Displaying items by tag: Andritz

ANDRITZ to supply four high-speed tissue production lines to Bracell SP Celulose Ltda., Brazil

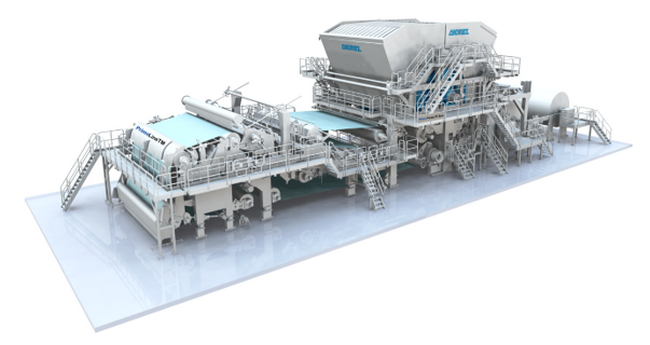

International technology group ANDRITZ has received an order from Bracell SP Celulose Ltda. to supply four PrimeLineTM W 2000 tissue production lines to its mill located in Lençóis Paulista, São Paulo. Start-up is scheduled for 2024.

The four tissue machines are of the type PrimeLineTM W 2000, with a design speed of 2,100 m/min and a working width of 5.68 m. They are equipped with fully cantilevered shoe presses for gentle dewatering and easy maintenance and 18 ft. steel Yankees with steam-heated hoods for energy-efficient drying.

The new tissue mill will be self-sufficient in steam and electricity consumption for the drying process, making it one of the tissue mills with the smallest CO2 footprint in the world.

ANDRITZ’s scope of supply – on EPC basis including civil construction – includes the stock preparation systems that will process slush pulp from Bracell’s own pulp mill, rewinders and roll handling, as well as roll covers, machine clothing, shoe press belts, and additionally more than 100 units of high-efficiency process pumps.

ANDRITZ PrimeLineTM W 2000 tissue machine. "Photo ANDRITZ"

ANDRITZ PrimeLineTM W 2000 tissue machine. "Photo ANDRITZ"

All four plants will be equipped with the Metris X integrated distributed control system (DCS), which ensures optimal plant operation. The combination of advanced data analytics, automatic condition monitoring system with Metris Vibe, integrated high-end advanced process controllers (APCs), artificial machine intelligence (AI), the implementation of digital twins and operator training simulators (OTS) support the rapid commissioning and optimal operation of the plants throughout their life cycle. Assistance in maintenance processes completes the package.

The lines will produce household paper, such as toilet paper, napkins, handkerchiefs, towels and facial tissue. Per Lindblom, Executive Vice President, Bracell, says: “Together with ANDRITZ, we recently started up the largest and greenest continuous cooking line in the world for dissolving pulp. When looking for a reliable full-line partner for our tissue business, ANDRITZ immediately came to mind.”

Carlos Gallo, Director Tissue Technology and R&D at ANDRITZ, explains: “Repeat orders like this once again confirm the success and customer benefits of our technologies. The four new lines will enable Bracell to produce high-quality tissue in a sustainable and environmentally friendly way.”

Bracell SP Celulose Ltda. is part of the Royal Golden Eagle (RGE) group, which manages world-class companies in the resource-based manufacturing industry. Among them is the Chinese tissue producer Asia Symbol, whose three new ANDRITZ tissue production lines will start up in the next few months.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro, and Separation. Technological leadership, global presence and sustainability are the cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 27,400 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation. Boilers for power generation, flue gas cleaning systems, various nonwoven technologies, panelboard (MDF) production systems, as well as recycling and shredding solutions for numerous waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

Sustainability in practice – ANDRITZ introduces performing technology solutions at MIAC

International technology group ANDRITZ will be presenting its innovative technologies for sustainable paper production at MIAC 2022, booth #72, in Lucca, Italy, October 12-14, 2022.

The ANDRITZ main motto for this year's MIAC is Sustainability in Practice. ANDRITZ will be presenting innovative technologies that enable customers to save energy, water and raw materials. The product portfolio ranges from specific solutions for the entire paper and board production process – from fiber preparation to the paper and board machine – that help to reduce production costs and increase output and product quality.

ANDRITZ will offer a comprehensive program of keynote presentations every 20 minutes on the first two days of the trade show, showing how paper producers can save energy, water or raw materials with ANDRITZ solutions.

SHOWCASING SUSTAINABLE SOLUTIONS AT THE ANDRITZ BOOTH

To meet the requirements resulting from the constantly increasing amounts of rejects in RCF material, ANDRITZ offers the PrimeSolve LC system. The main advantages are the reduction of fiber losses and the optimized removal of rejects. In addition, significant energy savings can be achieved through a new design of the pulper and detrashing pump. It also has an influence on product quality and allows for a higher reject amount in wastepaper.

In the field of lightweight packaging paper grades, ANDRITZ offers the EDC Forming Fabrics design, a specific solution that allows utilizing a wide production window on sophisticated paper machines. Using case studies, ANDRITZ will show how the EDC Forming Fabric solutions help to improve machine efficiency maintaining stable machine operation with less water and fiber carryover. As a result, the cleanliness of the machine improves and brake risks of paper sheets are reduced. Better dewatering efficiency at reduced vacuum levels allows a cost-efficient operation. The improved retention and paper sheet strength results in lower retention agent and chemical consumption and offers further significant advantages for efficient energy and raw material use.

Regarding savings solutions, the focus is on innovative digitization solutions via the manufacturing process. One example is Fiber GPS. It is a kind of digital twin for the refining in the stock preparation area. Goal of the digital twin or simulation based on the Metris IDEAS application is to model paper quality parameters such as burst strength and tensile strength after stock preparation with the existing refiner equipment. The benefits for the customer are savings due to the usage of more wastepaper instead of expensive fresh fiber and an increase in production as fresh fiber is limited. Stabilization of all control loops also leads to a more stable operation of the paper machine.

FULL AGENDA OF KEYNOTE PRESENTATIONS, OCTOBER 12 AND 13

Chapter Water Savings

- Alternative fibers for tissue production at Essity Mannheim

- Multi-injection chamber for cleaner plant market

- Forming fabrics on packaging gap former applications

Chapter Energy Savings

- Prime in pulping with the PrimeSolve LC System

- Refiner exchange within 24 hours

- Dilution upgrade for screening systems

- Effective energy and fiber savings with VIB SteamTech

Chapter Raw Material Savings

- Bar-Tec U-Twist: the perfect balance of screening efficiency, capacity and runnability

- Metris addIQ RheoScan: automatic polymer dosage in sludge dewatering

- Tissue: digital solution to reduce breaks and increase capacity (with case study)

- Paper Board: digital Twin Fiber GPS to replace fresh fiber (with case study)

- Upgrade On-the-Fly: a unique method for upgrading aging automation systems

Chapter General Sustainability

- Recycled press felts for better CO2 balance

- Smart Rolls: efficient production with dynamic NIP profile monitoring

- Competitive set of refiner plates for best sustainability in every application

- Portfolio introduction to doctor, crepping and coater blades

- Fossil free energy

More insights to our keynote presentations at MIAC 2022, with the opportunity to register for an individual introduction also outside the show, can be found here: www.andritz.com/sustainability-in-practice

CONFERENCE SPEECHES

ANDRITZ will also be represented at the MIAC conference with the following contributions:

- Solutions for sustainable and profitable tissue production

Marci Cattani, MIAC Tissue Conference, 12 October 2022, 14:20 - Security requirements, level of security and protection of employees

Thomas Nagler, MIAC Paperboard Conference, 14 October 2022, 12:10

Guangxi Chongzuo Lelin Forestry Development produces first fibers with the world’s largest pressurized refining system

Guangxi Chongzuo Lelin Forestry Development Co. Ltd., China, has successfully produced the first fibers with its high-capacity pressurized refining system delivered by ANDRITZ. The new system features a design capacity of 80 bdmt/h and is currently the largest of its kind in the world to form part of the largest MDF line.

ANDRITZ installed the complete system, from chip washing to refining. It comprises a 74” single-disc refiner with the largest flat refining surface available and highest axial load capacity ever built. With an impressive height of nearly 2.4 meters and a total weight (empty) of 21.7 tons, the HC refiner, type S2074M, is a real giant – built for outstanding production rates.

Wei Rengang, General Manager, Guangxi Chongzuo Lelin Forestry Development, says: “The entire line, and especially our new HC refiner is really impressive – not only because of its dimensions. It has already shown very promising performance. Our thanks go to ANDRITZ for their hard work and the exceptionally good collaboration.”

Wei Rengang, General Manager, Guangxi Chongzuo Lelin Forestry Development (left) and Huang Yongli, Technology Manager, ANDRITZ Panelboard. Photo Andritz

Wei Rengang, General Manager, Guangxi Chongzuo Lelin Forestry Development (left) and Huang Yongli, Technology Manager, ANDRITZ Panelboard. Photo Andritz

Guangxi Chongzuo Lelin Forestry Development Co. Ltd. is part of the Lelin Group, headquartered in Nanning, Guangxi, which has been focusing on wood-based panel production for nearly 20 years. In addition to two biomass power plants, the company owns four wood-based panel manufacturing enterprises and will have an annual fiberboard output of 1,300,000 m3 after the new line is completed. The Guangxi Lelin Group is well-known for its high-quality products, ranging from door panels, engraving and milling panels to formaldehyde-free board and furniture board.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro, and Separation. Technological leadership, global presence and sustainability are the cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 27,100 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation. Boilers for power generation, flue gas cleaning systems, various nonwoven technologies, panelboard (MDF) production systems, as well as recycling and shredding solutions for numerous waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ to supply tissue production line to Yuen Foong Yu Consumer Products, Taiwan

International technology group ANDRITZ has received an order from Yuen Foong Yu Consumer Products Co., Ltd. (CPG) to supply a PrimeLineCOMPACT M1600 tissue production line (PM10) to its mill located in Chingshui, Taiwan, Republic of China. Start-up is scheduled for the fourth quarter in 2023.

The new tissue machine will feature a design capacity of 112 admt/d, a width of 3.65 m and a maximum operating speed of 1,650 m/min. The line will produce household paper, such as toilet paper, napkins, handkerchiefs, and facial tissue. It will be equipped with the new PrimePress XT Evo shoe press for high-quality tissue with excellent bulk and an 18-ft PrimeDry Steel Yankee with PrimeDry Canopy Hood for highly energy efficient drying and significant steam savings.

The scope of supply also comprises the stock preparation system, processing a mixture of NBKP (Needle Bleached Kraft Pulp) and LBKP (Leaf Bleached Kraft Pulp), a state-of-the-art approach flow and broke system as well as an ANDRITZ PrimeControl DCS System. ANDRITZ will also supervise installation, commissioning, start-up, and training.

ANDRITZ PrimeLine COMPACT tissue machine. Photo Andritz

ANDRITZ PrimeLine COMPACT tissue machine. Photo Andritz

Mr. Mingfa Tang, Vice President, Yuen Foong Yu Consumer Products Co., Ltd., says: “We are sure that ANDRITZ’s superior technology will perfectly meet our requirements, enableing us to produce products at best quality while keeping operating costs and energy consumption low.”

The order once more confirms the long-term and fruitful relationship between the two companies and ANDRITZ’s strong position as one of the global market leaders for complete tissue production lines.

Yuen Foong Yu Consumer Products Co., Ltd. (CPG) was established in 2007 as subsidiary of Yuen Foong Yu Group. CPG is a leading supplier of household products in Taiwan with well-known brands such as “Mayflower”, “Tender” and “Delight”, and operates the largest production plant for consumer paper in Taiwan.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro, and Separation. Technological leadership, global presence and sustainability are the cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 27,400 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation. Boilers for power generation, flue gas cleaning systems, various nonwoven technologies, panelboard (MDF) production systems, as well as recycling and shredding solutions for numerous waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ has received final acceptance from Eldorado for biomass handling plant

ANDRITZ has successfully received the Final Acceptance Certificate for a biomass handling plant at Eldorado’s Onça Pintada site in Três Lagoas, Mato Grosso do Sul. This plant is part of the first thermoelectric power plant in Brazil to consume eucalyptus stumps and roots.

The plant will be able to generate 50 megawatts of electricity from an innovative source – eucalyptus stumps and roots, the parts of the trees not used in the pulp manufacturing process. This expands the capacity to generate energy from waste material originating from reforestation crops that are maintained by the company itself in the states of Mato Grosso do Sul and São Paulo.

The daily processing capacity is 1,500 tons of material that formerly went to waste in the forest – enough to generate the electricity needed to light up a city of 700,000 inhabitants in a fully sustainable way, and this power will also be fed to the Brazilian national grid.

ANDRITZ Biomass Handling Plant at Eldorado. Photo: ANDRITZ

ANDRITZ Biomass Handling Plant at Eldorado. Photo: ANDRITZ

ANDRITZ has played a key role in the project – from the EPC model to design and supply of the unique solutions and technologies required to implement a generating system for renewable energy. Among the innovations are the truck dumpers designed to receive the chips for feeding the boiler. These chips are delivered by large-capacity vehicles.

The receiving system consists of two truck dumpers coupled to respective hoppers. There is a belt conveyor to receive the material from these hoppers and transport it to the pile. A stacker-reclaimer with a capacity of up to 40,000 m³ has the functions to form the pile and feed a second belt conveyor, which is responsible for transporting the material to the power boiler.

The project is a pioneering one and the first to use residues left over from pulp production. It promotes sustainable power generation initiatives, drastically reducing the impact on the environment and encouraging energy generation and pulp production that respects the boundaries of natural resources renewal.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro, and Separation. Technological leadership, global presence and sustainability are the cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 27,400 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation. Boilers for power generation, flue gas cleaning systems, various nonwoven technologies, panelboard (MDF) production systems, as well as recycling and shredding solutions for numerous waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

Guangxi Jingui Pulp and Paper, China, issued the Final Acceptance Certificate for two P-RC APMP lines upgraded by ANDRITZ

International technology group ANDRITZ recently received the Final Acceptance Certificate for the upgrade of two ANDRITZ P-RC APMP (Pre-Conditioning Refiner Chemical Alkaline Peroxide Mechanical Pulp) fiberlines delivered to APP’s Guangxi Jingui Pulp and Paper, Guangxi Province, China.

The fiberlines – originally supplied by ANDRITZ in 2010 and the first mechanical pulping systems ever supplied to APP – were rebuilt to expand the aggregate capacity significantly and thus meet the considerably raised mechanical pulp demand resulting from the customer’s new board production line.

The project comprised the rebuild of the chip pre-treatment system for optimum chemical impregnation and the upgrade of the existing high-consistency (HC) refining stages with advanced feeding systems to ensure high capacity and even feeding. A new fiber-steam separation stage contributes to energy-efficiency by maximum steam recovery and low fiber losses in the steam.

TX68 refiner with advanced feeding system © ANDRITZ

TX68 refiner with advanced feeding system © ANDRITZ

The successful start-up was managed by the mill staff, supported by experienced engineers from ANDRITZ China on site as well as with the remote support from ANDRITZ experts in Europe.

Guangxi Jingui Pulp and Paper was established in 2003 and is part of Asia Pulp and Paper (APP), a leading global player in the production of a broad range of tissue, packaging, and paper products.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro, and Separation. Technological leadership, global presence and sustainability are the cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 27,400 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation. Boilers for power generation, flue gas cleaning systems, various nonwoven technologies, panelboard (MDF) production systems, as well as recycling and shredding solutions for numerous waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

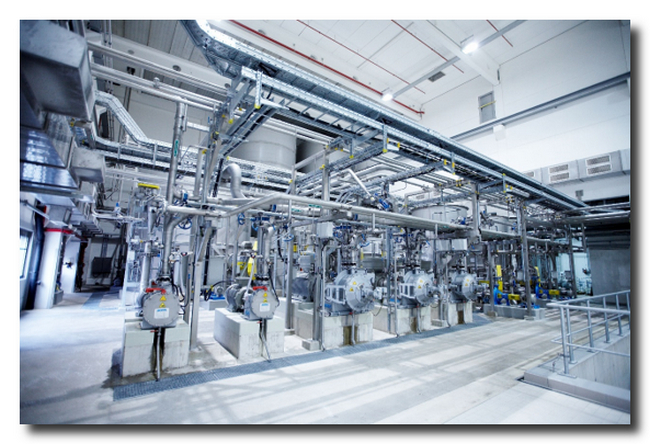

ANDRITZ to supply four stock preparation systems for tissue production to Guangxi Sun Paper, China

International technology group ANDRITZ has received an order from Guangxi Sun Paper Co., Ltd. to supply four stock preparation systems for its tissue machines PM 9 to 12 in Beihai, Guangxi Province, China. Start-up is scheduled for the third or fourth quarter of 2022.

The state-of-the-art stock preparation systems have an aggregate design capacity of 360 tons per day and process NBKP (Needle Bleached Kraft Pulp) and LBKP (Leaf Bleached Kraft Pulp) to produce tissue. ANDRITZ will install the complete process technology from pulping to refining, including fiber recovery. The scope of supply also comprises erection, commissioning, start-up, training, and service.

ANDRITZ stock preparation system “Photo: ANDRITZ”.

ANDRITZ stock preparation system “Photo: ANDRITZ”.

Guangxi Sun Paper and ANDRITZ have maintained a close business relationship for many years. Top-quality and energy-saving technology, as well as professional support during the complete project phase, were the decisive factors for once again placing their trust in ANDRITZ.

Since 2005, ANDRITZ has successfully supplied more than 100 stock preparation and paper machine approach flow systems for tissue production mills in China. The order once more confirms ANDRITZ’s strong position in this sector.

Guangxi Sun Paper was established in 2019 to build an integrated pulp and paper mill in Beihai. The mill will be built in two phases over a period of approximately five years. When completed, it will have a total annual capacity of 3.5 million tons of pulp and paper.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro, and Separation. Technological leadership, global presence and sustainability are the cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 27,100 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation. Boilers for power generation, flue gas cleaning systems, various nonwoven technologies, panelboard (MDF) production systems, as well as recycling and shredding solutions for numerous waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ to supply complete OCC line to Shanying Paper (Jilin), China

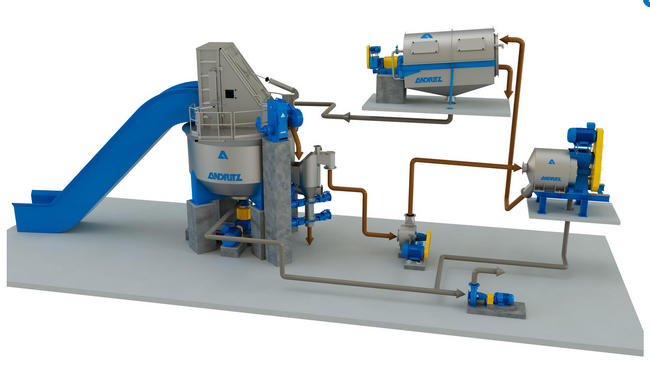

International technology group ANDRITZ has received an order from Shanying Paper (Jilin) Co. Ltd. to supply a complete OCC line, including fiber recovery and reject handling system, for its mill near Fuyu City, Songyuan, Jilin Province, China. Start-up is scheduled for the second quarter of 2023.

The OCC line will have a capacity of 950 bdmt/d to produce fluting paper. Its special process set-up will meet the requirement for higher efficiency and lower power consumption.

ANDRITZ PrimeSolve LC system as part of the scope of supply © ANDRITZ

ANDRITZ PrimeSolve LC system as part of the scope of supply © ANDRITZ

Yang Zhenliang, General Manager, Shanying Paper (Jilin) Co. Ltd., says: “With this project, we are investing RMB 11.2 billion in the mill’s production of pulp and industrial packaging paper. We will generate about 2,000 new jobs and are targeting an economic and ecological win-win situation by using plant-based agricultural residue of local origin. The professional technology, numerous OCC references and an ideal energy-saving solution were the decisive criteria for us to place the order with ANDRITZ.”

Shanying Paper (Jilin) Co., Ltd. was established in 2018 and produces about one million tons of pulp and industrial packaging paper per year. The company is part of Shanying International Holdings Co., which is a leading enterprise producing various paper products, such as cultural paper, kraft papers, various grades of packaging paper and board, and corrugated cardboard boxes.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro, and Separation. Technological leadership, global presence and sustainability are the cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 27,100 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation. Boilers for power generation, flue gas cleaning systems, various nonwoven technologies, panelboard (MDF) production systems, as well as recycling and shredding solutions for numerous waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ to supply combi-pulping system to Sichuan Huaqiao Fenghuang Paper, China

International technology group ANDRITZ has received an order from Sichuan Huaqiao Fenghuang Paper Co. Ltd. to supply a patented combi-pulping system for its mill in Guanghan, Deyang City, Sichuan Province, China. Start-up is scheduled for the third quarter of 2023.

The technological solution provided by ANDRITZ will be the first of its kind in China and combines ANDRITZ FibreFlow drum pulping, LC (low consistency) pulping, and HD cleaning in one innovative system. The new combi-pulping system provides the advantages of both pulping technologies to enable an exceptional design capacity of 2,200 t/d at superior slushing performance, low energy consumption and fiber loss, as well as highest operational availability. It will be part of production line PM2 and process LOCC (Local Old Corrugated Containers) for production of liner board.

ANDRITZ FibreFlow drum pulper. Photo: ANDRITZ

ANDRITZ FibreFlow drum pulper. Photo: ANDRITZ

Liu Jinwei, Deputy General Manager, Sichuan Huaqiao Fenghuang Paper Company, says: “Our experiences with the ANDRITZ approach flow system at our PM1 have been very positive. At the same time, we are impressed by the combi-pulping innovation and its successfully operating references in Malaysia and Vietnam. We have set very challenging targets as to capacity, flexibility and final pulp quality and believe that the ANDRITZ technology is the best solution on the market to achieve these goals.”

Sichuan Huaqiao Fenghuang Paper Co. Ltd. is a subsidiary of the Huaqiao Fenghuang Group, a multinational enterprise focusing on various business areas, such as agriculture, industrial manufacturing, real estate, commerce, finance, international investment, and trade. The Sichuan Huaqiao Fenghuang Paper Company is active in various business segments, such as papermaking, plastic packaging, and recovery of renewable resources.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services, and digital solutions for a wide range of industries and end markets. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro, and Separation. Technological leadership, global presence and sustainability are the cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 27,100 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation. Boilers for power generation, flue gas cleaning systems, various nonwoven technologies, panelboard (MDF) production systems, as well as recycling and shredding solutions for numerous waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ to supply SMART power boiler remote service using Metris BOA web platform to the Netherlands

International technology group ANDRITZ has received a five-year SMART service contract from BMC Moerdijk in the Netherlands to supply a Metris BOA platform including KPI dashboards and boiler operator advisor apps as well as automatically generated performance reports.

The SMART power boiler service uses the Metris BOA web platform – developed by ANDRITZ – to build KPI dashboards and operator advisor apps based on live as well as historical data to optimize and analyze power plant processes and monitor the equipment installed.

ANDRITZ Metris BOA digital advisor for power boilers

ANDRITZ Metris BOA digital advisor for power boilers

The tailored operation advisor apps will actively support the operator in increasing the efficiency of the boiler, detect opportunities to improve consumption values, and help start processes according to operational needs. Furthermore, automatically generated daily and bi-monthly performance reports comparing current data with data from previous periods will provide information at a glance for overall management of the power plant. The Metris BOA platform will be integrated into the control architecture as a third layer of automation and control together with the boiler protection and plant automation systems (DCS).

This is the third time that a Metris BOA platform will be installed in an existing plant and demonstrates the need for support tools to improve operations in the power plant market.

ANDRITZ is proud to provide another step from digital advisor to digital operator for power boilers. The order is an important part of ANDRITZ’s roadmap towards autonomous power boilers.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro, and Separation. Technological leadership, global presence and sustainability are the cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 27,100 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation. Boilers for power generation, flue gas cleaning systems, various nonwoven technologies, panelboard (MDF) production systems, as well as recycling and shredding solutions for numerous waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.