Displaying items by tag: Andritz

ANDRITZ to supply PrimeCal calenders and paper machine approach flow system to Henan Xinyaxin New Technology Packaging Material, China

International technology group ANDRITZ has received an order from Henan Xinyaxin New Technology Packaging Material, China, to deliver two calenders and a complete paper machine approach flow system for their new paper machine PM9 at the mill in Xinxiang City, Henan Province.

The PM9 has a design speed of 950 m/min with 5.7 m width at the pope reel. Start-up is scheduled for the end of 2022.

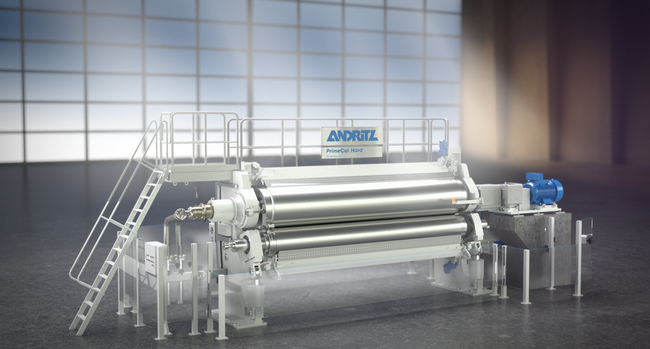

PrimeCal Hard calender for excellent paper surface properties © ANDRITZ

PrimeCal Hard calender for excellent paper surface properties © ANDRITZ

The ANDRITZ equipment will ensure production of high-quality folding boxboard paper (180 to 450 gsm):

- PrimeCal Hard calender with an advanced, zone-controlled PrimeRoll MHV will improve the surface properties of the paper and provide a consistent CD caliper profile.

- PrimeCal Soft calender featuring edge-controlled rolls with soft elastic covers will enhance the smoothness and gloss of the paper.

The scope of supply of the calenders includes drives, spare rolls, and auxiliaries. All components are based on the proven technology of ANDRITZ Küsters, Germany, the expert for finishing components, and will be delivered by ANDRITZ Foshan, China.

Henan Xinyaxin New Technology Packaging Material Co., Ltd. was founded in August 2015, mainly engaging in manufacture and sales of different kinds of paper, paper products and pulp. Its business also involves production and delivery of thermal power and energy, chemical products, and machinery.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,800 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ successfully starts up pressurized refining system at Biyang Huifeng, China

International technology group ANDRITZ has successfully completed the start-up of a pressurized refining system supplied to Biyang Huifeng Wood Industry Board Co., Ltd. at its MDF production plant in Biyang, Henan province, China.

With the new ANDRITZ pressurized refining system, the customer is capable of processing poplar wood chips as raw material. The heart of the new system is the innovative ANDRITZ 54-1CP refiner, which features high energy efficiency. The scope of supply also included a maintenance-friendly 20” discharger with the latest C-feeder concept, a compensator and a proven 20” ribbon feeder.

Weng Duansheng, Vice General Manager at Biyang Huifeng, says, “The excellent operation of our first pressurized refining system installed by ANDRITZ in our Jiangsu mill convinced us to trust once more in the know-how of ANDRITZ’s panelboard experts. The successful and timely start-up of our new line has proven that our decision was the right one.”

From left to right: Huang Yongli, MDF Technology Manager, ANDRITZ; Li Xingfeng, Vice General Manager, Biyang Huifeng; Weng Duansheng, Vice General Manager, Biyang Huifeng; Yu Hongsheng, Process Control Engineer, ANDRITZ; and Wang Hongren, Workshop Manager, Biyang Huifeng.

From left to right: Huang Yongli, MDF Technology Manager, ANDRITZ; Li Xingfeng, Vice General Manager, Biyang Huifeng; Weng Duansheng, Vice General Manager, Biyang Huifeng; Yu Hongsheng, Process Control Engineer, ANDRITZ; and Wang Hongren, Workshop Manager, Biyang Huifeng.

Michael Rupp, Vice President for Panelboard Systems at the ANDRITZ Paper, Fiber and Recycling Division, adds, “We always aim to continuously optimize our technology and services for our customers. Thus, it’s a pleasure to work with a forward-thinking customer like Biyang Huifeng, who values our efforts.”

Successful start-up of the new pressurized refining system in Biyang once again demonstrates ANDRITZ’s strong position in the Chinese panelboard industry, with more than 180 installations.

Biyang Huifeng Wood Industry Board was established in 2017 and is mainly active in the wood-working and panelboard industry.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient, and profitable. The publicly listed group has around 26,800 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power production, flue gas cleaning plants, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area.

ANDRITZ to supply a complete OCC line, including reject treatment, to Alizay Papier, France

International technology group ANDRITZ has received an order from Alizay Papier SASU to supply a complete OCC line – including a reject treatment system – with a capacity of 1,400 bdmt/d to the mill in Alizay, France.

Start-up is scheduled for the end of 2022.

ANDRITZ PrimePulping LC system for lowest fiber loss in slushing and reject removal © ANDRITZ

ANDRITZ PrimePulping LC system for lowest fiber loss in slushing and reject removal © ANDRITZ

ANDRITZ’s scope of supply comprises the entire equipment from pulping to the storage tower and features several technological highlights:

- PrimePulping LC system with innovative design for lowest fiber loss in slushing and reject removal

- Multi-stage fine screening with PrimeScreen X screens for highest efficiency and low power consumption

- PrimeFilter D disc filter with bagless sectors offering significant benefits in terms of thickening performance, energy consumption and maintenance

- State-of-the-art reject treatment with ADuro shredders and Reject Compactors processing the rejects from pulping and coarse screening as well as the pulper rags. A space-saving, automatic rag operation process will feed the rags directly into an ADuro C primary shredder. This eliminates the need for intermediate storage and transport and thus saves space, time and manpower.

ANDRITZ will also provide full detailed engineering as well as start-up and commissioning services.

Alizay Papier SASU is part of the VPK Group, a major international packaging supplier with more than 6,500 employees in over 70 plants operating in 20 countries.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,800 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ successfully starts up P-RC APMP line delivered to Guangxi Sun Paper, China

International technology group ANDRITZ has successfully started up a chemi-thermomechanical pulping system delivered to Sun Paper for its mill in the city of Beihai, Guangxi, China.

The proven ANDRITZ P-RC APMP (Pre-Conditioning Refiner Chemical Alkaline Peroxide Mechanical Pulp) line features a capacity of 600 admt/d and processes eucalyptus wood chips as raw material to produce high-quality pulp for the production of printing and writing paper. It is now the sixth

P-RC APMP line to be delivered to the Sun Paper Group by ANDRITZ.

The scope of supply comprises all key equipment for the fiberline, including the following technological highlights:

- Two-stage impregnation system with outstanding MSD Impressafiners for efficient pre-treatment and optimum chemical impregnation of wood chips prior to refining

- High-consistency (HC) refining stage with two parallel ANDRITZ S2070 single-disc refiners for superior fiber properties and highest production flexibility

- Low-consistency (LC) refining stage with ANDRITZ TwinFlo refiners to develop optimal pulp strength at lowest shive content

Successful start-up of the ANDRITZ P-RC APMP line at Guangxi Sun Paper’s Beihai mill © ANDRITZ

Successful start-up of the ANDRITZ P-RC APMP line at Guangxi Sun Paper’s Beihai mill © ANDRITZ

Cao Yanjun, Vice General Manager at Sun Paper, comments: “In close cooperation with the highly dedicated team from ANDRITZ China, we were able to start up the new P-RC APMP line at our Beihai mill in only 24 days. That’s an impressive start-up curve! The new line is already delivering excellent mechanical pulp within such a short time for our top-quality paper production.”

Li Ke, Project Director, Paper, Fiber and Recycling Division at ANDRITZ China, adds: “It’s an honor to have Sun Paper among our key customers and support them in achieving their goals. Our mission is to focus on all aspects of the project – future-oriented line set-up, superior technology, and all-in service.”

Guangxi Sun Paper was established in 2019 to build an integrated pulp and paper mill in Beihai. The mill will be constructed in two phases over approximately five years. When completed, it will have a total annual pulp and paper capacity of 3.5 million tons.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,800 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ successfully starts up new PrimeReel system at Knauf Petroboard, Russia

International technology group ANDRITZ has successfully started up a new reel as part of the KM2 board machine rebuild at Knauf Petroboard, in Kommunar, Russia.

The KM2 – with a basis weight range from 100 to 320 g/m2 – has a design speed of 700 m/min and a working width of 4.26 m. It has a maximum capacity of 155,000 t/a for production of gypsum board and uses 100% wastepaper as raw material.

The rebuild includes a new PrimeReel system with new reel spools, drives and controls, ensuring consistent paper quality from the first to the last wrap during reeling. The new reel reduces the volume of rejects previously generated and enables the use of larger reel diameters, thus resulting in less frequent reel spool changes.

ANDRITZ rebuilt the complete wet section (comprising the approach flow system and wire section) as well as the complete electrical drives (MMD) of KM2 in 2018.

The start-up team in front of the new PrimeReel system at Knauf Petroboard’s KM2 © ANDRITZ

The start-up team in front of the new PrimeReel system at Knauf Petroboard’s KM2 © ANDRITZ

Yuriy Mikhaylov, general director of Knauf Petroboard AG, says: "We are really impressed by the work of the ANDRITZ team. Despite the very challenging conditions due to the Covid pandemic, the start-up ran smoothly, and the rebuilt machine went into operation before the scheduled date.”

Knauf Petroboard, a member of the international Knauf Group, has a leading market position in Russia and the CIS countries in producing packaging board as well as gypsum board, which is used in the production of plasterboard.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,800 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, tissue, paper and board. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ successfully starts up a new HERB recovery boiler at Naini Papers Limited, India

International technology group ANDRITZ has successfully started up a new 550 t/d HERB chemical recovery boiler (upgradable to 700 t/d) at Naini Papers Limited in Kashipur, state of Uttarakhand, India.

The boiler is designed to handle a mixture of hardwood and agro-based black liquor and enables environmentally friendly and more energy-efficient operation compared to the black liquor incinerator previously used in the mill. Thus, the mill’s pulp production as well as the power-to-heat-ratio will increase substantially. The boiler also features a unique vertical air system to minimize air emissions.

The scope of supply also included:

- Engineering for the entire system except civil work and the electrical and automation equipment

- Complete pressure parts

- Auxiliaries such as start-up oil burners, black liquor burners, and smelt spouts

- Safety-related system (SRS)

View of the new ANDRITZ HERB recovery boiler at Naini mill © ANDRITZ

View of the new ANDRITZ HERB recovery boiler at Naini mill © ANDRITZ

Pawan Agarwal, Managing Director, Naini Papers Limited, says: “The entire ANDRITZ team has worked tirelessly and zealously to see to it that commissioning was trouble-free and fast. Team Naini conveys its warmest thanks to the ANDRITZ team for this wonderful support.”

This is the second of six ANDRITZ HERB recovery boilers currently being installed in India, thus showing the strong market share ANDRITZ holds in the Indian pulp and paper market.

Naini Papers is one of the leading paper brands in India and offers quality paper products from agricultural residue by using innovative, state-of-the-art technology, thereby providing an alternative to wood-based paper while conserving valuable resources and protecting the environment.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 27,200 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ successfully starts up tissue production line delivered to Xuong Giang Paper Mill, Vietnam

International technology group ANDRITZ has successfully started up the tissue production line delivered to Xuong Giang Paper Mill, Vietnam, a subsidiary company of Bac Giang Import Export JSC.

The PrimeLineCOMPACT S 1300 tissue machine has a design speed of 1,300 m/min and a paper width of 2.85 m, processing virgin pulp as raw material to produce high-quality facial and toilet tissue as well as napkins. It is equipped with a 12-ft. PrimeDry Steel Yankee – manufactured at the ANDRITZ Steel Yankee Business Center in Foshan, China – with a steam-heated hood to ensure highly efficient drying and substantial energy cost savings compared to operations with a cast-iron Yankee and gas-heated hood.

The scope of supply also includes the stock preparation plant, which processes short and long fibers in separate systems, the approach flow system, fiber recovery and broke handling equipment, and pumps. The press felts supplied by ANDRITZ Fabrics and Rolls in Geelong, Australia, enable stable and trouble-free operation with a high-quality end product. The complete line is equipped with an ANDRITZ PrimeControl automation package and a multi-motor drive system.

ANDRITZ successfully starts up a PrimeLineCOMPACT tissue production line at Xuong Giang Paper Mill, Vietnam “Photo: ANDRITZ”

ANDRITZ successfully starts up a PrimeLineCOMPACT tissue production line at Xuong Giang Paper Mill, Vietnam “Photo: ANDRITZ”

Thanks to the excellent cooperation between Xuong Giang and ANDRITZ China, the tissue production line went into operation smoothly despite the very challenging conditions caused by COVID-19.

Tran Xuan Nam, Deputy General Director, Xuong Giang Paper Mill, comments: “Thanks to the great support we received from ANDRITZ, our production line went into operation successfully and according to the time schedule. ANDRITZ supplied advanced technology, highly-efficient equipment, and professional service – this is why we are looking forward to a long-term partnership.”

This order once again confirms ANDRITZ’s strong market position as one of the leading suppliers of machines and systems to the Asian tissue industry as well as ANDRITZ’s expertise specifically in resource-saving components for tissue production like steel Yankees and steam-heated hoods. With three tissue machines successfully in operation in Vietnam, ANDRITZ is further strengthening its presence there.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,700 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ successfully starts up main equipment for alternative fiber processing system to be used in tissue production at Essity, Germany

International technology group ANDRITZ has successfully started up the main equipment forming part of an innovative mechanical pulping line supplied to hygiene and health company Essity in Mannheim, Germany.

The new system features a capacity of 100 bdmt/d and processes 100% wheat straw to produce bleached straw pulp for the mill’s own tissue production. As raw material for pulp production, the facility mainly uses FSC- and/or PEFC-certified thinning and waste wood from the area surrounding the mill. Essity has now also been using plant-based agricultural residue from local farms for the production of high-quality tissue since the new equipment was started up. The innovative process uses less water and energy and can thus be considered a breakthrough in sustainable tissue manufacturing. The plant in Mannheim is the first of its kind in Europe and the first in the world to operate on a large scale.

Dr. Martin Wiens, Factory and Project Manager for the new installation, says: “This is a big step for Essity – and the paper industry as well. Essity is the first company in the tissue industry to process agricultural residue on an industrial scale.” He adds: “We have developed unique processing technology that does not exist anywhere else in the world. The design is purely based on a small pilot installation and, together with ANDRITZ, we have managed to implement the concept in a little over two years. That is really impressive!”

Wheat straw mill of the hygiene and health company Essity in Mannheim, Germany. “Photo: Essity/Geiger”.

Wheat straw mill of the hygiene and health company Essity in Mannheim, Germany. “Photo: Essity/Geiger”.

ANDRITZ supplied most of the main equipment, from technology for cleaning, screening, dewatering and bleach tower discharge to refining. Mechanical installation, commissioning and start-up supervision were also part of the scope of supply.

In the run-up to the project, several trials for dewatering, refining, bleaching and the mixing behavior of wheat straw as well as extensive tissue production trials were conducted in ANDRITZ’s fiber preparation pilot plants and the PrimeLine TIAC – Tissue Innovation and Application Center.

Markus Pichler, Vice President for Mechanical Pulping Systems at the ANDRITZ Paper, Fiber and Recycling Division, congratulates: “I’m impressed by this future-oriented approach and regard Essity as a pioneer in the use of alternative fibers for tissue production. The new facility sets benchmarks for the industry.”

Essity is a globally leading hygiene and health company and operates four tissue mills in Germany. With an annual capacity of 283,000 tons produced on five paper machines and 23 converting lines, the Mannheim mill is the industry’s largest production facility in Europe.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,700 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ successfully starts up steel Yankee and air and energy systems at Kartogroup in Spain

International technology group ANDRITZ has successfully started up the new steel Yankee and air and energy systems at Kartogroup España S.L., Burriana mill, Spain.

The turnkey order included a steel Yankee with steam and condensate system for the PM2 tissue machine as well as two dust removal systems for PM2 and PM4. ANDRITZ Novimpianti provided the complete project management, commissioning, and start-up for all these key components.

“The whole project ran smoothly and on schedule”, says Pascual Gómez, COO of Kartogroup. “The new ANDRITZ technology contributes to a substantial reduction in energy consumption compared to traditional concepts. We are especially impressed by the new steel Yankee. Only a few days after the successful start-up it is already operating at full performance.”

Arrival of the 14 ft. PrimeDry Steel Yankee at Kartogroup España, Burriana mill, Spain. “Photo: ANDRITZ”.

Arrival of the 14 ft. PrimeDry Steel Yankee at Kartogroup España, Burriana mill, Spain. “Photo: ANDRITZ”.

Kartogroup España S.L., a member of the COMINTER GROUP, has more than 40 years’ experience in the tissue business. At its mills in Burriana and Hernani (both Spain), the company produces high-quality tissue grades for household and industrial applications.

ANDRITZ Novimpianti, located in Lucca, Italy, has been part of the ANDRITZ GROUP since 2018 and is one of the leading suppliers of drying and ventilation equipment for all kinds of paper machines. Over the past 35 years, Novimpianti has installed around 700 air and energy systems in more than 50 countries.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,700 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ receives order for a major disc filter rebuild from SCA Pulp, Sweden

International technology group ANDRITZ has received an order from SCA (Svenska Cellulosa Aktiebolaget) to rebuild a disc filter at their pulp mill in Ortviken, Sundsvall, Sweden.

After the rebuild, the production capacity of the disc filter (originally supplied by ANDRITZ) will be tripled to 900 bdmt/d, and the filtrate flow will be increased to a maximum of 130,000 l/min. The refurbished disc filter will ensure the requested throughput at different beating degree levels, ranging from 300 to 700 CSF, for the production of various high-quality pulp grades. Start-up is scheduled for the fourth quarter 2022.

The ANDRITZ scope of supply comprises the main disc filter components, such as:

- New hollow shaft with high-volume filtrate channels – the largest-volume filtrate channels ever designed for an ANDRITZ disc filter

- 396 ANDRITZ SuperFlow sectors for 22 filter discs with customized filter bags

- State-of-the art disc guiding system

- New filtrate valve with automated adjustment to the different beating degrees

- New knock-off and cleaning shower systems

- New repulper screw

- On-site services for installation and start-up as well as supervision of start-up

SCA Ortviken mill in Sundsvall, Sweden “Photo: SCA”.

SCA Ortviken mill in Sundsvall, Sweden “Photo: SCA”.

ANDRITZ has developed a new filter bag solution able to handle beating degrees above 600 CSF. The new development was tested on a full-size disc filter during a 3-day trial at the ANDRITZ pilot plant in Graz, Austria. This was the first time that a single disc filter could be operated at such a wide CSF range.

The disc filter rebuild order is part of SCA's ongoing project to transform the existing TMP (thermo-mechanical pulp) line at the Ortviken site into a CTMP (chemo-thermo-mechanical pulp) plant with an annual capacity of 300,000 tons per year.

SCA Pulp is part of the SCA Group, Europe’s largest private forest owner, which offers packaging material, pulp, wood products, and renewable energy. The SCA Pulp facility at Ortviken, Sundsvall is expected to be operational by the beginning of 2023. This strategic investment is SCA's answer to the constantly rising market demands in the field of packaging and hygiene products.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems and services for the pulp and paper industry, the hydropower sector, the metals processing and forming industry, pumps, solid/liquid separation in the municipal and industrial sectors, as well as animal feed and biomass pelleting. Plants for power generation, flue gas cleaning, recycling, and the production of nonwovens and panelboard complete the global product and service offering. Innovative products and services in the industrial digitalization sector are offered under the brand name Metris and help customers to make their plants more user-friendly, efficient and profitable. The publicly listed group has around 26,700 employees and more than 280 locations in over 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides equipment, systems, complete plants and services for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency and sustainability as well as lower overall operating costs. Boilers for power generation, flue gas cleaning systems, plants for the production of nonwovens and panelboard (MDF), as well as recycling and shredding solutions for various waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.