PA CKAGIN G INTERN AT IONAL

13 Valmet 10 Climate Adaption 8 Industry News 6 GREEN

Volume 3 Number 9 - Winter 2022

Green Packaging International c Winter 2022 2 THE REGISTRATION PLATFORM IS NOW OPEN

elcome to the Winter issue of Green Packaging International. When this year’s re-registration was completed at the end of October, it become clear from the responses to our reader questionnaire that we needed to make some positive changes going forward.

While the printed issue was appreciated, it had become apparent that the magazine was invariably being added to internal libraries or filed for possible reference in the future. Given the ever-increasing cost of paper, print and postage, producing over 15,000 copies has become very expensive, so we have taken the decision to move GPI on-line, with supporting bi-monthly E-newsletters.

By introducing these newsletters we can better report on news and developments that affect our industry in a more timely fashion and they will also help to reduce our own environmental impact, which is, after all, what our industry is striving to achieve.

Feedback via the questionnaire also related to the recyclability of new packaging, highlighting this as a key subject when it came to packaging selection. As an industry, we are fortunate to have various options for greener packaging, including paper, board, glass and metal.

Our E-newsletters will be launched in February, 2023, so any contributions should be received no later than 13th February as a word document supported, where appropriate, by high resolution illustrations.

Publisher

PA CKAGIN G INTERN AT IONAL

Volume 3, Number 9 – Winter 2022

Contact information

PUBLISHER & EDITORIAL DIRECTOR

Vince Maynard

KVJ Enterprises, Tralee, Hillcrest Road, Edenbridge, Kent, TN8 6JS, UK

Tel: +44 (0) 1732 505724 Mobile: +44 (0) 7747 002286 Email: pulppaperlogistics@virginmedia.com

CONSULTANT EDITOR

David Young

Tel: +44 (0) 1737 551687 Mobile: +44 (0) 7785 796826 Email: youngeditorial1@btinternet.com

REGIONAL REPRESENTATIVE

Einar Johansson

Mobile: +46 70 234 80 85 Email: einar.lennart@gmail.com

PRODUCTION

Anthony Wiffen

ASTAC Business Publishing

Tel: +44 (0) 1460 261011 Mobile: +44 (0) 7557 280 769 Email: anton_print_1@mac.com

PRINTING

Brown Knight and Truscott Tunbridge Wells, Kent, TN2 3BW, UK Tel: +44 (0)1892 511678

©2022 KVJ Enterprises

Contents

Events

Industry News Green Packaging International c Winter 2022 3

ISSN 2634-4394

13 10

8

Cullen Pro Carton

W

Comment/Contents Sustainable watch packagingat ‘FachPack 2022’

Industry News 4

Vince Maynard

GREEN

Winners of cartonboard packaging design competition New factory and innovation design hub for Glasgow

Antalis acquires premium range of fine papers

PulPac raises €31 million from cross-industrial alliance

The recent closing of a €31 million private placement has been announced by PulPac. Combining key global partnerships and investments has enabled the company to accelerate the roll-out out of its patented Dry Moulded Fibre technology globally. In this private placement, leading strategic partners (Aliaxis, Stora Enso, Amcor Ventures and Teseo Capital) join the existing shareholders of PulPac and its network to form a cross-industrial alliance. PulPac’s commercialisation

is catalysed across the scaling value-chain with the alliance, validating the global interest for the technology and its positive impact as a coming world standard in sustainable packaging. Each partner contributes complementary marketleading know-how that strongly contributes to the acceleration of Dry Moulded Fibre.

Existing investors (WPP, PP Intressenter AB and Marcus Palm) also participated in the equity raise, together with the founders through DryFiber Holding AB. Jointly, the private placement will enable

PulPac to make further investments in three key areas:

c Increased global presence and representation of PulPac and Dry Moulded Fibre to cater to enormous demand, building out application and demonstration centres in key markets close to industrial partners.

c Increasing product standardisation and roll-out of applications ready to use, including commercial and thirdparty validation.

c Supply chain acceleration in key partnerships on production

platforms and tooling, ensuring availability of material, chemistries, machines and tooling throughout the regional supply chains.

Collectively, these initiatives will facilitate PulPac’s target of replacing one million tons of single-use plastics by 2025, saving up to five million tons of CO2 emissions and up to one billion litres of water than if the products had been made with conventional wet moulded fibre.

More information: www.pulpac.com

New sustainable water bottling alliance

Following its announcement of a partnership with Aerosol LLC in the Summer edition of GPI, the Ball Corporation and Boomerang Water, a leader in sustainable water filtration and bottling equipment, have formed an alliance to bring consumers a sustainable way to stay hydrated.

At resorts, cruise lines, campuses and elsewhere, Ball will provide its aluminium bottles for the Boomerang Bottling System, a cutting edge technology that offers the convenience of bottled water in a sustainable package while limiting the environmental impact.

Boomerang’s system washes, sanitises, rinses, filters, fills and caps fresh water in refillable, returnable and recyclable Ball aluminium bottles, therefore eliminating the waste and carbon emissions produced by manufacturing and transporting traditional, disposable bottles.

Its new technology was successfully launched and implemented at the Four Seasons Resort Hualailai where Ball’s aluminium water bottles are widely available throughout the facility.

More information: www.ball.com

Industry News Green Packaging International c Winter 2022 4

Fredrik Östbye (left), Head of Aliaxis Next, and Linus Larsson Green, CEO of PulPac, at the PulPac Tech Centre in Gothenburg, Sweden.

French company Antalis has acquired a worldwide portfolio of brands, amongst them the wellknown Conqueror, Curious Collection, Keaykolour, Pop’Set and Rives ranges from its former historical supplier Arjowiggins Scotland Ltd, which was placed into administration in September of this year.

Together with the Olin brand, this acquisition demonstrates Antalis’ commitment to continue to offer

an attractive premium range of fine papers, including text and cover, letterheads, textured boards, premium coloured offset,lLabels and envelopes to its customers, printers, brandowners and creative agencies.

“We are happy to provide a longterm future for these iconic brands,” declared Xavier Jouvet, Antalis Group Papers Director. “We are already working on relaunching these brands with the support of best-in-class suppliers for a renewed assortment

with a focus on quality and service levels. In the meantime, we have also acquired the vast majority of the remaining finished goods of these brands. This additional stock, on top of the current inventory we already have in our warehouses, should allow us to respond to most of our customer demand in the coming months until the transition to new sourcing in Q1 2023.

“In countries where Antalis or other KPP Group distribution companies

Antalis acquires premium range of fine papers Management changes at Pro Carton and CEPI Cartonboard

It has been announced that Michele Bianchi (CEO of RDM Group) has been appointed as the new President of Pro Carton. The appointment was recently confirmed at the Annual General Meeting in Krakow, Poland. Michele will follow Horst Bittermann, who stepped down from his position after four years in office. Horst will head a consultation and reorganisation process and hold the position of Director-General for Pro Carton. Winfried Mühling will continue to serve Pro Carton in the role of Marketing and Communication

Director.

Members of both industry associations, Pro Carton and CEPI

Cartonboard, have expressed their intention to explore the possibility of merging into one strong association under the name Pro Carton. The main objective is to move closer together for more effectiveness, efficiency and voice of representation through new specific work streams, Marketing and Communications, and Public Affairs. The consultation process with the responsible resource, the DirectorGeneral, has already started and should be completed in 2023.

The new organisation will allow a stronger alignment of activities, drive

are not directly present, our plans are to continue to make these brands available through a network of distribution partners,” he added.

Alistair McAlinden, Managing Director at Interpath Advisory and Joint Administrator, said: “We are pleased to have concluded this transaction which safeguards the future of this portfolio of premium fine papers”.

More information: www.antalis.com

synergies, strengthening the voice of the industry and enforcing stronger member engagement.

Michele stated, “We are convinced that the new organisation will be the right platform for the future of the European cartonboard and folding carton industry. With stronger member engagement, co-operation across industry borders and closer collaboration with ECMA, we are confident our union will support the sustainable growth of our industry”. More information: www.procarton.com

Industry News Green Packaging International c Winter 2022 5

Michele Bianchi, President of Pro Carton.

Companies collaborate on MFL

The Moulded Fibre Labelling process allows MFL label and packaging to become one – in a single step. PulPac licensee Hébert Group, together with MCC Verstraete, Pagès Group and PulPac, is in a process of commercialising Moulded Fibre Labelling for Dry Moulded Fibre products, thus taking a lead in sustainable fibre-based packaging with high-quality decoration.

The Hébert Group is setting up production with PulPac Modula to supply the company’s clients – key FMCG brands, with Dry Moulded Fibre products. Hébert Group was an early adaptor of IML, now a widely used technology for high-quality graphic labels on plastic packaging. Together with PulPac, MCC

Verstraete and Pagès Group, Hébert Group is now developing MFL for Dry Moulded Fibre products and the parties aim to bring the pioneering concept to market.

MFL provides maximum print quality and precise printing, easyto-modify graphics and singlematerial packaging. These provide very competitive advantages as packaging is expected to play an increasingly important role in branding and promotion, demanding highly customised or personalised campaigns. The glue-free MFL labels used for Dry Moulded Fibre applications are fibre-based, and fully recyclable, ensuring that the final MFL packaging is fully compatible with the paper recycling stream and is biodegradable. The label is fused

with the product in-line as it is moulded.

Julien Hébert, Technical and Sales Director, Hébert Group, said: “We strongly believe in Dry Moulded Fibre as the future solution for fibrebased packaging. Having worked with IML for more than 35 years, we have continuously perfected the technology. Combining it with Dry Moulded Fibre was a given. The results we’ve achieved together in the lab are very promising and our respective teams are looking forward to bringing this gamechanger to the market”.

Nico Van de Walle, Product & Circular Economy Manager at MCC Verstraete, confirmed: “We have a stated and long-lasting commitment to be at the forefront of sustainable development.

Samples of MFL label and packaging made as prototypes.

Adapting our know-how in IML products and services to Dry Moulded Fibre allows us to offer a high quality and sustainable decoration method for dry fibre moulded parts to meet our sustainability strategy, which states that the final packaging should be recyclable, reusable, or compostable”

Romain Hervé, Business Development Director at Pagès Group, added: “As a leader in automation solutions driven by innovation, we are proud to contribute with our long experience of IML for the plastics industry and engineer it into this transformative solution for Dry Moulded Fibre packaging”.

More information: www.pulpac.com

Industry News Green Packaging International c Winter 2022 6

Recognition for Dries Van Noten bottle

The recently launched, refillable Dries Van Noten Eau de Parfum bottle was recognised as best in class in the category of Best Perfume Bottle and Flaconnage at the prestigious Formes De Luxe Awards in September. The eye-catching glass bottle is manufactured at Stoelzle Masnières Parfumerie and is comprised of ten shells on the bottom of the bottle, four materials (porcelain, plastic, wood and metal) and two types of lacquering (eight classic and two Quali Glass Coat 2.0, an exclusive STO ecological powder coating).

The first of its kind for Stoelzle, the innovative features entailed a development of ten products at once;

a complete multi-material product line, with the need to adapt the gluing process to take into account the dimensional differences, between the shell and the bottle, depending the material. Each of the ten bottles requires various bonding systems, culminating in a first for Stoelzle in combining so many materials at once.

The Dries Van Noten collectable bottle also offers a unique unscrewing system, with an internal thread so that the closing mechanism is invisible. A special key is supplied with the refill bottle to unlock the pump, as well as a funnel for easy filling. The innovative bottles are refillable and reusable, ensuring that they can be employed as a vase for a posy of flowers.

Alternatively, the bottles may be used as a perfume diffuser.

Creative Director of the brand that carries his name, Dries Van Noten was inspired by his passion for flowers and gardening when coming up with a concept for the bottles. The inspiration led to teaming up with 11 leading international perfumiers that interpreted different aspects of the unique design.

The brand entrusted Stoelzle Masnières with the exclusive production of both the glass and the decoration of these refillable bottles, which like the world of Dries Van Noten, are full of striking visual statements.

For Dries Van Noten, beauty,

integrity and sustainability are the roots of everything that is developed. All of its products are designed to be refillable and thus have less impact on the environment. The bottles are postconsumer recycled glass integrated with 11.6% of recycled industrial glass.

The beautiful Dries Van Noten bottles are available in ten variations of decoration methods, eight of which are lacquered: Jardin de l’Orangerie; Neon Garden; Rosa Carnivora; Cannabis Patchouli; Voodoo Chile; Rock the Myrrh; Fleur du Mal; andSoie Malaquais. The other two are powdered (Quali Glass Coat 2.0): Raving Rose; and Santal Greenery. More information: www.stoelzle.com

New designer for Cullen’s packaging

Following the announcement by Cullen Eco-Friendly Packaging of plans to invest £15 million in a new innovation and design hub, as well as an additional factory to meet soaring global demand for its moulded fibre and corrugated cardboard alternatives to single-use plastic packaging, the company has appointed Adam Troy as Senior Packaging Design Manager. His task will be to create an array of new design applications for its compostable corrugated cardboard materials.

Adam brings with him a wealth of experience in design management

from the likes of Elanders, WestRock Company and Chesapeake Branded Packaging. He will use his extensive experience to develop alternatives to plastic utilising corrugated packaging. These will help Cullen’s extensive array of brand clients to achieve sustainability goals, maximise brand impact and boost sales.

David MacDonald, Cullen’s owner, commented: “We’re growing fast and our exports tripled in the past five years, so it’s encouraging to see an increase in companies of all sizes, industry-wide, turning to our sustainable packaging solutions as

a greener alternative to single-use plastic. Bringing in a talented, creative and natural problem-solver like Adam is a great example of how Cullen is

meeting the rapidly-growing needs of sustainably-driven businesses, nationally and internationally”.

Adam Troy said, “As someone who is motivated by the opportunity to have a direct impact on the world, I am looking forward to starting a new role that will allow me to do exactly this. Cullen’s scale is unrivalled, making over one billion products for customers in over 34 countries. It’s a designer’s dream to be able to get innovation at that sort of scale that makes a genuine impact worldwide”. More information: www.cullen.co.uk

Industry News Green Packaging International c Winter 2022 7

New factory and innovation design hub for Glasgow

AGlasgow-based sustainable packaging innovator has revealed ambitious plans for a major expansion that will make it one of the world’s biggest fibre packaging manufacturers. Cullen Eco-Friendly Packaging is investing £15 million in

a new innovation and design hub, as well as an additional factory to meet soaring global demand for its moulded fibre and corrugated cardboard alternatives to single-use plastic packaging.

The growth plan will be a welcome employment boost as the firm is set to create more

than 120 new jobs at the site. Openings at Europe’s only combined manufacturer of moulded fibre and corrugated cardboard range from product design – where specialists develop the next world-changing sustainable products – to engineers and operators of Cullen’s in-house manufactured, bespoke machines

that power its 15 production lines that already produce 470 million pieces per year.

The expanded manufacturing facility increases the physical site to 14 acres and means Cullen can double its output to more than one billion pieces per year. The products include everything from

Industry News Green Packaging International c Winter 2022 8

Cullen

the ubiquitous supermarket avocado trays, coffee shop cup carriers and vital healthcare products made of moulded fibre created on site, to more intricate bespoke packaging that protects everything from fine wines to high-end electrical devices.

Leading global fast food chains, supermarkets and major national

healthcare services are driving a rethink in plastic packaging. In response, Cullen is launching its new world-class innovation design hub.

Earlier this year, the Cullen team developed one of the world’s most innovative moulded fibre dry goods packaging products, The Fibre Bottle, of which the company produces 270

million units per year. The innovation enables brands producing goods such as vitamins, supplements, dry foods, homecare and horticultural products to remove 270 million single-use plastic bottles or pouches from shelves annually.

David MacDonald, Cullen Eco-Friendly Packaging’s Owner, said: “It’s hugely exciting. The world’s biggest companies, across multiple industries, are looking to moulded fibre to solve many of their sustainability challenges faster than seems possible. To win, they need disruptive thinking – brilliant design and inspired innovation, but they also need those new products made at scale. That’s the really hard part, but we rise to that seemingly impossible and urgent challenge. Indeed, the expansion further enhances our ability, enabling Cullen to deliver more than one billion compostable and recyclable products per year. That makes us almost unique, globally, at helping to solve the biggest packaging challenges we’ve ever known.

“We have customers in over 34 countries, and our exports have tripled in the last five years. Across the whole business we have grown exponentially and expect that growth to continue at pace.

“I’m glad to be able to continue to increase game-changing capacity in our Scottish home. We have talent here, an incredible workforce, so are

excited to create green careers that people can be truly proud of.”

Sian Sutherland, co-founder of A Plastic Planet, agreed: “In our work at A Plastic Planet, we encounter many groundbreaking organisations, but rarely do they have the experience, ambition, talent and innovation of Cullen. They are the real deal; totally focused on the right metrics of success – people and planet before profit. Cullen is a business that has the potential to eliminate billions of pieces of toxic, indestructible plastic and sees no limit to the positive impact they can drive. Ideas are a start, but implementation is everything. Cullen’s ability to scale rapidly and execute a big vision is extremely unusual”.

Cullen’s self-funded investment comes on the heels of fast-rising global demand for its products. It supplies global names across 34 countries in the medical, food and drink, produce, retail and industrial sectors. It already makes 30 million square metres of corrugated (cardboard) packaging per year and cleverly uses the offcuts in its on-site closed loop recycling facility to make moulded pulp, an environmentallyfriendly ‘fibre’ used in turn for packaging that, when finished with, can be disposed of on the compost heap.

More information: www.cullen.co.uk

Industry News Green Packaging International c Winter 2022 9

Cullen

Winners of cartonboard packaging design competition

The winners of the Pro Carton Young Designers Award 2022, the leading packaging design competition, were announced on 15 September.

Horst Bittermann, Pro Carton President, introduced the winners in front of a packed audience at the European Carton Makers Associations (ECMA) Congress, in Krakow, Poland. Across four categories, including Creative Cartonboard Packaging (Food & Drink); Creative Cartonboard Packaging (All Other); Creative Cartonboard Ideas; and Sustainability, the jury was amazed by the quality of the submissions, with the next generation of packaging designers demonstrating their creativity in problem solving when it comes to packaging design. Two more awards were presented to the best Newcomer and the Public Award.

Burak Ayataç, the designer of Twin Bags for popcorn and beverages, has taken the top spot in the ‘Creative Cartonboard Packaging: Food & Drink’

Twin Bags for popcorn and beverages.

category, as well as scooping the Public Award. The Turkish student at Istanbul Technical University has solved the problem of transporting cinema snacks, creating an inventive way to carry two popcorn bags and

canned drinks from the counter to seat one-handed. The cartonboard design is not only useful but also collapsible, sturdy and easy-to-use. The cleverly-designed perforated base allows for seamless separation

to share out the snacks and drinks once seated. Roland Rex, one of the judges, described Burak’s design as ‘well executed’ and noted how the design provides room for additional printing and marketing opportunities.

This entry also won the Public Award, where the general public voted for their favourite creative carton concept in four categories: Food & Beverage, All Others, Creative Cartonboard Ideas and Sustainability.

Taking the top accolade in the ‘Creative Cartonboard Packaging (All Other) category for their Float design was duo Jana Becker and Wilma Schulz from the Münster School of Design in Germany. The aestheticallypleasing design offers a sustainable alternative to traditional packaging for bath salts. Demonstrating the structural capabilities of cartonboard, Float uses a creative folding mechanism constructed from one piece of cartonboard, allowing the bath salt package to transform into a floating ship. As you bathe, the ship sails around, turning your bath

Float design for bath salts.

Industry News Green Packaging International c Winter 2022 10

Pro Carton

into a relaxing, aromatic experience. Judge, Sanjeev Das, described Float as: ‘beautiful packaging of bath salts…with simplicity in execution, yet offering an incredible consumer experience’.

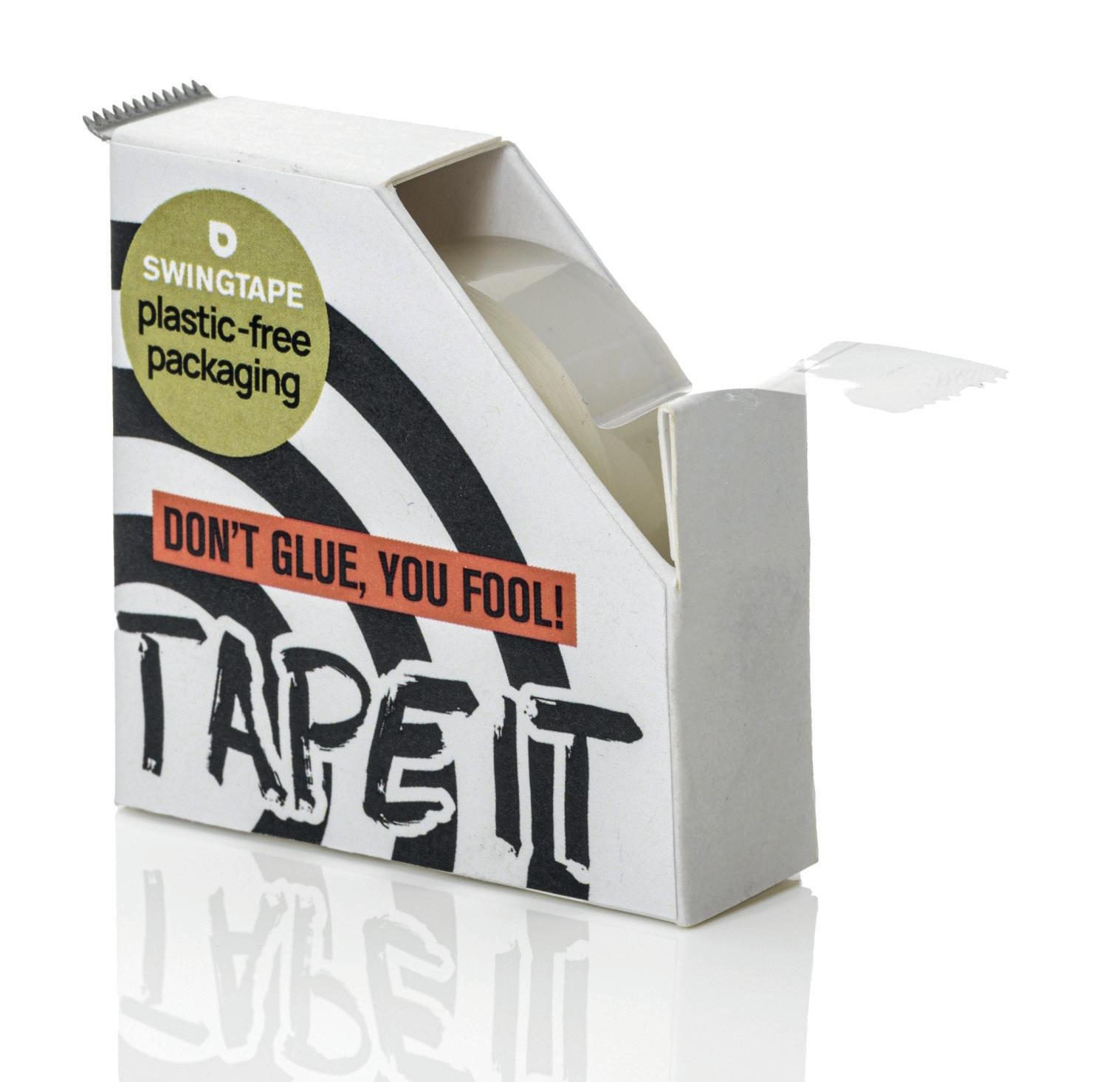

Demonstrating the opportunities to replace plastic with cartonboard, Austrian student Christian Jammernegg, was announced as the winner of the ‘Creative Cartonboard Ideas’ category with the design Swingtape. This compact tape dispenser design not only offers a sustainable alternative to plastic, but also solves the frustrating problem of tape re-sticking to the dispenser. Once a piece of tape is ripped off using the attached cutter, the tape roll will swing forward to allow easy access to the next piece. Roland Rex praised Swingtape in his judging remarks, saying: ‘This is an absolutely genius piece of packaging. The inventiveness and thought that went into it was thrilling’.

The penultimate award of the evening put sustainability firmly under the spotlight when Anna Grubing, Daria-Luna Sagurna and Sabrina Hofmann, from the Münster School of Design in Germany, were announced as winners for their entry:

Align. The ‘Sustainability Award’ winner tackles single use plastic packaging in the technology industry, specifically cable and wire packaging, by replacing it with cartonboard. The sustainable, consumer-focused product has two removeable tubes, which protect the original cable during initial transport, giving Align endless use for organising and sorting wires. The jury loved the entry, praising the students’ ‘very smart design thinking’.

The final Pro Carton Young Designer Award recognises aspiring new packaging designers and submissions from institutions entering the awards for the first time. Here, Oxana Zaporoniuc, from the Technical University of Moldova, won the ‘Newcomer’s Award’. The student’s sleek packaging design for liquids demonstrates the strength and durability of cartonboard. Oxana aimed to create packaging that removes the need for unnecessary

material, without compromising on protection, while also delivering shelf appeal. The eye-catching protective packaging uses smart lock-in features that do not obstruct any of the fragile items’ design or packaging. This year’s judges described the design as ‘a very good example of how to use the full potential of cartonboard’.

Winfried Muehling, General Manager of Pro Carton, said: “We were delighted to see a recordbreaking number of entries for this year’s Pro Carton Young Designer Awards. This year, we received more than 800 submissions from over 100 universities and educational institutions across Europe, a 28% increase on 2021. Each year, we see such ingenious, purposeful designs, which solve a wide range of problems, from daily inconveniences to global issues. The entries this year perfectly highlight the versatility of cartonboard. We thank everyone for their efforts and send huge congratulations to the 2022 winners. We cannot wait to see the impact these inspiring young designers have on the future of the packaging industry”.

More information: www.procarton.com

Industry News Green Packaging International c Winter 2022 11

Swingtape compact tape dispenser.

Cartonboard packaging for liquids.

Pro Carton

Align cable and wire packaging.

2 82.5%

Sustainable watch packaging at ‘FachPack 2022’

The FachPack packaging trade fair took place in Nuremberg from September 27-29. The event has been held for more than 40 years now and is one of the prime exhibitions for the packaging industry and its customers in Europe. The guiding theme of the 2022 event was ‘Transition in Packaging’, a challenge for Udo Hollbach, Managing Director at the Griez site of Koehler Paper, and Thilo Mühle, CEO of Mühle-Glashütte, who presented the sustainable watch packaging collaboration project between both family businesses on the Koehler stand at the exhibition.

Koehler Paper makes environmentally-friendly watch roll and the project involved the creation of a premium, yet sustainable, recycling paper for a luxury watch. As far as the watch manufacturer is concerned, implementing a sustainable packaging solution is not only a self-imposed obligation, but also an important step towards the future.

Udo Hollbach said, “There is a clear trend when it comes to packaging material options. Paper scores points right across the board and is becoming an increasingly important factor in consumer decisions”.

Together with ad agency Lehanka Kommunikationsagentur, the

packaging for a new S.A.R. MissionTimer TITAN model was designed on the occasion of the watch’s 20th anniversary and once all creative minds were aligned, a special unboxing experience for customers was brought to life.

The project makes it clear that there are no limits to creativity when it comes to the design of product packaging. In fact, the term ‘luxury packaging’ was the exact opposite of ‘sustainable packaging’ not that long ago – this project is a prime example

of how the two can go hand-in-hand without any major problems. It is the use of high quality recycling paper that sets this luxury eco-friendly packaging apart.

More information: www.koehlerpaper.com

Events Green Packaging International c Winter 2022 13

Udo Hollbach (left) and Thilo Mühle at FachPack 2022 (picture courtesy of the Koehler Group).