Ian Melin-Jones

Two 8-metre Paper Rewinders for Shanying Huazhong Paper Industry Co., Ltd

A.Celli Paper is pleased to confirm its ongoing and valuable collaboration with the Chinese group Shanying Huazhong Paper Industry Co., Ltd., enshrined in the agreement for the supply of two latest generation E-WIND® P100 rewinders, for the mill located in Jingzhou District, China.

The E-WIND® P100 Paper Rewinders, highly developed in terms of design, will have a paper width of 7960 mm and will guarantee a maximum production speed of 2500 mpm (design speed).

They will be able to accommodate large reels on the unwinder, with diameters up to 3800 mm and weighing about 65 t.

In addition, they are combined with sophisticated technological innovations including:

- Web-in technology, the automatic system that maximises the management of positioning cutting units without the need to break the web;

- Built-in spool-parking.

The machines, with start-up scheduled for the third quarter of 2019, will allow the Chinese group to process high-quality flat-paper and test-liner paper of the lowest grammage (from 50 to 110 gsm).

This new investment by Shanying Huazhong Paper Industry is further confirmation of how technologically reliable and evolved Paper A.Celli E-WIND® Rewinders can prove to be, and now A.Celli Paper is considered a valuable and expert partner, able to constantly support its customers, building and cultivating important professional relationships.

At Krasnokamsk paper mill, cutting-edge manufacturing technology produces banknotes and specialty papers

With the opening of its new production facility in Krasnokamsk on September 28, 2018, the Russian Goznak Group has commenced operation of one of the world's most modern paper machines for banknotes and specialty papers. The entire plant was developed under the direction of Voith.

- Voith supplies complete production facility to Krasnokamsk paper mill in Russia

- New banknote production line allows the Goznak Group to produce paper with the latest security features

- High level of automation improves quality, security and efficiency

The Russian Goznak Group has been developing and producing various products that are important for the state’s ability to function and for the citizens’ everyday life since 1818. To coincide with its 200th anniversary, the manufacturer of security products like banknotes, coins, passports, postage stamps, revenue stamps, ID cards, secure documents, government orders and medals, security and specialty papers successfully commissioned the PM 7, one of the world's most modern production facilities for banknotes and specialty papers, at one of its eight locations in Krasnokamsk in central Russia.

The guests at the official opening ceremony included Alexej Moiseev, Deputy Russian Finance Minister and Chairman of the Board of Goznak, and Alexej Chibisov, Minister of Industry, Economic Affairs and Trade for the Perm region. In his address, Arkady Trachuk, General Director of Goznak, pointed out: “Within a few years, we worked with the designers, equipment suppliers and contractors to create a production complex that is one of the best in the world.”

From left to right: Wolfgang Neuss, Purchase Director Mr. Kozlov, Günther Meuser, Senior Project Manager Voith Paper. In the background, the MasterVat and ShortFormer, which are the centerpiece of the new facility in Krasnokamsk. The technology they use forms the basis for the production of specialty papers with the strictest security features.

From left to right: Wolfgang Neuss, Purchase Director Mr. Kozlov, Günther Meuser, Senior Project Manager Voith Paper. In the background, the MasterVat and ShortFormer, which are the centerpiece of the new facility in Krasnokamsk. The technology they use forms the basis for the production of specialty papers with the strictest security features.

And Voith was on board from the very start. The technology group was responsible for the overall planning of the facility, providing expertise and technologies that were a crucial factor in the outstanding success of the new facility. Highly efficient machines from Voith, the integration of the group's innovative solutions and a high degree of automation allow Goznak to produce paper with cutting-edge security features.

One of the key components of the paper machine is the forming section. It contains a MasterVat, an optimized uniflow vat in which the watermark is created at the same time as the banknote paper, and the ShortFormer for the first ply of the two-ply papers. Both of these components ensure the high quality of the products. At the same time, they allow the integration of reliable security features or multi-colored watermarks.

The high degree of automation in Krasnokamsk is the cornerstone for the security of the papers. For example, there is an automatic quality control in all phases of paper production. At the same time, this increases the efficiency of the plant and helps to substantially reduce raw material losses and running costs.

Through their very close collaboration based on a spirit of trust and partnership, Voith and Goznak have created a benchmark for future plants with the facility in Krasnokamsk, says Wolfgang Neuss, Director Sales and Technology Banknote and Security Paper Machines at Voith.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, oil & gas, paper, raw materials and transport & automotive. Founded in 1867, the company today has more than 19,000 employees, sales of € 4.2 billion and locations in over 60 countries worldwide and is thus one of the large family-owned companies in Europe.

The Group Division Voith Paper is part of the Voith Group and a leading full-line supplier as well as pioneer in the paper industry. Through constant innovations Voith is optimizing the paper manufacturing process and facilitating resource-conserving production. With its Servolution concept, Voith offers its customers as reliable partner tailored service solutions for all sections of the production process. The company’s Papermaking 4.0 concept ensures that equipment is optimally networked, while the effective and secure use of the generated data enables paper manufacturers to improve their competitiveness.

ANDRITZ starts up modernized board machine successfully at R.D.M. Arnsberg

International technology Group ANDRITZ started up the modernized BM3 board machine successfully in Arnsberg, Germany, for R.D.M. Arnsberg GmbH at the beginning of January 2019 after a delivery time of just eight months.

In this contract, ANDRITZ was responsible for the new design of feed system for the new headbox, adapting the required dewatering capacity, and for recirculation of the white water. The components supplied by ANDRITZ are set up for a future production speed of 1,000°m/min and enable a significant improvement in the quality of formation as well as enhancing the profile stability of the top ply to obtain better processability of the finished products. At the moment, the production speed is approximately 780 m/min and the working width is 3.63 m.

In this contract, ANDRITZ was responsible for the new design of feed system for the new headbox, adapting the required dewatering capacity, and for recirculation of the white water. The components supplied by ANDRITZ are set up for a future production speed of 1,000°m/min and enable a significant improvement in the quality of formation as well as enhancing the profile stability of the top ply to obtain better processability of the finished products. At the moment, the production speed is approximately 780 m/min and the working width is 3.63 m.

The scope of supply includes a PrimeFlow SW headbox for the top ply, including a new headbox pipe, new dewatering elements, as well as a new white water channel with white water tank. In addition to installation of new frame parts needed for the top ply wire, the couch press frame was also repaired and adapted to meet future production requirements.

The work on the press frame and installation of the entire ANDRITZ scope of supply was performed by ANDRITZ Local Service Mönchengladbach.

The very successful and punctual project execution was all thanks to perfect coordination and, above all, close collaboration between ANDRITZ and R.D.M. The cornerstone of this success was laid in the project phase, when detailed concepts were developed in intensive cooperation with the customer. This successful start-up confirms ANDRITZ’s position as one of the world’s leading global suppliers of complete lines, key components, services and rebuilds for paper and board production.

The RDM Group is the second largest producer of coated recycled fiber board in Europe and the largest in Italy, France and the Iberian peninsula. The group also manufactures products based on virgin fibers. The location in Arnsberg produces coated liner grades for packaging made of corrugated board.

ANDRITZ GROUP

ANDRITZ is a globally leading supplier of plants, equipment, and services for hydropower stations, the pulp and paper industry, the metal working and steel industries, and for solid/liquid separation in the municipal and industrial segments. Other important fields of business are animal feed and biomass pelleting, as well as automation, where ANDRITZ offers a wide range of innovative products and services in the IIoT (Industrial Internet of Things) sector under the brand name of Metris. In addition, the international technology Group is active in power generation (steam boiler plants, biomass power plants, recovery boilers, and gasification plants) and environmental technology (flue gas cleaning plants) and offers equipment for the production of nonwovens, dissolving pulp, and panelboard, as well as recycling plants.

A passion for innovative technology, absolute customer focus, reliability, and integrity are the central values to which ANDRITZ commits. The listed Group is headquartered in Graz, Austria. With over 160 years of experience, 29,000 employees, and more than 280 locations in over 40 countries worldwide, ANDRITZ is a reliable and competent partner and helps its customers to achieve their corporate and sustainability goals.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper is a leading global supplier of complete plants, systems, equipment, and comprehensive services for the production and processing of all types of pulp, paper, board, and tissue. The technologies cover processing of logs, annual fibers, and waste paper; production of chemical pulp, mechanical pulp, and recycled fibers; recovery and reuse of chemicals; preparation of paper machine furnish; production of paper, board, and tissue; sizing, calendering and coating of paper; as well as treatment of reject materials and sludge. The service offering includes system and machine modernization, rebuilds, spare and wear parts, on-site and workshop services, optimization of process performance, maintenance and automation solutions, as well as machine relocation and second-hand equipment. Biomass, steam and recovery boilers for power production, gasification and flue gas cleaning plants, systems and plants for the production of nonwovens, dissolving pulp, and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area.

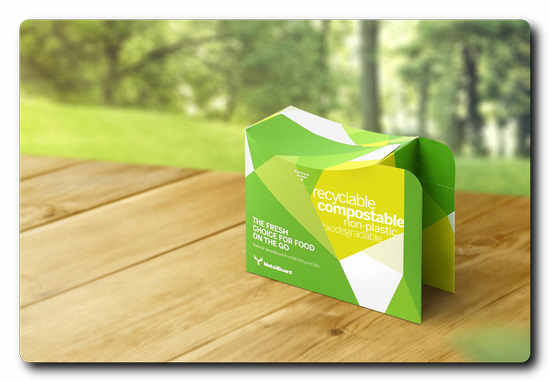

Industrial compostability certification for Metsä Board’s ground-breaking eco-barrier paperboard

The new eco-barrier paperboard, MetsäBoard Pro FSB EB1, which is manufactured by Metsä Board, the leading European producer of premium lightweight paperboards, has recently achieved the industrial compostability certification complying with DIN EN 13432 and ASTM D6400 standards. The certification is issued by DIN CERTCO and the testing was carried out by ISEGA laboratories.

Katja Tuomola, Business Development Director at Metsä Board, commented upon this important development: “Brand owners are looking for new, more ecological solutions made of renewable, non-plastic materials, which can be composted and recycled. This external certification helps them choose packaging materials that truly comply with their disposal requirements.”

DIN EN 13432 standard refers to ‘Requirements for Packaging Recoverable through Composting and Biodegradation’. US certification ASTM D 6400-12 covers the ‘Standard Specification for Labelling of Plastics Designed to be Aerobically Composted in Municipal or Industrial Facilities’.

The non-plastic special barrier treatment developed for MetsäBoard Pro FSB EB1 improves the grease resistance of the board and makes it an ecological and efficient packaging material for food, takeaway and food-on-the-go applications. The grease resistance can be cost-efficiently enhanced further at the converting stage with the addition of just one varnish layer. The product is safe for direct food contact and no optical brighteners (OBA free) or fluorochemicals have been used in the production. It is available in basis weights of 195–320 g/m2 and can be recycled with paper and board recycling schemes.

Metsä Board

www.metsaboard.com

Metsä Board is a leading European producer of premium fresh fibre paperboards including folding boxboards, food service boards and white kraftliners. Our lightweight paperboards are developed to provide better, safer and more sustainable solutions for consumer goods as well as retail-ready and food service applications. We work together with our customers on a global scale to innovate solutions for better consumer experiences with less environmental impact. The pure fresh fibres Metsä Board uses are a renewable resource, traceable to origin in sustainably managed northern forests.

The global sales network of Metsä Board supports customers worldwide, including brand owners, retailers, converters and merchants. In 2017, the company’s sales totalled EUR 1.8 billion, and it has approximately 2,350 employees. Metsä Board, part of Metsä Group, is listed on the Nasdaq Helsinki.

Valmet to replace a quality control system at Papelera del Principado, S.A. (Paprinsa), Spain

Valmet will supply a Valmet IQ Quality Control System, a related reporting system and a recently launched Valmet DNA IQ Dashboard to Papelera del Principado, S.A.'s (Paprinsa) cartonboard machine in Spain. The systems will improve machine runnability and the overall quality of the end-product.

The order is included in Valmet's fourth quarter 2018 orders received. Typically, the value of these kinds of automation system deliveries is below EUR one million.

"We are happy that the customer acknowledges us as the technology leader in the pulp and paper industry and as the supplier of the best QCS solution on the market. Our moisture management concept is unique. Valmet's reporting solution and strong local service played a crucial role in the customer's decision-making. Now, we will develop the reporting concept further with Paprinsa. We are really looking forward the cooperation," says Javier Navas, Sales Manager, Automation, Valmet.

Valmet will replace a quality control system at Papelera del Principado, S.A. (Paprinsa), Spain

Valmet will replace a quality control system at Papelera del Principado, S.A. (Paprinsa), Spain

Information about Valmet's delivery

Valmet's delivery consists of a Valmet IQ Quality Control System (QCS) with three scanners and related measurements and controls. With more process information available, the machine can be controlled much better than before, resulting in improved machine performance and end-product quality. In addition, faster start-ups and grade changes will increase production efficiency. The delivery also includes a connection to the existing distributed control system (DCS) and a Valmet DNA IQ Dashboard, which provides real-time and recent history information, allowing users to better react to changing situations.

The comprehensive Valmet IQ Reporting package consists of jumbo roll and customer roll reporting and management of laboratory data. With the help of reporting and laboratory data management, the mill operators can follow and control the paper quality and production online, as well as from a history point of view. With the help of the Valmet DNA Roll Monitoring tool, mill operators can easily access any customer roll quality data to confirm quality information for customer orders, if needed.

Information about the customer Papelera del Principado, S.A. (Paprinsa)

Founded in 1978, Paprinsa produces high-quality coated cartonboard for domestic and international markets using 100% recycled fiber. The company is known for its research and constant improvement, which has allowed it to offer superior products and service to its customers. Paprinsa bases its strength on high-quality products and production flexibility, adapting to meet customer needs.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2017 were approximately EUR 3.1 billion. Our more than 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

James Cropper helps to show how the uk can ‘leed’ by example

James Cropper has received the first bales of used coffee cups from a pioneering pilot scheme in collaboration with Forge Recycling, environmental charity Hubbub and Leeds City Council.

The delivery marks a significant step in the papermaker’s ambition to help recycle some of the estimated three billion take-away cups that are currently thrown away in the UK each year. Through its unique CupCycling™ technology - the world’s first process dedicated to upcycling disposable coffee cups – James Cropper has the capacity to upcycle 500 million used coffee cups.

Forge Recycling has collected 159,000 single-use coffee cups - from workplaces, coffee shops, universities, shopping centres and on street cup bins - since launching on 18thOctober 2018. Instead of the cups going to waste they have been delivered to James Cropper for upcycling.

Running until March 2019, the pilot runs alongside the #LeedsByExample campaign and seeks to improve the ‘on the go’ recycling infrastructure for coffee cups, and other packaging such as plastics and cans, for consumers in Leeds. Waste is collected by Forge Recycling, which has introduced a new paper cup collection service in parallel. Focusing on closed loop systems, Forge Recycling has performed a cup collection service for Leeds University and Leeds Beckett University.

With the help of James Cropper, all 159,000 cups collected will be given a second life as beautiful papers and packaging. The delivery will make its way through James Cropper’s CupCycling facility - which launched in September 2017 – and has already upcycled over 30 million disposable cups.

James Cropper Chairman and CEO Phil Wild said: “With the capacity to upcycle 500 million coffee cups per year we welcome the thousands of discarded cups brought to Kendal today and hope this is just one of many local initiatives we can support to meet the capacity that we have. This scheme demonstrates that with the right infrastructure, great in-roads can be made to tackle the coffee cup issue.

“There needs to be a change in mindset in how we handle waste and source materials, and ensuring packaging is easy for consumers to recycle is key to this. The delivery marks a pivotal moment for recycling in the UK – and for us, it’s a step towards realising the potential of our CupCycling capabilities.”

A host of major brands, such as such Asda, Coca-Cola GB, Costa Coffee, McDonald's, Pret a Manger, Starbucks and Shell, have joined Hubbub’s #LeedsByExample initiative to date. While the trial in Leeds ends in March 2019, Forge Waste & Recycling estimate that the number of coffee cups it could deliver to James Cropper in one year from Leeds alone could exceed one million – a fantastic example of the circular economy in action.

Gavin Ellis, Director at Hubbub, commented:“It’s not widely understood by consumers that coffee cups have to be recycled via a different waste stream, which is why we focus on developing infrastructure and communications in cities that make it easier for people to recycle properly while on-the-go.

“Almost three billion coffee cups go to waste every year. While the results of the trial are just the tip of the iceberg, they do demonstrate that with the right infrastructure and partners, coffee cups can become a profitable waste stream. Our goal is to extend the activity to include further cities in 2019 and encourage more waste companies to take inspiration from Forge and explore how they can adapt their operations to benefit from this valuable resource.”

Sam Goodall, Operations Director Forge Waste & Recycling said:“In just three months we’ve quickly moved from collecting very few cups to nearly two-hundred-thousand that are ready for delivery to the James Cropper mill. The pilot shows that the potential for our work with Hubbub and James Cropper to transform UK waste and embed circular economy thinking when it comes to coffee cups in cities is very real.”

The CupCycling process involves removing the plastic coating that makes take-away cups waterproof, while preserving the precious paper fibres and instead of going to waste, the cups are transformed into fine papers for consumer packaging such as the iconic yellow Selfridges carrier bag.

Going a step further, James Cropper’s latest innovation in plastic-free packaging – COLOURFORM™ – uses paper fibre from renewable forests, as well as used coffee cups to create moulded packaging. With over 173 years’ worth of experience in papermaking behind it, COLOURFORM was a natural evolution for James Cropper, offering brands like LUSH, and in turn consumers, more choice. The packaging is recyclable and biodegradable, which means that even if it is not recycled, it breaks down without any harm to the environment.

Phil Wild concludes: “We’re incredibly proud to work with Forge and Hubbub, who have successfully delivered a game-changing system which can help usbecome a nation that truly creates value from waste. We encourage more cities across the country to explore how they can adopt this pioneering initiative.”

About James Cropper

James Cropper is a prestige paper innovator based in the English Lake District, supplying distinct, custom-made paper products to many of the world’s leading luxury brands, art galleries and designers.

Throughout 173 years of high-quality paper production, the business has been carefully stewarded and nurtured by six generations of the Cropper family and is renowned globally for individual expertise in colour, dedicated responses to the most challenging custom projects and award-winning commitment to the highest standards of sustainability.

James Cropper is a member of the Paper Cup Recovery & Recycling Group (PCRRG), a cross-industry group that exists to develop collection and recycling opportunities for paper cups and identify and support solutions that sustainably transform used paper cups into a valuable resource. For more information, visit www.pcrrg.uk.

About Hubbub

Hubbub is a charity which explores innovative ways to interest mainstream consumers in important sustainability issues, through different ‘hubs’ of activity: Food; Fashion; Homes; Neighbourhoods. Hubbub’s previous campaigns have included #SquareMileChallenge, the UK’s first large scale solution to coffee cup recycling, #NeatStreets to cut litter in UK cities and For Fish’s Sake (#FFSLDN) to tackle litter in the Thames.

About Forge Waste & Recycling

Forge Recycling are a local company, established in November 2010, with a depot and office team based in Leeds, West Yorkshire. Forge offer a flexible waste management service with an emphasis on making recycling easy. Forge understands the importance of combining a cost effect service, with the highest rates of recycling as possible. Alongside its Commercial/Business waste collection service, Forge also offer a full recycling service; collecting mixed recyclables, food waste, paper and card, glass bottles, and most recently ‘Paper Cups’; all recovered using a fleet of specialist collection vehicles.

About #LeedsByExample

#LeedsByExample is a 6 month trial led by Hubbub to test different ways to recycle food and drink packaging on the go in Leeds city centre. Successes from the trial will be rolled out to other UK cities to revitalise on the go recycling in the UK.

#LeedsByExample partners include Forge Recycling, Leeds City Council, HW Martin and Zero Waste Leeds, and the initiative is backed by a unique collaboration of companies: Alupro, Asda, Association of Convenience

Stores, Ball Beverage Packaging Europe, British Plastics Federation, Bunzl, Caffe Nero, Coca-Cola GB, Costa, Co-op, Crown Packaging, Danone, Ecosurety, Greggs, Highland Spring, Innocent, Klöckner Pentaplast (kp), Lucozade Ribena Suntory, Marks and Spencer, McDonald’s, Morrisons, PepsiCo, Pret, Starbucks and Shell.

Stora Enso rated a global leader for climate action by CDP

Stora Enso has been top-rated in combatting global warming by the international non-profit organisation CDP, which works to build a sustainable global economy. CDP has included Stora Enso on its new 2018 Climate A List, which identifies the global companies that are taking leadership in climate action.

“We are proud of this recognition of our long-term work to reduce our emissions,” says Noel Morrin, EVP Sustainability at Stora Enso. “For over a decade we have been actively reducing the energy intensity of our operations and our dependence on fossil fuels. In December 2017, Stora Enso became the first forest products company to set ambitious science-based targets for reducing greenhouse gas emissions throughout our value chain.”

“We are proud of this recognition of our long-term work to reduce our emissions,” says Noel Morrin, EVP Sustainability at Stora Enso. “For over a decade we have been actively reducing the energy intensity of our operations and our dependence on fossil fuels. In December 2017, Stora Enso became the first forest products company to set ambitious science-based targets for reducing greenhouse gas emissions throughout our value chain.”

Stora Enso has also signed a Revolving Credit Facility (RCF) loan where part of the pricing is based on the group’s performance in reducing greenhouse gas emissions. This progress is reported in Stora Enso’s annual and interim reports. In addition, Stora Enso has published a Green Bond Framework and asks suppliers about their carbon dioxide emissions in all tenders.

“Ultimately, it is our renewable materials that make a difference,” Morrin says. “They are a key solution to combatting global warming as they store carbon and replace fossil-based materials.”

Paul Simpson, CEO of CDP says: “Congratulations to all companies that made it onto CDP’s A List this year. We need to urgently scale up environmental action at all levels in order to meet the goals of the Paris Agreement and the Sustainable Development Goals. It’s clear that the business world is an essential player in this transition and the A List companies are set to make a substantial contribution to those goals.”

Thousands of companies annually submit climate disclosures to CDP. In 2018, disclosures were requested by 650 investors representing over USD 87 trillion in assets, and over 7 000 companies submitted their climate data.

In addition to the CDP rating, Stora Enso has been top-ranked in both the quality of greenhouse gas management and carbon performance by the Transition Pathway Initiative (TPI). TPI is a global initiative led by asset owners and supported by asset managers and looks into how companies’ carbon performance now and in the future might compare to the international targets and national pledges made as part of the Paris Agreement.

Stora Enso’s fossil carbon emission summary for 2017

CDP is an international non-profit that drives companies and governments to reduce their greenhouse gas emissions, safeguard water resources and protect forests. Voted number one climate research provider by investors and working with institutional investors with assets of US$87 trillion, we leverage investor and buyer power to motivate companies to disclose and manage their environmental impacts. Over 7,000 companies with over 50% of global market capitalization disclosed environmental data through CDP in 2018. This is in addition to the over 750 cities, states and regions who disclosed, making CDP’s platform one of the richest sources of information globally on how companies and governments are driving environmental change. CDP, formerly Carbon Disclosure Project, is a founding member of the We Mean Business Coalition. cdp.net

Part of the bioeconomy, Stora Enso is a leading global provider of renewable solutions in packaging, biomaterials, wooden constructions and paper. We believe that everything that is made from fossil-based materials today can be made from a tree tomorrow. Stora Enso has some 26 000 employees in over 30 countries. Our sales in 2017 were EUR 10 billion. Stora Enso shares are listed on Nasdaq Helsinki (STEAV, STERV) and Nasdaq Stockholm (STE A, STE R). In addition, the shares are traded in the USA as ADRs (SEOAY). storaenso.com

Metsä Board amongst an elite group of companies scoring ‘A’ for both CDP Climate and CDP Water programmes

Metsä Board has once again been highlighted as a global leader in corporate sustainability by CDP, a non-profit global environmental disclosure platform, by achieving a place on the CDP A List for both climate change and water security. This is the fourth consecutive year that the company has been included on the CDP Water A List and the third consecutive year on the CDP Climate A List. Metsä Board also scored A- in the CDP’s Forest programme.

Metsä Board is among the top 27 companies placed on the global Water A List. This achievement is in recognition of Metsä Board’s actions in the last reporting year to manage water more sustainably. Additionally, Metsä Board is among the top 126 of companies featured on the global Climate A List. This positioning is a recognition for the company’s activities in cutting emissions, mitigating climate risks and developing the low-carbon economy. In 2018, over 7,000 companies disclosed through CDP.

“We all need to act to combat climate change. Sustainability has to be an integral part of a responsible business and it must lead to concrete actions. I am proud that the work we do at Metsä Board was once again acknowledged by CDP and that we held our A level rating in both Climate and Water programmes,” says Mika Joukio, CEO of Metsä Board.

Metsä Board

www.metsaboard.com

Metsä Board is a leading European producer of premium fresh fibre paperboards including folding boxboards, food service boards and white kraftliners. Our lightweight paperboards are developed to provide better, safer and more sustainable solutions for consumer goods as well as retail-ready and food service applications. We work together with our customers on a global scale to innovate solutions for better consumer experiences with less environmental impact. The pure fresh fibres Metsä Board uses are a renewable resource, traceable to origin in sustainably managed northern forests.

The global sales network of Metsä Board supports customers worldwide, including brand owners, retailers, converters and merchants. In 2017, the company’s sales totalled EUR 1.8 billion, and it has approximately 2,350 employees. Metsä Board, part of Metsä Group, is listed on the Nasdaq Helsinki.

Valmet achieves the best rating in CDP's climate program ranking

Valmet has been recognized for its actions and strategy to mitigate climate change by receiving the best A rating in CDP's climate program ranking. The results were published today, January 22, 2019.

CDP's evaluation is based on the company's 2018 disclosure about its actions in the last reporting year to cut emissions, mitigate climate risks and develop the low-carbon economy.

CDP's evaluation is based on the company's 2018 disclosure about its actions in the last reporting year to cut emissions, mitigate climate risks and develop the low-carbon economy.

"It is an honor to receive this acknowledgement for our contribution to climate change mitigation. Valmet's technology and services increase raw material efficiency and enable our customers to manufacture sustainable products from renewable resources. We also have a systematic program to reduce CO2 emissions in our own operations with a focus on sustainable transportation, energy-efficiency improvements and process optimization. We continuously investigate new ways to improve the energy, water and material efficiency of our solutions and to bring new innovations to the market," says Anu Salonsaari-Posti, Senior Vice President, Marketing, Communications and Sustainability at Valmet.

Valmet's mission is to convert renewable resources into sustainable results. Valmet's comprehensive Sustainability360º agenda focuses on five core areas: sustainable supply chain; health, safety and environment; people and performance; sustainable solutions, and corporate citizenship.

In 2018 Valmet was also included in Dow Jones Sustainability Index (DJSI) and Ethibel Sustainability Index (ESI) Excellence Europe.

About CDP

CDP is an international non-profit that drives companies and governments to reduce their greenhouse gas emissions, safeguard water resources and protect forests.

CDP's list of all companies publicly taking part in climate change program this year is available on CDP's website https://www.cdp.net/en/scores

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2017 were approximately EUR 3.1 billion. Our more than 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Stora Enso announces startups selected for its second Accelerator Programme

Stora Enso has chosen six startups to join its second Accelerator Programme, a joint startup initiative organised by Stora Enso, Aalto University Developing Entrepreneurship (Aalto ENT) and Vertical Accelerator.

The Accelerator programme provides an exceptional opportunity for disruptive startups and Stora Enso to actively ideate and innovate new solutions. This year’s programme focuses specifically on the circular economy, especially in regard to circular solutions, raw material management, packaging, separation and sorting, and energy.

The Accelerator programme provides an exceptional opportunity for disruptive startups and Stora Enso to actively ideate and innovate new solutions. This year’s programme focuses specifically on the circular economy, especially in regard to circular solutions, raw material management, packaging, separation and sorting, and energy.

“With global megatrends, the circular economy will play a significant role in business and society in the coming years. We are teaming up with startups to further explore how Stora Enso can best contribute,” says Malin Bendz, Executive Vice President, HR. “We have been greatly encouraged by our first Accelerator programme, which has resulted in two ongoing partnerships, with Sulapac and Trä Group, building on renewable solutions.”

The final six startups emerged from a rigorous and competitive selection process. After submitting a written application and video, more than 85 startups were evaluated and filtered down to the top 40. Reviewed by Stora Enso Scouts and Vertical, 20 of these startups were invited to Selection Days, a two-day event for presentations and intensive interviews. A shortlist of twelve startups presented to Stora Enso’s Group Leadership Team for the selection of the final six.

The startups invited to join the 2019 Accelerator Programme are:

- Effa http://effabrush.com

- RePack https://www.originalrepack.com

- Alucha http://www.alucha.com

- Bloom http://www.bloombiorenewables.com

- MiWa http://www.miwa.eu

- SFTec https://www.sftec.fi

Over the next few months, the startups will work side by side with Stora Enso participants, delving into and advancing know-how, capabilities, technologies and market opportunities. Co-location takes place at Vertical accelerator, one of the largest and most prominent startup communities in Finland.

Part of the bioeconomy, Stora Enso is a leading global provider of renewable solutions in packaging, biomaterials, wooden constructions and paper. We believe that everything that is made from fossil-based materials today can be made from a tree tomorrow. Stora Enso has some 26 000 employees in over 30 countries. Our sales in 2017 were EUR 10 billion. Stora Enso shares are listed on Nasdaq Helsinki (STEAV, STERV) and Nasdaq Stockholm (STE A, STE R). In addition, the shares are traded in the USA as ADRs (SEOAY). storaenso.com