Man-made Fibres Congress, Dornbirn: new studies & our latest developments

Every year, we present our latest research results and our new fibre developments at the Man-made Fibers Congress at Dornbirn. This year, Kelheim Fibres made four presentations - as you see, our R&D team has been very busy! Here is a short summary of two of the presentations - more next time!

- Dr. Roland Scholz, R&D Kelheim Fibres and

- Ina Sigmund, Saxony Textile Research Institute (STFI): Viscose Fibers for Improved Dispersibility of Wet Wipes

Wipes for personal hygiene applications are frequently flushed into toilets - and risk blocking the waste water system. In the course of the study nonwovens based on 100% viscose fibres were tested for flushability according the demands of EDANA/-INDA’s “Guidance Document for Assessing the Flushability of Nonwoven Consumer Products”.

Wipes for personal hygiene applications are frequently flushed into toilets - and risk blocking the waste water system. In the course of the study nonwovens based on 100% viscose fibres were tested for flushability according the demands of EDANA/-INDA’s “Guidance Document for Assessing the Flushability of Nonwoven Consumer Products”.

The results: the two crucial factors for dispersability and transportability through sewer pumps are the fibre-length and the strength of the nonwoven web. Both factors have to be sensitively balanced to achieve sufficient web strength, easy break-up of the nonwoven and a complete dispersion of the fibres.

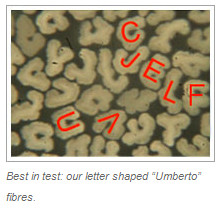

Nonwoven fabrics based on 20mm viscose fibres with round cross-sections and with the letter shaped cross section of our new “Umberto” fibres achieved the best test results for flushability.

Statement from : Matthew North, Commercial Director Kelheim Fibres

A Specialist specialises

We are proud to hold an excellent position in an increasingly competitive global market - what are the reasons for our success? First of all, we understand the challenges we face - and how to turn them into advantages.

As a medium-sized company in a high cost area we have skilled and reliable workforce and easy access to R&D resources. Our location on the banks of the Danube near a residential are means high environmental costs - yet at the same time it forces us to maintain the state-of-art technology of our plant. With eleven relatively small spinning lines our production capacity is limited - but we are highly flexible and can manufacture small lot sizes of speciality fibres competitively.

To guarantee our future success, our strategy focuses on four key elements: The effective and efficient use of available equipment and technology is the first important step. Based on that, we build leading positions in key markets and maintain them by continuous improvement of our products and production processes. To name just one example: We hold the number one position as supplier for short cut fibres for wet laid applications - 70% of viscose fibres used world wide in the manufacture of speciality papers are produced in Kelheim.

Forming strong partnerships with universities and research institutes and using the versatile viscose fibre process to our advantage, we adapt existing technologies for innovation. And last but not least, we establish new business in new applications, in the paper industry or filtration for example, where our speciality fibres offer benefits for an enhanced performance of the end product.

Our success is therefore not based on coincidence but solidy and strategically planned. With us, our customers have a reliable partner not just short-term, but also in the long run.