Displaying items by tag: Andritz

ANDRITZ to supply key equipment and processes to Stora Enso in Oulu, Finland

ANDRITZ has received an order from Stora Enso to deliver a new debarking line, a new biomass boiler, and to upgrade the recausticizing plant for its Oulu mill in Finland.

- ANDRITZ sustainable technologies help Stora Enso achieve its sustainability goals

- ANDRITZ debarking line minimizes wood losses, biomass boiler ensures lowest emissions, and recausticizing plant minimizes effluent volume

ANDRITZ is suppling sustainable technologies, including a new debarking line, a new biomass boiler, and a recausticizing plant upgrade, to help Stora Enso achieve its sustainability commitments at its Oulu mill, Finland. © ANDRITZ

ANDRITZ is suppling sustainable technologies, including a new debarking line, a new biomass boiler, and a recausticizing plant upgrade, to help Stora Enso achieve its sustainability commitments at its Oulu mill, Finland. © ANDRITZ

The scope of supply, on EPC basis, includes:

- New debarking line, equipped with digital Smart Wood Processing products, with a capacity of about 270 m3 solid wood over-bark per hour, providing excellent debarking results with very low wood losses.

- New biomass power boiler with a steam production capacity of 216 t/h based on the high-efficiency ANDRITZ EcoFluid bubbling fluidized bed (BFB) technology, ensuring low NOx and other gaseous emissions.

- Recausticizing plant upgrade for 5,000 m3/d white liquor production. The delivery includes new generation LimeLine recausticizing equipment such as LimeWhite-H filter maximizing the white liquor quality and minimizing effluent amount, and StiroX white liquor oxidizer.

The order is part of Stora Ensoʼs project to convert a former paper machine at the Oulu mill into a high-volume consumer board production line.

This order demonstrates the ongoing solid business relationship between ANDRITZ and Stora Enso. ANDRITZ also supplied production technologies and key process equipment to the Oulu mill for the first machine conversion from paper to kraftliner in 2021, which included the rebuild of the fiberline and drying machine, as well as modernization of the stock preparation system.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro, and Separation. Technological leadership, global presence and sustainability are the cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 27,900 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation. Boilers for power generation, flue gas cleaning systems, various nonwoven technologies, panelboard (MDF) production systems, as well as recycling and shredding solutions for numerous waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ to supply VIB moisturizing technology for Xianhe Group in Hubei Province, China

International technology group ANDRITZ has received an order from Xianhe Co., Ltd., in Hubei Province, China, for the supply of VIB moisturizing technology for two new paper machines.

The plants will supply 300 t/day décor paper with a machine speed of 1,000 m/min and a paper width of 3,860 mm. The equipment installation is expected to be completed during the second half of 2023.

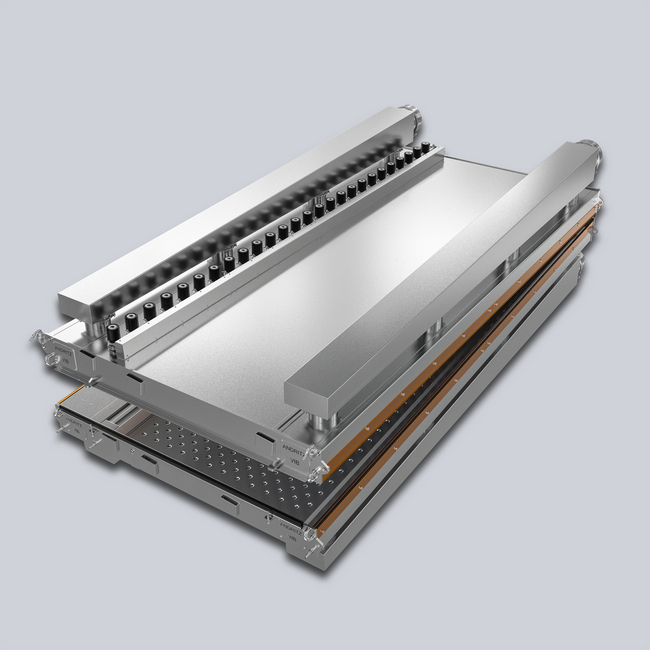

The air water spray will be installed below the last cooling cylinder to increase the paper moisture up to 3.5% with a 2-sigma value below 0.1%. The VIB MoistureTech will be installed before the machine calender to ensure highest paper quality standards. Precise steam application and the unique design comprising dwell zone provide best paper parameters for efficient calendering. The VIB MoistureTech is not only used for decor paper but also for conditioning and curl control on laminated grades and silicone papers.

The scope of supply also comprised spray boom with 80 nozzles, air and water supply, edge trim control, VIB MoistureTech with 2 x 30 zones, steam supply including desuperheater system as well as the corresponding CD control hard- and software and control cabinets. ANDRITZ will execute installation supervision, start up and performance optimization.

ANDRITZ VIB MoistureTech © ANDRITZ

ANDRITZ VIB MoistureTech © ANDRITZ

During the last decade, ANDRITZ has already supplied VIB technology successfully for several paper machines of Xianhe Group. Considering the experience with ANDRITZ VIB this new order placement was corollary to strengthen the long-lasting partnership between ANDRITZ and Xianhe Group.

As a world market leader, ANDRITZ offers steam-profiling solutions for the entire paper machine and paper moisturizing technology to improve the sheet’s cross-directional moisture profile.

Xianhe Co., Ltd. is the leading enterprise of specialty paper in China and one of the largest enterprises in the research and development and production of functional materials in China. It has the production capacity of the whole industrial chain including forest land, chemical industry, pulp making, energy, logistics, and paper products. The company invested 10 billion RMB in Shishou, Hubei Province with an annual output of 2.5 million tons of pulp and paper, so called "high-performance new material recycling economy" project.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro, and Separation. Technological leadership, global presence and sustainability are the cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 27,900 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation. Boilers for power generation, flue gas cleaning systems, various nonwoven technologies, panelboard (MDF) production systems, as well as recycling and shredding solutions for numerous waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ receives follow-up order from Xuan Mai Paper, Vietnam

International technology group ANDRITZ has received an order from Xuan Mai Paper Co. Ltd. to supply a PrimeLineCOMPACT S1800 tissue machine for its production line PM2 at its mill located in Ho Chi Minh City, Vietnam. The tissue machine will enable the production of high-quality tissue grades made of either 100% virgin or 100% deinked pulp (DIP). Start-up is scheduled for 2024.

The tissue machine will have a design speed of 1,800 m/min, a width of 2.85 m and a design capacity of 72 admt/d. The suction pressure roll will be covered with a poly-soft polyurethane cover for high-performance dewatering. The PrimeDry Steel Yankee (16 ft. diameter) in combination with a steam-heated COMBO hood enables highly efficient drying with substantial energy savings.

ANDRITZ will also deliver stock preparation and automation equipment, as well as process-, fan- and multistage pumps and auxiliaries.

The signing of the contract for the follow-up order. "Photo ANDRITZ"

The signing of the contract for the follow-up order. "Photo ANDRITZ"

Pham Van Dung, Vice President of the Board of Xuan Mai Paper, says: “ANDRITZ’s innovative tissue solutions offer both economic and ecological benefits. Professional service offers perfectly complement the technology. Since 2012, we have established a long-term cooperation that is built on mutual respect and trust. Our joint projects are in the areas of old corrugated containerboard lines, deinked pulp lines, and tissue production lines.”

In 2020, ANDRITZ already started up a complete tissue production line at Xuan Mai Paper. This follow-up order once again confirms ANDRITZ’s strong position as a long-term partner to the global tissue industry and as the number one supplier to the Asian tissue industry.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro, and Separation. Technological leadership, global presence and sustainability are the cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 27,900 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation. Boilers for power generation, flue gas cleaning systems, various nonwoven technologies, panelboard (MDF) production systems, as well as recycling and shredding solutions for numerous waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ to supply key components for broke handling to Sappi Austria, Gratkorn mill

International technology group ANDRITZ has received an order from Sappi Austria Produktions GmbH & Co KG to supply key components for a new broke handling system for its mill in Gratkorn, Austria.

Start-up is scheduled for the third quarter of 2023.

The new broke handling will be part of the production line PM9 producing high-quality wet strength paper, such as label paper in the future. ANDRITZ will deliver high-consistency (HC) pulping, high-density (HD) cleaning and deflaking for processing the special type of broke.

Specific trials on pulping and deflaking of wet-strength paper were conducted at the ANDRITZ stock preparation pilot plant in Graz, Austria in advance. The trials were carried out with comparable raw material from Sappi and confirmed the pulp properties and operating characteristics required by Sappi for the future.

hown on the right: ANDRITZ DeFlaker for optimal defibering © ANDRITZ

hown on the right: ANDRITZ DeFlaker for optimal defibering © ANDRITZ

Flavio Froehli, VP Marketing & Sales at Sappi Europe: “We are very pleased that we will also be able to produce wet-strength label paper at our Gratkorn mill in the future. This investment underscores our strategy to establish Sappi as the leader within the label sector, adding to the supply of value adding products across our entire business.”

Sappi Austria is part of the Sappi group, a leading global provider of sustainable wood fiber products and solutions, in the fields of dissolving pulp, printing papers, packaging and specialty papers, casting and release papers, biomaterials and bioenergy. Its mill in Gratkorn produces 950,000 tons per annum of high-quality, double- and triple-coated papers, used for premium quality publications all over the world, as well as one-side coated label papers. The mill also produces 250,000 tons per annum of totally chlorine-free (TCF) bleached chemical pulp for its own consumption and it has an annual sheet finishing capacity of 875,000 tons.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro, and Separation. Technological leadership, global presence and sustainability are the cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 27,900 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation. Boilers for power generation, flue gas cleaning systems, various nonwoven technologies, panelboard (MDF) production systems, as well as recycling and shredding solutions for numerous waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

Klabin successfully starts up new gasification plant supplied by ANDRITZ

Klabin has successfully started up a biomass gasification plant at the Puma Unit, located in Ortigueira/PR, Brazil, with a new biomass treatment line supplied by ANDRITZ.

- The ANDRITZ gasification plant enables entirely fossil-free operation of the lime kiln by replacing 100% of the heavy fuel oil with a biomass-derived gas.

- Biomass gasification is part of ANDRITZ’s CircleToZero product portfolio, which focuses on optimizing side streams, creating new added-value products, and laying the foundation for zero emissions and zero waste production.

The gasification plant enables 100% fossil-free operation of the lime kiln by replacing all heavy fuel oil currently burned in one of the mill’s lime kilns, significantly reducing the Klabin pulp mill’s carbon footprint.

ANDRITZ gasifiers enable entirely fossil-free operation of lime kilns © Klabin

ANDRITZ gasifiers enable entirely fossil-free operation of lime kilns © Klabin

The main ANDRITZ scope of supply included:

- 51 MW gasification plant

- Belt dryer

- Multi-fuel lime kiln burner

- Biomass handling equipment

- Electrical building

ANDRITZ was chosen as the gasification supplier because of successful previous references and was also the main supplier of Klabin’s Puma I and II projects, which were started up successfully in 2016 and 2021, respectively.

ANDRITZ gasification plants are part of the company’s CircleToZero initiative, which includes new technologies aimed at optimizing pulp mill side streams. This global initiative for our pulp and paper customers brings together the continuous development and improvement of existing ANDRITZ technology solutions with an ambitious innovation goal for the future: To eliminate unused side streams, create new added-value products, and lay the foundation for zero emissions and zero waste production.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro, and Separation. Technological leadership, global presence and sustainability are the cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 27,900 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation. Boilers for power generation, flue gas cleaning systems, various nonwoven technologies, panelboard (MDF) production systems, as well as recycling and shredding solutions for numerous waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ Oy and LUT University open new fiber research laboratory in Lahti, Finland

ANDRITZ Oy, part of international technology group ANDRITZ, and LUT University (Lappeenranta-Lahti University of Technology LUT) launched an extensive collaboration in the field of fiber technology a year ago. As a result, a new state-of-the-art research laboratory for the joint development of sustainable fiber technologies will open at the LUT campus in Lahti on November 3, 2022. The unique corporate collaboration model is a substantial step towards a new way of sharing infrastructures and intensifying research work with external partners.

The new research laboratory and LUT's academic expertise bring added value to ANDRITZ’s own research and innovation. Collaboration with LUT strongly supports ANDRITZ’s development of highly efficient, sustainable products and technologies. In addition, ANDRITZ aims to strengthen its position as a pioneer in innovative technologies whilst supporting its position as one of the most attractive employers in the Finish fiber industry.

Kari Tuominen, President and CEO of ANDRITZ Oy, says: “Locating the research laboratory in Lahti will enable close collaboration between ANDRITZ and LUT researchers. Our cooperation has always been fruitful and effortless for both parties. We’re glad that LUT managed to build the laboratory nearly on schedule despite the logistical challenges related to the global situation.”

“The brand-new laboratory enables us to study, test and analyse on biomass-based fibres and fibre products even better than before. The new facilities will meet the needs of LUT research groups, ANDRITZ and regional industry,” adds Mari Kallioinen-Mänttäri, LUT University Dean.

As a result of the collaboration, a modern research laboratory meeting the highest industry standards will be opened on the LUT campus in Lahti, Finland. Photo: Andritz

As a result of the collaboration, a modern research laboratory meeting the highest industry standards will be opened on the LUT campus in Lahti, Finland. Photo: Andritz

The aim is to strengthen the bioeconomy cluster in the Lahti area and support the start-up and growth of new businesses. Biorefinery research currently employs four professors and ten researchers on the Lahti campus. LUT aims to increase the overall number to 40 in the near future.

Mari Kallioinen-Mänttäri points out that such a large-scale investment would not have been possible without considerable financial support by the university’s partners.

“Collaboration with ANDRITZ constitutes one of the largest business commissions in LUT’s history. In addition to current joint research, we are exploring possibilities to expand our collaboration beyond fiber research. For students, it will mean more thesis and job opportunities,” says Mari Kallioinen-Mänttäri.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro, and Separation. Technological leadership, global presence and sustainability are the cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 27,400 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation. Boilers for power generation, flue gas cleaning systems, various nonwoven technologies, panelboard (MDF) production systems, as well as recycling and shredding solutions for numerous waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ OY

ANDRITZ Oy is a leading global supplier of systems, equipment and services for the pulp and paper industry including wood processing, fiber processing, chemical recovery, and stock preparation. In addition, ANDRITZ Oy offers biomass boilers and gasification plants for energy production. ANDRITZ Hydro Oy, located in Tampere, delivers systems, equipment, and services for hydraulic power generation. The number of employees of ANDRITZ companies in Finland is approximately 1 600. The Center of Excellence are Kerava, Kotka, Lahti, Lappeenranta, Savonlinna, Tampere, Vantaa, and Varkaus. The Headquarters are located in Helsinki, Finland. President and CEO is Kari Tuominen. The company is owned by ANDRITZ AG of Austria.

LUT UNIVERSITY

Clean energy, water and air are life-giving resources for which we at LUT University seek new solutions with our expertise in technology, business and social sciences. We help society and businesses in their sustainable renewal. Our international community consists of 7 500 members. Our campuses are in Lappeenranta and Lahti, Finland. We are the world’s ninth best university for climate action. lut.fi/en

ANDRITZ to supply complete stock preparation line for wastepaper and special grades to Steinbeis Papier GmbH, Germany

International technology group ANDRITZ has received an order from Steinbeis Papier GmbH to supply a complete stock preparation line for conventional wastepaper and special grades, featuring a capacity from 78 to 200 t/d, for its mill in Glückstadt, Germany.

Start-up is planned for the end of the first quarter of 2023.

The new line will process various types of raw material, such as wet-strength and coated paper grades, labels with high wet strength, wet beer-bottle labels, and plastic-laminated wastepaper. In close collaboration with the customer, ANDRITZ has developed a comprehensive and particularly flexible technological solution that can be adapted to suit the different raw material requirements in terms of pulping and reject content. The scope of supply comprises the entire key equipment – from pulper feeding to fine screening – as well as basic engineering, supervision of installation, and start-up.

ANDRITZ FibreSolve FSH pulper © ANDRITZ

ANDRITZ FibreSolve FSH pulper © ANDRITZ

Andreas Rauscher, CEO of Steinbeis Papier GmbH, says: “With its products, Steinbeis Papier focuses on the principles of a resource-saving, circular economy. The latest product – called Steinbeis Label, a wet-strength and alkali-resistant label paper – brought about the idea of a new wastepaper processing line to create the preconditions for a closed-loop process in Glückstadt. Thus, wet-strength and alkali-resistant label paper can be recycled and used as the raw material for new label paper. The previously unused wastepaper volume that could not be processed using conventional methods and had to be incinerated can thus be made available to the recycling loop in future.”

Steinbeis Papier GmbH in Glückstadt is the European market leader for graphic recycled papers made from 100% wastepaper. The product range comprises printing and copy paper, coated offset paper, as well as paper for digital printing and label paper. Steinbeis Papier GmbH is part of Steinbeis Holding, which unites various companies from ecological paper production, the circular economy, and environmentally friendly energy production under one roof.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro, and Separation. Technological leadership, global presence and sustainability are the cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 27,100 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation. Boilers for power generation, flue gas cleaning systems, various nonwoven technologies, panelboard (MDF) production systems, as well as recycling and shredding solutions for numerous waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ invites you to “Tissue World Talks” on November 3, 2022

Talk, listen, debate with our expert Carlos Gallo, Director Tissue Technology and R&D, at Tissue World Talks in the online panel discussion on the future direction of the tissue market.

- Challenges for tissue manufacturers are rising substantially

- How can machine suppliers like ANDRITZ help to mitigates these challenges?

- Is sustainability at risk?

Tissue World Talks – the online panel discussion on November 3, 2022

Tissue World Talks – the online panel discussion on November 3, 2022

Interrupted supply chains, the threat of discontinued gas supply in several countries, and peak values for main cost components like fiber, gas and electricity - the challenges for operating tissue mills - not only, but especially in Europe – are becoming ever greater. Demand for tissue is expected to remain strong, but how can tissue manufacturers cope with these challenges when the pressure is coming from so many directions? How can tissue machine suppliers help to mitigate these challenges? Is now the time to pro-actively invest in new machines? What about sustainability?

It’s time to talk about implications and potential consequences, but also about possible solutions. Carlos Gallo, together with key industry leaders and you in the audience, will discuss the best way forward during Tissue World’s virtual panel discussion on November 3, 2022 at 11 AM CET (Central European Time).

ANDRITZ is looking forward to meeting you at Tissue World Talks! To register free of charge, please visit https://www.tissueworldmagazine.com/webinar/webinar-series-tissue-world-talks-the-road-to-dusseldorf/ or contact us at This email address is being protected from spambots. You need JavaScript enabled to view it..

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro, and Separation. Technological leadership, global presence and sustainability are the cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 27,400 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation. Boilers for power generation, flue gas cleaning systems, various nonwoven technologies, panelboard (MDF) production systems, as well as recycling and shredding solutions for numerous waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

Klabin successfully starts up the world’s first commercial-grade, concentrated sulfuric acid plant in a pulp mill

Klabin has successfully started up a sulfuric acid plant supplied by ANDRITZ at its Ortigueira/PR plant in Brazil. The plant is a world first and has the capacity to produce 150 tons of commercial-grade sulfuric acid per day from concentrated odorous gases and elemental sulfur. It serves the pulp lines at Klabin's Puma Unit and makes the site completely self-sufficient in sulfuric acid by recycling sulfur from the waste streams.

- ANDRITZ sustainable technologies enable production of commercial-grade sulfuric acid from the mill’s odorous gases, making the mill self-sufficient in sulfuric acid

- The plant is part of the ANDRITZ CircleToZero product portfolio that focuses on eliminating unused side streams, creating new added-value products and laying the foundation for zero emissions and zero waste production

The sulfuric acid plant helps Klabin to control the sodium and sulfur (Na/S) balance and also the sulfidity of the mill. In addition, less sulfate will now be discharged due to the optimized Na/S balance, hence improving the efficiency of input use at the Ortigueira plant. Furthermore, there is no need in future to transport hazardous inputs such as sulfuric acid to the plant and the unit also optimizes resources overall, with a large reduction in transportation volume. As the sulfuric acid plant meets stringent air emission limits, the process significantly improves the overall footprint of the Ortigueira mill.

Klabin's Director of Projects and Engineering, João Antônio Braga, says "Operation of the sulfuric acid plant at the Puma Unit, Ortigueira, represents a significant advance in the circularity of the installation. The new plant allows the Puma Unit to be self-sufficient in sulfuric acid, with the additional option of selling any excess production to the market. This innovative technology, a first in this industry worldwide, supports our efforts to optimize productivity and is an important milestone in our ambition to achieve our sustainability goals.”

The sulfuric acid plant at Klabin’s Ortigueira facility is the first worldwide to produce commercial-grade, concentrated sulfuric acid at a pulp mill © Klabin

The sulfuric acid plant at Klabin’s Ortigueira facility is the first worldwide to produce commercial-grade, concentrated sulfuric acid at a pulp mill © Klabin

Klabin's Manager of Projects, Recovery and Utilities, Walter de Oliveira, adds "The quality parameters are being met and the sulfuric acid is being used successfully in several operations at the plant, replacing the commercial acid we were using before. Besides optimizing resources, installation of the plant brings greater independence because we do not have to rely on an external supplier for our sulfuric acid needs.”

The ANDRITZ scope of supply included technologies on EPCC basis for handling elemental sulfur, combustion of sulfur and concentrated non-condensable gases (CNCG) to form sulfur dioxide (SO2), and conversion of sulfur dioxide into concentrated sulfuric acid, as well as a flue gas treatment system.

Sulfuric acid plants are part of the company's CircleToZero initiative, which includes technologies that aim to reduce and/or eliminate waste from pulp mills. This global initiative for pulp and paper customers brings the continuous development and improvement of existing ANDRITZ technology solutions together with an ambitious, future innovation goal: to eliminate unused side streams, create new value-added products, and establish a foundation for zero emissions and zero waste production.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro, and Separation. Technological leadership, global presence and sustainability are the cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 27,400 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation. Boilers for power generation, flue gas cleaning systems, various nonwoven technologies, panelboard (MDF) production systems, as well as recycling and shredding solutions for numerous waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ to supply complete OCC line to Minhan Paper, Vietnam

International technology group ANDRITZ has received an order from Minhan Paper Joint Stock Company to supply a complete OCC line for its mill in Van Lam, Hung Yen Province, Vietnam.

ANDRITZ will deliver the complete OCC line – from pulping to approach flow – including fiber recovery and also broke and reject handling. ANDRITZ will install several of its innovative Prime stock preparation products, such as a PrimeSolve LC system for optimum slushing at lowest fiber loss and efficient reject removal. PrimeScreens X with new PrimeRotors will enable highly efficient screening and fractionation at significantly lower energy consumption.

PrimeSolve LC system "Photo: Andritz"

PrimeSolve LC system "Photo: Andritz"

The new OCC line will have a capacity of 700 t/d and process a mixture of AOCC and LOCC as raw material to produce testliner and medium-weight board. The scope of supply also comprises the auxiliary equipment, detailed engineering as well as supervision of erection, commissioning, and start-up.

This order further strengthens ANDRITZ’s leading position in the Asian board production sector, with 30 OCC lines supplied to customers in South-East Asia since 2005.

Minhan Paper Joint Stock Company was established in 2020 and focuses on the manufacture of corrugated paper, paperboard and containerboard.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro, and Separation. Technological leadership, global presence and sustainability are the cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 27,400 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation. Boilers for power generation, flue gas cleaning systems, various nonwoven technologies, panelboard (MDF) production systems, as well as recycling and shredding solutions for numerous waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.