations at the Future Square Stage. The startup competition presents the most interesting innovations during the event. The three-day PulPaper will be held from 7 – 9 June 2022. ChemBio Finland and Helsinki Chemicals Forum will be arranged at the same time at Helsinki Expo and Convention Centre.

The theme of the forest industry’s international PulPaper 2022 event is Building Tomorrow’s Bioeconomy. The PulPaper event, free of charge for professionals in the field, introduces company presentations at Future Square. Forest industry companies such as Stora Enso, Metsä Group, UPM, and Sappi meet their customers and present their products in the exhibition area and host programs at the Future Square. The PulPaper Conference and the Green Economy Business Summit, which both require a separate entrance ticket, will also be organized in connection with the event. Excursions to VTT, Bioruukki, and UPM Kymi will be arranged on 6th June.

“The events are very important for professionals within the trade. After a long break, we want to organise a meeting place where the visitors have the possibility to study the development within the branch, new products, and information”, says Business Manager Marcus Bergström from Messukeskus. “The forest industry event PulPaper 2022 was postponed from March to June to make networking opportunities better. We are now looking forward to the upcoming event.”

PulPaper Conference brings forth six themes

The themes of the PulPaper Conference are IT and Automation, Environment and Sustainability, Safety and Risk Management, New Textile Products, Efficiency, and Packaging Solutions. The conference will open with three keynote speeches. The first keynote will be presented by Hannu Kasurinen, Executive Vice President Packaging Materials Division at Stora Enso. The topic of the second keynote is Sustainability leading company strategy and will be presented by Riikka Joukio, Director Corporate Responsibility and Public Relations at Kesko. Executive Vice President, Head of Management Consulting Roland Lorenz from AFRY is the third keynote speaker on the topic Changes in consumer behaviour following the COVID pandemic. After the opening speeches, the conference will continue in two parallel sessions with three topical expert presentations on each of the six themes. PulPaper Conference 2022 partners are Andritz and Sulzer.

New Green Economy Business Summit

The Green Economy Business Summit on 8th June is targeted towards corporate management and stakeholders. The program has been compiled in co-operation with the forest-based and chemical industries. The keynote Circular bioeconomy – a sustainable source of growth is presented by President of Sitra Jyrki Katainen. The other keynote is held by Commissioner for Industry and Internal Market Thierry Breton from the EU Commission. Breton’s keynote deals with sustainability and climate change and is a video presentation. Breton will be introduced by Kristin Schreiber, Director at the European Commission who leads the Directorate Ecosystems in DG GROW. She will also respond to any questions raised by keynote speech. The Summit also presents an interesting panel discussion on the topic How to reach sustainability and climate neutrality at company level with Director General Ilkka Hämälä from Metsä Group, Managing Director Salla Roni-Poranen from Borealis Polymers, Executive Vice President Jussi Manninen from VTT, and Home Care Chief R&D Officer Mike Parkington from Unilever as panelists.

Meet startup companies at PulPaper

The startup competition on 8 June 2022 looks for the most promising and potential growth companies in the forest bioeconomy field. The PulPaper Award will be presented to a Finnish company that has developed an innovation that produces a positive image for the forest bioeconomy industry and from which an internationally significant product or service can be developed. At its best, the solution also opens up new perspectives in the forest bioeconomy sector. The winner receives a 5000 € award funded by the Finnish Fair Foundation.

The New Wood project at the event

New Wood has its own stand at PulPaper. The goal of the New Wood project is to increase awareness of the wood-based bioeconomy; highlighting new and existing products and solutions, exploring their impact on society and offering expert perspectives on the outlook for this innovative industry. Comprising more than 20 Finnish organisations, New Wood is a community that promotes the wood-based bioeconomy and provides information to influencers and political decision-makers about the significance and value of wood-based products. The New Wood product 2022 will be announced at PulPaper Future Square on 7th June.

Visitors can register for the PulPaper event free of charge at www.pulpaper.fi.

Messukeskus organizes the PulPaper 2022 event in cooperation with The Finnish Forest Products Engineers’ Association. ChemBio Finland and Helsinki Chemicals Forum will be organized at the same time by Messukeskus. ChemBio Finland is arranged in cooperation with the Finnish Chemical Societies, Finnish Bioindustries FIB and the Chemical Industry Federation of Finland.

More information:

Business Manager Marcus Bergström, tel. +358 44 562 4524, This email address is being protected from spambots. You need JavaScript enabled to view it.

Communications Manager Teija Armanto, tel. +358 50 376 0804, This email address is being protected from spambots. You need JavaScript enabled to view it.

New Valmet Retention Measurement provides more stable wet end operation from day one

Valmet introduces the latest generation of the Valmet Retention Measurement for continuous measurement of total and true ash consistencies at the wet end.

Capable of dealing with various pulps and fillers in the headbox and white-water, the Valmet Retention Measurement offers a solid base for fully automatic retention aid control to vastly improve runnability, efficiency and product quality. Pre-calibration models for various pulp types make it possible to secure valid measurement results from day one with the ability of storing up to 8 different models for smooth grade changes.

“Our challenging target was to raise the Valmet Retention Measurement, which is already recognized as the industry standard, to the next performance level. Now with superior accuracy, availability, and state-of-the-art user interface of the new generation measurement, I am confident that we have achieved that target,” says product manager Timo Rantala.

Secured lifecycle

The redesigned optics and electronics are also available for existing users with upgrades to extend the useful lifecycle of earlier generation Valmet Retention Measurement sensors.

This includes easier commissioning and operation with the Valmet Bridge user interface, a 7’’ touch screen control platform designed for use with Valmet process sensors. The sensor features comprehensive diagnostics, data storage capabilities and variety of the communication protocols with Valmet Industrial Internet capabilities to enhance performance as well as access to local or remote support.

The latest generation Valmet Retention Measurement

The latest generation Valmet Retention Measurement

Stabilized wet end

Control packages for the wet end that fully utilize Valmet Retention Measurement capabilities include the Valmet Stand-Alone Retention Control (Valmet RET) as well as integrated applications for Valmet DNA process control and Valmet IQ quality control systems.

Stabilized wet end operation is achieved with Valmet’s well proven white-water consistency and breaktime headbox ash control in use on hundreds of paper and board machines worldwide.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2021 were approximately EUR 3.9 billion. Our more than 14,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward – every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Stora Enso introduces renewable high-strength material for shopping and takeaway bags

To support the shift to renewable and recyclable materials in shopping and takeaway bags, Stora Enso launches CarrEco Brown™. Made from 100% fresh fibers, the material has high strength and tear resistance properties and is also safe for direct food contact.

By offering renewable, fiber-based materials suited for paper bags, Stora Enso accelerates the shift away from plastic. Stora Enso now expands its paper bag materials portfolio with CarrEco Brown, a new unbleached and uncoated board that is fully recyclable. Through its unique three-layer structure, CarrEco Brown offers exceptional strength properties suitable for strong shopping bags. The material is also safe for direct food contact and contains only FDA-compliant chemicals which makes it ideal for takeaway food and groceries.

“Unbleached paper bags are a good fit with the preferences of today’s eco-conscious consumers. We are well-positioned to meet the growing demand for paper bags, especially in trending end-use areas such as takeaway food. Our newest material CarrEco Brown can help our customers seize these growth opportunities in a sustainable way,” says Oscar Duarte, Business Segment Director, Kraftliners at Stora Enso Packaging Materials.

More about CarrEco Brown material

CarrEco Brown is made 100% from renewable fresh fibers from sustainably managed forests and it has a three-layer structure made with patent-pending Tri-Ply™ technology by Stora Enso. CarrEco Brown’s high tensile and tear strength properties make it suitable for strong shopping bags. CarrEco Brown is also safe for direct food contact and contains only FDA-compliant chemicals which makes it ideal for takeaway and grocery bags.

In addition to strength and purity, CarrEco Brown has a natural look and feel and does not contain any optical bleaching agents. The material’s smoothness and formation qualities enable great printability possibilities for brand owners. Available in grammages starting from 85 gsm, CarrEco Brown allows Stora Enso’s customers to grow and expand to new segments within the paper bag market.

Part of the global bioeconomy, Stora Enso is a leading provider of renewable products in packaging, biomaterials, wooden construction and paper, and one of the largest private forest owners in the world. We believe that everything that is made from fossil-based materials today can be made from a tree tomorrow. Stora Enso has approximately 22,000 employees and our sales in 2021 were EUR 10.2 billion. Stora Enso shares are listed on Nasdaq Helsinki Oy (STEAV, STERV) and Nasdaq Stockholm AB (STE A, STE R). In addition, the shares are traded in the USA as ADRs (SEOAY). storaenso.com/investors