Super User

BIO-LUTIONS partners with PulPac - sets up large-scale Dry Molded Fiber production

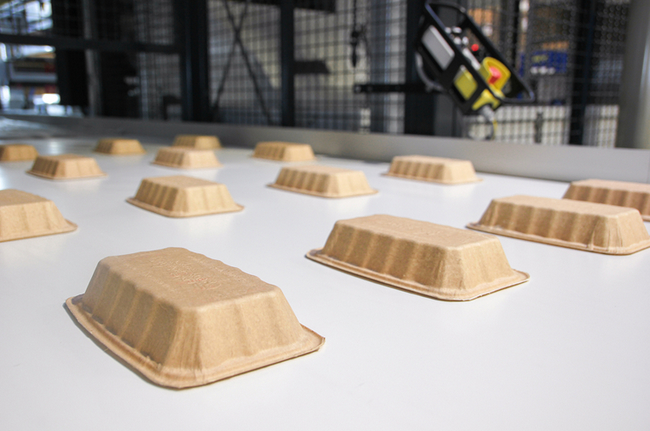

The German Clean Tech Startup BIO-LUTIONS and PulPac, the Dry Molded Fiber pioneer, are natural allies in their objective to replace single-use plastics globally. Together with machine suppliers they have developed a Dry Molded Fiber production line, set to start production in the new BIO-LUTIONS factory in Schwedt/Oder, Germany by the summer of 2022.

BIO-LUTIONS mechanically converts agricultural residues into unique, self-binding, durable fibcro® natural fibers. This patented method eliminates the need for binding agents or chemical cellulose isolation, as the whole fiber is used. From these fibers together with the dry moulding technology, BIO-LUTIONS will produce a variety of sustainable single-use disposable products such as service food items (cutlery and tableware) as well as protein, fruit and vegetable packaging. By introducing the new dry moulding technology provided by PulPac, production can now benefit from the unique cost and quality advantages compared to existing cellulose forming solutions.

The cooperation with PulPac opens the door to an additional production technology for fibre moulding, allowing for technology diversification as well as optimisation of dry moulding processes. The Dry Molded Fiber technology saves significant amounts of valuable water resources and energy, resulting in up to 80% lower CO2 footprint compared to alternatives. The process is extremely fast and more efficient than conventional fiber forming methods. While Dry Molded Fiber technology will not be used for all BIO-LUTIONS’ products, it does offer significant production advantages for a large variety of single use products.

“Each company brings something unique and valuable to the table. Being able to create partnerships that prioritize creating real solutions to the plastic age, rather than trying to build walls is what will make true change possible. That is why we are very excited to include dry moulding from PulPac as a second core production technique” Eduardo Gordillo, CEO BIO-LUTIONS.

The new factory in Germany will be up and running this summer and brings together two unique innovations, BIO-LUTIONS’s fibcro® natural fibers and PulPac’s Dry Molded Fiber technology – delivering truly sustainable and competitive fiber-based packaging to the world.

The new factory in Germany will be up and running this summer and brings together two unique innovations, BIO-LUTIONS’s fibcro® natural fibers and PulPac’s Dry Molded Fiber technology – delivering truly sustainable and competitive fiber-based packaging to the world.

“BIO-LUTIONS is an innovative and fast-moving partner. We share a doer attitude and a clear-cut commitment to replace single-use plastics at scale. Having products on the market already this year will take the concept of sustainable packaging a big leap forward. We look forward to a long-term partnership where we can share know-how and expertise to leverage the full potential of dry moulding within BIO-LUTIONS’ operations and customer network.” says Linus Larsson, CEO, PulPac AB.

About PulPac

PulPac provides the packaging industry with a groundbreaking manufacturing technology for low-cost, high-performance fiber-based packaging and single-use products. By pioneering the technology of cellulose molding PulPac enables their customers to replace single-use plastics with a sustainable and cost competitive alternative globally.

For additional information about PulPac, please visit www.pulpac.com or follow us on social media.

About BIO-LUTIONS

BIO-LUTIONS is a Hamburg-based green tech start-up that has developed its own innovative natural fibre technology, used to produce sustainable packaging and disposable tableware. The production process gives a second life to currently unused agricultural residuals as raw material to replace con-ventional plastic and paper products. BIO-LUTIONS was founded in 2017 and is currently expanding in Asia and Europe. With the purely mechanical process BIO-LUTIONS creates stable structures and products without additional binding agents. The application of this innovative fibre technology was

developed in Germany, at their technical centre in Schwedt, Brandenburg. The first factory was opened in Bangalore, India and now follows the new production facility in Schwedt, Germany. As part of the Innovation Campus Schwedt, BIO-LUTIONS is a part of the new hub for innovative technology in Brandenburg.

For more information, please visit: www.bio-lutions.com

About Dry Molded Fiber

Dry Molded Fiber, invented and patented by PulPac, is a manufacturing technology designed for the circular economy. It leverages globally available, affordable, and renewable cellulose fibers to produce high performance fiber-based packaging and single-use products with highly competitive unit economics. Dry Molded Fiber also saves significant amounts of valuable water resources and energy, resulting in up to 80% lower CO2 footprint compared to alternatives. The process is up to ten times as efficient as conventional fiber molding invented over 100 years ago.

ANDRITZ successfully starts up dissolving pulp production plant for Bracell’s “STAR” project, Brazil

International technology group ANDRITZ has successfully started up an environmentally friendly production plant for dissolving pulp at Bracell’s “STAR” project in Lençóis Paulista, São Paulo.

In April 2022, one of the two flexible hardwood fiberlines that were started up successfully in September 2021 was switched from kraft to dissolving pulp production. High capacity with premium quality was reached within a few days of the switch.

For this trendsetting project, ANDRITZ is using its self-developed A-ConFlex™ continuous kraft and dissolving pulping technology. It enables full flexibility in production, switching between high-quality dissolving pulp and kraft pulp in a very short time to meet the market demand.

The world’s largest EvoDry™ pulp drying system from ANDRITZ, with two energy-efficient pulp drying lines enabling efficient and very fast switches between dissolving pulp and kraft pulp production, was also supplied to the mill.

ANDRITZ started up two environmentally friendly hardwood pulp production lines for the STAR project, Brazil, in September 2021. © ANDRITZ

ANDRITZ started up two environmentally friendly hardwood pulp production lines for the STAR project, Brazil, in September 2021. © ANDRITZ

The STAR project is one of the largest and most sustainable pulp mills in the world, complying with the highest environmental standards. It features two flexible, environmentally friendly hardwood fiberlines for a total capacity of 2.6 to 2.8 million tons/year of bleached kraft pulp or 1.5 million tons/year of dissolving pulp made from sustainably cultivated eucalyptus.

Per Lindblom, Bracell’s Vice President, says, “We are pleased and proud to now have the largest and greenest continuous cooking line in the world for dissolving pulp at the Bracell mill in São Paulo, utilizing proven ANDRITZ technology. We started up quickly after the switch and were soon producing top-quality pulp. This success is clearly down to the close teamwork between Bracell and ANDRITZ as well as both companies’ complementary expertise in dissolving pulp technology and production.”

With this start-up, ANDRITZ once again confirms its position as the only technology supplier with solid references and experience in continuous cooking of dissolving pulp.

The ANDRITZ scope of supply includes:

- a complete high-capacity wood processing plant, enhanced with state-of-the-art autonomous wood processing solutions from ANDRITZ to ensure optimum chip quality,

- two flexible fiberlines with DD-Washer technology ensuring low operating costs, low emissions, extremely high washing efficiency, and excellent fiber quality,

- the world’s largest EvoDryTM pulp drying system equipped with the Metris DryQ smart pulp drying solution,

- the largest HERB recovery boiler in the world from ANDRITZ, with a capacity of 13,000 tons per day,

- a non-condensable gas (NCG) treatment system.

ANDRITZ GROUP

International technology group ANDRITZ offers a broad portfolio of innovative plants, equipment, systems, services and digital solutions for a wide range of industries and end markets. ANDRITZ is a global market leader in all four of its business areas – Pulp & Paper, Metals, Hydro, and Separation. Technological leadership, global presence and sustainability are the cornerstones of the group’s strategy, which is focused on long-term profitable growth. The publicly listed group has around 27,100 employees and over 280 locations in more than 40 countries.

ANDRITZ PULP & PAPER

ANDRITZ Pulp & Paper provides sustainable technology, automation, and service solutions for the production of all types of pulp, paper, board and tissue. The technologies and services focus on maximum utilization of raw materials, increased production efficiency, lower overall operating costs as well as innovative decarbonization strategies and autonomous plant operation. Boilers for power generation, flue gas cleaning systems, various nonwoven technologies, panelboard (MDF) production systems, as well as recycling and shredding solutions for numerous waste materials also form a part of this business area. State-of-the-art IIoT technologies as part of Metris digitalization solutions complete the comprehensive product offering.

Meet and discuss with Adven at PulPaper 2022

PulPaper, the leading international event for the forest industry, will be held from 7 to 9 June 2022 at Helsinki Expo and Convention Centre. Adven is present and facilitates discussions on business drivers and technology development for improving cost competitiveness and sustainability performance.

Our electricity- and energy markets are unpredictable, and it is becoming increasingly important to invest in energy capabilities to secure competitiveness. The question is, how best to do that?

With Adven as a long-term partner, you build up competitive advantages from energy, heat, and water without taking too much time from the business you want to outperform.

Welcome to Adven’s stand 6f58 to talk with energy experts about:

- Recovery of side streams – waste to income

- Fuel conversions – e.g. lime kilns and dryers

- Steam delivery based on opportunity fuels – cost advantage with maximal supply security

- Advanced water treatment – for better performing process and tighter permits

Industry Lead, Louise Kierkegaard, will also elaborate on the topic on the Future Square stage on Thursday, 9 June 2:40 pm – 3:00 pm.

Register as a free visitor here. See you at the fair!

Presentation: Energy as a Service® partnership – enabling mills to transform by improving cost competitiveness and sustainability profiles

Presentation: Energy as a Service® partnership – enabling mills to transform by improving cost competitiveness and sustainability profiles

Future Square Stage | Thursday, 9 June 2022 | 14:40-15:00

The presentation will address how Energy-as-a-Service business models make industrial companies more competitive, based on increased focus on improving core processes and their products.

How to build up competitive advantages from energy, heat, and water without taking too much time from the business you want to outperform? With Adven as a long-term partner, you can utilize energy in a new way – and at the same time focus on strengthening your business for the future. More and more industries choose to go this way. After the presentation, you will know why.

For more information, contact our event hosts:

Juha Elo, Director, Sales Project Development, +358 40 594 4755, This email address is being protected from spambots. You need JavaScript enabled to view it.

Louise Kierkegaard, Industry Lead, Pulp & Paper, +46 72 73 15 557, This email address is being protected from spambots. You need JavaScript enabled to view it.

Teemu Kivimäki, Sales Manager, New Industrial Sales, +358 10 344 5122, This email address is being protected from spambots. You need JavaScript enabled to view it.

New TAPPI Standard T582 – High Shear Capillary Viscosity of Coating Color on Paper and Paperboard – Now available!

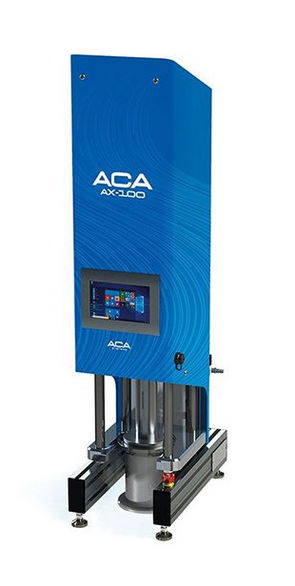

Understanding coating color rheology is a key for the coating color quality control, development and coater runnability optimization. Rheology characteristics are especially significant in high-speed industrial coating applications such as blade-, film- and curtain coating. Complex deformations of coating colors can be generated in paper coating application under very high shear rates. The deformation needs to be controlled in order to secure stable runnability and good end product quality. The newly published TAPPI standard is a method to measure the viscosity of the coating color at process relevant shear rate (exactly at 500 000 1/s). ACA AX-100 high pressure capillary rheometer is the used instrumentation to fulfill the standard requirements.

Understanding coating color rheology is a key for the coating color quality control, development and coater runnability optimization. Rheology characteristics are especially significant in high-speed industrial coating applications such as blade-, film- and curtain coating. Complex deformations of coating colors can be generated in paper coating application under very high shear rates. The deformation needs to be controlled in order to secure stable runnability and good end product quality. The newly published TAPPI standard is a method to measure the viscosity of the coating color at process relevant shear rate (exactly at 500 000 1/s). ACA AX-100 high pressure capillary rheometer is the used instrumentation to fulfill the standard requirements.

The approval of the standard was a result of the great contribution from SSIG (Standard-Specific Interest Group) members during the draft reviews and balloting. The new standard benefits the whole coating industry world-wide and is aiming to help companies in developing new sustainable solutions for example in food packaging.

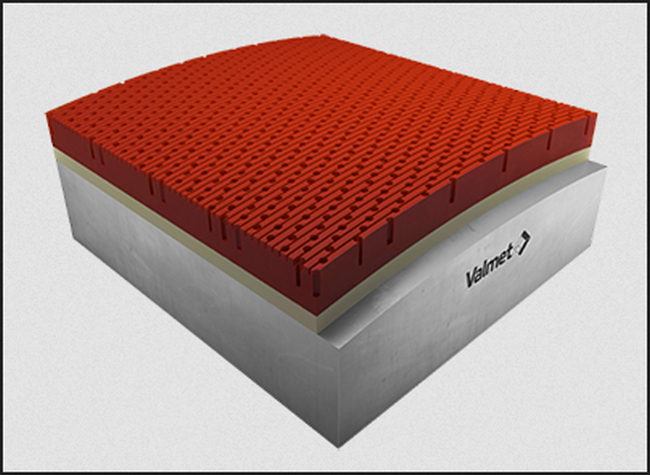

The new Valmet Press Roll Cover PL leads to energy savings in tissue production

To broaden its offering for tissue machines, Valmet launches a new polyurethane roll cover, Valmet Press Roll Cover PL. The roll cover’s wear-resistant material and adaptive structure are developed to cope with the harsh operating conditions in tissue production, thus leading to longer lifetime of roll cover and energy savings.

Tissue machines represent the most challenging environment for press rolls due to high machine speeds and extreme Yankee cylinder temperatures – placing high demands on the roll covers as well.

“The new Valmet Press Roll Cover PL is a long-lasting polyurethane roll cover especially designed for tissue pressing applications. It complements the existing applications on the market with unique properties that further improve the tissue production line’s efficiency, capacity, and product quality”, says Ulla Kanerva, Global Technology Manager, Roll Covers and Maintenance, Valmet.

Compared to other cover products, Valmet Press Roll Cover PL is available with wider hardness range together with improved mechanical properties, from 5P&J to 50P&J.

Valmet Press Roll Cover

Valmet Press Roll Cover

Significant cost-saving potential

The adaptive roll cover structure of Valmet Press Roll Cover PL helps to achieve more uniform nip profiles and bulk savings.

“To limit the energy needed for drying the tissue sheet, we usually concentrate on improving the post-press dryness. It reduces the energy demand on the Yankee dryer, which in turn removes bottlenecks in the dryer’s performance and operating costs”, Ulla Kanerva explains.

Valmet Press Roll Cover PL offers the possibility for high open grooved areas and large void volumes, assuring maximal nip dewatering and consistent tissue quality. By selecting optimal roll covers and surface topography with a matching press felt, tissue makers can further improve dewatering.

“To summarize, choosing Valmet Press Roll Cover PL leads to energy savings, better runnability and improved time efficiency in tissue production. On the other hand, the wear-resistant polyurethane material also extends the roll cover change intervals, leading to further cost savings”, Kanerva continues.

Read more about Valmet Press Roll Cover PL

Valmet is a leading global developer and supplier of process technologies, automation and services for the pulp, paper and energy industries. With our automation systems and flow control solutions we serve an even wider base of process industries.

We aim to become the global champion in serving our customers. Our 17,000 professionals work close to our customers and are committed to improving our customers’ performance – every day.

The company has over 220 years of industrial history and a strong track record in continuous improvement and renewal. In 2022, a major milestone was achieved when the flow control company Neles was merged into Valmet. The combined company’s net sales in 2021 was approximately EUR 4.5 billion based on the respective company figures.

Valmet’s shares are listed on the Nasdaq Helsinki and the head office is in Espoo, Finland.

Follow us on valmet.com

Solenis Recognizes Contact Energy as Winner of a 2021 Sustainability Award for Project That Significantly Offset Carbon Dioxide Emissions

Solenis LLC, a leading global producer of specialty chemicals, is proud to announce that Contact Energy Limited is a winner of a 2021 Solenis Sustainability Award. Contact Energy’s Wairakei geothermal power plant in Taupō, New Zealand, has received recognition for a project that offset carbon dioxide emissions by around 57,000 tons of CO2 equivalent (tCO2e, which includes methane) over one year, compared to coal.

Contact Energy’s project was focused on returning an 8-megawatt geothermal well to full production capacity. Buildup of minerals, mostly in the channels through the rocks underground near the well (formation scale), reduced the flow of steam so severely that the well could no longer contribute to the electricity output of the plant.

Any shortfall in low-carbon geothermal electricity generation in New Zealand is made up by fossil fuels, increasing the country’s carbon footprint. Abandoning the well and drilling a new one would cost up to $10 million, which was not a satisfactory option. Cleaning the well with harsh chemicals, such as hydrofluoric acid, was also unattractive because of its cost, aggressive nature, risks to operators and short-term effectiveness, especially on the silica formation scale seen at Wairakei.

Contact Energy needed a solution and partnered with Solenis field professionals and technical specialists to work on the problem. Solenis recommended a new method of cleaning the rock formation that combined advanced concepts from reservoir engineering, geology and pumping dynamics. The solution used low concentrations of chemicals, high pressure, high flow rates and carefully controlled flow to allow cleaning chemicals to penetrate the fissures in the rock formation and dissolve the scale buildup.

Trials showed it was so effective that a well’s output capabilities could not only be recovered but expanded. The expansion is attributed to stimulation of the formation near the wellbore by dissolution of rock minerals, creating slightly larger pathways for flow. In addition to the method’s effectiveness, the chemical portfolio developed by the Solenis team performed exceptionally well in geothermal conditions, had a significantly improved safety profile and was far more cost-effective than conventional methods.

Solenis recognized Contact Energy’s Wairakei geothermal power plant with a 2021 Solenis Sustainability Award for a project that reduced scale and improved power generation, saving around 57,000 tons of CO2 equivalent over one year compared to coal.

Solenis recognized Contact Energy’s Wairakei geothermal power plant with a 2021 Solenis Sustainability Award for a project that reduced scale and improved power generation, saving around 57,000 tons of CO2 equivalent over one year compared to coal.

The solution developed by Contact Energy and Solenis produced outstanding results. With the wellbore cleaned of scale, output peaked at 130 percent of the well’s expected recoverable capacity, which translated to an increased power generation of around 50,000 megawatt-hours over the year following the clean.

Because this geothermal energy source is very low carbon, it has a positive effect on carbon emissions. Estimated emissions from this geothermal generation over that one year are 1,080 tCO2e, significantly less than fossil fuel alternatives. Generating the same power from coal would produce around 58,600 tCO2e, or 23,900 tCO2e from combined-cycle gas.

Contact Energy was very pleased with the outcome of the project. John Clark, Chief Generation Officer at Contact Energy, said, “Our company strategy is to lead New Zealand’s decarbonization journey, and our renewable generation capacity has a critical role to play. To be able to take our existing operations and continuously improve and deliver better outcomes for the whole of New Zealand is incredibly exciting. We will continue to invest our time and resources to build a better New Zealand for future generations.”

Solenis was equally pleased by the partnership. Andrew Dine, the New Zealand commercial lead at Solenis, said, “Our company values collaboration. We try to be present with advice for our customers in their water-intensive tasks or long-term strategies. Wherever these goals and sustainability intersect, we’ll be there.”

The Solenis Sustainability Awards program reviews customer projects completed over the previous 12 months and chooses those delivering high value and high impact. The awards recognize projects in five sustainability categories, including reduced water use, reduced energy use, improved carbon footprint, reduced waste and optimized raw material utilization. To learn more about Solenis and sustainability, visit the Solenis website at: www.solenis.com/en/sustainability/strategic-vision

About Solenis

Solenis is a leading global producer of specialty chemicals, focused on delivering sustainable solutions for water-intensive industries, including the pulp, packaging paper and board, tissue and towel, oil and gas, petroleum refining, chemical processing, mining, biorefining, power, municipal, and pool and spa markets. The company’s product portfolio includes a broad array of water treatment chemistries, process aids and functional additives, as well as state-of-the-art monitoring and control systems. These technologies are used by customers to improve operational efficiencies, enhance product quality, protect plant assets, minimize environmental impact and maintain healthy water. Headquartered in Wilmington, Delaware, the company has 47 manufacturing facilities strategically located around the globe and employs a team of over 6,000 professionals in 120 countries across five continents. Solenis is a 2022 US Best Managed Company.

For additional information about Solenis, please visit solenis.com

About Contact Energy

Contact Energy is one of New Zealand’s largest energy retailers and generators. The company generated 8.4 terawatt hours of electricity from hydro, geothermal and gas last year and managed more than 550,000 customer connections. Contact Energy’s vision is to build a better New Zealand and play a leading role in the decarbonization of the energy sector and wider economy.

Toscotec to supply a wet end rebuild to Cartiere di Guarcino in Italy.

Specialty paper manufacturer Cartiere di Guarcino selected Toscotec for the rebuild of PM2 at its Guarcino paper mill near Frosinone in Italy. The project is scheduled for December 2022.

The rebuild consists of the modification of the paper machine’s forming and press sections with installation of both Toscotec’s and Voith’s technology. In the forming section, the supply of a customized breast roll and Voith’s FloatBearings will substantially enhance paper formation by boosting the performance of an existing shaking unit. Secondly, the installation of Voith’s EdgeMasters on the forming wire will deliver optimal paper web edge. Finally, the rebuild of the Fourdrinier section will be completed by a new wire stretcher and tail cutting unit.

In the press section, Toscotec will supply an additional press nip with associated felt run, the overhauling of the hydraulic system, and a technological doctoring system equipped with savealls to improve water removal. PM2’s press rolls will be equipped with polyurethane covers customized by Voith for each position: an AquaFlow cover on the first nip to minimize shadow marking and a SolarPress cover on the second and third nips to optimize dewatering. The service package of the rebuild includes erection supervision, commissioning, and start-up assistance.

The project has a twofold purpose of enhancing paper quality and increasing production capacity. By ensuring the shaking system’s efficient operation, the rebuild will increase fibres orientation in cross direction and deliver a more homogeneous distribution. This will result in better formation and improved paper quality. The modification of the press section will boost post-press drying rate, leading to a production increase.

Cartiere di Guarcino’s paper mill in Italy.

Cartiere di Guarcino’s paper mill in Italy.

Simone Principia, Plant Manager of Cartiere di Guarcino, says: “This investment fits into the growth strategy of Neodecortech Group. Cartiere di Guarcino is set to increase production performance through a fully customized technological solution. We aim to raise the bar on product quality and achieve the utmost differentiation in the high-end market of decor papers.”

Enrico Fazio, Sales Director of Toscotec’s Paper & Board division, says: “On this new project, we have achieved a very strong synergy with Voith and were able to meet the favour of Cartiere di Guarcino by including both Toscotec’s and Voith’s highly technological solutions. In the spirit of great flexibility that defines Toscotec, we devised a tailor-made solution for their unique and demanding market segment. Cartiere di Guarcino certainly has all the papermaking skills to realize the full potential of our technology.”

About Cartiere di Guarcino S.p.A.

Cartiere di Guarcino, part of Neodecortech Group, is an Italian manufacturer of decor specialty papers operating a production facility in Guarcino, Frosinone. It specializes in high quality products for application in office and home furniture and laminate flooring, including unicolours, print base papers, backer papers and underlays. In line with its sustainability-focused strategy, the paper mill uses electrical and thermal energy produced by Bio Energia Guarcino, a carbon-free cogeneration plant fuelled by animal fats and vegetable oil residues.

For more information, please contact:

Enrico Fazio, Sales Director, Paper & Board division, This email address is being protected from spambots. You need JavaScript enabled to view it.

A Series of EU Parliament votes on Fit for 55 sends wrong signals on industry decarbonisation & bioeconomy development

The European Parliament’s ENVI Committee (has voted today on a series of key pieces of the ‘Fit for 55’ package, which was proposed last year by the European Commission. The legislative package aims to cut the EU’s CO2 emissions by 55 percent until 2030. The outcome of the votes offers a few positive signs to the pulp and paper industry, as the Committee members acknowledged some of the contributions of the broader forest sector to climate action. But some legal provisions could paradoxically make it very challenging for the pulp and paper industry to decarbonise. In the upcoming plenary votes, the EU Parliament should focus on supporting the development of a European circular bioeconomy.

A first vote, on the land use, land-use change, and forestry (LULUCF) regulation, has brought forth the principle that carbon removals from forest sinks should support, but not replace, efforts to reduce fossil emissions. In other words, forests should not be used to compensate for other sectors’ emissions, including non-CO2 agricultural emissions. This is a balanced approach to the integration of land-based removals to the overall objective of net carbon neutrality.

Other proposed changes to the Commission’s proposal point towards the potential of forest products to help decarbonise the EU by substituting carbon-intensive ones. But one amendment which increases the target amount of carbon to be removed from the atmosphere by forests, up to 360 million tons of CO2 by 2030, may at the same time negatively affect the development of renewable and sustainable forest products by setting aside some forests for carbon offsets.

Other proposed changes to the Commission’s proposal point towards the potential of forest products to help decarbonise the EU by substituting carbon-intensive ones. But one amendment which increases the target amount of carbon to be removed from the atmosphere by forests, up to 360 million tons of CO2 by 2030, may at the same time negatively affect the development of renewable and sustainable forest products by setting aside some forests for carbon offsets.

Other positions held by the ENVI Committee are similarly contradictory. A vote on the revision of the Emissions Trading Scheme (ETS) Directive, while it would severely reduce financial resources for low-carbon investments has also recognised the contribution that biomass could offer as a clean source of energy for industries. However, an ENVI opinion on the revision of the Renewable Energy Directive (RED) seems to call the same principle into question. The opinion not only favours secondary over primary biomass use for energy by excluding the latter from national support schemes. It even excludes primary biomass complying with all sustainability criteria from counting towards the renewable energy target. Still, primary biomass currently accounts for nearly 50 percent of the wood input used for bioenergy, which in turn represents almost 60 percent of the renewable energy consumption in the EU.

As part of the revision, the Commission has proposed that 40 percent of the EU’s energy mix should come from renewables. The compromise amendments to the ENVI Committee’s draft report suggest increasing that target to 45 percent. That higher goal could be out of reach if primary biomass is excluded from the outset. Cepi calls on the Members of the European Parliament to correct this contradiction in the upcoming plenary vote in June.

Without requesting an in-depth impact assessment and industry consultation, the Committee also voted for the extension of the carbon border adjustment mechanism (CBAM) to all ETS sectors. CBAM is meant to protect energy intensive industries from carbon leakage: an unintended increase in CO2 emissions, as a result of the EU’s comparatively cleaner industry losing to global competitors. However, for some ETS sectors with very specific value chains, products and global trade flows, such as the pulp and paper industry, a CBAM will not be an effective tool to address carbon leakage and reduce emissions. The Committee’s vote notably fails to provide a concrete solution for exports, while accelerating free allowances phasing-out and threatening the existing indirect carbon cost compensation scheme.

Quote:

“We call on the Members of the European Parliament to ensure in plenary that the Fit for 55 package enables the EU economy to deliver on high climate ambitions in the next decade. Unfortunately, the version of Fit for 55 pushed forward by the ENVI Committee makes investing in decarbonisation and in the development of the circular bioeconomy sector very challenging.”

Jori Ringman, Director General – Cepi (Confederation of the European Paper Industries)

About Cepi :

Cepi is the European association representing the paper industry. We offer a wide range of renewable and recyclable wood-based fibre solutions to EU citizens: from packaging to textile, hygiene and tissue products, printing and graphic papers as well as speciality papers, but also bio-chemicals for food and pharmaceuticals, bio-composites and bioenergy. We are a responsible industry: 86% of our raw materials are sourced from within the European Union and 78% of the wood comes from certified forests, 92% of the water we use is returned in good condition to the environment. We are the world champion in recycling at the rate of 73.9%. At the forefront of the decarbonisation and industrial transformation of our economy, we embrace digitalisation and bring 18.5 billion value addition to the European economy and €4.5 billion investments annually. Through its 18 national associations, Cepi gathers 495 companies operating 895 mills across Europe and directly employing more than 180,000 people.

More information about our sustainability performance here.

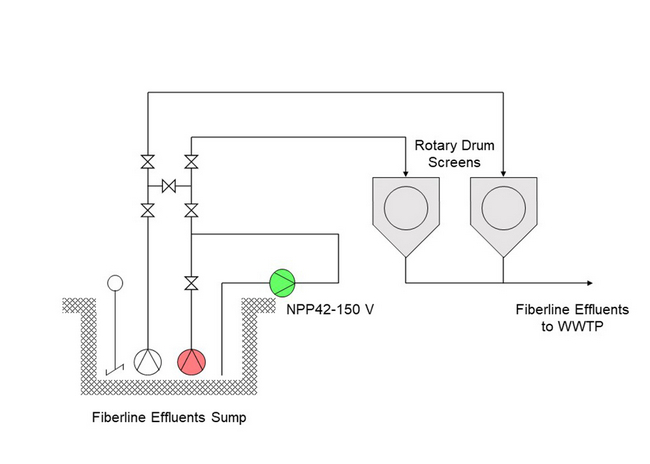

AHLSTAR™ with Sulzer Ejector improves sump pumping in a cardboard mill

A cardboard mill customer suffered from regular pump breakdowns in the fiber line effluent sump. Sulzer replaced the two existing submersible pumps by one non-clogging AHLSTAR NPP42-150 pump equipped with a Sulzer Ejector. After more than two years in operation, there has been no disturbance.

The challenge

This European mill produces 240’000 tons of cardboard from wastepaper per year. The cardboard is used to make plasterboard and for packaging. Various effluents from the mill are collected in different steps of the process and then treated in a modern, integrated wastewater treatment plant.

The main effluents from the fiber line process are collected in a large, 2.5 m deep sump prior to being pumped further through rotary drum screens and sent to the wastewater treatment plant. The liquids in the sump have varying char- acteristics and can be highly polluted with all kinds of solid particles (fibers, clips, tapes, ropes, etc.).

AHLSTAR™ with Sulzer Ejector improves sump pumping in a cardboard mill.

AHLSTAR™ with Sulzer Ejector improves sump pumping in a cardboard mill.

The initially installed sump pumps failed frequently. The two non-Sulzer submersible pumps were regularly clogged, disturbing the whole process and generating high repair costs. The customer decided to look for a more reliable pumping system and asked Sulzer for help.

The solution

After thorough discussions, the client and Sulzer agreed on a radical alternative: one dry-installed process pump with a complete priming system. An AHLSTAR NPP42-150 non-clogging pump unit with ejector soon replaced the fail- ing submersible pumps. The installation was fast and easy, and only minor piping modifications were needed.

The NPP42-150 pump unit is located above the liquid level in the sump. At each pump start, a fully automated priming is done in a few seconds with the Sulzer Ejector package. The NPP42-150 pump has been running smoothly for more than two years now, without any blockage. One of the initial submersible pumps was removed from the sump and the other one is kept as standby, only being used from time to time in parallel with the NPP42-150, when a maximum drainage flow is required.

Customer benefit

The AHLSTAR non-clogging NPP42-150 with vortex impeller is the right pump for sump applications where liquids are heavily polluted with debris and other big solid particles.

The previously installed submersible pumps were of cast iron, whereas all the wetted parts of the NPP42-150 pump are of duplex stainless steel. This material is ideal for liquids which can be both corrosive and abrasive. It ensures a much longer pump service life with minimum wear of parts.

The NPP42-150 pump unit is above the sump liquid level, and this makes all maintenance operations rapid and safe. Several other AHLSTAR process pumps are installed in the cardboard mill. The inventory control of spares is therefore easy.

Sump pumping diagram.

Sump pumping diagram.

The Sulzer Ejector is an inexpensive and simple device powered by compressed air from the mill network. It allows full priming of the inlet pipe and pump in a few seconds. After priming, the ejector is stopped, and the NPP42-150 pump starts running. No compressed air is required during normal pumping operation.

The Sulzer Ejector was delivered with an automation package that makes the whole priming operation extremely simple

“The AHLSTAR pump with a Sulzer Ejector is the prime solution!” - Fabrice Martin, Business Development Manager

Product data

AHLSTAR non-clogging pump unit for wastewater sump (pit depth 2.5 m)

| Flow | 350 m³/h |

| Head | 20 m |

| Speed | 1’000 rpm |

| Motor power | 55 kW |

| Impeller | Vortex – 340 mm |

| Max. solids passage | 80 mm |

| NPSHr | 5 mcL |

Complete Sulzer Ejector package including:

- Ejector

- Valves with actuators for motive air and ejection suction pipe

- Level control switch

- Control box with logic

Read our ejector brochure for further information.

About Sulzer

Sulzer is a global leader in fluid engineering. We specialize in pumping, agitation, mixing, separation and application technologies for fluids of all types. Our customers benefit from our commitment to innovation, performance and quality and from our responsive network of 180 world-class production facilities and service centers across the globe. Sulzer has been headquartered in Winterthur, Switzerland, since 1834. In 2021, our 13’800 employees delivered revenues of CHF 3.2 billion. Our shares are traded on the SIX Swiss Exchange (SIX: SUN). The Flow Equipment division specializes in pumping solutions specifically engineered for the processes of our customers. We provide pumps, agitators, compressors, grinders and screens developed through intensive research and development in fluid dynamics and advanced materials. We are a market leader in pumping solutions for water, oil and gas, power, chemicals and most industrial segments.

UPM Specialty Papers commissioned study: In 2040 a fifth of all food packaging could still be landfilled or incinerated unless packaging innovations accelerate

A key trend that emerges from a study commissioned by UPM Specialty Papers is that while recycling, reuse and composting of packaging will all increase significantly, a fifth of all food packaging could still find its way to landfill and incineration even in two decades time.

Today, food packaging is predominantly plastic and recycling rates are relatively low. While, fibre-based packaging is widely recycled in non-food uses, the industry believes that by 2040 fibre-based packaging will approach circularity as technical development broadens its suitability for food packaging. Recycling rates for plastics are also projected to grow.

“The packaging industry will focus research and development efforts to meet increasing consumer and regulatory demand for more recyclable and compostable packaging”, believes Maria Saloranta, Vice President, Strategy for UPM Specialty Papers. “As a result, we expect the share of fibre-based food packaging to grow, accelerated by breakthroughs in barrier properties and use of smart technologies that help relay information to consumers quickly and easily”.

In the report, more than 200 global packaging professionals from across the value chain contributed to the first-ever collective assessment of key trends that are projected to drive sustainability in the food packaging industry by 2040. The industry anticipates the global share of polymer-based packaging will fall by half over the next two decades in sustainable food packaging applications, while fibre-based materials are projected to contribute to over 40% of all materials in use for food packaging.

“The survey shows the industry is anticipating a USD 20 billion-dollar shift from polymer-based to fibre-based packaging by 2040,” notes Ciaran Little, Global VP of Business Development, Smithers. “The use of polymer packaging will not be eliminated but will focus on robust applications in which high strength barrier requirements and reusability are critical.”

“The survey shows the industry is anticipating a USD 20 billion-dollar shift from polymer-based to fibre-based packaging by 2040,” notes Ciaran Little, Global VP of Business Development, Smithers. “The use of polymer packaging will not be eliminated but will focus on robust applications in which high strength barrier requirements and reusability are critical.”

Download the report to learn what trends will dominate sustainable food packaging in 2040.

UPM Specialty Papers

UPM Specialty Papers answers the world’s need for sustainable products with high-performance, fossil-free materials for packaging and labelling, and in APAC the most sustainable office and graphic papers available. Our approximately 1,900 dedicated experts help customers co-create solutions to their business challenges. UPM Specialty Papers’ global team and mills in China, Finland and Germany serve customers consistently and reliably around the world.

Find out how our products are special by nature at upmspecialtypapers.com | #beyondfossils #specialbynature

UPM

We deliver renewable and responsible solutions and innovate for a future beyond fossils across six business areas: UPM Fibres, UPM Energy, UPM Raflatac, UPM Specialty Papers, UPM Communication Papers and UPM Plywood. As the industry leader in responsibility, we are committed to the UN Business Ambition for 1.5°C and the science-based targets to mitigate climate change. We employ 17,000 people worldwide and our annual sales are approximately EUR 9.8 billion. Our shares are listed on Nasdaq Helsinki Ltd. UPM Biofore – Beyond fossils. www.upm.com

Smithers

Founded in 1925 and headquartered in Akron, Ohio, Smithers is a multinational provider of testing, consulting, information, and compliance services. With operations and laboratories in North America, Europe, and Asia, Smithers supports customers in the packaging, transportation, life science, materials, components, consumer, and energy industries. Smithers delivers accurate data, on time, with high touch, by integrating science, technology, and business expertise, so customers can innovate with confidence. www.smithers.com