Displaying items by tag: fabio perini spa

Fabio Perini S.p.A. only one in the tissue industry to obtain the prestigious AEO F certification, allowing simpler and faster export

Fabio Perini S.p.A. obtained by the Customs Authority the award of the status of AEO F -– Authorized Economic Operator Full for customs simplifications and safety/security.

The AEO authorization grants Fabio Perini the recognition of its status of customs reliability, valid at European level (but internationally recognized); the appointment is the result of a process of adjustment of internal procedures and successful audits, carried out by the certifying body, of the regulatory requirements related to customs compliance, keeping of accounting records, financial solvency and safety/security standards.

The direct and indirect benefits provided by AEO have an immediate, positive impact on the whole international logistic chain operated by Fabio Perini and its customers, such as:

- fewer document and safety controls

- priority shipment treatment

- better relations with Customs authorities

- rapidity in procedures

- fewer delays of shipments at borders, resulting in less time and costs and also less risk of theft and loss of goods, and of safety-related accidents

All this results in greater efficiency in customs procedures and, consequently, in the offer of customer services.

“The path to this achievement has been going on for about a year - said Paolo Sodero, Fabio Perini S.p.A’s responsible for Digitalization and Export Control Manager – involving almost all the company departments, and aligning all employees to this key world-class goal.”

This authorization, allowing the offer of better customer assistance, represents a major strength for Fabio Perini to keep its leading position in the global market of machinery for tissue production. In fact, Paolo Sodero commented: “Our Company is the only one in our sector to have achieved this type of authorization”.

In fact, as of today, the recipients of AEO F authorizations - excluding companies exclusively dealing in shipments and logistic and customs services operators – amounts to 400 companies, all representative of Italian excellence.

100% of Engraving Solutions to Fabio Perini

Simec Group signs the agreement for the sale of the shares

Fabio Perini S.p.A. and NARA S.r.l. (Simec Group) have completed the transfer of all the investments in Engraving Solutions S.r.l. to Fabio Perini S.p.A. which already held 70% of the company's shares.

The consolidated industrial partnership between the two groups will remain active in the future for a better customer satisfaction and will continue to innovate following the needs of the market.

Engraving Solutions was founded in 2003 thanks to the union of intentions of Fabio Perini and Simec Group, a leader in the production of rolls with surface machining for different application sectors. Thanks to the know-how and technological excellence of the two companies, it immediately distinguished itself in the market for its ability to develop new designs and to support the customer in the study of engravings for embossed products in the Tissue sector.

More than 4,000 rolls already produced, the creation of over 12,000 embossing graphics solutions and 15 patents active all over the world, are the assets of Engraving Solutions. Currently, 20 employees work at the Lucca plant. Among the most successful products at the international level, we mention the Softop, PP-Evo, 4D, and Pixel.

"This acquisition is in line with our growth strategy 2025 and strengthens our positioning on the Tissue Area business market - says Oswaldo Cruz, CEO of Fabio Perini S.p.A. - Engraving Solutions is an important and strategic resource for our tissue companies that will benefit from this consolidated experience and will be able to provide increasingly customized and innovative solutions to maximize the added value of our customers' finished products ".

“This experience - states Laura Della Torre, Member of the board of Simec Group - has made possible the exchange of knowledge between the parties involved and has enriched the background and the specific know-how of the sector. Simec Group has also been able to focus on other segments, strengthening its production assets and nowadays it is a leading company thanks to the wide range of applications available in its product portfolio”.

Fabio Perini S.p.A. with its five production sites in Italy, the United States, Brazil and China, it is the only company, on a global scale, capable of producing complete lines of tissue production, integrating converting and packaging, offering exceptional advantages in controlling the entire production process, optimizing performance, maximizing the quality of the finished product and reducing operating costs. An extraordinary value for customers who find solutions for their activities in a single partner.

The new way of interpreting Industry 4.0 has led Fabio Perini S.p.A. to define new solutions to manage the machines, lines, and production, processes, and activities that set the world of Digital Tissue™. All this helps to have intelligent structures that allow maximizing the production efficiency of the individual machines, the complete lines and even more the effectiveness of the production sites.

Today Fabio Perini companies have a total of 150,000 square meters dedicated to research, development, and assembly of machinery with the Bologna site exclusively devoted to packaging solutions. A total of around 1,100 employees, investments in R&D equal to 7% of annual turnover and 1,000 patents active internationally.

Stefan Kirschke to be new Körber Chief Financial Officer

Stefan Kirschke was named the new Chief Financial Officer (CFO) at Körber AG, effective December 14, 2017.

Stefan Kirschke succeeds Harald Vogelsang as Group CFO. Vogelsang left the Group on December 14, 2017, by mutual agreement. The Supervisory Board of Körber AG formally adopted this change at its meeting on December 14, 2017.

The Supervisory Board of Körber AG thus fulfilled Vogelsang’s request for a premature release from his current contract, due to personal reasons.

Stefan KirschkeRichard Bauer, Chairman of the Supervisory Board of Körber AG: “We are pleased that with Stefan Kirschke we were able to appoint an experienced internal finance expert to quickly fill this extremely important role within the Group. Mr. Kirschke was substantially involved in the realignment and the strong growth of the Business Area Körber Tissue in recent years. Thanks to his extensive expertise and his detailed knowledge and many years of reliable collaboration with all Business Areas, in his new role he will successfully continue the growth course of the Group together with the other members of the Group Executive Board. On behalf of the Supervisory Board, I would like to thank Mr. Vogelsang for the work he has done.”

Stefan KirschkeRichard Bauer, Chairman of the Supervisory Board of Körber AG: “We are pleased that with Stefan Kirschke we were able to appoint an experienced internal finance expert to quickly fill this extremely important role within the Group. Mr. Kirschke was substantially involved in the realignment and the strong growth of the Business Area Körber Tissue in recent years. Thanks to his extensive expertise and his detailed knowledge and many years of reliable collaboration with all Business Areas, in his new role he will successfully continue the growth course of the Group together with the other members of the Group Executive Board. On behalf of the Supervisory Board, I would like to thank Mr. Vogelsang for the work he has done.”

Over the last few years, Stefan Kirschke has held various leadership positions within the Körber Group. Most recently he served as CFO in the Business Area Körber Tissue. Prior to joining Körber, Kirschke worked at the auditing firm Ernst & Young and held various management positions in the field of strategic brand consulting. Stefan Kirschke has a degree in Business Management from the University of Münster.

Successor to Stefan Kirschke in the role of CEO of the Business Area Körber Tissue will be Oswaldo Cruz. Cruz joined Fabio Perini Brazil in 1994 as a Sales Manager, and was appointed as Managing Director there in 2007.

Dineo Silverio, currently Head of Sales and Customer Service with Fabio Perini Brazil, was already appointed as the successor to Oswaldo Cruz as Managing Director of the company with effect on January 1, 2018.

Together with Oswaldo Cruz, Markus Fröhlich (CFO) and Dr. Luca Frasnetti (CTO and COO as dual responsibility) will form the new management team for the Business Area Körber Tissue.

Oswaldo CruzMarkus Fröhlich currently serves as Director of Administration & Controlling at Fabio Perini. After earning his Master of Engineering Management degree, he began his career at Kugler-Womako, a company in the group’s former paper division. In 2011, Fröhlich became an investment controller at the former Körber Process Solutions. During this time, he also took part in the Körber Finance Program. As part of this program, he worked on projects at Fabio Perini Brazil before moving to Fabio Perini in Lucca in 2015.

Oswaldo CruzMarkus Fröhlich currently serves as Director of Administration & Controlling at Fabio Perini. After earning his Master of Engineering Management degree, he began his career at Kugler-Womako, a company in the group’s former paper division. In 2011, Fröhlich became an investment controller at the former Körber Process Solutions. During this time, he also took part in the Körber Finance Program. As part of this program, he worked on projects at Fabio Perini Brazil before moving to Fabio Perini in Lucca in 2015.

Dr. Luca Frasnetti currently serves as the Chief Technology Officer (CTO) at Fabio Perini in Lucca. He holds a doctorate in Electrical Engineering and has been with the Körber Group since 2014. Earlier in his career, he served as a Global Electronic Technology Leader at Whirlpool Italy and most recently as Head of Technology and R&D at the Italian subsidiary of the Candy Hoover Group.

“I’m really pleased that our long-term succession and development planning has enabled us to appoint internal experts to fill these critical positions in the Business Area Körber Tissue. With their know-how and deep understanding of this special market, we are in the best possible position for additional growth in this business division. I wish the new management team every conceivable success!” said Stefan Kirschke.

About Körber Tissue

The Business Area Körber Tissue, which includes the brands Fabio Perini, Casmatic and MTC, is synonymous with innovation, state-of-the-art technologies, end-to-end solutions for processing and packaging machinery for toilet paper, folded tissue and paper towels. Cutting-edge offerings and a systematic customer orientation make the Business Area the technology and market leader in the sector.

About Körber

Körber AG is the holding company for an international technology group with approx. 11,500 employees around the world. The Group comprises leading-edge technology companies and more than 130 production, service, and sales entities.

At locations around the globe, Körber combines the benefits of a globally-present organization with the strengths of highly-specialized, flexible, medium-sized enterprises that offer their customers solutions, products, and services in the Business Areas of Automation, Logistics Systems, Machine Tools,

Pharma Systems, Tissue, Tobacco, Corporate Ventures and in the near future Digital Solutions.

179AX, the new log saw by Fabio Perini S.p.A.

In perfect Industry 4.0 spirit, Fabio Perini S.p.A. presents the new Smart Machine 179AX: a log saw with 4 infeed lanes, unique in its kind, that allows fast & automatic blade replacement in total safety and without the need for operator intervention.

The machine is equipped with a 5-slot warehouse feeding an automatic change system of the worn blade in less than 3 minutes.

The blade change operation can be started up through a button from the OP or from remote control through All In One, if the log saw is part of a line equipped with this Smart Application.

The blades can be loaded in the warehouse without stopping the machine.

Additionally, the speed of the 179AX has been increased up to 270 cuts per minute and all adjustments for product change have been rendered automatic and can be stored in recipes, reducing operator intervention.

The quality of the cut has been optimized: the new grinding wheels geometry yields a higher quality of the blade edge, requiring fewer interventions for sharpening and thus guaranteeing greater blade life.

Reliability and ergonomics have also been enhanced by using timing belts instead of chains for pusher movement and by larger internal spaces that facilitate access for maintenance and cleaning.

COMPANY PROFILE

Fabio Perini S.p.A. was born in 1966 in Lucca, Italian hub and world tissue production and converting technology center. Today, with its 5 production facilities in Italy, the United States, Brazil and China, it helps its customers stay competitive and grow thanks to complete production solutions for converting and packaging. Technology, globalization and ongoing, continuous investments in research have led the company to stand out internationally and to be acknowledged as a true excellence in the world of tissue.

DIGITAL TISSUE™

Digital Tissue™ is Fabio Perini’s interpretation for the offer of predictive and self-learning systems with a view towards Industry 4.0 in Tissue. It is the instrument that helps Fabio Perini customers build ecosystems characterized by continuous improvement in skills, methods and information. A vision that aspires to be global, where every ecosystem can exist on its own but at the same time contribute to the global growth of the Tissue industry by creating a sturdy and reliable system where errors, loss of time and variability in product quality are overcome.

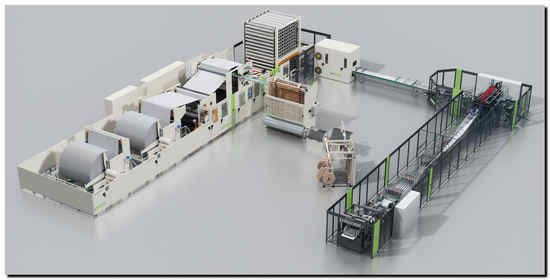

MYPERINI: the complete range of Fabio Perini S.p.A. lines

Fabio Perini S.p.A. offers MyPerini, a range of complete Converting and Packaging lines suitable for every production demand at a highly competitive price. MyPerini lines are characterized by the best consolidated, leading-edge technologies and include Fabio Perini S.p.A. patented systems.

Designed to meet most production demands, they are the perfect balance to optimize TCO (Total Cost of Ownership) and attain the best OEE (Overall Equipment Effectiveness).

MyPerini lines are proposed in several versions and in the 2800-mm format.

Fruit of the high technological level of Fabio Perini S.p.A., they include the consolidated “Sincro” transfer system and, based on the model and version, the patented winding system with active Punzoncini and the Catalyst technology for the embosser.

As for Converting, the MyPerini family is comprised of 3 versions suitable for different production needs: MySincro, MyLine and Mytime.

All the lines feature the possibility of completing the system by including the MyPack offer for packaging up to 200 packs/min and 20 bundles/min.

Choosing a MyPerini solution means having not only a quick answer in terms of delivery and startup, but also an optimal one thanks to the balanced configuration, reduced line space and ease of use by the operator. Additionally, MyPerini is a guarantee of a long-lasting solution due to its consolidated technology, to the technical updates in the course of time and to the high level of post-sales service that have always characterized Fabio Perini S.p.A.

COMPANY PROFILE

Fabio Perini S.p.A. was born in 1966 in Lucca, Italian hub and world tissue production and converting technology center. Today, with its 5 production facilities in Italy, the United States, Brazil and China, it helps its customers stay competitive and grow thanks to complete production solutions for converting and packaging. Technology, globalization and ongoing, continuous investments in research have led the company to stand out internationally and to be acknowledged as a true excellence in the world of tissue.

DIGITAL TISSUE™

Digital Tissue™ is Fabio Perini’s interpretation for the offer of predictive and self-learning systems with a view towards Industry 4.0 in Tissue. It is the instrument that helps Fabio Perini customers build ecosystems characterized by continuous improvement in skills, methods and information. A vision that aspires to be global, where every ecosystem can exist on its own but at the same time contribute to the global growth of the Tissue industry by creating a sturdy and reliable system where errors, loss of time and variability in product quality are overcome.

Digital Tissue[™] Fabio Perini S.p.A.: predictive systems with a view towards Industry 4.0

In the era of Industry 4.0, technology, digitalization, connectivity and integration of systems and people are foundational elements for consistent and growing performance. This type of evolution also closely concerns the Tissue field, where the ability to manage and drive the entire production process of the whole supply chain becomes the true added value. Being able to define and design a complete line to manufacture a finished product means totally understanding customers’ production demands.

Fabio Perini S.p.A. is the only company in the world capable of creating complete lines integrating converting and packaging, hence creating the product and the process together with the Customer in order to optimize the quality of the finished product. An extraordinary value for customers, who find the production solutions for their Business 4.0 in one unique partner.

Fabio Perini S.p.A. has defined this new way of seeing its customers’ factory using a very precise term: Digital Tissue™.

The new way to interpret Factory 4.0 has led Fabio Perini S.p.A. to define new technological solutions to manage the machines, the lines and business processes. All this will aid in having a smart factory capable of collecting, interpreting and sharing data with the purpose of maximizing the production efficiency of the individual machines, of the complete line and the efficiency of the production sites even further. Fabio Perini S.p.A. customers can already count on products and services developed pursuant to this approach and others will follow, keeping the focus on increasing performance and optimizing operational costs.

Fabio Perini S.p.A. is not new to the ability of reading and seizing market and technological trends. In the 1980s, it revolutionized the world of converting with the Sincro technology and has continued along the road to research and development, attaining the highest expression of innovation in 2015 with Constellation, thus projecting itself into the era of Industry 4.0.

The concept of Digital Tissue™ is the guiding principle behind the most recent innovations, too, such as Constellation, Catalyst, All In One and Weareable: product already used by Fabio Perini customers worldwide as concrete answers to the demands of converting, packaging and service. And this is just the beginning of the process of innovations that are clearly visible in the eyes of the final consumers.

COMPANY PROFILE

Fabio Perini S.p.A. was born in 1966 in Lucca, Italian hub and world tissue production and converting technology center. Today, with its 5 production facilities in Italy, the United States, Brazil and China, it helps its customers stay competitive and grow thanks to complete production solutions for converting and packaging. Technology, globalization and ongoing, continuous investments in research have led the company to stand out internationally and to be acknowledged as a true excellence in the world of tissue.

DIGITAL TISSUE™

Digital Tissue™ is Fabio Perini’s interpretation for the offer of predictive and self-learning systems with a view towards Industry 4.0 in Tissue. It is the instrument that helps Fabio Perini customers build ecosystems characterized by continuous improvement in skills, methods and information. A vision that aspires to be global, where every ecosystem can exist on its own but at the same time contribute to the global growth of the Tissue industry by creating a sturdy and reliable system where errors, loss of time and variability in product quality are overcome.