Super User

ANDRITZ to deliver complete old corrugated containers line to Papel Prensa, Argentina

International technology group ANDRITZ has received an order from Papel Prensa S.A. to supply a complete old corrugated containers (OCC) line including a reject handling system to its mill in Buenos Aires, Argentina.

In its initial production phase, the new line will process 180 t/d of local OCC. The line’s processing capacity can be easily increased through a minor adjustment to configuration to support the expected rise in pulp demand for the production of corrugated paper. The new line will provide high pulp quality at cost-efficient and resource-saving operation, with the latest technology available.

Diego Colabardini, CEO of Papel Prensa S.A., says: “Our goal is to produce top-quality paper while reducing our environmental footprint through the efficient use of energy and natural resources, based on our strategy of promoting circular economy in a sustainable business. ANDRITZ’s advanced technology and extensive experience in pulping will help us achieve this goal."

PrimeScreen X for improved energy efficiency, screening performance, and maintainability. Photo Andritz

PrimeScreen X for improved energy efficiency, screening performance, and maintainability. Photo Andritz

ANDRITZ’s scope of supply comprises

- the complete LC pulping system with a FibreSolve FSR pulper and an innovative detrashing system to ensure superior slushing of the raw material at minimum fiber loss

- the protection cleaning, fractionation and screening stage including a PrimeScreen X with newly developed PrimeRotor for high screening efficiency at lower power consumption

- an innovative reject handling system featuring a Reject Compactor ReCo to dewater the rejects to the highest possible dry content

- erection supervision, commissioning, start-up, and training

Start-up of the new line is scheduled for 2024.

This order further strengthens ANDRITZ's presence in the South American recycled pulp market.

Papel Prensa S.A. is a leading Argentinean paper manufacturing company with the country´s highest paper production volume. The company specializes in the production of newsprint, printing paper, and packaging paper.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. Sustainability is an integral part of the company’s business strategy and corporate culture. With its extensive portfolio of sustainable products and solutions, ANDRITZ aims to make the greatest possible contribution to a sustainable future and help its customers achieve their sustainability goals. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro and Separation. Technological leadership and global presence are cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 30,000 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation.

The product portfolio also includes boilers for power generation, flue gas cleaning systems, various nonwoven technologies, and panelboard (MDF) production systems. With waste-to-value recycling, shredding and energy solutions, waste and by-product streams from production are converted into valuable secondary raw materials as well as into sustainable resources for energy generation. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

Valmet to supply key technology for Shandong Jin Tian He Paper’s board machine in China

Valmet will supply key technology to Shandong Jin Tian He Paper’s board machine PM 13 food grade folding boxboard line in China. The delivery will include headboxes, a former and press section, finishing technologies, automation and services.

The order is included in Valmet’s orders received of the fourth quarter 2023. The value of the order will not be disclosed, but such an order is typically worth of EUR 20 million to EUR 30 million.

The start-up of the folding boxboard machine is scheduled for the second quarter of 2025.

“Shandong Jin Tian He Paper develops high-end food grade coated white cardboard to meet the people’s yearning for a better life and the social demand for high-end packaging products. We chose Valmet because they are one of the best pulp and paper equipment manufacturers in the world, with reliable quality, proactive service and good communication, which helps us reach our goals,“ says Xu Zhenli, Chairman, Shandong Jin Tian He Paper.

“Valmet’s offering, including high performance coating technology, and unique advantages combining process technologies, services and automation are confirmed and trusted by the customer to meet their high-quality targets. Valmet and Shandong Jin Tian He Paper are working closely together, not only executing a successful project but also deepening partnership,” says Daniel Li, Sales Manager, China, Valmet.

Shandong Tianhe Paper Co., Ltd. office building in Tai’an, China

Shandong Tianhe Paper Co., Ltd. office building in Tai’an, China

Technical information about the delivery

Valmet’s delivery for the board machine PM 13 will include three OptiFlo Fourdrinier headboxes, IntelliTop Former forming section, IntelliPress Linear press section, five OptiCoat Roll coating stations, OptiDry Coat air drying technology and two OptiCalender Soft calenders.

The delivery will also include Valmet DNA Machine Controls (MCS), Cross Direction (CD) and Machine Direction (MD) controls, headbox dilution profilers, basic engineering, spare parts packages, and Valmet Industrial Internet solutions with connectivity.

The 6,320 mm wide (wire) PM 13 will produce food grade folding boxboard with basis weight range of 170-400 g/m2 at production speed of 800 m/min.

About the customer

Shandong Jin Tian He Paper Co., Ltd., established in 2022, is a subsidiary of Shandong Tianhe Paper Co., Ltd. which was established in 1978. Shandong Tianhe Paper Co., Ltd. is a pulp-paper integrated enterprise. Its main products include, for example, mechanical pulp, fine paper, package paper and specialty paper. The company has more than 1,500 employees.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our more than 19,000 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. Valmet’s net sales in 2022 were approximately EUR 5.1 billion.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Emerson Named ‘Industrial IoT Company of the Year’

Award recognises Emerson’s software and technology innovation helping global companies achieve optimal performance

Global technology and software leader Emerson (NYSE: EMR) has been named IoT Breakthrough ‘Industrial IoT Company of the Year’ for the sixth time. The 2024 award recognises Emerson’s advances in sustainability-enabling technologies and software, efforts to accelerate the development and delivery of life-saving drugs, and the company’s industry-leading Boundless Automation™ vision of a next-generation, software-defined industrial automation architecture.

“Emerson’s culture of innovation and extensive automation portfolio are addressing the most urgent challenges of our time: a shrinking experienced industrial workforce, the low-carbon energy transition and the ever-evolving search for new drug treatments,” said Lal Karsanbhai, president and chief executive officer of Emerson. “We are honoured to receive this award that recognises the value Emerson delivers to help customers in so many critical industries achieve their maximum performance.”

Emerson is using its decades of automation expertise to help some of the largest companies in the world meet their sustainability goals. The company’s recent advances in this space include its Ovation™ Green portfolio of renewable power solutions to decarbonise, reduce emissions and seamlessly add more renewable energy to power grids, and Floor to Cloud™ solutions that continuously monitor and visualise critical production data to improve energy efficiencies in factories.

Emerson is using its decades of automation expertise to help some of the largest companies in the world meet their sustainability goals. The company’s recent advances in this space include its Ovation™ Green portfolio of renewable power solutions to decarbonise, reduce emissions and seamlessly add more renewable energy to power grids, and Floor to Cloud™ solutions that continuously monitor and visualise critical production data to improve energy efficiencies in factories.

The award also recognises Emerson’s leadership in developing digital technologies aimed at accelerating drug development. The company recently announced One-Click Technology Transfer™ software that will convert today’s life sciences manufacturing recipe transfer process into a digitalised production platform, helping get new drug therapies to patients faster.

This year, Emerson announced the first of a series of new technology releases that build upon its Boundless Automation vision and serve as the foundation of its next-generation, software-centric automation platform. The new DeltaV™ Edge Environment moves data securely and seamlessly between the intelligent field, the edge and the cloud without losing operational context, enabling greater access to data and faster decision-making.

“Emerson is a consistent winner of our Industrial IoT Company of the Year award because of how effectively it leverages its decades of expertise in digitalisation and automation to help industry leaders transform their operations to address the needs of the future,” said Steve Johansson, managing director at IoT Breakthrough. “We congratulate the Emerson team for taking home our ‘Industrial IoT Company of the Year’ award in the eighth annual IoT Breakthrough Awards programme.”

IoT Breakthrough, which recognises the excellence, creativity and success of Internet of Things (IoT) companies, technologies and products, received more than 4,300 nominations for the 2024 competition. The awards honour the world’s best companies, leaders, technologies and products in a range of IoT categories — from industrial and enterprise, to consumer and connected home. Winners are selected by a panel of senior-level professionals experienced in the IoT space, including journalists, analysts and technology executives.

For more information on Emerson’s automation solutions, please visit Emerson.com.

Runtech Systems delivers vacuum system to Sonoco, Indonesia

Runtech Systems delivers a RunEco vacuum system rebuild to Sonoco Products Co. Subang mill in Indonesia. The delivery includes a RunEco EP600 Turbo Blower with EcoDrop water separator and EcoFlow dewatering measurements.

“Our EP Turbo Blowers are ideal for rebuilds as they are compact and easy to install and very economical to own and operate. Upgrading the vacuum system not only saves energy but also brings flexibility. With our turbo blower technology, the turbo speed is automatically adapted to the needed vacuum level,” says Hannu Kääriä, Sales Director, Runtech Systems.

Environmentally friendly and energy efficient, RunEco vacuum system provides a reliable, completely water free vacuum solution. Less energy and no water contribute to lower CO2 emissions and smaller environmental footprint. EP Turbo Blowers are always variable speed and capacity, which allows the vacuum system to be optimized quickly without bleed air and with minimal throttling and expansion losses. With integrated high-speed motor controlled by a frequency converter, rotation speed and vacuum level can be adjusted according to the process requirements.

RunEco EP Turbo Blower

RunEco EP Turbo Blower

EcoFlow dewatering measurement provides accurate real-time feedback about the dewatering performance along the paper machine which can be used to optimize dewatering and vacuum levels in the forming and press sections.

About Sonoco Products Co.

Since 1899, Sonoco has partnered with customers to provide dependable service and quality products. Today, the team includes approximately 22,000 employees working in 300+ operations around the world.

More information:

Hannu Kääriä, Sales Director, Asia-Pacific; This email address is being protected from spambots. You need JavaScript enabled to view it., tel. +358 40 828 6840

Read more about RunEco solution https://www.runtechsystems.com/en-fi/energy-and-vacuum-systems

Runtech Systems is a global provider of engineered systems tailored to the pulp and paper industries. Runtech works with customers to better understand and control their operational conditions to maximize efficiency and cost effectiveness.

Runtech Systems delivers a vacuum system to Sonoco Stainland

Runtech Systems delivers a RunEco vacuum system rebuild Sonoco Cores and Paper Limited Stainland mill in United Kingdom. The delivery includes a RunEco EP600 Turbo Blower with ABB motor and drive, transformer, new EcoSep pre-separators, EcoFlow dewatering measurements and detailed engineering.

“With today’s energy challenges and the aim to lower carbon footprint it is even more important that our Turbo Blowers are very economical to own and operate. A tailored solution with flexible and variable capacity can help balance supply and demand, leading to optimized dewatering and minimized power consumption,” says Jussi Lahtinen, Sales Director, Runtech Systems.

“Runtech vacuum system concept is very interesting for us because by using Ecoflows we can actually see how much vacuum is needed. We started the project by doing a Runtech vacuum audit and after that pre-engineering including the 3D scan and 3D modelling of the existing vacuum system. Pre-engineering gave us all necessary information to calculate the project costs and ROI accurately. Now we are able to execute the project much quicker when a big part of the engineering is already done so good pre-engineering saves also time,” says Peter Donnelly, Mill Manager, Sonoco Board Mill, Stainland, Halifax.

Environmentally friendly and energy efficient, RunEco vacuum system provides a reliable, completely water free vacuum solution. Less energy and no water contribute to lower CO2 emissions and smaller environmental footprint. EP Turbo Blowers are always variable speed and capacity, which allows the vacuum system to be optimized quickly without bleed air and with minimal throttling and expansion losses. With integrated high-speed motor controlled by a frequency converter, rotation speed and vacuum level can be adjusted according to the process requirements.

EcoFlow dewatering measurement provides accurate real-time feedback about the dewatering performance along the paper machine which can be used to optimize dewatering and vacuum levels in the forming and press sections.

About Sonoco Products Co.

Since 1899, Sonoco has partnered with customers to provide dependable service and quality products. Today, the team includes approximately 22,000 employees working in 300+ operations around the world.

More information:

Jussi Lahtinen, Sales Director, Runtech Systems; This email address is being protected from spambots. You need JavaScript enabled to view it., tel. +358 40 079 0950

Read more about RunEco solution https://www.runtechsystems.com/en-fi/energy-and-vacuum-systems

Runtech Systems is a global provider of engineered systems tailored to the pulp and paper industries. Runtech works with customers to better understand and control their operational conditions to maximize efficiency and cost effectiveness.

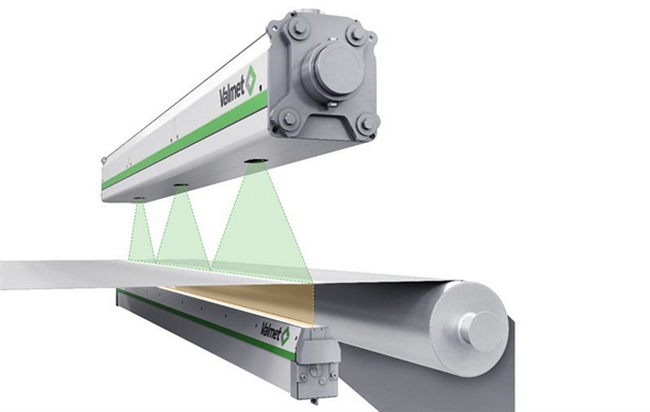

Valmet to supply IQ Web Inspection System to Yueyang Forest & Paper Co., Ltd. in China

Valmet has received an order from Yueyang Forest & Paper Co., Ltd. to supply IQ Web Inspection System for its paper machine PM 8. The IQ Web Inspection System will replace an existing system from another supplier. Yueyang Forest & Paper’s PM 8 has already been equipped with Valmet IQ Web Monitoring System in 2019. After the implementation, Valmet’s machine vision systems will improve the operating efficiency and optimize the final paper quality of the PM 8.

The order is included in Valmet’s orders received of the fourth quarter 2023. The delivery will take place in July 2024. The value of the order will not be disclosed.

“We have been using Valmet IQ Web Monitoring System since 2019 and we are pleased with its performance. That is why we continue our cooperation with Valmet. The new investment of IQ Web Inspection System will help us to quickly detect quality defects and identify their root causes quickly and easily, which will improve our runnability and product quality,” says Mingyi Yu, Automation Manager at Yueyang Forest & Paper Co., Ltd.

“We are very happy that our advanced technology can support Yueyang Forest & Paper stay competitive in the market. The upgrade will significantly improve image quality and provide a good basis for analysis and precaution for defects,” says Zhifeng Pan, Sales Manager, Automation Systems business line, Valmet.

Valmet has received an order from Yueyang Forest & Paper Co., Ltd. to supply IQ Web Inspection System for its paper machine PM 8.

Valmet has received an order from Yueyang Forest & Paper Co., Ltd. to supply IQ Web Inspection System for its paper machine PM 8.

Technical information about the delivery

Valmet IQ Web Inspection System (WIS) delivery includes ultra-high resolution 8K dual-line cameras with advanced image processing and synchronized high power stroboscopic LED lighting. Real-time and history defect maps with defect details and trends are available on operator stations. IQ Web Inspection System also supports both rule-based classification as well as classification based on artificial intelligence (AI) with easy drag and drop teaching. In addition, a two-year optimization service is also included.

About the customer Yueyang Forest & Paper Co., Ltd.

Yueyang Forestry & Paper Co., Ltd., formerly known as Yueyang Paper Mill, was founded in 1958 and listed on the Shanghai Stock Exchange in May 2004. The company is a subsidiary of China Paper Corporation, part of China Chengtong Holdings Group Co., Ltd. China Paper Corporation is the only state-owned company mainly engaged in the forest-pulp-paper business.

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries. Our more than 19,000 professionals around the world work close to our customers and are committed to moving our customers’ performance forward – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. Valmet’s net sales in 2022 were approximately EUR 5.1 billion.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Voith and Sun Paper achieve early start-up of Nanning PM 2 and PM 3 state-of-the-art packaging paper machine

Recently, Sun Paper's two state-of-the-art packaging paper machines PM 2 and PM 3 were successfully commissioned at the Nanning, China site within one month. PM 3 successfully passed the tests in only three weeks and achieved a record-breaking start-up time of only one hour from stock on wire to the first saleable paper roll. With the start-up of the two state-of-the-art XcelLine machines from Voith, Sun Paper consolidates its leading position in the global paper industry and sets another milestone in the long-standing cooperation between the two companies. The exceptional performance is the result of many years of trust and close cooperation between the Sun Paper and Voith teams. The daily exchange of knowledge and thorough project preparation led to significantly reduced downtimes during project implementation.

- Within a month, Sun Paper has started up two packaging paper machines ahead of schedule – this is the fourth follow-up order of this kind between Voith and Sun Paper

- PM 3 sets a new start-up world record: Only one hour from stock on wire to the first saleable paper roll

- Voith's XcelLine machines are characterized by the highest performance: PM 2 reached the designed production within three weeks after start-up, PM 3 within two weeks. The paper produced is of stable quality and already meets customer requirements from the first reel

“PM 2 and PM 3 in Nanning are the 13th and 14th paper machines in the partnership between Sun Paper and Voith. Our long-standing cooperation with Voith has taught us that a good business relationship is not only based on one-time success but also on mutual support and long-term growth,” says Li Lu, Chairman of Sun Holdings Group. “We continue to work closely together in the packaging paper business. From PMs 31/32 and PMs 36/37 in Zoucheng to PM 1/2s in Laos and PMs 2/3 in Nanning, we and Voith have demonstrated through concrete actions that a true partnership is based on deep mutual trust and shared values.”

“The highly efficient implementation and rapid commissioning of the Nanning project is just one example of this successful long-term strategic alliance,” confirms Ying Guangdong, Vice General Manager and Chief Engineer of Sun Paper. “It not only strengthens the cooperation between Sun Paper and Voith in the field of packaging paper but also shows our determination to jointly seek sustainable and innovative solutions.”

Operating efficiency is an important parameter to judge the success of a project, according to Fu Guoling, Project Director of Nanning PM 2/3 and Zoucheng PM 36/37 production line, and continues, “Voith's machines have superior performance: PM 2 reaches designed production within three weeks after start-up, PM 3 within two weeks”, Guoling explains. “The paper is of excellent and stable quality and has been very well received by the market. At the same time, excellent management on both sides has significantly shortened the project duration, resulting in an even faster economic profitability. In addition, the installation of two machines for the left and right sides optimizes the investment by reducing operating and maintenance costs, maximizing the utilization of raw materials, and thus further improving economic return.”

The PM 2 and PM 3 machines in Nanning have a wire width of 7.3 m and has achieved a design speed of 1,200 m/min. PM 2 produces high-quality packaging paper with a basis weight of 140-250 gsm and an annual capacity of around 520,000 tons. PM 3 specializes in high-quality packaging paper with a basis weight between 100-160 gsm and has an annual capacity of around 480,000 tons. As the leading full-line supplier, Voith supplied all components from headbox to reel, including industry-leading automatic control systems and digitalization solutions from the Papermaking 4.0 portfolio, such as MCS, QCS and OnCare.Health.

Kurt Yu, President of Voith Paper Asia, says, “We are very honored to be the key partner in Sun Paper's ambitious plans for the packaging paper sector. Each follow-up order is not only a recognition of the product, but also an expression of appreciation for our many years of trustful cooperation.”

With the successful commissioning of the two machines in Nanning, Sun Paper achieves a significant milestone in the coordinated development of the Guangxi Beihai-Nanning region and its sites in Shandong, Laos and Guangxi. This step strengthens the company's position and promotes the creation of a self-sufficient forest pulp-paper system. Through a low-carbon, circulating production chain, Sun Paper ensures efficient raw material control and strengthens its competitiveness in the market.

About Sun Paper

Founded in 1982, Shandong Sun Paper is a leader in the papermaking industry in China. It ranks among China's Fortune 500 companies and is one of the world's 30 largest paper manufacturers. It has been awarded the National Green Factory recognition. The company possesses strong technological innovation capabilities, being responsible for one project in the National 863 Program and over 30 technology research projects at national and provincial levels, as well as being the proud recipient of significant technology innovation awards such as first place in the National Prize for Progress in Science and Technology, the Commendation Award in the China Grand Awards for Industry, and second place in the National Award for Technological Invention. By inventing the world’s first process of continuous cooking of dissolved wood pulp, extracting xylose from hydrolyzed liquid, and making the world’s first sheet of chemical-free paper in its “Additive Free” household paper range, the company has achieved “Three World Firsts” with its technological innovations.

Sun Papers strives to implement its ESG policies to create a sustainable and respected world-class enterprise. Based on its leading implementation and outstanding achievements in years of environmental, social and corporate governance management, Sun Paper (002078.SZ) has been incorporated by Hang Seng Indexes as one of the constituents in the Hang Seng (China A) Corporate Sustainability Benchmark Index. The company is proud to be amongst China's Top 100 ESG Listed Companies, and has been incorporated into the China Securities Index’s Securities Times ESG 100 Index.

About Sun Holdings

Shandong Sun Holdings Group Co. Ltd. is the controlling shareholder of Sun Paper and a leading cross-national papermaking group integrating forestry, pulp and papermaking. For a long time, Sun Holdings has been unwavering in its implementation of new development strategies, deepening its promotion of replacing old energies with new, expanding foreign business, implementing the “double carbon” strategy and actively participating in the “One Belt One Road” initiative. It has strived to create a green circulatory production chain that integrates forestry, pulp and papermaking, pushing ahead with a highly efficient and coordinated development of the three important bases of Shandong, Guangxi and Laos. In 2022, Sun Holdings achieved a 70.6 billion Yuan turnover, becoming one of China's 500 largest companies and one of the top 500 Chinese private enterprises. It ranked first in an Overall Review of the Top 10 Papermaking Enterprises in China's Light Industry.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, Voith today has around 21,000 employees and earns 4.9 billion euros in sales. It has locations in more than 60 countries and is one of Europe’s major family-owned companies.

The Group Division Voith Paper is part of the Voith Group. As the full-line supplier to the paper industry, it provides the largest range of technologies, services and products on the market, and offers paper manufacturers integrated solutions from one source. The company’s continuous stream of innovations facilitates resource-conserving production and helps customers minimize their carbon footprint. With its comprehensive automation products and leading digitalization solutions from the Papermaking 4.0 portfolio, Voith offers its customers state-of-the-art digital technologies to improve plant availability and efficiency for all sections of the production process.

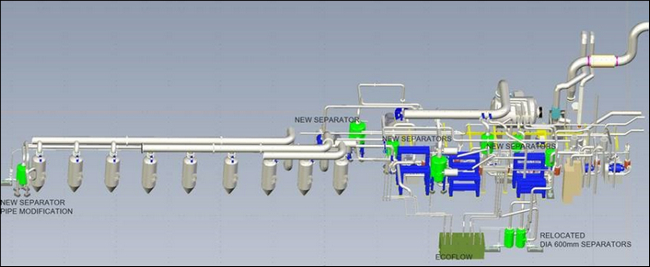

Rebuild by ANDRITZ gives Shandong Huatai Paper the world’s largest mechanical pulping line while saving energy and resources

Shandong Huatai Paper has successfully started up a mechanical pulping line rebuilt by ANDRITZ at the mill in Dongying, Shandong Province, China. The rebuild not only increased the line’s capacity from 100,000 t/a to 300,000 t/a, making it the world’s largest mechanical pulping line for printing and writing paper production. It also considerably reduced the line’s energy consumption and increased its pulp yield and quality.

Wei Lijun, Director of Shandong Huatai Paper, says: “Thanks to the close cooperation between the teams of ANDRITZ and Shandong Huatai, we were able to start up the rebuilt line as scheduled. We are delighted about the massive increase in capacity as well as the additional benefits of the modernization. Energy consumption has dropped by about 15% and pulp quality has greatly improved. The amount of fiber shives has also gone down significantly. As a result, we are able to cut back on imported chemi-mechanical pulp in our raw material structure, which lowers costs and supports our environmental performance.”

Successful start-up of the world’s largest mechanical pulping line for P&W grades at Shandong Huatai Paper, China. Photo Andritz

Successful start-up of the world’s largest mechanical pulping line for P&W grades at Shandong Huatai Paper, China. Photo Andritz

ANDRITZ rebuilt the two high-consistency (HC) refiners and the screw presses, disc filters, and screens, and supplied new equipment for other process steps. The line now features the following technological highlights:

- New PrimeMSD Impressafiner for optimum wood chip maceration and chemical impregnation

- New Side-Entry Plug Feeder (SEPF) feeding system for constant and efficient HC refiner feeding

- New DCS system as a future-oriented control system for the new fiberline

- ANDRITZ Hydraulic Commander to improve the HC refiners’ operability and supply top quality fiber with lower energy consumption

ANDRITZ also provided the basic engineering and supervised the mechanical installation, commissioning, and start-up.

Shandong Huatai Paper Industry Shareholding is part of the listed Huatai Group, an important global player in the paper and chemical production sectors. The group is the world’s largest producer of newsprint and China’s largest producer in the chlor-alkali industry. In addition, the group makes all sorts of P&W paper, tissue, and specialty paper grades. The Huatai Group produces three million tons of paper and board as well as two million tons of chemicals per year.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. Sustainability is an integral part of the company’s business strategy and corporate culture. With its extensive portfolio of sustainable products and solutions, ANDRITZ aims to make the greatest possible contribution to a sustainable future and help its customers achieve their sustainability goals. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro and Separation. Technological leadership and global presence are cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 30,000 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation.

The product portfolio also includes boilers for power generation, flue gas cleaning systems, various nonwoven technologies, and panelboard (MDF) production systems. With waste-to-value recycling, shredding and energy solutions, waste and by-product streams from production are converted into valuable secondary raw materials as well as into sustainable resources for energy generation. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

Toscotec to supply major rebuild to Hamburger Containerboard Group

Toscotec will supply an entire dryer section rebuild to Hamburger Turkey, part of the Hamburger Containerboard Group, at their paper mill in Çorlu in Northern Turkey. The project focuses on their containerboard machine (PM3) and is planned for the end of 2024.

Targets: production increase and basis weight range expansion

The rebuild has two main targets. Firstly, the replacement of the existing cast-iron dryer cans with Toscotec’s custom-sized TT SteelDryers will increase the sheet drying width by 90 mm while maintaining the same face length and using the existing machine frame. This will lead to an increase of PM3’s production capacity.

The second target is to expand the basis weight range and produce lower grammages to enter a new market for lighter testliner products through an improvement in the wet section.

The scope of supply

Toscotec will supply thirty seven TT SteelDryers for a full upgrade of the dryer section and new TT UniRoll vacuum rolls in the first dryer group. The scope also includes all the mechanical drives and doctor blades of the dryer section. Toscotec will also upgrade PM3’s press section and the sheet stabilization system from the press to the second dryers’ group. The service package includes the erection supervision, training, commissioning, and start-up assistance.

Hamburger Turkey’s paper mill in Çorlu (Turkey).

Hamburger Turkey’s paper mill in Çorlu (Turkey).

Faik Ozturk, Project Manager at Hamburger Containerboard, says, “Our cooperation with Toscotec began in 2020 when we purchased our first TT SteelDryer. This new rebuild is part of an important market strategy. It will bring great results with minimal intervention because it maintains the non-technological components of the machine. Therefore, we will realize the complete upgrade of PM3’s dryer section in an easy and cost-effective way.”

Fabrizio Charrier, Sales Manager of Toscotec’s Paper & Board division, says, “I’m very proud to have reached this agreement with Hamburger Containerboard in Turkey. Toscotec’s customized technology precisely meets the needs of this project. This order also comes from an efficient and professional approach during the technical analysis phase. I’m confident that this synergy will lead to a long-term cooperation with their group on future projects.”

About Hamburger Containerboard Group

Hamburger Turkey, part of the Hamburger Containerboard Group, is a leading manufacturer of high-quality corrugated base paper. It has two production facilities: in Çorlu and in Denizli, where it manufactures corrugated case material products. The Hamburger Containerboard Group, part of the Austrian Prinzhorn Holding, dates as far back as 1853. With 10 locations in 5 different countries, the group has a total production capacity of more than 3 million tons/year, which comprises brown and white uncoated papers, white coated papers, and plasterboard.

Metsä Group and Sweco have signed an agreement for the design of Kerto LVL mill in Äänekoski

Metsä Group and Sweco, a specialist in the built environment and industry, have signed an agreement for the implementation planning of the new Kerto LVL mill in Äänekoski, Finland.

"We have strong confidence in Sweco's expertise and resources from our previous collaboration projects. It is therefore natural that we continue our cooperation in this project to develop the Äänekoski mill area," says Jaakko Anttila, Executive Vice President at Metsä Wood.

Sweco is responsible for the complete implementation planning of the mill project, including structural, process and plant design. Sweco was also responsible for the design of Metsä Group’s Äänekoski bioproduct mill, which started operations in 2017, and the planned wood product mill will apply the synergy benefits offered by the mill area.

"For example, the steam needed in the production process of Kerto LVL will be produced at the Äänekoski bioproduct mill, and the condensate generated in the process will be utilized for heating the building. It is great to be involved in designing a resource-efficient production plant whose material-efficient wood products store carbon and reduce the carbon footprint of construction," says Tuulamari Helaja, Business Unit Director, Industry and Energy at Sweco Finland.

Construction of the Kerto LVL mill in Äänekoski has progressed according to plan. Land construction works and the main frame installations are currently underway in the area.

The mill will have an annual production capacity of around 160,000 cubic metres of Kerto LVL and is expected to start production in the second half of 2026. When completed, the mill will employ around 150 people directly and 200 people in its value chain.

Metsä Group

www.metsagroup.com

Metsä Group is leading the way in advancing the bioeconomy. We invest in growth, bioproduct development and a fossil free future. The raw material for our products is renewable wood from sustainably managed northern forests. We focus on the growth sectors of the forest industry: wood supply and forest services, wood products, pulp, fresh fibre paperboards, as well as tissue and greaseproof papers.

Metsä Group’s annual sales amount to approximately EUR 7 billion, and we have around 9,500 employees in 30 countries. Our international Group has its roots in the Finnish forests: our parent company is Metsäliitto Cooperative which is owned by more than 90,000 forest owners.