The Voith Group performed satisfactorily in a challenging environment over the 2022/23 fiscal year (October 1, 2022 to September 30, 2023). Both in terms of operating business and financially, Voith remains in a robust position. The Company increased all key performance indicators in the reporting year and reached the defined growth and earnings objectives. Group net income improved compared to the previous year. The broad sectoral and geographical diversification, the established market position in the three Group Divisions and regional supply chains contributed to the encouraging development.

- Orders received see a favorable development, orders on hand once again at all-time high

- Group sales (+13 percent) and EBIT increased

- Increase in cash flow and Group net income

- All three Group Divisions make contribution to positive development

“In the past fiscal year, Voith has once again proven its resilience. Despite a challenging economic environment, we continued to generate profitable growth and increased cash flow. The clear focus on sustainable technologies is paying off,” comments Dr. Toralf Haag, CEO of Voith.

2022/23 fiscal year at a glance: All key performance indicators improved

The Voith Group increased all of its key performance indicators over the 2022/23 fiscal year. All three Group Divisions contributed to this development.

At € 6.14 billion, orders received exceeded expectations once again and increased 19 percent on the high level seen in the previous year. The orders on hand reached a new all-time high at € 7.22 billion. Over the same period, Group sales rose by 13 percent to € 5.51 billion. The operating result (EBIT) was € 245 million. The return on sales improved to 4.4 percent (previous year: 4.1 percent), while the return on capital employed (ROCE) increased to 12.1 percent (previous year: 10.5 percent). The Group net income rose to € 73 million as a result of the favorable development of the operating business over the reporting period and despite the higher interest rate level and the associated increase in financing costs.

The increase in earnings was achieved and further investments in the future were made. Expenditure on research & development increased by 9 percent to € 232 million. Financially, the Voith Group remains in a sound position. The equity ratio stood at 23.9 percent in the reporting year (previous year: 24.1 percent). The operating net cash flow saw a positive development in comparison to the previous year and returned a figure of € 306 million (previous year: € 93 million). Likewise, the net debt also improved.

Dr. Toralf Haag: “Our net assets and financial position are sound. The reliable long-term access to capital gives us the necessary entrepreneurial scope to invest in further profitable growth and into the future viability of Voith.”

Strategic focus: Industrial sustainability

Voith continues its commitment to the megatrends of decarbonization and digitalization. The ongoing transformation from a traditional mechanical engineering company to a sustainable technology group with a high level of digital expertise offers promising new business opportunities. To this end, Voith is continually investing in the strategic and technological refinement of its product portfolio, in new growth areas as well as in efficient structures and processes.

Voith has identified hydrogen technology, electrical drive systems, cargo rail and energy storage as growth areas – with the objective to use Voith’s existing broad expertise in the areas of hydropower, paper production, mobility and industrial applications beyond the current product portfolio.

Along with organic growth, Voith benefited from two acquisitions in the Group Division Turbo in the reporting period. IGW Rail (acquired in October 2022) and Argo-Hytos (acquired in August 2022) were included for the first time and for the full fiscal year for the first time, respectively, in the reporting year. This resulted in an acquisition-related increase of around € 210 million in orders received and around € 230 million in sales.

In the 2022/23 fiscal year, all three Group Divisions contributed to positive development

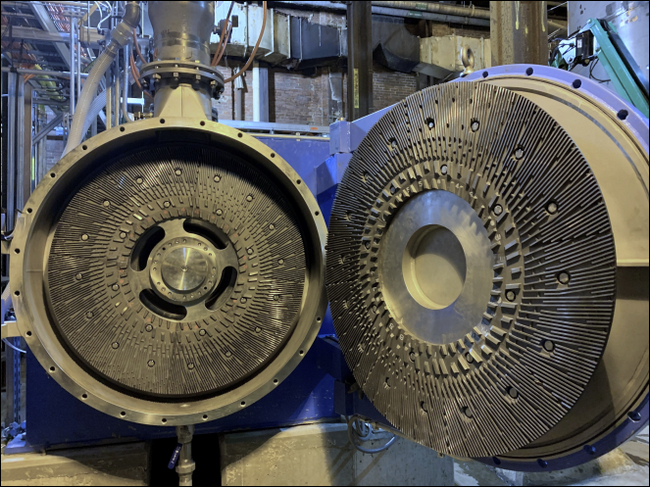

The Group Division Hydro sustained its position in the 2022/23 fiscal year in an ongoing challenging market environment. Orders received grew to € 1.92 billion (previous year: € 1.18 billion). One of the main reasons for the growth is the increase in volume in a current major project. Sales improved to € 1.19 billion (previous year: € 1.05 billion). EBIT increased minimally to € 6 million (previous year: € 2 million). Increasing profitability remains an important objective for the Group Division Hydro.

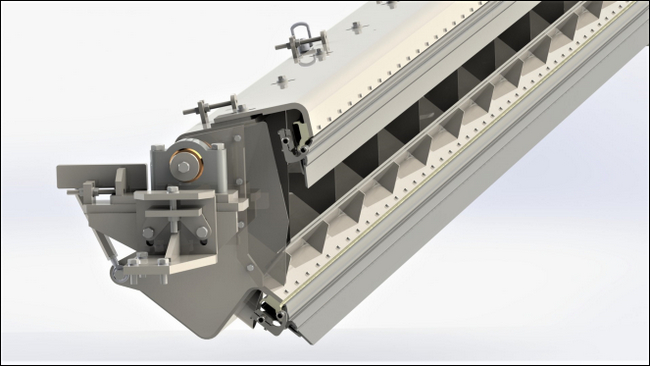

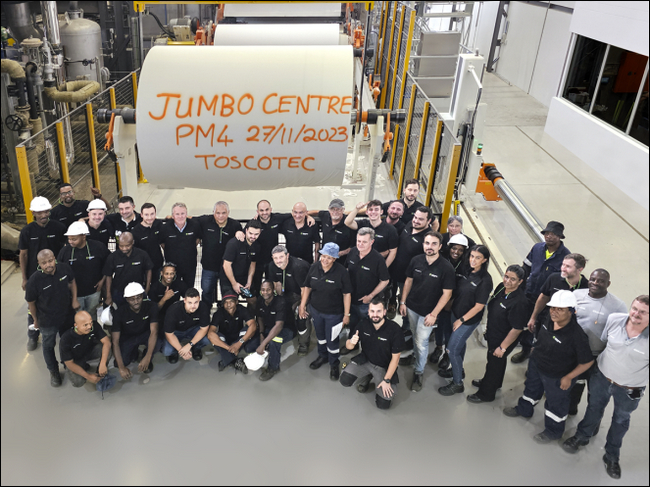

The Group Division Paper once again made the largest contribution to the sales and earnings of the Voith Group. The operating result (EBIT) reached € 145 million (previous year: € 131 million). Sales grew to € 2.24 billion (previous year: € 2.20 billion). Orders received decreased slightly on the high previous-year figure to € 2.10 billion (previous year: € 2.26 billion).

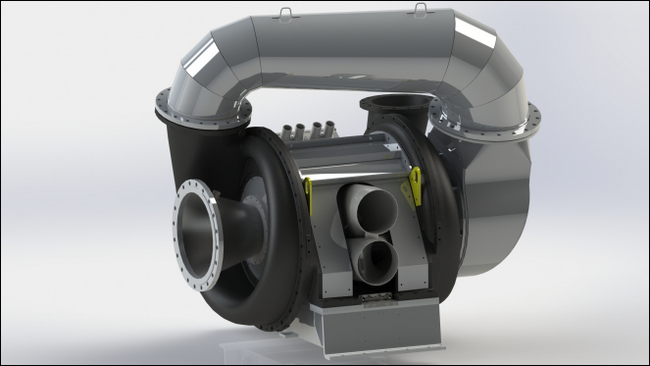

The Group Division Turbo recorded the clearest sales and EBIT growth of all three Group Divisions, also benefiting from the two acquisitions. Sales and EBIT increased to € 1.99 billion (previous year: € 1.56 billion) and € 80 million (previous year: € 48 million), respectively. Orders received grew from € 1.64 billion to € 2.05 billion.

Outlook 2023/24 fiscal year: Slight decline on high level of orders received and sales, further increase in earnings anticipated

The current 2023/24 fiscal year is accompanied by great economic and geopolitical uncertainties. Alongside the war in Ukraine, these include the new conflict in the Middle East. Economic factors are also placing a burden on the development of the global economy. The extraordinarily high inflation rates in most countries and the associated restrictive monetary policy by central banks are dampening global economic growth. The growth prospects worldwide are continuing to deteriorate as a result.

Voith sees itself well prepared to meet these challenges. The broad sectoral and geographical diversification; the established market position in all three Group Divisions; and, a sound balance sheet makes the Company resilient. A conscious decision has been made to continue investing, even in times of crisis, in research and development, partnerships and innovations, vocational training and in the ongoing strategic and organizational development of the Company. By doing so, Voith is in a good position to continue generating sustainable and profitable growth.

For the 2023/24 fiscal year, Voith expects a stable development in its key performance indicators. In particular, profitability shall further improve. With regard to the operating result (EBIT), the Company assumes a slight increase. Likewise, growth in the return on capital employed (ROCE) is planned. The level of orders received and Group sales below the high figures seen in the reporting year is anticipated.

About the Voith Group

The Voith Group is a global technology company. With its broad portfolio of systems, products, services and digital applications, Voith sets standards in the markets of energy, paper, raw materials and transport & automotive. Founded in 1867, Voith today has around 21,000 employees and earns 4.9 billion euros in sales. It has locations in more than 60 countries and is one of Europe’s major family-owned companies.