Displaying items by tag: Toscotec

Toscotec achieves 200 TT SYD Steel Yankee Dryers sold worldwide.

Only 18 years after the introduction of the first steel Yankee dryer in the market, Toscotec achieved the unheard-of result of 200 TT SYD (Toscotec Steel Yankee Dryer) sold worldwide. Looking back, let us retrace the steps of this incredible journey.

Toscotec’s TT SYD: from invention to innovation.

Building on 40 years of experience in the construction of steel cylinders, in 1999 Toscotec started designing steel Yankee dryers for the tissue industry. In 2000, it launched the world's first TT SYD. With this breakthrough, Toscotec introduced a major change in the market, which was dominated at the time by cast iron dryers and used steel Yankees only for limited applications on tissue machines. It was the beginning of a technological revolution, which led to the supremacy of steel technology over cast iron.

Although the tissue industry criticized this new technology when Toscotec first introduced it, steel Yankee dryers are now acknowledged as the best drying technology for tissue and have been embraced by all major manufacturers.

Toscotec’s innovation tapped into the industry’s need for energy savings in the energy-intensive papermaking process: the use of steel instead of cast iron allowed a reduction in shell thickness that decreases thermal resistance and thus increases heat transfer. The result was higher drying capacity, achieved by increased steam condensation inside the dryer. Data obtained from steel Yankee dryer’s installations confirmed that the heat exchange coefficient and the drying capacity of steel Yankees exceed those of cast iron by more than 30%, given the same dimensions and operating pressures.

Furthermore, Toscotec’s patent technology of head insulation guarantees a further reduction in steam energy loss, an important improvement in drying efficiency.

In October 2012, Toscotec celebrated its 100th TT SYD sold worldwide. This achievement had already proven the scale of this technological innovation and the added value of Toscotec’s design, but the Italian supplier continued pursuing its strive for innovation and launched the second generation of steel Yankee dryers in 2013. This newly improved design increased TT SYD’s grooves in length and width therefore expanding the heat transfer surface, decreased the Yankee’s shell thickness and improved its linear pressure.

In 2017, Toscotec installed the biggest steel Yankee dryer ever used on a tissue machine, TT SYD-22FT with web width 5600 mm, diameter 22 feet (6705 mm). This application represents the result of the successful combination of research, development and targeted investments.Toscotec is also the only worldwide supplier to have steel Yankee dryers running in five continents.

Toscotec’s TT SYD Technology Lab.

In December 2016, Toscotec inaugurated the TT SYD Technology Lab, a new technology centre completely dedicated to the design and manufacturing of steel Yankee dryers.

Strategically located in the province of Massa Carrara near the port, to ensure easy shipping of large diameter Yankees, this fully integrated facility operates assembly, machining and finishing of TT SYD of diameters up to 26 ft.

All new Steel Yankee Dryers in Western Europe are Toscotec-supplied.

The Italian supplier sets yet another record, an unprecedented result in the tissue industry worldwide: Toscotec supplied 100% of new steel Yankee dryers currently installed in paper mills in Western Europe. The technology-obsessed European market is testament to the undeniable advantage of TT SYD’s design.

For more than 18 years, Toscotec has been the world's undisputed leader in the supply of steel Yankee dryers, boasting a market share of over 60%.

Toscotec achieves 100 TT SYDs sold in Asia.

Toscotec’s achievement in Asia is the result of its flexibility and the capability of its R&D and Engineering departments to develop steam energy-based customized solutions. Focused on the specific requirements of this market area, Toscotec developed a new line of tissue machines and energy recovery solutions, with the lowest possible energy consumptions and the potential for future implementations to increase production. Toscotec’s steel Yankee dryer is at the core of this concept: TT SYD ensures the highest drying efficiency, hence allowing paper mills to cut their energy bill significantly.

As a result, TT SYDs sold in the Asian market exceed 100 units, including Yankee replacements and complete new plants, where they are paired with Toscotec’s Yankee hoods and recovery systems based on the available energy (steam, exhaust from cogeneration, diathermic oil).

YES YANKEE DRYERS: the TOSCOTEC INFINITELife Service for Steel Yankee Dryers.

Strong of 18 years of experience on steel Yankee dryers, Toscotec Service team offers a comprehensive package of services for TT SYD, focused on regular maintenance and periodic inspections. The former aims at maintaining optimal performance and ensure their endless life. The latter consists of structural periodic checks aimed at testing and inspecting the conditions of the Yankee’s structural welds, to satisfy requirements from insurance and local authorities. A team of highly specialized professionals also offers counselling and problem shooting on water/steam quality and treatment, sharing their experience on how to best deal with this sensitive and complex aspect of the tissue making process.

Conclusion

Looking into the future, Toscotec is developing the new Steel Yankee Dryer, which will represent another turning point in tissue manufacturing. A great challenge for a supplier with a lustrous past. With a record-breaking 200 steel Yankee dryers sold worldwide under its belt, the Italian company has proved the superiority of its state-of-the-art TT SYD technology in today’s tissue industry.

Toscotec identified in London Stock Exchange Group’s ‘1000 Companies to Inspire Europe’ report

Toscotec identified in London Stock Exchange Group’s ‘1000 Companies to Inspire Europe’ report.

Toscotec recognised in second edition of London Stock Exchange Group’s 1000 Companies to Inspire Europe report

Toscotec recognised in second edition of London Stock Exchange Group’s 1000 Companies to Inspire Europe report

Report demonstrates critical importance of high-growth private small and medium sized companies (SMEs) to future European economic growth, innovation and job creation

As one of the most advanced industries in the manufacturing and engineering sector, Toscotec talks about its history, its mission and the new challenges of its competitive market.

Toscotec has been identified as one of London Stock Exchange Group’s 1000 Companies to Inspire Europe. The report is a celebration of high-growth and most dynamic small and medium sized businesses across Europe.

To be included in the list, companies needed to show consistent revenue growth over a minimum of three years, significantly outperforming their country peers. More detail on the methodology can be found in the report online at www.1000companies.com.

About Toscotec

Since 1948 Toscotec specializes in the design and manufacturing of machines, systems and components for the Tissue and Paper & Board industries. Headquartered in Lucca, at the centre of the Italian paper district, we are a leading player on the international markets, with a strong focus on customer partnership and project customization. Building on more than 60 years of experience, we offer state-of-the-art technology and customized solutions, such as turnkey projects, complete production lines and plant retrofits, to leading paper producers around the world. Every day we work hard to gain and maintain the trust of our customers. Our R&D team strives to tackle the most challenging problems of paper mills and develop their needs into newly improved technology. Our Technical Department works out the best possible applications for their specific production conditions, with focus on energy efficiency. Our Service team works to satisfy their demands, offering remote and on-site assistance for all maintenance needs and for the good operation of their plants. Overall, we provide our customers with high standards of efficiency and a real competitive edge in the marketplace. Expertise, production excellence, respect for people and ongoing research on the best solutions, in order to anticipate needs and achieve customer satisfaction: these are our key values. Maximum production efficiency, reduced consumptions and operating costs, finished products of the highest quality and respect for the environment: these are our results. And our new point of departure.

Alessandro Mennucci, Toscotec’s CEO stated: “know-how, production excellence, respect for people, and ongoing research into the best solutions to achieve customer satisfaction by anticipating needs.”

Alessandro Mennucci, Toscotec’s CEO stated: “know-how, production excellence, respect for people, and ongoing research into the best solutions to achieve customer satisfaction by anticipating needs.”

Toscotec’s Group CFO Davide Raviola said: “Europe is not a place for low-cost production. Its quality and innovative solutions are widely recognised, particularly in our sector.”

Xavier Rolet, Chief Executive, London Stock Exchange Group said: “If Europe is to have a sustainable economic future, it must back its engines of economic growth and only real source of potential job-creation: its 23million SMEs. It is critical that we continue improving access and cutting the cost of finance for fast growing companies, giving them access to long-term patient equity capital to fund their enormous potential. This is an ambition we share with the EU Commission and applaud its initiative to develop deeper and more connected capital markets across the continent through the Capital Markets Union project.

“LSEG has long been committed to supporting high growth companies. Together our 1000 Companies to Inspire Europe reports, international growth market, AIM, and business support and capital raising programme, ELITE, shine a light on the fastest growing companies across the continent and their critical importance to innovation, job creation and Europe’s future economic resilience.”

Valdis Dombrovskis, Vice-President for the Euro and Social Dialogue, also in charge of Financial Stability, Financial Services and Capital Markets Union:

"Europe needs more fast-growing and innovative companies as they are the backbone of our future economic development and job creation. This is why improving the ability of dynamic SMEs to access finance is one of my priorities. We need to make sure that our rules are proportionate and fit for purpose. We should remove barriers to cross-border provision of financing and ensure that SMEs can tap capital markets across Europe."

A full searchable database of all of the companies along with a downloadable pdf of the publication can be found online at www.1000companies.com

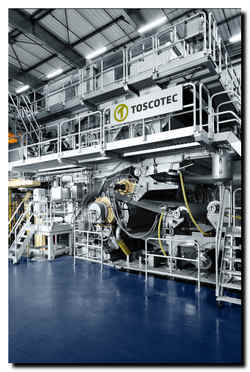

Vinda Paper (Zhejiang) Co., Ltd successfully starts up two Toscotec supplied tissue machines.

Vinda Paper Zhejiang fired up two Toscotec supplied tissue machines, TM 3 and 4, at its Longyou mill in Zhejiang province. The mill successfully achieved start-up according to schedule and thus increased its production capacity by 60,000 tons/year.

The new AHEAD-2.0M tissue lines are designed for the production of premium quality tissue products, including toilet paper and facial tissue. Vinda Zhejiang’s new mill currently has four Toscotec’s tissue machines, two AHEAD-1.5M fired up in 2014 and the new AHEAD-2.0M. In view of the superior performance of the first two, the Vinda Group chose to invest in Toscotec’s top-of-the-line tissue machines. The AHEAD-2.0M advanced technology delivers top quality products, in line with Vinda’s highest quality standards, and guarantees the lowest possible energy consumption, thanks to a comprehensive energy saving concept, the TT DOES solution (Drying Optimization for Energy Saving).

“I was proud to see another Toscotec’s tissue machine start up at Vinda’s mill. Under the expert operation of Vinda Zhejiang’s technicians, the new AHEAD-2.0M lines will perform to meet the customer’s expectations. We also expect to achieve yet again great results in terms of reductions of the energy cost.” said Marco Dalle Piagge, Toscotec’s Sales Director.

About Toscotec

Toscotec is a turnkey projects supplier to the global paper industry. Since 1948, Toscotec offers complete production lines, plant retrofits, turnkey projects and individual machineries. The Group serves all the leading paper producers with customized solutions, leveraging on the experience gained in more than 60 years of activities.

Toscotec supplied AHEAD tissue machine started-up at Paper Prime S.A. in Vila Velha de Rodão, Portugal.

Paper Prime, a company belonging to the Trevipapel Group, and Toscotec announce the successful start-up of the new TM1. The installation and commissioning were performed according to the scheduled time and the start-up went very smoothly.

Toscotec’s turn-key project for TM#1 includes a stock preparation plant for dry virgin pulp, AHEAD-2.0S tissue machine with Steel Yankee Dryer TT SYD-16FT, machine auxiliaries including Milltech Gas fired Hood, steam & condensate and dust removal system, electrification starting from medium voltage cabinets & control system, additional plants and complete engineering and erection activity. A three unwind stand rewinder TT WIND-H completes the supply.

“This start-up is a good example of what the two teams can achieve thanks to the efficient combination of Toscotec’s latest technology and excellent team work. We finalized the installation and commissioning in time and only two weeks after start-up the new Toscotec AHEAD-2.0S has achieved the operating speed of 2,000 mpm. It has been a pleasure to be a part of PaperPrime's project and we wish them good luck for their new business." says Marco Dalle Piagge, Sales Director of Toscotec S.p.A.

Located in Lousã, district of Coimbra, Portugal, Trevipapel S.A also has 2 converting plants strategically located in the center of the country, where are converted 20.000 tpy, serving the internal market and exporting its Joker brand products to Spain, central Europe, Africa and South America.

About Toscotec

Toscotec is a turnkey supplier to the global tissue industry. Since 1948, Toscotec offers complete production lines, plant retrofits, turnkey projects, and individual machineries. Headquartered in Lucca, the nerve center of the Italian paper district, with offices and service centers in China and North America, the Group serves all the leading paper producers with customized solutions, leveraging on the experience gained in more than 60 years of activities. Key to the Group’s success is the engineering and R&D department, run by a team of highly qualified engineers. Read more at www.toscotec.com

Trevipapel, S.A

Established in 1999 with the objective to convert part of the products sold by the company Socigene, Trevipapel S.A. has grown from a small private company into one of the leading manufacturer providers of professional hygiene products (AfH) in Portugal. www.trevipapel.com

Toscotec finalizes a drying section rebuilding project including a new drive system and tail feeding for Smurfit Kappa Italia - at Ponte all’Ania, Lucca.

Smurfit Kappa Italia has successfully started up its PM3 at Ponte dell’Ania mill, after a dryer section rebuild supplied by Toscotec.

The scope of the delivery was an advanced mechanical transmission section in “silent drive” with a new frame on the drive side for the whole machine, the installation of uni-run vacuum rolls in the first drying battery and an automatic air paper threading system in the first two drying sections and on the size press. The modification has completely changed the dryer section layout with the relocation of fabric rolls, improving machine runnability and reducing noise and vibration.

![]() Toscotec service specialists have provided the complete mechanical erection and supervision of the project and the commissioning and start up assistance for the fine-tuning of the new equipment.

Toscotec service specialists have provided the complete mechanical erection and supervision of the project and the commissioning and start up assistance for the fine-tuning of the new equipment.

“The project was completed before the date agreed upon with SK and the performance was achieved immediately after start-up. The new drive technology exceeds all our expectations with regard to downtime improvements and it allowed a considerable reduction of noise and vibration that will reduce maintenance cost” - says Massimiliano Listi, Mill Manager of Smurfit Kappa Ania.

“This project contributes to strengthening the partnership between Smurfit Kappa and Toscotec” - says Enrico Fazio, Toscotec Sales Manager – P&B division.

“It is worth mentioning that, in addition to this project, which consolidates the long-standing collaboration with Lucca-based SK Ania, in the last two years Toscotec has taken part in almost all the projects developed by Smurfit in South America (Colombia, Mexico and Argentina) and it has just begun an important cooperation with the group in France. With this important rebuild project, Toscotec consolidates its leadership in the dryer section best available technology.”.

About Smurfit Kappa Ania

Smurfit Kappa Ania is one of the main producers of recycled paper jumbo rolls in Italy.

The mill occupies an area of 100,000 sqm and employs 120 people.

The annual production is over 200,000 tpy, with 100% recycled fibers.

The mill operates two paper machines, which produce corrugated cardboard packaging in a wide range of paper grades out of recycled fibers.

About Toscotec - The flexibility and intense activity of research and development enable Toscotec to supply equipment and machinery for all the paper industry and to meet customer requirements.

Since 1948, Toscotec is a leader supplier offering proprietary solution from complete production lines to rebuilds, modernization projects and even single components.

Italian Cartiere Modesto Cardella enhances dryer section with repeated orders to Toscotec S.p.A.

In the last year, the partnership between the Italian machinery supplier and Cartiere Modesto Cardella, became closer with three important orders of advanced TT SteelDryers to rebuild the dryer sections of PM3 and PM4.

A first order of 8 TT SteelDryers and 4 TT Uni-Run Vac-Rolls were supplied and started up in 2014, a second order of 14 new TT SteelDryers in place of cast iron dryers were provided for PM3 in 2016 and already successfully started-up. A third order of 17 TT SDs has been repeated for the PM4.

A first order of 8 TT SteelDryers and 4 TT Uni-Run Vac-Rolls were supplied and started up in 2014, a second order of 14 new TT SteelDryers in place of cast iron dryers were provided for PM3 in 2016 and already successfully started-up. A third order of 17 TT SDs has been repeated for the PM4.

Toscotec Technical specialists will provide supervision, commissioning and start up assistance. The final start-up is scheduled for fall of this year, 2017.

Toscotec Steel Dryer is a well-known and a proven solution with over 1200 Dryers running worldwide, providing extremely high drying capacity.

The specific design of TT SteelDryer with flat heads welded to the shell allows to produce a wider and uniformed dried sheet. Toscotec was the first to introduce the revolutionary concept of Steel Dryers in the paper industry and it continues as the undisputed leadership worldwide.

About Cartiere Modesto Cardella.

The mill, whose location in San Pietro a Vico (Lucca) dates back to 1908, was taken over in 1946 by Cardella’s family. The company has invested progressively in rebuilding, technological upgrading and innovation, to achieve current levels of production for corrugated cardboard made from waste paper with a capacity of 200 thousand tonnes per year. Over the years new paper machines were continuously introduced, up to the current day capacity which sees the MC3 (size 250 cm) and the MC4 (width 280 cm) in production.

About Toscotec.

Since 1948, Toscotec offers complete production lines, plant retrofits, and individual machineries. Headquartered in Lucca, the nerve center of the Italian paper district, with offices in China and North America, the Group serves all the leading paper producers with customized solutions, leveraging on the experience gained in more than 60 years of activities.

Hygienic Tissue successfully starts up a Toscotec-supplied tissue machine at its Pietermaritzburg plant, in South Africa.

On 4th April, the South African tissue producer Hygienic Tissue started up their new MODULO-PLUS tissue machine supplied by Toscotec.

With an annual production capacity of 27,000 tonnes, the unit will increase the total mill’s production capacity by threefold. Hygienic Tissue provides its customers with a wide range of products for hygienic use and AFH market, made from 100% virgin pulp as well as from recycled paper.

Based on an intensive energy-saving concept, Toscotec’s scope of supply included the approach flow system, featuring the ultimate TT SAF® technology, a MODULO-PLUS tissue machine with single-layer headbox, single press configuration and TT SYD-12FT with TT Milltech-MYH (Monosystem gas heated hood), Turbo Blower and Core Extraction unit. The supply also included an electrification and controls package and the steam & condensate system. Toscotec’s TT WIND-P tissue slitter rewinder completed the scope of supply.

Based on an intensive energy-saving concept, Toscotec’s scope of supply included the approach flow system, featuring the ultimate TT SAF® technology, a MODULO-PLUS tissue machine with single-layer headbox, single press configuration and TT SYD-12FT with TT Milltech-MYH (Monosystem gas heated hood), Turbo Blower and Core Extraction unit. The supply also included an electrification and controls package and the steam & condensate system. Toscotec’s TT WIND-P tissue slitter rewinder completed the scope of supply.

The excellent cooperation between Toscotec and Hygienic Tissue has allowed the South African tissue maker to achieve immediately high quality tissue paper, optimizing the production cycle, both in terms of performance and energy saving.

Hygienic Tissue Mill plays an important role in the South African tissue market, producing higher value disposable paper products, including toilet tissue, napkins, towels, facial and jumbo rolls. Since 2000 the company has been investing in state of the art manufacturing machinery. This is the first MODULO-PLUS tissue machine installed by Toscotec in South Africa and increases Hygienic Tissue Mill's capacity to make it the largest independent producer of Tissue in South Africa.

Toscotec S.p.A.

Leader in innovative solutions, Toscotec is the ideal partner for the tissue and paper industry. Since 1948 it designs and manufactures technological solutions for the world’s major paper industries: from complete production lines to rebuilds and upgrades, to individual components. With a global presence and a strong service offer, the company aspires to be a reference for its customers, distinguishing itself for quality and reliability.

Center of excellence in the production of TT SYD, the company stands for tradition of innovation, manufacturing quality and energy savings. Toscotec is market leader in the sale of tissue machines.

WEPA starts up the new AHEAD-2.0S PM21 tissue machine at its Piechowice plant in Poland.

WEPA group, based in the Westphalian city of Arnsberg, announces the successful start-up of the new Toscotec’s 32,000 tpy tissue line installed at Piechowice Mill, Poland. The machine went easily in operation on 9th February, eleven months after the beginning of the works and six days in advance of the official scheduled start-up.

Following the almost twenty-year partnership in supplying new tissue machines, equipment and services for several well-known WEPA’s projects, the Italian manufacturer Toscotec was chosen to be the right supplier for the new plant again. The Toscotec turn-key delivery includes a stock preparation system for virgin pulp and brokes, an AHEAD-2.0S tissue machine equipped with TT SYD-15FT and all auxiliaries, electrification & control system. Full engineering, erection, erection supervision, training, start-up and commissioning were also included in the scope of the supply.

The new machine has a width of 2.8 m and will run at a maximum speed of 2,000 m/min, producing, among the other grades, super soft toilet paper from virgin pulp as well as recycled fibre as a raw material.

The new paper machine is already working efficiently, in particular from an energy point of view, and contributes in reducing the ecological footprint of the WEPA Group by reducing CO2 emissions.

The new project will allow the WEPA to optimize the existing logistics structures of all European sites, thus enhancing the competitiveness of the entire group.

ABOUT WEPA _ The WEPA Group, which is based in Arnsberg (NRW), Germany, is a family business which manufactures high quality tissue paper. With 11 plants in Europe, WEPA produces toilet paper, kitchen roll, pocket tissues, cosmetics tissues, serviettes, industrial rolls and paper towels. www.wepa.de

Italian producer Ariete S.r.l. – Futura Line S.p.a. Group – chooses Toscotec for the installation of a new tissue machine.

Ariete S.r.l., Italian company producing high quality tissue paper, has ordered a new MODULO-PLUS machine from Toscotec for its paper mill in Cava dei Tirreni (Salerno), Italy.

The new tissue machine replaces the exiting one and startup is scheduled for July 2017.

All the dismantling and assembly operations will be performed and synchronized in order to minimize the mill’s downtime. The scope of the supply includes a

MODULO-PLUS in Crescent Former configuration with single-layer headbox.

Approach flow, electrical and control systems together with dismantling of the existing machine and installation of the new one, supervision and assistance for startup will all be performed by Toscotec.

Ariete S.r.l. has been working in the field of tissue paper since 1965, manufacturing qualitatively high standard products capable of meeting the different and changing demands of the market.

The paper mill, headquartered in Italy in Cava dei Tirreni (Salerno), spans along a property of 14,000 m2 and has a production capacity of 22,000 tons/year. The company offers its customer a wide range of semi-finished products for hygienic use and for use in the food industry, with productions that vary from 15 gr/m2 to 38 gr/m2 and from 1 to 4 plies of pure cellulose. Traditionally oriented towards innovation and quality in full respect of people and of the environment, Ariete has decided to make this investment pursuant to a new strategy focused on maximizing efficiency.

“Toscotec’s offer turned out to be the best on a technological level and the most suitable to our needs. To be competitive on the market, we must have the proper instruments: we are convinced that the new MODULO-PLUS is the technical solution that we were looking for and that will allow us to increment quantity and quality”, states Nicola Salsano, Chairman of the Board of Directors at Ariete S.r.l.

Toscotec S.p.A.

Leader in innovative solutions, Toscotec is the ideal partner for the tissue and paper industry. Since 1948 it designs and manufactures technological solutions for the world’s major paper industries: from complete production lines to rebuilds and upgrades, to individual components. With a global presence and a strong service offer, the company aspires to be a reference for its customers, distinguishing itself for quality and reliability.

Center of excellence in the production of TT SYD, the company stands for tradition of innovation, manufacturing quality and energy savings. Toscotec is market leader in the sale of tissue machines.

Toscotec has received in total 8 (eight) Tissue Machine order from APP

Toscotec has received in total 8 (eight) Tissue Machine order from APP. Two of the Tissue Machines are scheduled to come on stream in Q4 2017 and Q1 2018, respectively. In the meantime, the Italian supplier is manufacturing other 6 tissue machines which are planned for delivery between the Q3 2017 and the first half of 2018. Each tissue machine is capable of producing, among other tissue grades, 300 tpd or about 100,000 tpa of high gsm tissue.

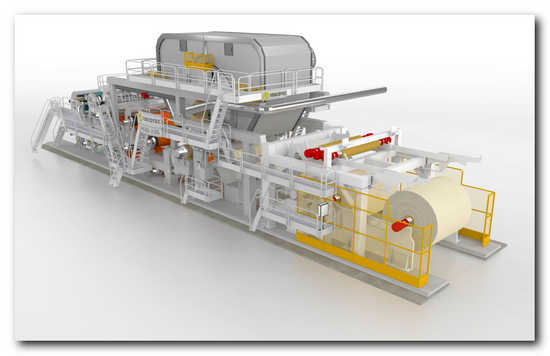

Based on a continued strategic expansion, APP has decided to choose Toscotec’s state of the art technology, with the objective of using the most “green solution” available on the market and reducing energy costs. The scope of supply of this major order includes AHEAD-2.0L crescent former tissue machines, with a net trim width of 5.6m, 22 FT diameter Steel Yankee Dryer TT SYD-22FT and Steam Heated Yankee Hoods.

This is Toscotec’s most recent innovation, PRODERGY, a new concept developed from the Company’s successful line, the AHEAD-2.0, which significantly boosts production and cuts down on the energy costs. In fact, PRODERGY is the 1st tissue machine to combine top production performance and top product quality, with energy efficiency. Its unique configuration of the drying section has taken tissue technology to a whole new level and has set new records for the industry. The first record to be broken is the diameter of the Steel Yankee: 22 feet, the largest Steel Yankee Dryer ever built for tissue production. The second record pertains to the speed, and therefore to the production output, as Prodergy is the first tissue machine relying on steam energy only that can achieve a maximum operation speed of 2000 m/min. These features make Prodergy the most green cutting-edge technology available on the tissue market nowadays. Its use of steam energy in the hoods guarantees the lowest possible emissions and environmental impact.

This major order confirms the long-standing cooperation between APP and Toscotec, which in the past has already provided APP with a significant number of Steel Yankee Dryers.

About Toscotec S.p.A.

Toscotec is a turnkey supplier to the global tissue industry. Since 1948, Toscotec offers complete production lines, plant retrofits, turnkey projects, and individual machineries. Headquartered in Lucca, the nerve center of the Italian paper district, with offices in China and North America, the Group serves all the leading paper producers with customized solutions, leveraging on the experience gained in more than 60 years of activities. Key to the Group’s success is the engineering and R&D department, run by a team of highly qualified engineers.