Displaying items by tag: Andritz

ANDRITZ launches new intelligent instrument portfolio at Pulp & Beyond in Helsinki

International technology group ANDRITZ is responding to the pulp and paper producers’ need to meet their process efficiency and environmental sustainability targets by launching a portfolio of intelligent instruments called the Smart Series at the Pulp & Beyond exhibition in Helsinki on April 11.

The portfolio includes a comprehensive range of measurements, analyzers, machine vision systems, condition monitoring solutions as well as robotics and mechatronics. They provide customers with an intelligent instrumentation foundation, paving the way for advanced process optimization.

“With the introduction of the Smart Series, we are laying a solid foundation for an autonomous future, enabling our customers to significantly improve their process efficiency, reliability, safety and environmental sustainability – and ensuring these improvements are sustained over time," says Johanna Newcomb, Vice President, ANDRITZ Automation and Digitalization – Smart Solutions.

“With the introduction of the Smart Series, we are laying a solid foundation for an autonomous future, enabling our customers to significantly improve their process efficiency, reliability, safety and environmental sustainability – and ensuring these improvements are sustained over time," says Johanna Newcomb, Vice President, ANDRITZ Automation and Digitalization – Smart Solutions.

The Smart Series: Valuable Data - Predictive Maintenance - Enhanced Safety with Robotics

Emission and gas analyzers, process measurement and vision systems complement pulp and paper plants by providing a deeper understanding of the process and machine condition than possible before. With condition monitoring solutions for a wide range of process equipment and process areas, the Smart Series helps manufacturers move toward predictive maintenance, reducing unplanned downtime and extending the lifetime of equipment and components. Integrated robotics and mechatronics applications reduce the need of human intervention in hazardous areas of pulp and paper mills, reschedule regular tasks and contribute to optimizing maintenance.

The Smart Series complements and is integrated with Metris, ANDRITZ's digitalization platform that leverages the latest IIoT technologies to improve plant efficiency and profitability.

The use cases at the Pulp & Beyond exhibition include the autonomous log yard and robots for the recovery boiler area. More information will be shared at our booth A48 in exhibition room B6-3.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. Sustainability is an integral part of the company’s business strategy and corporate culture. With its extensive portfolio of sustainable products and solutions, ANDRITZ aims to make the greatest possible contribution to a sustainable future and help its customers achieve their sustainability goals. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydropower and Environment & Energy. Technological leadership and global presence are cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 30,000 employees and over 280 locations in more than 80 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation.

The product portfolio also includes boilers for power generation, various nonwoven technologies, and panelboard (MDF) production systems. With waste-to-value recycling, shredding and energy solutions, waste and by-product streams from production are converted into valuable secondary raw materials as well as into sustainable resources for energy generation. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ to supply high-temperature Yankee hood and air system to Northwood Tissue, England

International technology group ANDRITZ has received a turn-key order from Northwood Tissue Ltd. to supply a new PrimeDry Hood and an air system for a tissue machine rebuild at the mill in Chesterfield, Derbyshire, England. Start-up is planned for the third quarter of 2024.

PrimeDry Hood HT manufacturing at ANDRITZ Novimpianti. Photo "Andritz"Installation of the new ANDRITZ gas-heated PrimeDry Hood HT (High-Temperature) will increase the drying capacity thanks to an impingement temperature of up to 530°C. It will also enable a higher heat transfer rate, resulting in considerable energy optimization per ton of tissue produced.

PrimeDry Hood HT manufacturing at ANDRITZ Novimpianti. Photo "Andritz"Installation of the new ANDRITZ gas-heated PrimeDry Hood HT (High-Temperature) will increase the drying capacity thanks to an impingement temperature of up to 530°C. It will also enable a higher heat transfer rate, resulting in considerable energy optimization per ton of tissue produced.

ANDRITZ’s scope of supply includes installation work, supervision of mechanical installation, commissioning, and start-up. Guido Lenzi, Area Sales Manager at ANDRITZ Novimpianti, says, “The new drying equipment will support our customer on its path towards more sustainable and cost-efficient tissue production. This is the second order of that kind that Northwood Tissue has placed with us, and we are looking forward to continuing our partnership.”

David Harries, Director at Northwood Tissue adds, “This investment is another milestone in improving carbon footprint and operational efficiencies. ANDRITZ is a reliable partner for projects of this kind, and I look forward to the successful completion.”

Northwood Tissue (Chesterfield) Ltd. is a member of the Northwood Group, with over 50 years’ experience in the tissue and paper business. At its mills in Chesterfield, Disley and Lancaster, England, the company produces high-quality tissue grades for Consumer and Away from Home applications. The group has paper making capability in excess of 100,000 t/a in the UK and Spain, which it all processes through internal converting plants. Northwood’s business has a high focus on sustainability throughout its vertically integrated supply chain, with a long proud history in the recycled paper sector.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. Sustainability is an integral part of the company’s business strategy and corporate culture. With its extensive portfolio of sustainable products and solutions, ANDRITZ aims to make the greatest possible contribution to a sustainable future and help its customers achieve their sustainability goals. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydropower and Environment & Energy. Technological leadership and global presence are cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 30,000 employees and over 280 locations in more than 80 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation.

The product portfolio also includes boilers for power generation, various nonwoven technologies, and panelboard (MDF) production systems. With waste-to-value recycling, shredding and energy solutions, waste and by-product streams from production are converted into valuable secondary raw materials as well as into sustainable resources for energy generation. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ to deliver complete old corrugated containers line to Papel Prensa, Argentina

International technology group ANDRITZ has received an order from Papel Prensa S.A. to supply a complete old corrugated containers (OCC) line including a reject handling system to its mill in Buenos Aires, Argentina.

In its initial production phase, the new line will process 180 t/d of local OCC. The line’s processing capacity can be easily increased through a minor adjustment to configuration to support the expected rise in pulp demand for the production of corrugated paper. The new line will provide high pulp quality at cost-efficient and resource-saving operation, with the latest technology available.

Diego Colabardini, CEO of Papel Prensa S.A., says: “Our goal is to produce top-quality paper while reducing our environmental footprint through the efficient use of energy and natural resources, based on our strategy of promoting circular economy in a sustainable business. ANDRITZ’s advanced technology and extensive experience in pulping will help us achieve this goal."

PrimeScreen X for improved energy efficiency, screening performance, and maintainability. Photo Andritz

PrimeScreen X for improved energy efficiency, screening performance, and maintainability. Photo Andritz

ANDRITZ’s scope of supply comprises

- the complete LC pulping system with a FibreSolve FSR pulper and an innovative detrashing system to ensure superior slushing of the raw material at minimum fiber loss

- the protection cleaning, fractionation and screening stage including a PrimeScreen X with newly developed PrimeRotor for high screening efficiency at lower power consumption

- an innovative reject handling system featuring a Reject Compactor ReCo to dewater the rejects to the highest possible dry content

- erection supervision, commissioning, start-up, and training

Start-up of the new line is scheduled for 2024.

This order further strengthens ANDRITZ's presence in the South American recycled pulp market.

Papel Prensa S.A. is a leading Argentinean paper manufacturing company with the country´s highest paper production volume. The company specializes in the production of newsprint, printing paper, and packaging paper.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. Sustainability is an integral part of the company’s business strategy and corporate culture. With its extensive portfolio of sustainable products and solutions, ANDRITZ aims to make the greatest possible contribution to a sustainable future and help its customers achieve their sustainability goals. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro and Separation. Technological leadership and global presence are cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 30,000 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation.

The product portfolio also includes boilers for power generation, flue gas cleaning systems, various nonwoven technologies, and panelboard (MDF) production systems. With waste-to-value recycling, shredding and energy solutions, waste and by-product streams from production are converted into valuable secondary raw materials as well as into sustainable resources for energy generation. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

Rebuild by ANDRITZ gives Shandong Huatai Paper the world’s largest mechanical pulping line while saving energy and resources

Shandong Huatai Paper has successfully started up a mechanical pulping line rebuilt by ANDRITZ at the mill in Dongying, Shandong Province, China. The rebuild not only increased the line’s capacity from 100,000 t/a to 300,000 t/a, making it the world’s largest mechanical pulping line for printing and writing paper production. It also considerably reduced the line’s energy consumption and increased its pulp yield and quality.

Wei Lijun, Director of Shandong Huatai Paper, says: “Thanks to the close cooperation between the teams of ANDRITZ and Shandong Huatai, we were able to start up the rebuilt line as scheduled. We are delighted about the massive increase in capacity as well as the additional benefits of the modernization. Energy consumption has dropped by about 15% and pulp quality has greatly improved. The amount of fiber shives has also gone down significantly. As a result, we are able to cut back on imported chemi-mechanical pulp in our raw material structure, which lowers costs and supports our environmental performance.”

Successful start-up of the world’s largest mechanical pulping line for P&W grades at Shandong Huatai Paper, China. Photo Andritz

Successful start-up of the world’s largest mechanical pulping line for P&W grades at Shandong Huatai Paper, China. Photo Andritz

ANDRITZ rebuilt the two high-consistency (HC) refiners and the screw presses, disc filters, and screens, and supplied new equipment for other process steps. The line now features the following technological highlights:

- New PrimeMSD Impressafiner for optimum wood chip maceration and chemical impregnation

- New Side-Entry Plug Feeder (SEPF) feeding system for constant and efficient HC refiner feeding

- New DCS system as a future-oriented control system for the new fiberline

- ANDRITZ Hydraulic Commander to improve the HC refiners’ operability and supply top quality fiber with lower energy consumption

ANDRITZ also provided the basic engineering and supervised the mechanical installation, commissioning, and start-up.

Shandong Huatai Paper Industry Shareholding is part of the listed Huatai Group, an important global player in the paper and chemical production sectors. The group is the world’s largest producer of newsprint and China’s largest producer in the chlor-alkali industry. In addition, the group makes all sorts of P&W paper, tissue, and specialty paper grades. The Huatai Group produces three million tons of paper and board as well as two million tons of chemicals per year.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. Sustainability is an integral part of the company’s business strategy and corporate culture. With its extensive portfolio of sustainable products and solutions, ANDRITZ aims to make the greatest possible contribution to a sustainable future and help its customers achieve their sustainability goals. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro and Separation. Technological leadership and global presence are cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 30,000 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation.

The product portfolio also includes boilers for power generation, flue gas cleaning systems, various nonwoven technologies, and panelboard (MDF) production systems. With waste-to-value recycling, shredding and energy solutions, waste and by-product streams from production are converted into valuable secondary raw materials as well as into sustainable resources for energy generation. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ to supply high-temperature Yankee hood and air system to Kartogroup, Spain

International technology group ANDRITZ has received an order from Kartogroup España S.L. to supply a new high-temperature PrimeDry Hood HT and an air system for a tissue machine rebuild at the mill in Burriana, Spain. Start-up is scheduled for the first quarter of 2024.

The new gas-heated hood will enable Kartogroup to achieve a higher drying capacity with a hood design impingement temperature of 530°C, a higher heat transfer rate and a significant reduction of energy consumption per ton of paper produced.

The special set of advanced solutions for the drying section rebuild include optimized impingement distribution of the hood nozzle boxes, a heat recovery system, a state-of-the-art burner management system and Yankee head insulation. Representing ANDRITZ’s latest developments in tissue drying technology, these solutions maximize the heat transfer rate, ensure higher safety, lower emissions and significantly reduce steam consumption.

ANDRITZ’s scope of supply also comprises supervision of installation, commissioning, start-up, and training.

PrimeDry Hood HT at the ANDRITZ Novimpianti workshop. Photo Andritz

PrimeDry Hood HT at the ANDRITZ Novimpianti workshop. Photo Andritz

This order reflects the trustful relationship between the two companies, which started in 2020 with a turnkey order for ANDRITZ that included a steel Yankee with steam and condensate system, two dust removal systems, and an air-to-air heat exchanger.

Pascual Gómez, COO Kartogroup, says, “We trust in ANDRITZ’s expertise to upgrade machines for a more efficient and sustainable tissue production. The innovative high-temperature hood perfectly meets our requirements for energy saving, high thermal efficiency, and stable drying results. We look forward to continuing our collaboration with ANDRITZ on new R&D energy efficiency projects next year.”

Kartogroup España S.L., a member of the Cominter Group, has more than 40 years’ experience in the tissue business. At its mills in Burriana and Hernani, Spain, the company produces high-quality tissue grades for household and industrial applications.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. Sustainability is an integral part of the company’s business strategy and corporate culture. With its extensive portfolio of sustainable products and solutions, ANDRITZ aims to make the greatest possible contribution to a sustainable future and help its customers achieve their sustainability goals. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro and Separation. Technological leadership and global presence are cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 30,000 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation.

The product portfolio also includes boilers for power generation, flue gas cleaning systems, various nonwoven technologies, and panelboard (MDF) production systems. With waste-to-value recycling, shredding and energy solutions, waste and by-product streams from production are converted into valuable secondary raw materials as well as into sustainable resources for energy generation. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ to supply dewatering and dispersing equipment to Rondo Ganahl’s paper mill in Austria

International technology group ANDRITZ has received an order from Rondo Ganahl AG to supply dewatering and dispersing equipment to be installed in its paper mill in Frastanz, Austria. Start-up is scheduled for end of 2024.

This upgrade will help the customer make his paper mill fit for the future to meet growing demands in the production process. ANDRITZ will replace the complete dewatering and dispersing equipment, which will increase the capacity of the system up to 230 bdt/d. Centerpiece of the new technology will be a Twin Wire Press, type TWP2833L, which will feature a custom-tailored modular design optimized for the limited space conditions at the installation site. The ANDRITZ Twin Wire Press is perfectly suited for dewatering all types of fibers, but especially when a high pulp dryness or the separation of water loops are required. ANDRITZ will also provide the basic engineering, supervision of erection, commissioning, and start-up as well as the operator training.

ANDRITZ Twin Wire Press. Photo Andritz

ANDRITZ Twin Wire Press. Photo Andritz

Bertram Elsensohn, Division Manager Technology, Rondo Ganahl AG, says: “This investment will allow us to expand our production capacity and improve the performance of our stock preparation line. We will thus be able to respond even better to market requirements in the future.”

Rondo Ganahl AG is an Austrian family business, whose roots go back to the year 1797. The company is specialized in manufacturing corrugated board packaging products and corrugated case material as well as in the collection of paper and packaging.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. Sustainability is an integral part of the company’s business strategy and corporate culture. With its extensive portfolio of sustainable products and solutions, ANDRITZ aims to make the greatest possible contribution to a sustainable future and help its customers achieve their sustainability goals. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro and Separation. Technological leadership and global presence are cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 30,000 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation.

The product portfolio also includes boilers for power generation, flue gas cleaning systems, various nonwoven technologies, and panelboard (MDF) production systems. With waste-to-value recycling, shredding and energy solutions, waste and by-product streams from production are converted into valuable secondary raw materials as well as into sustainable resources for energy generation. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ to increase mechanical pulp production at Dezhou Taiding with another high-performance line

International technology group ANDRITZ has received an order from Dezhou Taiding New Material Science and Technology Co., Ltd., China, to deliver a second chemi-thermomechanical (P-RC APMP) line to the mill in Pingyuan County, Dezhou City, Shandong Province, China. The ANDRITZ fiberline already installed at the mill supplies the company’s paper machines producing printing and writing paper and board grades. It has been operating successfully since 2021.

Zhang Qingchao, Vice General Manager of Production, Dezhou Taiding, says: “The ANDRITZ P-RC APMP line at our mill has consistently shown top fiber quality, remarkably low energy and chemical consumption, and high operational reliability. It was clear for us to partner with ANDRITZ again for our capacity increase.”

The new line with a capacity of 400 admt/d will process poplar wood chips into high-quality mechanical pulp. ANDRITZ will furnish the fiberline with its state-of-the-art key equipment, covering all stages from chip washing to pulp storage. The scope of supply also comprises the basic engineering and on-site services including installation, commissioning, and start-up supervision. Start-up is scheduled for the beginning of 2025.

ANDRITZ PrimeMSD Impressafiner and vertical Impregnator running in Taiding mill. Photo Andritz

ANDRITZ PrimeMSD Impressafiner and vertical Impregnator running in Taiding mill. Photo Andritz

Dezhou Taiding is a joint-stock company focusing on the pulp production, papermaking and thermo-electricity business. It is one of the most important players in the paper industry in the Shandong region, China.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. Sustainability is an integral part of the company’s business strategy and corporate culture. With its extensive portfolio of sustainable products and solutions, ANDRITZ aims to make the greatest possible contribution to a sustainable future and help its customers achieve their sustainability goals. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro and Separation. Technological leadership and global presence are cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 30,000 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation.

The product portfolio also includes boilers for power generation, flue gas cleaning systems, various nonwoven technologies, and panelboard (MDF) production systems. With waste-to-value recycling, shredding and energy solutions, waste and by-product streams from production are converted into valuable secondary raw materials as well as into sustainable resources for energy generation. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

GUTEX produces first fibers for insulation board with new ANDRITZ fiber preparation system

Wood fiber insulation board manufacturer GUTEX has successfully produced first fibers with its new ANDRITZ fiber preparation system in Eschbach, Germany. This is the second system ANDRITZ has delivered to GUTEX.

Oliver Bauch, Plant Manager, GUTEX, says: “The new line will perfectly support the environmentally friendly production approach for our ecological insulation board products. Thanks to the excellent cooperation and the great effort of the whole ANDRITZ team we were able to produce first fibers even ahead of schedule.”

From left to right: Rudolf Hafner, Site Manager, ANDRITZ; Slavisa Radovic, Head of Maintenance in Eschbach, GUTEX; Gerhard Zauner, Project Manager, ANDRITZ. Photo " Andritz "

From left to right: Rudolf Hafner, Site Manager, ANDRITZ; Slavisa Radovic, Head of Maintenance in Eschbach, GUTEX; Gerhard Zauner, Project Manager, ANDRITZ. Photo " Andritz "

Michael Rupp, Vice President for Panelboard Systems, ANDRITZ, adds: “We are proud that GUTEX again chose to collaborate with us and that we had the opportunity to provide them with our complete front-end technology.”

The scope of supply comprised a complete fiber preparation line, including a debarking and chipping line as well as the steel structure, piping material and installation work. The highly efficient system processes softwood chips as raw material and features the following technological highlights:

- ANDRITZ RotaBarker debarking system and horizontally fed HHQ-Chipper for consistently good chip quality at high production rates

- Fully automatic chip storage system with reclaiming and screening equipment

- High-consistency pressurized refining system to obtain high fiber quality and low specific energy consumption

- Steam Recovery System (SRS) for efficient recovery of surplus steam and greater thermal efficiency of the fiber preparation system

GUTEX is one of Europe’s pioneers in ecological insulation solutions. The family business based in the German Black Forest started making wood fiber insulation products back in 1932. In 2006, GUTEX was the first company to start producing wood fiberboard insulation with a homogeneous raw density profile using an innovative drying process. This technique allows GUTEX to manufacture single-layer wood fiber insulation board up to 240 mm thick and with significant quality advantages.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. Sustainability is an integral part of the company’s business strategy and corporate culture. With its extensive portfolio of sustainable products and solutions, ANDRITZ aims to make the greatest possible contribution to a sustainable future and help its customers achieve their sustainability goals. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro and Separation. Technological leadership and global presence are cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 29,900 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation.

The product portfolio also includes boilers for power generation, flue gas cleaning systems, various nonwoven technologies, and panelboard (MDF) production systems. With waste-to-value recycling, shredding and energy solutions, waste and by-product streams from production are converted into valuable secondary raw materials as well as into sustainable resources for energy generation. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

GUTEX produces first fibers for insulation board with new ANDRITZ fiber preparation system

Wood fiber insulation board manufacturer GUTEX has successfully produced first fibers with its new ANDRITZ fiber preparation system in Eschbach, Germany. This is the second system ANDRITZ has delivered to GUTEX.

Oliver Bauch, Plant Manager, GUTEX, says: “The new line will perfectly support the environmentally friendly production approach for our ecological insulation board products. Thanks to the excellent cooperation and the great effort of the whole ANDRITZ team we were able to produce first fibers even ahead of schedule.”

Michael Rupp, Vice President for Panelboard Systems, ANDRITZ, adds: “We are proud that GUTEX again chose to collaborate with us and that we had the opportunity to provide them with our complete front-end technology.”

From left to right: Rudolf Hafner, Site Manager, ANDRITZ; Slavisa Radovic, Head of Maintenance in Eschbach, GUTEX; Gerhard Zauner, Project Manager, Andritz. Photo Andritz

From left to right: Rudolf Hafner, Site Manager, ANDRITZ; Slavisa Radovic, Head of Maintenance in Eschbach, GUTEX; Gerhard Zauner, Project Manager, Andritz. Photo Andritz

The scope of supply comprised a complete fiber preparation line, including a debarking and chipping line as well as the steel structure, piping material and installation work. The highly efficient system processes softwood chips as raw material and features the following technological highlights:

- ANDRITZ RotaBarker debarking system and horizontally fed HHQ-Chipper for consistently good chip quality at high production rates

- Fully automatic chip storage system with reclaiming and screening equipment

- High-consistency pressurized refining system to obtain high fiber quality and low specific energy consumption

- Steam Recovery System (SRS) for efficient recovery of surplus steam and greater thermal efficiency of the fiber preparation system

GUTEX is one of Europe’s pioneers in ecological insulation solutions. The family business based in the German Black Forest started making wood fiber insulation products back in 1932. In 2006, GUTEX was the first company to start producing wood fiberboard insulation with a homogeneous raw density profile using an innovative drying process. This technique allows GUTEX to manufacture single-layer wood fiber insulation board up to 240 mm thick and with significant quality advantages.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. Sustainability is an integral part of the company’s business strategy and corporate culture. With its extensive portfolio of sustainable products and solutions, ANDRITZ aims to make the greatest possible contribution to a sustainable future and help its customers achieve their sustainability goals. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro and Separation. Technological leadership and global presence are cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 29,900 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation.

The product portfolio also includes boilers for power generation, flue gas cleaning systems, various nonwoven technologies, and panelboard (MDF) production systems. With waste-to-value recycling, shredding and energy solutions, waste and by-product streams from production are converted into valuable secondary raw materials as well as into sustainable resources for energy generation. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

ANDRITZ plant will prepare date palm waste for fiberboard production

International technology group ANDRITZ will supply a complete fiber preparation line for a greenfield plant in the Toshka area in the south of Egypt. The pioneering and eco-friendly plant will produce high-density and medium-density fiberboard (HDF/MDF) from date palm fronds, a material normally considered farm waste.

ANDRITZ will execute this order in cooperation with the engineering, procurement and construction (EPC) specialist WESER Industrie- und Anlagentechnik GmbH and DIEFFENBACHER GmbH Maschinen- und Anlagenbau, a leading manufacturer of press systems and complete plants for the wood-based panel industry. On behalf of Egypt’s National Service Projects Organization (NSPO), the German company WESER is acting as the general contractor for this turnkey project.

Michael Frint, Director Technology Panelboard Systems at ANDRITZ says: “Alternative raw materials, in particular from waste streams, are becoming increasingly important in the panel industry. Participating in this innovative and sustainable NSPO project is an important milestone for us.”

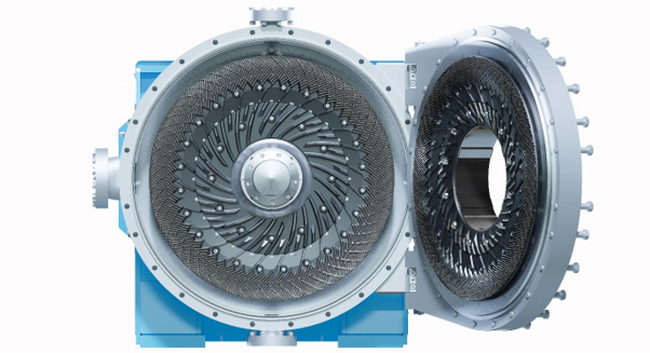

Well proven ANDRITZ refiner designed to achieve highest fiber quality at reduced electrical energy consumption. Photo "Andritz"

Well proven ANDRITZ refiner designed to achieve highest fiber quality at reduced electrical energy consumption. Photo "Andritz"

The ANDRITZ line, with a capacity of up to 14 bdmt/h, will process date palm fronds from a nearby 40,000-acre date farm. It includes a system to wash and condition the chips from the palm frond stems, and a pressurized refining system with a well-proven refiner to process the washed and conditioned chips into high quality fibers at very low energy consumption. The fibers will be used to produce high quality fiberboards, mainly for the flooring and furniture industries. The plant is scheduled to commence production in the autumn of 2025.

About Andritz

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. Sustainability is an integral part of the company’s business strategy and corporate culture. With its extensive portfolio of sustainable products and solutions, ANDRITZ aims to make the greatest possible contribution to a sustainable future and help its customers achieve their sustainability goals. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro and Separation. Technological leadership and global presence are cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 29,900 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation.

The product portfolio also includes boilers for power generation, flue gas cleaning systems, various nonwoven technologies, and panelboard (MDF) production systems. With waste-to-value recycling, shredding and energy solutions, waste and by-product streams from production are converted into valuable secondary raw materials as well as into sustainable resources for energy generation. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.