Displaying items by tag: fabio perini

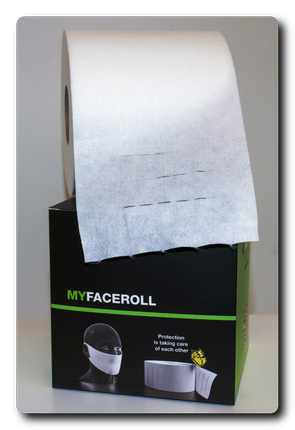

From toilet paper to face masks

Fabio Perini patents technology to produce up to 10,000 biodegradable bamboo masks per minute

The upgrade is available for Fabio Perini converting lines, new and/or already installed

A technological innovation capable of producing up to 10 thousand face masks per minute, which can be adapted to all main "non-woven" materials, including a particular bamboo-based material that can be disposed of with other organic waste. This is the patent filed by Fabio Perini, a Lucca based company which is part of the Körber Tissue Business Area. The technology, which developed in just over a month during lockdown, can be quickly added to the company’s converting machines, new and/or already installed with customers all over the world.

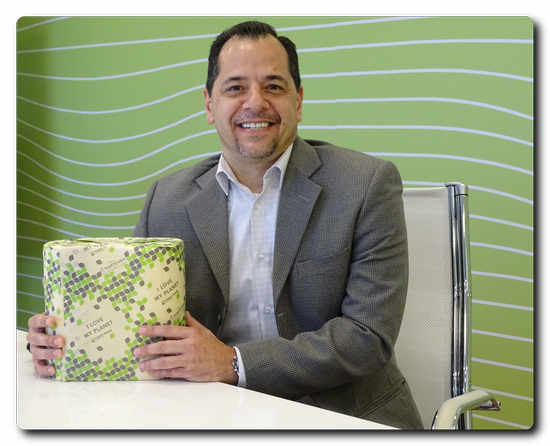

Oswaldo Cruz Jr., CEO of Fabio Perini S.p.A. and the Körber Tissue Business Area, has this to say about the technology: “Opportunities for innovation are everywhere, even in the midst of a health crisis, and during the lockdown our team got to work to respond to two needs: on the one hand, the huge demand for face masks – the Polytechnic University of Turin , for example, estimates that Italian companies alone will need almost 1 billion a month -; on the other, the issue of their disposal. In just over a month, from ideation to production, we arrived at the solution: a technological update that would allow the production of up to 10,000 masks (in rolls) per minute, and the use of a bamboo-based non-woven fabric that is biodegradable and can be disposed of with other compostable waste”.

These single-layer masks are very useful for daily, collective, and community use in places such as airports, public transportation, shopping malls, supermarkets, groceries and of course in our workplaces.

“The solution makes our machines also capable of manufacturing certified masks; however, pairing these materials with plastic would make the masks non-biodegradable. Nevertheless, together with different raw materials suppliers in the industry we are testing specific material solutions and we are confident of finding a solution soon” continues O. Cruz.

Coronavirus has thus also diversified Fabio Perini's business. O. Cruz concludes: “On this innovation, all over the world, we have had excellent feedback from our customers and we expect a significant grow in our business. In fact, from our own privileged point of view - we work with toilet paper and paper towel manufacturers across the world, from China to the United States - we have seen an important change. Initially the request was to increase the production capacity of the machines, especially those for toilet paper, due to the "stock effect" of these products, and to cope with this we even introduced a service for the fast delivery of machines (and those who know our sector know very well that this is not easy!). As weeks went by, demand has focused more on folded tissue paper products, due to the increase in the number of disposable items being used to meet greater hygiene needs. I believe this will continue as a trend for a long time to come”.

Coronavirus has thus also diversified Fabio Perini's business. O. Cruz concludes: “On this innovation, all over the world, we have had excellent feedback from our customers and we expect a significant grow in our business. In fact, from our own privileged point of view - we work with toilet paper and paper towel manufacturers across the world, from China to the United States - we have seen an important change. Initially the request was to increase the production capacity of the machines, especially those for toilet paper, due to the "stock effect" of these products, and to cope with this we even introduced a service for the fast delivery of machines (and those who know our sector know very well that this is not easy!). As weeks went by, demand has focused more on folded tissue paper products, due to the increase in the number of disposable items being used to meet greater hygiene needs. I believe this will continue as a trend for a long time to come”.

Fabio Perini and MTC: prompt delivery for converting and packaging machines and lines

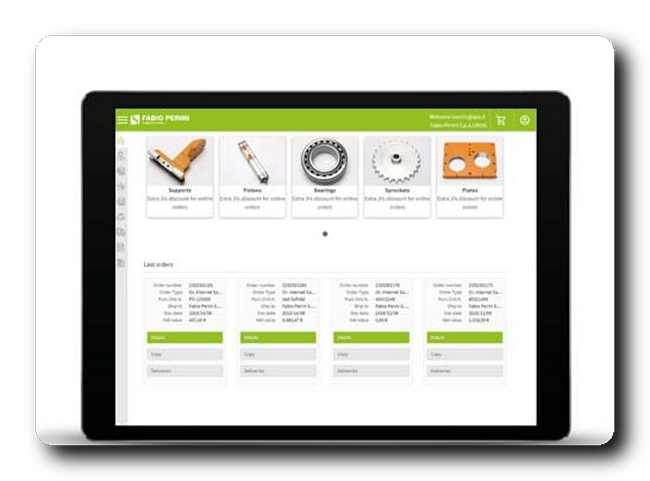

And on the webshop, over 80 thousand Fabio Perini spare parts immediately available

The fear generated by the coronavirus and the closures in several countries to fight the pandemic have triggered a rush to buy, or "panic buying" as the British call it. Not only food products such as pasta, milk, flour, eggs, water, but also toilet paper and tissue products are disappearing from the shelves. Many companies in the Tissue industry around the world have increased production to the maximum, however exposing machines to high risk of failure, and some of them do not have the ability to produce more. This is why Fabio Perini and MTC, Körber companies in the Tissue division, thanks to their leadership in the sector, their financial stability, and their strong worldwide presence, have decided to make available in a short time a selection of standard machines and lines for converting and packaging.

"In addition to the health emergency that we are facing globally, as a company we are committed to further develop our activities in order to respond promptly to the current production needs of the market - comments Mauro Luna, Global Sales Director Fabio Perini S.p.A. - In this historical moment the advantage of being able to deliver converting and packaging machines in a fast way is certainly an added value that we can offer our customers".

Several machines and lines are available such as, for example, for converting, the Constellation S8 and Proxima S6 or for folded products the Star M2 Napkin Folder, for packaging the A6T and CMW208 packaging machines. All can be delivered worldwide in less than 4 months. On the website northamerica.fabioperini.com/equipment you can find the available technologies with features and benefits and the possibility to contact directly the company's sales team for information and quotes.

The fast procurement and delivery of spare parts is also very important because it minimizes downtime. Fabio Perini, through the Spares Online e-commerce platform, provides over 80 thousand spare parts, all available for fast delivery. On the webshop, available 24/24 from all devices, the customer can keep track of the order phases: check stock availability and delivery dates in real time, print commercial documents and track the order until it is delivered to his plant. The webshop also allows the creation of wishlists for repetitive orders and enables to receive personalized offers and promotions.

"During this period the production of equipment is pushed to its maximum with demands that far exceed normal use. - comments Gianfranco Agnusdei, Global Customer Service Director, Fabio Perini S.p.A. - Unexpected equipment failure can lead to costly downtime and delays. Investing in and storing spare parts can help maximize production time and keep operations running smoothly. It is therefore critical to have an adequate supply of OEM spare parts that can help maximize operations".

Fabio Perini solutions to guarantee operational continuity in times of Coronavirus

Augmented reality, a team of online experts, and the Tissue Performance Center for real time monitoring and technical support to the lines

The power of technology and human ingenuity allows solving problems thousands of kilometers away, without moving engineers nor tools, with the recourse to remote assistance and augmented reality. Fabio Perini has been working for a long time at solutions for remote and real time assistance to monitor information about the status of the lines, as well as for intervening in a punctual, timely manner. These solutions are proving particularly effective in circumstances like the present one.

“In these days of emergency, – Oswaldo Cruz Junior, Fabio Perini S.p.A. CEO, comments – Fabio Perini is able to offer concrete and effective support to its customers, to guarantee their operational continuity: we have in place already an outstanding infrastructure for remote connectivity and we can count on our global presence and on the know-how of all our teams around the world".

The Tissue Performance Center is a state-of-the-art technological environment where experienced technicians, with the support of the company's data scientists, continuously collect and analyze customer data to provide information on the status of their machines and suggest improvements to maximize the Overall Equipment Effectiveness (OEE) of their production lines.

A direct connection to the customers' machines makes the Tissue Performance Center's work proactive by predicting potential downtime. Thanks to the visualization of the operating parameters, the online team of experts provides an assessment of the health status of the lines and highlights any anomalies. Periodically, the customer also receives a "medical record" on the production status of the connected lines and identifies, together with Fabio Perini's converting experts, what improvements can be implemented.

"At Fabio Perini we have more than 10 people who provide assistance to over 60 customers who are sharing with us the data of 1000 machines – Gianfranco Agnusdei, Fabio Perini S.p.A. Global Customer Service Director, comments – Whenever we find anomalies, we immediately contact our customers, help them identify the causes, find appropriate solutions and thus reduce costly downtime. In the future we could also offer a predictive maintenance service: this will allow us to anticipate and thus further improve performance".

The technical support is complemented by the TeamViewer Pilot, an augmented reality technology that allows viewing machines remotely to evaluate problems and suggest appropriate solutions. Through a video streaming directly from the camera of the smartphone and tablet, in real time, Fabio Perini technicians, also through 3D markers and indications applied to the real environment, are able to observe any problem and are able to guide the customer to a complete and rapid solution of the problem, anywhere in the world.

Valmet and Fabio Perini start Industrial Internet ecosystem partnership to provide digital solutions for tissue production and converting

Valmet and Fabio Perini have established an Industrial Internet ecosystem partnership to strengthen collaboration in the tissue industry. The target is to allow tissue producers and converters to work together more efficiently, and to exchange knowledge and resources for the benefit of their customers.

The partnership combines Valmet's comprehensive tissue making technology and process optimization know-how with Fabio Perini’s strong expertise in complete solutions for converting and packaging machines as well as in the converting process and technology. The two companies’ solid expertise combined with data from tissue mills and converting plants will provide a new dimension to tissue mill optimization.

The collaboration aims at providing an unbroken chain of production data from the tissue machine to the converting line and utilizing artificial intelligence-driven applications in the tissue production process to make the converting operations downstream more efficient. This will bring significant mill-level quality and efficiency improvements for tissue producers and converters.

The collaboration aims at providing an unbroken chain of production data from the tissue machine to the converting line and utilizing artificial intelligence-driven applications in the tissue production process to make the converting operations downstream more efficient. This will bring significant mill-level quality and efficiency improvements for tissue producers and converters.

“Starting from customer needs, Valmet and Fabio Perini are now taking the first steps to develop solutions where innovation goes beyond company borders, covering both tissue production and converting processes. Through collaboration with our common customers we can provide new digital solutions and services to help move tissue mills’ performance forward,” says Jari Almi, Vice President, Industrial Internet, Valmet.

“We believe an open innovation model is a key concept through which companies within tissue business can create different partnerships to make their innovation process more efficient, as well as exchange knowledge and resources. By combining the strengths of our companies, we can facilitate broad innovation and fast adaptation, enable new business and service models and help improve the profitability of companies in the tissue business,” says Oswaldo Cruz Junior, CEO of Körber's Business Area Tissue.

Both Valmet and Fabio Perini have a long history in offering measurement and optimization applications for tissue production. These reliable measurements have provided proven results for their customers.

Information about Fabio Perini

Fabio Perini S.p.A. with the brands Fabio Perini, Casmatic and Concept X, is specialized in the production of machinery, lines and integrated systems, for the converting and packaging of tissue paper, for a wide range of products: toilet rolls, kitchen towels, industrial rolls. Founded in 1966 at Lucca, the Italian district of tissue production and converting technology, Fabio Perini is a point of reference for its high level of innovation and advanced technology. Fabio Perini S.p.A. is the leading company of the Körber Group’s Business Area Tissue. www.fabioperini.com

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2018 were approximately EUR 3.3 billion. Our more than 13,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Fabio Perini Brazil is enlarging its premises and is aiming for a growth rate of around 15% over the coming 5 years

Fabio Perini S.p.A. Brazil is enlarging its administrative offices in Joinville and its production plant to handle the increasing demand from the Brazilian and South American market for tissue paper and folded paper products.

“Brazilian and South American markets today are rapidly expanding and show a higher long-term growth rate than more mature markets like those in Europe and the US”, comments Dineo Eduardo Silverio, Chairman of Fabio Perini Ltda. “In South America, the tissue paper market has been growing by at least 3% a year, and we estimate a growth of around 15% over the next five years”.

The enlargement of the Joinville plant is also marked by the entry of MTC, technology leader in solutions for folded tissue products, in order to answer growing market demand in the tissue field from all over South America.

In late November 2019, an Open House was set up at the Joinville premises, where visitors could see in function, the first MTC machine made entirely in Brazil. A strategic move that aims at reinforcing the company on the market, increasing its competitive edge and providing on-site sales and after-sales services.

“Part of the growth of the tissue market comes from increased consumption of folded paper products, and one of the reasons which drove us to bring MTC technology into Brazil was to answer this growing demand: surely one of the main requests coming from the Latin American and South American market is for machinery to produce folded tissue paper products. In the coming years, we expect a further upward push”, says Dineo Eduardo Silverio.

In late July 2019, Roll-Tec, Brazil’s specialist in rolls for embossing and tissue production, was bought by the Körber Group’s Tissue Business Area. The purchase was intended to develop and reinforce the position of tissue on the Latin American market, driving Fabio Perini Brazil to study market expansion strategies in North America as well, in an effort to consolidate and expand their leadership in the Americas.

Fabio Perini presents the Tissue Performance Center

Over 1000 machines all over the world connected to the Lucca Control Room for real-time line control

Fabio Perini presented at MIAC the Tissue Performance Center, a next generation technologic environment where expert engineers, supported by company data scientists, continuously register and analyze customers’ data to supply information on the machines status and suggest improvements to maximize the overall equipment effectiveness (OEE) of the production lines.

Thanks to a direct connection with the customers’ machines, the Tissue Performance Center can now work proactively, not just reactively as it used to in the past. The on-line visualization of operating parameters allows a continuous evaluation of their status and helps pointing out potential anomalies.

“The customer connects his machine to the Tissue Performance Center - Franco Franceschi, Customer Service Performance Services Manager, explains – This way, output data, engines’ temperature and parameters’ settings are kept under constant monitoring. These values, compared also with historic production data, allow the Fabio Perini experts not only to remotely implement corrections to enhance the efficiency of the production lines, but also to detect possible causes of malfunctioning and to establish beforehand the appropriate actions to solve them.

Performance reports, background analyses to evaluate cause/effect and now also control on energy consumption are part of an articulated path – Franceschi concludes – that will lead us in the near future to a learning machine capable of autonomously interpreting data and of improving by its own the machine performances under every condition”.

Fabio Perini presents in world premiere at MIAC the prototype of the 100% ecologic kitchen roll

Big news at Fabio Perini, as the company presents at MIAC, in absolute world premiere, the prototype of a totally ecologically sustainable, coreless and glueless kitchen roll.

“With this prototype - Enrico Zino, Fabio Perini Head of Marketing, declares – we provide the answer to three market requirements: delivering our clients as much product as possible without increasing bulkiness and without giving up quality; reducing waste consequent to core disposal, maintaining the product’s structural characteristics across the whole logistic chain; and turning out a 100% ecologic product”.

“Up to this time - Zino points out – several technologies had made possible an “environment friendly focus” limited to certain production phases: doing without the core for our rolls, eliminating glue or focusing on replacing plastics in packaging. Now, Fabio Perini is the first in the world to present a prototype of kitchen/towel roll combining already existent technologies with an absolute novelty, just patented and which will be moving to the industrial phase shortly after MIAC, that is, water lamination also for kitchen rolls”.

“Up to this time - Zino points out – several technologies had made possible an “environment friendly focus” limited to certain production phases: doing without the core for our rolls, eliminating glue or focusing on replacing plastics in packaging. Now, Fabio Perini is the first in the world to present a prototype of kitchen/towel roll combining already existent technologies with an absolute novelty, just patented and which will be moving to the industrial phase shortly after MIAC, that is, water lamination also for kitchen rolls”.

Fabio Perini has always had a green vocation, which in the past prompted the launch on its markets of ecofriendly solutions, even anticipating trends.

In 2010, Fabio Perini was the first company to propose gluefree solutions, barring the use of glue both in lamination (Aquabond) and in the initial pickup f tissue around the core (Web Tuck system Rewinder), reducing environmental impact and saving the cost of glue and the ensuing maintenance; it launched on the market the patented Solid and Solid+ coreless technology to produce full rolls that can keep the product’s structural characteristics, increasing by 16% the amount of tissue per roll with the same diameter, and attaining a 10% reduction of packaging required for the same amount of product transported. In addition, Fabio Perini recently presented a series of packaging solutions based on paper coupled with ecologic bioplastics, derived from vegetable starch and waste, creating a product whose characteristics are comparable to those of plastic polymers. This 100% compostable packaging can be processed maintaining the machinery speed at almost the same speed as with polyethylene production.

To all this, Fabio Perini is adding several solutions to limit the energy consumption of its machinery thanks to high efficiency engines and inverters, which consume less and have regenerative feedback capabilities, hybrid energy control-panel cooling, led lights drastically reducing the lighting energy absorption, inside the machines and the control-panels.

“The definition of sustainable development dates back to 1987 - Enrico Zino, Fabio Perini Head of Marketing, declares – but while at that time companies who embraced a growth compatible with environmental preservation were doing so by choice, today, as we become aware that our planet can no longer compensate the deep impact of our production and lifestyle, it has become a duty and a responsibility for all. For us at Fabio Perini – Zino concludes – nature and technology represent two sides of the same coin: nature is a perfect technology and our technology must be perfect for nature. We aim at offering, even at industrial level, a more and more sustainable business, by acting as key partners for all the companies that give the utmost priority to environmental compatibility”.

From plastic to paper and bioplastics: Fabio Perini and Casmatic make eco-friendly tissue products packaging conversion possible

Replace plastic packaging with a new eco-friendly, combined paper and bio-plastic material on Casmatic packaging machines.

Plastics are the most used materials in the world of packaging, but they need to be limited in light of recent restrictions of the European Commission concerning disposable products. In response, Fabio Perini has developed a "green" primary and secondary packaging solution that can easily adapt to current systems and existing equipment. This provides cost efficiencies for Fabio Perini customers and helps them actively contribute to safeguarding the environment while keeping up with technology and productivity.

To accomplish this, Fabio Perini had to identify the most suitable alternative to plastic for primary packaging. This material had to be not only eco-sustainable, recyclable and/or compostable, but also as versatile as the polyethylene in terms of abundant availability, product protection, packaging options, printability, and resistance to production-related mechanical stress.

Fabio Perini and a partner company conducted numerous materials tests on the latest generation packaging machines such as the CMW1000 and Carbon T, and ultimately developed an innovative, totally ecological material that combines paper and bioplastic to form properties that can be interchanged with normal polyethylene.

The new Paper Packaging Solution addresses the facts that paper alone is not strong enough and water-repellent for primary packaging and that bioplastic alone is not economically viable for use on an industrial scale. Paper Packaging Solution is a paper coupled with Mater-Bi, a totally ecological bioplastic having the same properties as plastic polymers, but with the added benefits of being recyclable, biodegradable, and compostable.

Two different types of Paper Packaging Solution products are available: a low-weight paper, 25 gm2, and a thicker paper, 40 gm2. Both are FSC-certified and are laminated or extruded with bioplastics with thicknesses ranging from 7 to 9 microns to ensure high pack weldability and an excellent product hygroscopic barrier.

Further, Paper Packaging Solution products are available in virgin paper or recycled paper. The 100% biodegradable virgin paper is certified "Vinicotte OK compost," which has the fibers closely joined to accommodate the higher heat needed for bioplastic fusion and perfect packaging seals, as well as being more resistant. The 100% recyclable and compostable paper has looser fibers. The

heat passes through it more easily to create package seals, but the looser fibers affect its resistance.

Paper Packaging Solution products are fully compatible with Casmatic's latest generation packaging machines — such as Casmatic A6T, CMW1000 and the new Carbon T — thanks to the "bio-pack kit." This innovative device makes it is possible to select the desired type of packaging material from the control panel and the Casmatic packaging machine automatically sets various parameters, including heat and time, required to perfectly seal the packages according to the packaging composition.

Mauro Luna appointed Fabio Perini S.p.A. new Global Sales Director

Mr. Mauro Luna appointed Fabio Perini S.p.A. new Global Sales Director. After graduating in Mechanical Engineering at the University of San Paolo in Brazil, Mr. Luna completed his studies by attending a course in Marketing at the University of Berkeley in California and a Master of Business Administration in Brazil. He has developed a professional career in Sales, starting as Sales and Application Engineer with Voith Brazil and, in the following years, worked as Sales Director, Marketing and Business Development with SKF, where he had the opportunity to take up the role of Chief Executive Officer of SKF’s branch in Peru. His last job was as Commercial Director for Amcor Rigids Plastics. Mr. Luna will lead Fabio Perini’s Sales department at global level.

“He will enhance Perini’s existing markets and customers” says Oswald Cruz CEO of Fabio Perini S.p.A. “and thanks to his many years of sales experience and his knowledge of different contexts he will lead the Global Sales of Fabio Perini to understand the current needs of the market, and to be closer to each journey of our Customers with our products and services”.

Fabio Perini Digital Tissue™: in 6 months over 130 lines worldwide

Fabio Perini Digital Tissue™: in 6 months over 130 lines worldwide, connected with the Lucca headquarters for a constant control of fact-based production. The future? A line integrated with the whole plant and the global tissue ecosystem

Six months after its disclosure, Fabio Perini Spa takes stock of Digital Tissue™, the suite of digital solutions for the tissue ecosystem aimed at optimizing the overall equipment effectiveness (OEE) of the lines: as of today, over one hundred thirty lines all over the world (between Europe, the Americas, Asia and Africa) are connected to the Lucca headquarters allowing to constantly control the fact-based production thanks to a “graphic thermometer” which keeps the customer and Fabio Perini engineers up-to-date on the machines’ status in an intuitive way.

“The aim of Fabio Perini – Antonio Mosca, Head of Fabio Perini S.p.A Digital Transformation, comments – is not only to be a supplier of converting and packaging lines, but also to offer a complete digital proposal, with smart software and controllers which, by collecting the data directly from the machines, can allow management of the whole production line, optimization of the output and definition of specific KPIs”.

“With Tissue Data Cloud – Mosca adds – we have concretely demonstrated the potential of the new digital services to our customers. Data collection and analysis, processed into easy and intuitive indicators, offer immediate evidence of the machines’ performance, while the detection of irregular trends allows our technicians to put in place immediate actions to recover the efficiency of the production line. However, our objective is to go beyond emergency rescue, that is to be able to predict potential anomalies and propose a “treatment plan” personalized for each customer”.

The future of Digital Tissue™ is not limited to single machines or lines. “We want to see the machine integrated with the line and we are preparing to receive data both upstream and downstream from the machine, so as to realize an integrated OEE for the line, all the way to being able to analyze the performance of the whole plant. Our dream - and an operational plan already exists to realize it - is to integrate the plant with the overall production chain, from the tree in the forest to the tissue roll in the household”.

Digital Tissue™ revolves around four pillars:

Tissue Data Cloud

Data processing through several performance indicators offers the customer immediate visibility of the critical steps of the process. By using a dashboard, directly accessible from the Fabio Perini Customer Service Portal using PC, Tablet and Smartphone, the data of the lines are processed in an easy and intuitive way. Thanks to the analysis of these indicators and to the expertise of the company technicians, customers are offered a real Digital Audit enabling them, even remotely, to detect the causes of line malfunctions and to establish ahead of time the actions to solve them.

Process Control

Process control is a service and solutions package which now can be installed not only on all the new converting lines, but also on installed bases already operating in production. Thanks to Process Control, the tissue ply and the finished product can be measured and the data collected to be converted into information that is useful for productive efficiency.

All-in-one

All-in-One is the Smart Application that allows automatic management of the change of format of the whole line by communicating the type of recipe and the configuration of production parameters. In addition, All-in-One manages the line’s output flow and can modify the speed of each machine by modulating the capacity of the accumulator, allowing the operators to act without interrupting production.

Condition Monitoring

Condition Monitoring is a solution for predictive maintenance that, thanks to vibrational analyses, pinpoints possible anomalies or deviations from planned patterns, allowing to plan maintenance on the basis of the actual status of the equipment and avoiding untimely stops or unnecessary replacements.

Digital Customer Service,

The WECARE platform together with the processing and analysis of production data, combined with the technical expertise of the Fabio Perini staff, enables customers to preserve the value of their capital asset over time and to optimize the Overall Equipment Effectiveness (OEE) of their lines.

For further info: