Displaying items by tag: valmet corporation

Valmet to convert a recovery boiler into a biomass boiler at DA Alizay in France

Valmet has received an order from Biomasse Energie d'Alizay to convert a recovery boiler into a biomass boiler utilizing bubbling fluidized bed combustion technology (BFB) at DA Alizay mill in France. Biomasse Energie d'Alizay will start producing steam and electricity from biomass at the existing power plant.

The order is included in Valmet's first quarter of 2019 orders received. Typically, the value of this kind of order is EUR 20 million. Valmet's delivery is scheduled for 2020.

"Valmet is the leader in BFB conversion with more than 60 references over the past 30 years, including boilers initially manufactured by third parties. It is very efficient and cost-saving way to modernize and prolong the lifetime of high-capex plants to serve the customers' future needs," says Jouko Kylänpää, Director, Rebuilds and Conversions, Pulp and Energy business line, Valmet.

"Valmet is the leader in BFB conversion with more than 60 references over the past 30 years, including boilers initially manufactured by third parties. It is very efficient and cost-saving way to modernize and prolong the lifetime of high-capex plants to serve the customers' future needs," says Jouko Kylänpää, Director, Rebuilds and Conversions, Pulp and Energy business line, Valmet.

Information about Valmet's delivery

Valmet's delivery scope includes converting the existing recovery boiler into a biomass boiler utilizing bubbling fluidized bed combustion technology (BFB). Electricity production of the plant will be 50 MWe, and it will also produce process steam for the paper mill. Additionally, Valmet will deliver a complete Valmet DNA automation system for the power plant, including steam network optimization with the paper mill. The plant is expected to start in 2020.

Information about Biomasse Energie d'Alizay and DA Alizay mill

Biomasse Energie d'Alizay is a subsidiary of DA Alizay SAS. DA Alizay mill employs about 180 people and has an annual production capacity of 300,000 tons of paper. The mill is specialized in high quality paper.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2018 were approximately EUR 3.3 billion. Our more than 13,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland, and its shares are listed on the Nasdaq Helsinki.

Valmet to deliver fifth tissue production line to Papel San Francisco in Mexico

Valmet will supply an Advantage DCT 100TS tissue production machine to Papel San Francisco in Mexico. The new machine will be installed at the company's mill in Mexicali and the start-up is planned for the third quarter of 2020.

The order is included in Valmet's first quarter 2019 orders received. The value of the order is not disclosed.

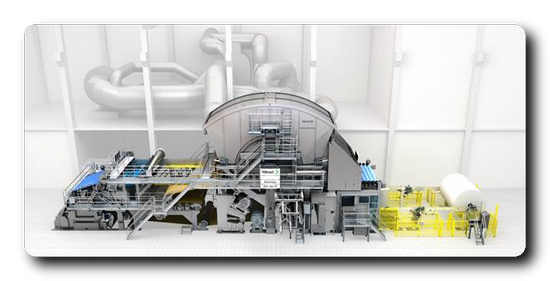

Valmet Advantage DCT 100TS tissue machine

Valmet Advantage DCT 100TS tissue machine

The new tissue line will fulfill Papel San Francisco's need of new capacity for standard tissue products. Valmet has previously delivered four tissue machines to the company. Three Advantage DCT machines started up in 2006, 2009 and 2018. In addition, Papel San Francisco was the first to start up an Advantage NTT line in 2013, which fulfills the company's demand of textured tissue.

"The choice to select the Advantage DCT machine was quite easy. Equipped with the Advantage ViscoNip press, it is the most efficient and best choice for the grades we need to produce. It is also in our philosophy to go for low energy consumption and lowest possible emissions to air and water. With this new tissue line, we expect to achieve the best tissue quality combined with lowest energy consumption," says Dario Palma y Meza Espinoza, Operational Director, Papel San Francisco.

"We are very proud to be the chosen supplier and partner for yet another expansion by Papel San Francisco. After many years of several projects together, we know that Papel San Francisco is a very demanding customer expecting continuous improvements. The company is continuously running their assets at or near world record speed and still achieving very high efficiency numbers. This is yet another opportunity for us to take another step forward in performance in a very strong and trustful relationship," says Jan Larsson, Director of Sales, North America, Tissue Mills Business Unit, Valmet.

From left: Jan Erikson (Valmet), Dario Palma y Meza (PSF), Julio Rodriguez (PSF), Jan Larsson (Valmet), Fernando De La Torre (PSF), Enrique Zarate (PSF), Anders Lorentzon (Valmet) and Jose Luis Emanuel Garcia (PSF).

From left: Jan Erikson (Valmet), Dario Palma y Meza (PSF), Julio Rodriguez (PSF), Jan Larsson (Valmet), Fernando De La Torre (PSF), Enrique Zarate (PSF), Anders Lorentzon (Valmet) and Jose Luis Emanuel Garcia (PSF).

Technical information about the delivery

The new tissue machine will have a width of 2.8 m and a design speed of 2,200 m/min. It will add 30,000 tons tissue paper per year to Papel San Francisco's current production of toilet tissue, kitchen towels and napkins.

Valmet's scope of delivery will comprise an Advantage DCT 100TS tissue machine. The machine will be equipped with OptiFlo headbox and cast alloy Yankee cylinder. The machine will also be featured with the well proven Advantage tissue technology including ViscoNip press, AirCap hood and WetDust dust system. Start-up and commissioning are also included in the delivery.

About the customer Papel San Francisco

Papel San Francisco started up their first tissue machine in 1980. In the past 35 years the company has grown steadily and is today operating six tissue machines with a yearly capacity of 180 000 tons of tissue products.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2018 were approximately EUR 3.3 billion. Our more than 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet to supply a containerboard line for GS Paperboard & Packaging in Malaysia

Valmet will supply OptiConcept M containerboard making line with automation solutions and a winder for GS Paperboard & Packaging (GSPP) Sdn., Bhd. in Selangor, Malaysia. With the new production line PM 3, GSPP will produce high-quality testliner and fluting grades as well as strengthen its position in the Malaysian market. The start-up of PM 3 is scheduled for 2021.

The order is included in Valmet's first quarter of 2019 orders received. The value of the order will not be disclosed. The total value of order of this type is typically around EUR 60-70 million.

"We have built a strong and long-lasting relationship with Valmet, which set a very good base for the negotiations. Valmet's excellent references were another important cornerstone. OptiConcept M boardmaking lines stand out with their energy- and resource-efficient processes and high-speed production. We are convinced with Valmet's technology, which is reliable throughout the whole boardmaking line," says Sia Boon Soon, President of GS Paperboard & Packaging.

"We have built a strong and long-lasting relationship with Valmet, which set a very good base for the negotiations. Valmet's excellent references were another important cornerstone. OptiConcept M boardmaking lines stand out with their energy- and resource-efficient processes and high-speed production. We are convinced with Valmet's technology, which is reliable throughout the whole boardmaking line," says Sia Boon Soon, President of GS Paperboard & Packaging.

"The customer had a clear idea about the machine concept from the very beginning. Thanks to our close cooperation and interactive discussions with the PM3 project team, we were able to find together a solution that fits well for the customer's needs," says Timo Puijola, Senior Sales Manager, Valmet.

Technical details about the delivery

Valmet's delivery will include equipment for stock preparation system with broke and approach flow systems. The delivery for the new high-capacity containerboard machine will include an OptiConcept M containerboard machine, which is already the 26th OptiConcept M line sold globally. The delivery consists of a complete machine from headbox to reel followed by an OptiWin Drum two-drum winder with transfer rails. The delivery will also include an OptiAir Hood high humidity hood, OptiAir Recovery heat recovery with other related air and ventilation systems, a surface starch preparation system and supply system for sizer as well as Valmet Paper Machine Clothing package for start-up. The automation delivery includes Valmet DNA Automation System for process and machine controls and Valmet IQ Quality Management Solution.

The 7,250-mm wide (wire) containerboard machine will produce fluting and testliner grades with a design basis weight range of 70-180 g/m2. The design speed of the machine will be 1,200 m/min and the design daily capacity 1,445 tonnes.

About the customer GS Paperboard & Packaging

GS Paperboard & Packaging Group Sdn., Bhd. (GSPP) is the largest containerboard and integrated paper and packaging manufacturer in Malaysia with 2 paper machines and 18 converting machines. It operates as a subsidiary of Oji Holdings Corporation, which is Asia's biggest and the world's fourth largest pulp and paper company.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2018 were approximately EUR 3.3 billion. Our more than 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Read more www.valmet.com

Valmet strengthens its wastewater automation business in Norway by signing a distributor agreement with Endress+Hauser

Valmet has extended the cooperation with Endress+Hauser by signing a distributor agreement for wastewater automation. Valmet's target is to strengthen and expand its wastewater business in Norway and help the wastewater industry to improve and optimize its processes.

According to the agreement, Valmet provides its advanced wastewater automation and measurement technology, while Endress+Hauser is responsible for sales, engineering and services in Norway. Valmet and Endress+Hauser already have similar agreements regarding wastewater business in Finland, Sweden, and Switzerland.

According to the agreement, Valmet provides its advanced wastewater automation and measurement technology, while Endress+Hauser is responsible for sales, engineering and services in Norway. Valmet and Endress+Hauser already have similar agreements regarding wastewater business in Finland, Sweden, and Switzerland.

Beneficial collaboration with a strategic approach

Endress+Hauser has long experience of the business environment and wastewater industry in Norway. Together with Valmet's strong automation expertise and advanced technology, the companies can develop wastewater automation and measurement business forward.

"The cooperation helps to expand Valmet's wastewater business in Norway. Endress+Hauser AS has good knowledge about Norway's wastewater customers and business environment, and Valmet's wastewater products fit very well to the existing offering of Endress+Hauser," says Heli Karaila, Business Manager, Wastewater, Automation, Valmet.

"We wish to express our global and strategic approach into the water and wastewater industry, especially when it comes to sludge measurement and handling. In Norway, we have dedicated microwave specialists for this purpose, which is why we think it's natural and beneficial to join forces with Valmet in this specific industry. The products are fitting nicely into our product portfolio as complementary devices for sludge measurement and handling. We find the experience and the closeness of Valmet's competence hubs in Finland and in Sweden as a great advantage for both us and our customers," says Tore Sandvoll, CEO, Endress+Hauser AS Norway.

Information about Valmet's measurement solutions

Valmet's automation and measurement solutions portfolio includes a long tradition of pioneering innovative measurement solutions for wastewater. Valmet's solid sensors provide proven results for all sludge processing stages in over 1,000 references in municipal and industrial wastewater treatment plants globally. Read more about Valmet's offering: www.valmet.com/wastewater

Information about Endress+Hauser

Endress+Hauser is a global leader in measurement instrumentation, services and solutions for industrial process engineering. The group employs more than 13,000 personnel across the globe, generating net sales of over 2.2 billion euros in 2017. Endress+Hauser provides sensors, instruments, systems and services for level, flow, pressure and temperature measurement as well as analytics and data acquisition. The company supports customers with automation engineering, logistics and IT services and solutions.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2018 were approximately EUR 3.3 billion. Our more than 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet to supply a new brown stock washing and screening line to Sappi Saiccor mill in South Africa

Valmet has received an order for the new magnesium oxide (MgO) no 3 brown stock washing and screening line for the Sappi Saiccor mill in South Africa. The delivery is part of the Vulindlela Project which targets to reduce the Saiccor mill's air emissions and effluents, and to increase its total production from 783,000 ADt/a to 890,000 ADt/a. The capacity of the new MgO no 3 brown stock and screening line will be 720 ADt/d.

The order is included in Valmet's third quarter of 2018 orders received. The value of the order will not be disclosed. An order with this scope of supply is usually valued in the range of EUR 5-10 million. The new line is scheduled to start up in June 2020.

The agreement is a continuation to the long-term successful cooperation of Sappi and Valmet. Valmet has earlier delivered key processes to other Sappi mills in South Africa.

Sappi Saiccor mill

Sappi Saiccor mill

"Valmet and its TwinRoll press technology was selected due to the ease of access for descaling and maintenance, high washing efficiency, low water consumption and low fugitive emissions to atmosphere," says Wayne Weston, Project Director at Sappi Saiccor projects.

"Valmet's large reference base for fiberline key equipment, such as the TwinRoll presses for Sulphite pulp/dissolving pulp, gives confidence to our customers that we can handle their special processes. We are happy to be a part of the Vulindlela Project and it is an important breakthrough for Valmet to utilize the TwinRoll presses in the Saiccor mill," says Eva Engelfeldt, Sales Manager, Fiber Processing Business Unit, Valmet.

Details about Valmet's delivery

Valmet's delivery includes equipment for the deknotting, screening and brown stock washing area, and auxiliaries like centrifugal pumps, field instruments, control valves, tower and tanks. The delivery also includes a service agreement on performance and reliability monitoring for the TwinRoll presses. The monitoring consists of a cloud application on the Valmet platform.

Valmet TwinRoll Evolution wash press (TRPE)

Valmet TwinRoll Evolution wash press (TRPE)

Information about the customer Sappi

Sappi is a global diversified woodfibre company focused on providing dissolving wood pulp, specialties and packaging papers, graphic/printing papers, as well as biomaterials and biochemicals to their direct and indirect customer base. Sappi has over 12,000 employees in over 20 countries.

The Saiccor mill is situated south of the port of Durban in South Africa. With a capacity of 800,000 tons per annum of Verve sulphite Dissolving Wood Pulp (DWP), it is the world's single largest manufacturing site for fully bleached sulphite DWP.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2017 were approximately EUR 3.1 billion. Our more than 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

Valmet opens a new spreader roll service workshop in South America

Valmet has expanded the operations of its service center in Sorocaba, Brazil, to include comprehensive spreader roll services. The new spreader roll workshop is ready to serve customers in the pulp, paper, board and tissue industries as of November 2018.

"With this investment Valmet is able to offer spreader roll services for its customers in all continents. We have already got very positive feedback from our Brazilian customers for these services," says Jukka K. Toikkanen, Global Technology Manager, Roll Maintenance, Valmet. "Our state-of-the-art spreader roll service workshop in Sorocaba, provides high quality and fast services to our customers. We have invested in a separate dust-free clean room for the handling and installation of bearings, which ensures high quality and contributes to longer roll running times."

"With this investment Valmet is able to offer spreader roll services for its customers in all continents. We have already got very positive feedback from our Brazilian customers for these services," says Jukka K. Toikkanen, Global Technology Manager, Roll Maintenance, Valmet. "Our state-of-the-art spreader roll service workshop in Sorocaba, provides high quality and fast services to our customers. We have invested in a separate dust-free clean room for the handling and installation of bearings, which ensures high quality and contributes to longer roll running times."

Valmet spreader roll reconditioning services result in a clear increase in service intervals and cut overall maintenance costs. In addition to keeping spreader rolls in excellent condition, spreader roll services also ensure optimized roll performance, improved end product quality and reliable, wrinkle-free runs.

Information about Sorocaba service center

Valmet's roll service center in Sorocaba, Brazil provides modular maintenance solutions such as roll maintenance services, roll reconditioning services and roll upgrades for all type of rolls - now also for spreader rolls.

Valmet is constantly expanding its services offering close to customers all around the world, by providing services from own service centers, on site and through the help of Industrial Internet applications and remote connections. In addition to Sorocaba, Valmet provides spreader roll services from seven other locations around the world.

Read more: Spreader roll services

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2017 were approximately EUR 3.1 billion. Our more than 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

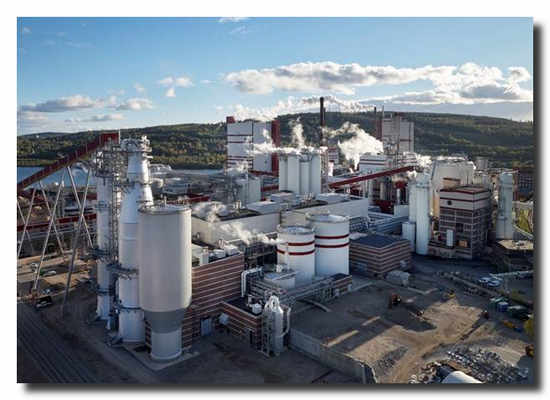

Valmet-supplied world's largest production line for bleached softwood pulp successfully started up at SCA Östrand mill in Sweden

The expanded pulp mill SCA Östrand in Timrå, Sweden, was started up end of June 2018, according to plan. SCA invested SEK 7.8 billion in Östrand pulp mill expansion project making it one of the largest industrial investments in Sweden to date. With this project SCA Östrand doubled its production capacity from 430,000 tonnes to 900,000 tonnes per year and became the largest production line for bleached softwood kraft pulp in the world.

"The rebuild and expansion of Östrand pulp mill is one of the greatest industrial investments in northern Sweden ever. In spite of complexities such as building a twice as big pulp mill in a running mill, we started up the new plant on schedule and budget. The success is the work of many actors, not the least our supplier Valmet", says Ingela Ekebro, Project Director, SCA.

"The start-up went very well. Valmet delivered the most sustainable solution available today consisting of the new cooking, fiber line and evaporation plants," says Stefan Mattsson, Sales Director, Fiber Processing Business Unit, Valmet.

Östrand pulp mill. Picture: Torbjörn Bergkvist.

Östrand pulp mill. Picture: Torbjörn Bergkvist.

The project was implemented in phases, and the new evaporation plant was started up some months before the cooking and fiber line. Very soon after the start-up, pulp was produced with high strength, purity and brightness. In the next phase, the production is increased gradually towards the new nominal production capacity.

State-of-the-art technology and environmental performance

Valmet's delivery to the project included new cooking, fiber line and evaporation plant. The cooking plant has the world's largest soft wood digester, while the new evaporation plant is Sweden's largest with an evaporation capacity of 1,150 tons of water per hour.

The 7-effect evaporation plant is extremely energy-efficient, with its in-built possibility to also recover excess heat from Valmet's cooking plant and includes a methanol plant for producing liquid methanol. This enables Östrand to sell surplus energy in the form of green electricity.

Following the investment, SCA Östrand mill has state-of-the-art technology to minimize emissions to air and water. Customers will be offered both TCF (total chlorine free) and ECF (elemental chlorine free) pulp, produced with wood from sustainable forestry.

Information about the customer SCA

The core of SCA's business is the forest, Europe's largest private forest holding. Around this unique resource, SCA has built a well-developed value chain based on renewable raw material from own and others' forests. SCA offers paper for packaging and print, pulp, wood products, renewable energy, services for forest owners and efficient transport solutions. In 2017, the forest products company SCA had approximately 4,000 employees and its sales amounted to approximately SEK 16.7 bn (EUR 1,6 bn). SCA was founded in 1929 and has its headquarters in Sundsvall, Sweden.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2017 were approximately EUR 3.1 billion. Our more than 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

SVEZA Group and Valmet have signed a Memorandum of Understanding regarding the planned greenfield pulp mill project in Vologda Region of Russia

SVEZA Group is planning to construct a modern pulp mill in the Russian Federation, Vologda region. In November 2017, SVEZA selected Valmet as a partner to execute the potential pulp mill's basic engineering, which has now been completed.

On September 26, 2018, Valmet and SVEZA have signed a Memorandum of Understanding with the objective of further cooperation in the planned pulp mill project. SVEZA is now proceeding with preparations, including environmental permits, for the possible pulp mill.

On September 26, 2018, Valmet and SVEZA have signed a Memorandum of Understanding with the objective of further cooperation in the planned pulp mill project. SVEZA is now proceeding with preparations, including environmental permits, for the possible pulp mill.

Information about the customer SVEZA

SVEZA is a worldwide known plywood producer. Currently the company produces high-quality plywood of natural Russian birch at its 6 mills. With annual production of 1,260,000 m3 the company is the world's largest producers of natural Russian birch plywood.

Valmet is the leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. We aim to become the global champion in serving our customers.

Valmet's strong technology offering includes pulp mills, tissue, board and paper production lines, as well as power plants for bioenergy production. Our advanced services and automation solutions improve the reliability and performance of our customers' processes and enhance the effective utilization of raw materials and energy.

Valmet's net sales in 2017 were approximately EUR 3.1 billion. Our more than 12,000 professionals around the world work close to our customers and are committed to moving our customers' performance forward - every day. Valmet's head office is in Espoo, Finland and its shares are listed on the Nasdaq Helsinki.

For further information, please contact:

Bertel Karlstedt, President, Pulp and Energy, Valmet, tel. +358 10 672 0000

Valmet to supply new winding technology for Papier- u. Kartonfabrik Varel in Germany

Valmet will supply new winding technology and surrounding equipment for Papier- u. Kartonfabrik Varel GmbH & Co. KG in Germany. The existing winder will be replaced with this new winder to meet the increasing line production of paper machine PM4. The start-up is scheduled for the beginning of 2020.

The order is included in Valmet's third quarter of 2018 orders received. The value of the order will not be disclosed. The total value of an order of this type is typically around EUR 5-10 million.

A photo after the winder deal, from left: Esa Ananin (Valmet), Ulrich Lange (Varel), Sami Anttilainen (Valmet), Thomas Müller (Varel) and Dirk Petersen (Valmet).

A photo after the winder deal, from left: Esa Ananin (Valmet), Ulrich Lange (Varel), Sami Anttilainen (Valmet), Thomas Müller (Varel) and Dirk Petersen (Valmet).

"We needed a reliable and high-capacity winder for our upcoming production capacity increases. Valmet's two-drum winder with Dual Unwinding technology were answers to these needs. Especially, the Dual Unwinding technology was a must to get to the required capacity level," says Thomas Müller, General Production Manager of Papier- u. Kartonfabrik Varel. "Papier u. Kartonfabrik Varel is a medium-sized family owned business. We produce cardboards and corrugated papers for our customers in the packaging industry on the basis of waste paper using state-of-the-art, highly available and reliable technologies. We were convinced of the large number of Valmet's references of both two-drum winders and Dual Unwinding," he continues.

Technical details about the delivery

Valmet's delivery for the new high-capacity winder area will include an OptiWin Drum two-drum winder with transfer rails, a parent roll turning table, a reel rebuild and an OptiSlush Broke pulper. The winder is equipped with a Dual Unwind two-unwind system. This feature makes it possible to change the parent roll in only one minute giving the winder more capacity. The Dual Unwind sequence is fully optimized and independent of a crane.

The winder with a web width of 5,600-mm will be designed for recycled testliner grades with a basis weight range of 100 - 280 g/m2. The production speed will be 2,700 m/min.

About the customer Papier- u. Kartonfabrik Varel

Papier- u. Kartonfabrik Varel is a medium-sized family business with about 540 employees. It produces cardboard and corrugated board from waste paper for the German and international packaging industry, using the latest environmentally friendly technologies, which are at the heart of the packaging solutions of many well-known products. With an annual production capacity of over 850,000 tonnes on four modern production lines, Papier- u. Kartonfabrik Varel is one of the largest production sites of the European paper industry.

Valmet to supply web monitoring systems to Shanying Huazhong Paper in China

Valmet has received orders for next-generation web monitoring systems from Shanying Huazhong Paper Industry Co., Ltd. in China. The full-scale Valmet IQ Web Monitoring Systems will be installed on two paper machines at the company to improve and maintain machine productivity.

The orders were included in Valmet's first and second quarter 2018 orders received. Typically, the order value of these kinds of automation system deliveries is below EUR one million.

"Shanying has a clear strategy for the Industrial Internet and developing the automation level of its machines, and we are now taking steps forward with this. We believe that with Valmet's solutions and services, we can improve our product quality and machine runnability, as well as optimize machine efficiency," says Liu Fubin, Purchasing Director of Shanying International Holdings Co., Ltd.

"Valmet is capable of offering complete automation packages, including process controls and quality controls. Valmet IQ Web Monitoring System plays a vital role in developing quality and total machine efficiency. We are delighted to be able to provide all the applications and services that our customer needs to achieve these demanding targets," says Zhutuan Guo, Sales Director, China, Automation, Valmet.

Technical information about Valmet IQ Web Monitoring System

Valmet IQ Web Monitoring System is a tool to improve the runnability of all production machines in the paper industry. Excellent image quality, synchronized video recordings and an easy-to-use operator interface ensure quick root cause analyses of web breaks. Spearhead technology utilized in system components, together with field-tested hardware and professional services, make Valmet the market leader of web monitoring systems.

Information about the customer

Shanying Huazhong Paper Industry Co., Ltd. is a part of Shanying International Holdings Co., Ltd., one of the largest industrial papermaking enterprises and packaging board manufacturers in China. Established in 1999, the company has been listed on Shanghai Stock Exchange since 2001. In 2013, the company was restructured as part of Ji'an Group Co., Ltd. The company has subsidiaries in the Anhui, Zhejiang, Jiangsu, Fujian, Hubei and Tianjin provinces, among others. It has set up wholly owned companies, for example, in the US, UK, Netherlands Germany, Japan, Australia and Hong Kong. Shanying International has an annual yield of 3,050,000 tons of paper and 1 billion square meters of cardboard and paper carton, ranking top within the industry in terms of scale.