Displaying items by tag: fabio perini

179AX, the new log saw by Fabio Perini S.p.A.

In perfect Industry 4.0 spirit, Fabio Perini S.p.A. presents the new Smart Machine 179AX: a log saw with 4 infeed lanes, unique in its kind, that allows fast & automatic blade replacement in total safety and without the need for operator intervention.

The machine is equipped with a 5-slot warehouse feeding an automatic change system of the worn blade in less than 3 minutes.

The blade change operation can be started up through a button from the OP or from remote control through All In One, if the log saw is part of a line equipped with this Smart Application.

The blades can be loaded in the warehouse without stopping the machine.

Additionally, the speed of the 179AX has been increased up to 270 cuts per minute and all adjustments for product change have been rendered automatic and can be stored in recipes, reducing operator intervention.

The quality of the cut has been optimized: the new grinding wheels geometry yields a higher quality of the blade edge, requiring fewer interventions for sharpening and thus guaranteeing greater blade life.

Reliability and ergonomics have also been enhanced by using timing belts instead of chains for pusher movement and by larger internal spaces that facilitate access for maintenance and cleaning.

COMPANY PROFILE

Fabio Perini S.p.A. was born in 1966 in Lucca, Italian hub and world tissue production and converting technology center. Today, with its 5 production facilities in Italy, the United States, Brazil and China, it helps its customers stay competitive and grow thanks to complete production solutions for converting and packaging. Technology, globalization and ongoing, continuous investments in research have led the company to stand out internationally and to be acknowledged as a true excellence in the world of tissue.

DIGITAL TISSUE™

Digital Tissue™ is Fabio Perini’s interpretation for the offer of predictive and self-learning systems with a view towards Industry 4.0 in Tissue. It is the instrument that helps Fabio Perini customers build ecosystems characterized by continuous improvement in skills, methods and information. A vision that aspires to be global, where every ecosystem can exist on its own but at the same time contribute to the global growth of the Tissue industry by creating a sturdy and reliable system where errors, loss of time and variability in product quality are overcome.

New Management Team for Körber Tissue

Stefan Kirschke will take over as CEO of Körber Tissue, a Business Area of the international technology group Körber. In his new role, he will execute the functions of CEO and CFO as dual responsibility and will lead the Business Area together with Oswaldo Cruz, currently Managing Director of Fabio Perini Brazil. Kirschke succeeds Stefano Di Santo, who will become CEO of the newly established Körber Digital Unit, which is part of the Group's digital transformation process.

Stefan KirschkeStefan Kirschke holds a Master’s degree in Business Administration and joined Körber in 1995. Since 2012, he has been CFO of Fabio Perini S.p.A., the leading company of the Business Area Körber Tissue, fostering the Business Area’s growth alongside with Stefano Di Santo. Together with Oswaldo Cruz, currently Managing Director at Fabio Perini Ltda., Brazil, he will form the Business Area Management team from January 1, 2018. In addition to his role within the Business Area Management team, Oswaldo Cruz will succeed Alessandro De Matteis as Managing Director of the company MTC, part of the Business Area Körber Tissue, as of April 1, 2018. Cruz joined Fabio Perini as Sales Executive in 1994 and became Managing Director of Fabio Perini Brazil in 2007.

Stefan KirschkeStefan Kirschke holds a Master’s degree in Business Administration and joined Körber in 1995. Since 2012, he has been CFO of Fabio Perini S.p.A., the leading company of the Business Area Körber Tissue, fostering the Business Area’s growth alongside with Stefano Di Santo. Together with Oswaldo Cruz, currently Managing Director at Fabio Perini Ltda., Brazil, he will form the Business Area Management team from January 1, 2018. In addition to his role within the Business Area Management team, Oswaldo Cruz will succeed Alessandro De Matteis as Managing Director of the company MTC, part of the Business Area Körber Tissue, as of April 1, 2018. Cruz joined Fabio Perini as Sales Executive in 1994 and became Managing Director of Fabio Perini Brazil in 2007.

"I am very happy that with Stefan Kirschke I hand over to an experienced colleague who is dedicated to the further growth of Körber Tissue. We have worked very closely together over the last years and I am sure that together with his team he will guarantee the continued success of the Business Area”, emphasizes Di Santo.

“I am excited about the opportunity to further shape the Business Area – especially in light of the impact of digitization and further internationalization in our market. In addition I am very much looking forward to welcoming Oswaldo Cruz in Lucca soon”, says Stefan Kirschke. “We surely won a manager with comprehensive know-how and years of experience for this important position. Together with Oswaldo, I will be focusing on making the most of our core competencies in order to continuously offer our customers cutting-edge products and solutions as well as first class services.”

Following Oswaldo Cruz, Dineo Silverio, currently Director Sales and Customer Service at Fabio Perini Brazil, will succeed Oswaldo Cruz as the company’s Managing Director as of January 1, 2018.

Based on his experience in successfully initiating the digital transformation within the Business Area Körber Tissue, Stefano Di Santo will continue his career within the Körber Group and seize the opportunity to establish Körber Digital. Körber Digital is a new Unit, which will drive the further digital development of the Group while at the same time working on new digital business models for the diverse markets the Group operates in.

About Körber Tissue

The Business Area Körber Tissue, which includes the brands Fabio Perini, Casmatic and MTC, is synonymous with innovation, state-of-the-art technologies, end-to-end solutions for processing and packaging machinery for toilet paper, folded tissue and paper towels. Cutting-edge offerings and a systematic customer orientation make the Business Area the technology and market leader in the sector.

About Körber

Körber AG is the holding company for an international technology group with approx. 11,500 employees around the world. The Group comprises leading-edge technology companies and more than 130 production, service, and sales entities. At locations around the globe, Körber combines the benefits of a globally-present organization with the strengths of highly- specialized, flexible, medium-sized enterprises that offer their customers solutions, products, and services in the Business Areas of Automation, Logistics Systems, Machine Tools, Pharma Systems, Tissue, Tobacco, Corporate Ventures and in the near future Digital Solutions.

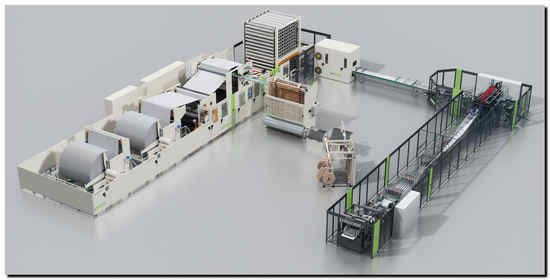

MYPERINI: the complete range of Fabio Perini S.p.A. lines

Fabio Perini S.p.A. offers MyPerini, a range of complete Converting and Packaging lines suitable for every production demand at a highly competitive price. MyPerini lines are characterized by the best consolidated, leading-edge technologies and include Fabio Perini S.p.A. patented systems.

Designed to meet most production demands, they are the perfect balance to optimize TCO (Total Cost of Ownership) and attain the best OEE (Overall Equipment Effectiveness).

MyPerini lines are proposed in several versions and in the 2800-mm format.

Fruit of the high technological level of Fabio Perini S.p.A., they include the consolidated “Sincro” transfer system and, based on the model and version, the patented winding system with active Punzoncini and the Catalyst technology for the embosser.

As for Converting, the MyPerini family is comprised of 3 versions suitable for different production needs: MySincro, MyLine and Mytime.

All the lines feature the possibility of completing the system by including the MyPack offer for packaging up to 200 packs/min and 20 bundles/min.

Choosing a MyPerini solution means having not only a quick answer in terms of delivery and startup, but also an optimal one thanks to the balanced configuration, reduced line space and ease of use by the operator. Additionally, MyPerini is a guarantee of a long-lasting solution due to its consolidated technology, to the technical updates in the course of time and to the high level of post-sales service that have always characterized Fabio Perini S.p.A.

COMPANY PROFILE

Fabio Perini S.p.A. was born in 1966 in Lucca, Italian hub and world tissue production and converting technology center. Today, with its 5 production facilities in Italy, the United States, Brazil and China, it helps its customers stay competitive and grow thanks to complete production solutions for converting and packaging. Technology, globalization and ongoing, continuous investments in research have led the company to stand out internationally and to be acknowledged as a true excellence in the world of tissue.

DIGITAL TISSUE™

Digital Tissue™ is Fabio Perini’s interpretation for the offer of predictive and self-learning systems with a view towards Industry 4.0 in Tissue. It is the instrument that helps Fabio Perini customers build ecosystems characterized by continuous improvement in skills, methods and information. A vision that aspires to be global, where every ecosystem can exist on its own but at the same time contribute to the global growth of the Tissue industry by creating a sturdy and reliable system where errors, loss of time and variability in product quality are overcome.

Digital Tissue[™] Fabio Perini S.p.A.: predictive systems with a view towards Industry 4.0

In the era of Industry 4.0, technology, digitalization, connectivity and integration of systems and people are foundational elements for consistent and growing performance. This type of evolution also closely concerns the Tissue field, where the ability to manage and drive the entire production process of the whole supply chain becomes the true added value. Being able to define and design a complete line to manufacture a finished product means totally understanding customers’ production demands.

Fabio Perini S.p.A. is the only company in the world capable of creating complete lines integrating converting and packaging, hence creating the product and the process together with the Customer in order to optimize the quality of the finished product. An extraordinary value for customers, who find the production solutions for their Business 4.0 in one unique partner.

Fabio Perini S.p.A. has defined this new way of seeing its customers’ factory using a very precise term: Digital Tissue™.

The new way to interpret Factory 4.0 has led Fabio Perini S.p.A. to define new technological solutions to manage the machines, the lines and business processes. All this will aid in having a smart factory capable of collecting, interpreting and sharing data with the purpose of maximizing the production efficiency of the individual machines, of the complete line and the efficiency of the production sites even further. Fabio Perini S.p.A. customers can already count on products and services developed pursuant to this approach and others will follow, keeping the focus on increasing performance and optimizing operational costs.

Fabio Perini S.p.A. is not new to the ability of reading and seizing market and technological trends. In the 1980s, it revolutionized the world of converting with the Sincro technology and has continued along the road to research and development, attaining the highest expression of innovation in 2015 with Constellation, thus projecting itself into the era of Industry 4.0.

The concept of Digital Tissue™ is the guiding principle behind the most recent innovations, too, such as Constellation, Catalyst, All In One and Weareable: product already used by Fabio Perini customers worldwide as concrete answers to the demands of converting, packaging and service. And this is just the beginning of the process of innovations that are clearly visible in the eyes of the final consumers.

COMPANY PROFILE

Fabio Perini S.p.A. was born in 1966 in Lucca, Italian hub and world tissue production and converting technology center. Today, with its 5 production facilities in Italy, the United States, Brazil and China, it helps its customers stay competitive and grow thanks to complete production solutions for converting and packaging. Technology, globalization and ongoing, continuous investments in research have led the company to stand out internationally and to be acknowledged as a true excellence in the world of tissue.

DIGITAL TISSUE™

Digital Tissue™ is Fabio Perini’s interpretation for the offer of predictive and self-learning systems with a view towards Industry 4.0 in Tissue. It is the instrument that helps Fabio Perini customers build ecosystems characterized by continuous improvement in skills, methods and information. A vision that aspires to be global, where every ecosystem can exist on its own but at the same time contribute to the global growth of the Tissue industry by creating a sturdy and reliable system where errors, loss of time and variability in product quality are overcome.

PIVOT unlocks data for tissue converters: grand opening in Green Bay, US

The worldwide tissue market continues to undergo changes. Consumer preferences, economic uncertainty and improved technology offer more questions than answers. Tissue manufacturers have an increasing amount of data available to make decisions. “The challenge is collecting and measuring that data and turning it into actionable decisions. As a result, many wonder about future success.” says Dario Giannini, Fabio Perini S.p.A. Business Development Manager.

Manufacturers must continue to win customer loyalty while maintaining profit margins. “This requires concise, usable information. Old methods do not work. Industry 4.0 is here, opening a new realm of data-driven decision-making.” Asserts Nicola Scaramuzza, Fabio Perini S.p.A. Global Marketing Director.

New Data-driven Service Available

Fabio Perini, a global leader in tissue converting, recently introduced PIVOT: the company's answer to data based tissue solutions. It is a breakthrough initiative providing tissue converters data easily understood and collected in a simplified manner. “This in-house laboratory helps understand tissue from pulp fibers to finished product. But it is more than a laboratory.” Says Claudio Munoz, Strategic Marketing Manager of Fabio Perini North America.

“PIVOT is an advisory service unlocking data for every aspect of tissue converting. It tracks data for web handling, embossing, winding, log formation and packaging. The result is actionable information on every stage of the tissue converting process. Even interactions between machinery and paper will reveal a path to optimized performance.” Adds Dario Giannini

Tissue converters now have a data resource covering caliper, firmness, absorbency, and strength. PIVOT also collects data on machine parameters such as speed, pressure of rubber rolls and other parameters. This provides a high-level of information helping optimize manufacturing for maximum profitability.

Tissue converters now have a data resource covering caliper, firmness, absorbency, and strength. PIVOT also collects data on machine parameters such as speed, pressure of rubber rolls and other parameters. This provides a high-level of information helping optimize manufacturing for maximum profitability.

The PIVOT laboratory service began in 2016 at Fabio Perini corporate headquarters in Lucca, Italy. A second lab is now in Green Bay, Wis., the company’s North American headquarters. A third facility in Brazil will open late in 2017 followed by a fourth lab in China in 2018. “The goal is helping customers around the world with easy access to critical data. All data is collected into a centralized, global database, providing customers a powerful resource.” Declares Claudio Munoz

Benefits for Tissue Converters

Besides learning more about a converter's paper, PIVOT also provides data on machinery. This is an added benefit for tissue converters. Too often companies buy machinery without full understanding of the capabilities. PIVOT analyzes data of a company’s tissue samples and the machine. It translates that data into:

- Recommendations on the best machine configuration for the paper product

- Suggestions to deliver consistent quality

PIVOT is only two years old, but has already demonstrated value for customers:

- PIVOT troubleshoots problems and maximizes test duration during checkouts. “A recent checkout revealed an opportunity for product optimization. Data provided by PIVOT measured tissue caliper and tensile strength at different stages of converting. This did reveal the best embossing pattern compatible to use in bulk production of the tissue.” says Dario Giannini

- Another checkout helped a customer after purchasing new equipment. “The customer wanted to measure characteristics of a certain paper. They were not getting the results expected on the new equipment and hoped PIVOT could help. PIVOT's data identified the best paper to run on the machine and maximize line productivity.” adds Dario Giannini

- Data from PIVOT helped a customer make an informed buying decision. “The original intent was making products with a larger diameter. Data from PIVOT confirmed the ability to make larger products. It also uncovered more reasons to invest in Constellation technology. It could use a less expensive fiber mix while maintaining strength and faster production.” Concludes Dario Giannini

PIVOT has already provided many concrete answers based upon data. “This is the goal of Industry 4.0” says Nicola Scaramuzza “using that data to drive the manufacturing process. PIVOT’s unique database is both local and global, helping deliver answers tissue converters need. These answers also include direction for better packaging results.”

Data from PIVOT has another use that benefits tissue converters. Fabio Perini engineers use this data to develop better tissue converting technology, such as Constellation.

Total Solution Package for Tissue Converting

A total solution for tissue converting is here: PIVOT, a global database that is the lynchpin in the spirit of Industry 4.0. It harnesses data to support customers in growing their business profitably and sustainably in the years to come. In a highly competitive market, where premiumization is one of the big challenges, it becomes vital to bring the right value on the shelves and PIVOT is the way.

Learn more about PIVOT and Fabio Perini S.p.A. at http://www.fabioperini.com

Augustine named 2017 Tappi Fellow

Peter R. Augustine, President of Fabio Perini North America was named a 2017 TAPPI Fellow. TAPPI, a leading association for the global pulp, paper, packaging, tissue and converting industries honored Augustine with the title in Minneapolis, Minn., during PaperCon. The Fellow designation is given to less than three percent of the association’s membership based upon significant technical or service contributions to the industry and/or TAPPI.

Augustine joined Fabio Perini S.p.A. in 2011 as General Manager for North America and promoted to his current position as President in 2013. He oversees the entire operation for Fabio Perini in North America, including strategic planning, sales and production. Augustine holds a Bachelor of Science from the University of Wisconsin and an MBA from Purdue. He also served as a Captain in the United States Army.

Augustine joined Fabio Perini S.p.A. in 2011 as General Manager for North America and promoted to his current position as President in 2013. He oversees the entire operation for Fabio Perini in North America, including strategic planning, sales and production. Augustine holds a Bachelor of Science from the University of Wisconsin and an MBA from Purdue. He also served as a Captain in the United States Army.

During his tenure with Fabio Perini, the company has introduced several technological innovations for the tissue converting industry. These include ConstellationÔ and its Weareable remote service product. ConstellationÔ changed the tissue converting industry by providing control, quality and production efficiencies previously unavailable in the industry while Weareable offers unsurpassed ability to provide technical service even when on-site service is not available.

“Pete was brought to my attention a few years ago as a strong leader, futuristic thinker and a man of integrity,” said Larry Montague, TAPPI CEO & President. “He has certainly lived up to these descriptions. Our goal was to expand our reach into the tissue arena and eventually have a tissue division. His commitment to developing a strong global strategy for the tissue industry is evident. The name Pete Augustine and Fabio Perini has brought instant validity to the world that shows TAPPI and Fabio Perini are dedicated to tissue.”

Augustine currently serves on the TAPPI Board of Directors as its Vice Chair in addition to his duties as President of Fabio Perini North America.

COMPANY PROFILE

Fabio Perini S.p.A. was born in 1966 in Lucca, Italian hub and world tissue production and converting technology center. Today, with its 5 production facilities in Italy, the United States, Brazil and China, it helps its customers stay competitive and grow thanks to complete production solutions for converting and packaging. Technology, globalization and ongoing, continuous investments in research have led the company to stand out internationally and to be acknowledged as a true excellence in the world of tissue.

Fabio Perini technology set to dominate tissue world Sao Paulo

Technological expertise will be on display as Fabio Perini Brazil demonstrates its complete solution capabilities for the South American tissue converting market when Tissue World convenes in Sao Paulo, Brazil from May 31 to June 2. Fabio Perini Brazil is the only supplier of tissue converting and packaging equipment with full-scale capabilities in South America. Its customer service and replacement part staff are unrivaled and ready to support manufacturers in Brazil and the rest of South America.

Constellation™, the company’s newest converting technology will be available at the conference. Launched in June 2015, Constellation™ introduced a new era in tissue technology and has quickly become a success on a global scale: in just 18 months, over 50 lines have been sold throughout the 5 continents. Constellation™ is a solution that offers unprecedented winding quality and opportunities for product differentiation. Log growth during winding is managed by an innovative algorithm that characterizes Constellation™ technology, which result in greater control, quality and production efficiencies, previously unavailable in the industry.

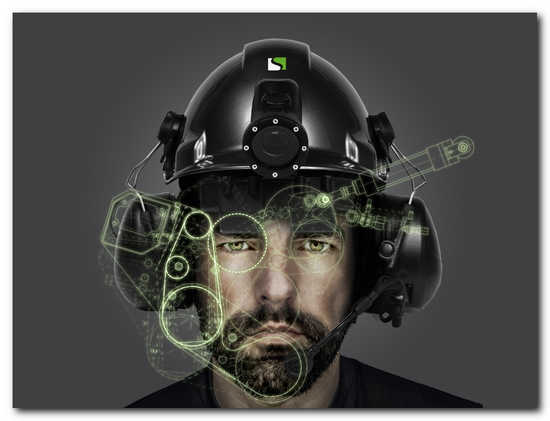

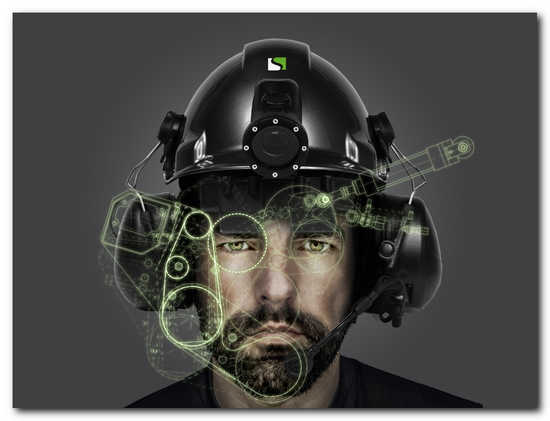

Technology is not limited to Fabio Perini Brazil’s products as the company expands customer service capabilities with its Weareable remote support service. While technical support is always available to customers, reality makes it difficult to send a technician to every location regardless of distance in a timely manner. The Weareable technology changes this. All that is required is an Internet connection. The Weareable helmet uses bi-directional audio-visual capabilities, allowing a Fabio Perini Brazil technician to remotely examine the issue and offer a solution in real time. The innovative approach to addressing service issues demonstrates Fabio Perini Brazil’s commitment to superior technical support while actively pursuing solutions in keeping with Industry 4.0 technology.

Lastly, technology’s impact on the global tissue market is in the midst of a new era. Fabio Perini Director of Sales for South America, Dineo Silverio, will deliver the conference’s keynote address: “The Global Tissue Market has Entered a New and Exciting Phase,” on June 2. Innovations such as Constellation™, remote wearables and other technology are changing the tissue converting industry. These will allow manufacturers to remain competitive on the shelf, decrease manufacturing costs while maintaining a positive customer experience and brand image. Silverio noted this paradigm shift began 20 months ago and his address will narrate how Fabio Perini is changing the way tissue rolls are produced in new and exciting ways all around the world.

COMPANY PROFILE

Fabio Perini S.p.A. was born in 1966 in Lucca, Italian hub and world tissue production and converting technology center. Today, with its 5 production facilities in Italy, the United States, Brazil and China, it helps its customers stay competitive and grow thanks to complete production solutions for converting and packaging. Technology, globalization and ongoing, continuous investments in research have led the company to stand out internationally and to be acknowledged as a true excellence in the world of tissue.

Weareable: Comprehensive Remote Support

Fabio Perini concretely interprets the extraordinary challenge proposed by the Industry 4.0 macro trend by presenting the device that bridges distances: Weareable.

“We followed our vision: the customer at the center. We were looking for a solution that would allow us to be in immediate contact with our customers’ needs”, explains Francesco Maltagliati, Chief Customer Service Officer at Fabio Perini. “With Weareable, we acquire the ability to see, listen and react in a few minutes around the world, using our experience transversally, on every type of request, whether electronic or mechanical, and across our product range, limiting the presence of our hyper-specialized technicians to where and when the customer unquestionably needs them, yielding speed and efficiency. A wearable technology to share in real time videos, audio, diagrams and precise graphic indications between the operator on-board the machine and the pool of online Fabio Perini experts at our operational centers disseminated in the four continents where we are present with production sites”.

The device is comprised of bi-directional audio-video instrumentation. Thanks to the incorporated visor, the two Full HD support video cameras – one located directly on the helmet and one pivoting – to the integrated audio system and to the data connection, the technician at the operational center can precisely understand what the operator with the Weareable helmet on is showing simply by directly facing the “problem”. And all this allows the technician to provide indications on how to proceed to promptly solve the issue.

Activating the Fabio Perini technicians and receiving 50 years of experience and knowledge at one’s facilities is simply a matter of connecting to the Internet. Just a simple click of a button away!

A few minutes, and Weareable - whether in New Caledonia or in Canada, passing through Nigeria or the Virgin Islands - becomes operational.

The final experimentation phase on the field began in November 2016: Weareable was successfully used by our customers in the Middle East and then in Europe and the United States. “We are answering the concrete needs of our market”, continues Francesco Maltagliati, “through our propensity - consolidated in the course of the years - for technological innovation at the service of the true needs of all our customers”.

And Weareable is not the only innovation that Fabio Perini S.p.A. is proud of: Web applications, upgrade programs, high quality original spare parts are our spearheads. For this market, for the market of the future.

COMPANY PROFILE

Fabio Perini S.p.A. was born in 1966 in Lucca, Italian hub and world tissue production and converting technology center. Today, with its 5 production facilities in Italy, the United States, Brazil and China, it helps its customers stay competitive and grow thanks to complete production solutions for converting and packaging. Technology, globalization and ongoing, continuous investments in research have led the company to stand out internationally and to be acknowledged as a true excellence in the world of tissue.

Digital Tissue(™): Fabio Perini’s value proposition for industry 4.0

In the era of Industry 4.0, managing the entire production process becomes the true added value for the tissue industry as a whole. Being able to define and map out a complete line to manufacture the finished product means fully understanding customers’ production needs.

Fabio Perini is the only company in the world capable of producing complete lines integrating converting and packaging, hence creating the product and the process together with the customer in order to optimize efficiency, reduce costs and maximize the quality of the finished product. An extraordinary value for customers, who find in Fabio Perini their one-stop interlocutor and all-in-one provider of production solutions for their business.

Fabio Perini is the only company in the world capable of producing complete lines integrating converting and packaging, hence creating the product and the process together with the customer in order to optimize efficiency, reduce costs and maximize the quality of the finished product. An extraordinary value for customers, who find in Fabio Perini their one-stop interlocutor and all-in-one provider of production solutions for their business.

“A holistic vision of the business is what the market demands”, comments Stefano Di Santo, CEO at Fabio Perini, “and it is in this direction that the technological and service development is projected at our company. We have used a very specific term to call this new way of considering our customers’ 4.0 facility by speaking of Digital Tissue™. It is not just a question of adding sensors to our technology or into the solutions we propose, but rather to create predictive and self-learning systems that allow maximizing the production efficiency of the individual machines and even more, the efficiency of the complete line.”

The concept of Digital Tissue™ has been our guiding light also in the recent innovations that Fabio Perini S.p.A. has brought about, such as All-In-One and Weareable: products that are already available as concrete answers to converting, packaging and service demands.

More evolution will follow, with the aim to always put our customers at the center and to deliver visible innovation to the eyes of the consumer.

COMPANY PROFILE

Fabio Perini S.p.A. was born in 1966 in Lucca, Italian hub and world tissue production and converting technology center. Today, with its 5 production facilities in Italy, the United States, Brazil and China, it helps its customers stay competitive and grow thanks to complete production solutions for converting and packaging. Technology, globalization and ongoing, continuous investments in research have led the company to stand out internationally and to be acknowledged as a true excellence in the world of tissue.

The Constellation(™) Effect

Constellation™ introduces a new era in tissue converting. Launched in June 2015, Constellation™ has quickly become a success on a truly global scale: in just 18 months, over 50 lines have been sold throughout the 5 continents. A result fruit of considerable investments in means and people: 3 Constellation™ lines in Italy, Brazil and the USA are dedicated to customers to perform tests and to confirm in an industrial production setting Constellation™’s exceptional performance in terms of product and production technology. All these benefits are certified by the new Pivot service. Pivot is much more than a laboratory for the characterization of the toilet roll or kitchen towel: it is the missing link between technology, the industrial process and the market. A holistic vision of business that allows generating true value in a commodities market such as tissue.

Constellation™ is the technology patented by Fabio Perini S.p.A., a solution that offers unprecedented winding quality. An innovative geometry consisting of mobile rolls with independent drives accompany the log from first to last sheet with consistency and uniformity. Complete log control during its formation allows attaining production efficiencies unobtainable until today.

Log growth during winding is managed by an innovative algorithm that characterizes Constellation™ technology, eliminating variability in the quality of the finished product and ensuring a repeatability never experienced before, yielding clear advantages throughout the converting process.

Additionally, the new Easy HMI operator panel makes managing the machine easier and more immediate, since it focusses on the parameters that characterize the finished product, such as internal core diameter, external roll diameter, meters of paper, perforation length. This means that thanks to the Easy HMI software, Constellation™ autonomously adapts to produce the perfect roll, exactly as it has been set on the operator panel. This simplicity of use is further underscored in product changes because all the operator needs to do is recall the recipe saved and the system begins producing immediately with no waste. This benefit translates into greater efficiency and unprecedented cost reduction. Easy HMI becomes a true assistant capable of supporting both less-experienced operators and department supervisors in guaranteeing consistent, qualitatively superior output.

“Constellation™ is a milestone for the tissue industry” comments Matteo Benedusi, CSO at Fabio Perini S.p.A. “because it represents perfect winding, something never attained with traditional technology until today. And also because it is oriented towards Industry 4.0. thanks to the on-board software and hardware that allow interacting and retroacting with the machines upstream and downstream of the rewinder. This means optimizing the production process and hence maximizing the competitive advantage for all our customers”.

COMPANY PROFILE

Fabio Perini S.p.A. was born in 1966 in Lucca, Italian hub and world tissue production and converting technology center. Today, with its 5 production facilities in Italy, the United States, Brazil and China, it helps its customers stay competitive and grow thanks to complete production solutions for converting and packaging. Technology, globalization and ongoing, continuous investments in research have led the company to stand out internationally and to be acknowledged as a true excellence in the world of tissue.